Yanmar 2YM15 Operation Manual

Marine engines

Hide thumbs

Also See for 2YM15:

- Operation manual (116 pages) ,

- Service manual (231 pages) ,

- Operation manual (57 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Yanmar 2YM15

-

Page 1: Marine Engines

OPERATION MANUAL MARINE ENGINES 2YM15 3YM20 3YM30E 3YM30 English... - Page 2 We reserve the right to make any change at any time without notice. Yanmar and are registered trademarks of YANMAR CO., LTD. in Japan, the United States and/or other countries. All Rights Reserved:...

-

Page 3: Table Of Contents

APPLICATIONS ............11 New Engine Break-In......... 12 COMPONENT IDENTIFICATION ......13 Right Side (Viewed from Flywheel) - 2YM15 ..13 Left Side (Viewed from Flywheel) - 2YM15 ..13 Right Side (Viewed from Flywheel) - 3YM20 ..14 Left Side (Viewed from Flywheel) -3YM20 ..14 Right Side (Viewed from Flywheel) - 3YM30(E) 15 Left Side (Viewed from Flywheel) - 3YM30(E)... - Page 4 TABLE OF CONTENTS BEFORE YOU OPERATE ..........25 INTRODUCTION ............25 SAFETY PRECAUTIONS......... 25 DIESEL FUEL............26 Diesel Fuel Specifications ........26 Filling the Fuel Tank........... 29 Bleeding the Fuel System ........30 ENGINE OIL ............. 31 Engine Oil Specifications ........31 Engine Oil Viscosity ..........

- Page 5 The Importance of Daily Checks ....... 51 Keep a Log of Engine Hours and Daily Checks 51 Yanmar Replacement Parts ......51 Tools Required ..........51 Ask Your Authorized Yanmar Marine Dealer or Distributor for Help..........51 Tightening Fasteners ......... 52 EPA MAINTENANCE REQUIREMENTS....53 EPA Requirements for USA and Other Applicable Countries..........

- Page 6 TABLE OF CONTENTS SPECIFICATIONS ............83 PRINCIPAL ENGINE SPECIFICATIONS ....83 2YM15 Engine Specifications ......84 3YM20 Engine Specifications ......85 3YM30E Engine Specifications ......86 3YM30 Engine Specifications ......87 Marine Gear and Sail Drive Specifications..88 SYSTEM DIAGRAMS............. 89 PIPING DIAGRAMS ..........

-

Page 7: Introduction

• Make sure this manual is transferred to manufacture. subsequent owners. This manual should To help you enjoy your Yanmar YM series be considered a permanent part of the engine for many years to come, please engine and remain with it. -

Page 8: Ym Series Emission Control System Warranty-Usa, The Environmental Protection Agency (Epa) Only

YM series engines come with an emission control system warranty. In all states, 2009 and later compression-ignition engines must be designed, built and equipped to meet the United States EPA emissions standards. Yanmar warrants the emission control system on your YM series engine for the periods of time listed below. -

Page 9: Record Of Ownership

INTRODUCTION 12/05 RECORD OF OWNERSHIP Take a few moments to record the information you need when you contact Yanmar for service, parts or literature. Engine Model: __________________________________________________________ Engine Serial No.: _______________________________________________________ Date Purchased: ________________________________________________________ Dealer: ________________________________________________________________ Dealer Phone: __________________________________________________________ YM Series Operation Manual... - Page 10 INTRODUCTION This Page Intentionally Left Blank YM Series Operation Manual...

-

Page 11: Safety

SAFETY Yanmar considers safety of great DANGER importance and recommends that anyone that comes into close contact with its Indicates a hazardous situation which, products, such as those who install, if not avoided, will result in death or operate, maintain or service Yanmar serious injury. -

Page 12: Safety Precautions

• Safety signs and labels are additional reminders for safe operating and maintenance techniques. Store any containers containing fuel or • Consult authorized Yanmar Marine other flammable products in a dealer or distributor for additional well-ventilated area, away from any training. - Page 13 SAFETY 12/05 Exhaust Hazard WARNING Never block windows, vents Sever Hazard or other means of ventilation if the engine is Rotating parts can cause operating in an enclosed severe injury or death. area. All internal combustion engines Never wear jewelry, create carbon monoxide gas during unbuttoned cuffs, ties or operation and special precautions are...

- Page 14 If a Yanmar Marine Engine is installed at an angle that exceeds the specifications stated in the Yanmar Marine Installation Manuals, engine oil may enter the...

- Page 15 This water could cause seizure of the non-running engine(s). Consult authorized Yanmar Marine dealer or distributor for a complete explanation of this condition. If you have an installation with two or three...

-

Page 16: Location Of Safety Decals

SAFETY LOCATION OF SAFETY DECALS Figure 1, show the location of safety decals on Yanmar YM series marine engines. YM Engines 051101-00X00 Figure 1 1–Part Number: 128990-07270 2–Part Number: 128377-07350 3–Part Number: 196630-12980 YM Series Operation Manual... -

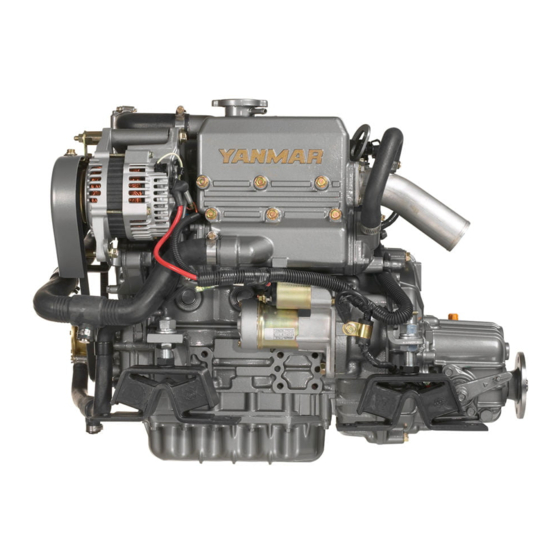

Page 17: Product Overview

Any auxiliary equipment equipped with liquid coolant systems. attached to the engine should be easy to The 2YM15 is a 2-cylinder engine and is use and accessible for service. To handle naturally aspirated. the drive equipment, propulsion systems... -

Page 18: New Engine Break-In

• With the clutch in NEUTRAL, accelerate lifetime. from the low-speed position to the high-speed position briefly. A new Yanmar diesel engine must be operated at suitable speeds and power • Repeat this process five times. settings during the break-in period to make... -

Page 19: Component Identification

Left Side (Viewed from Flywheel) - 2YM15 IDENTIFICATION Right Side (Viewed from Flywheel) - 2YM15 Figure 1 and Figure 2 illustrate a typical version of a 2YM15 engine. Your engine may have different equipment from that illustrated. 051098-00X00 Figure 2 1 – Seawater Pump 2 –... -

Page 20: Right Side (Viewed From Flywheel) - 3Ym20

PRODUCT OVERVIEW Right Side (Viewed from Left Side (Viewed from Flywheel) Flywheel) - 3YM20 -3YM20 Figure 3 and Figure 4 illustrate a typical version of a 3YM20 engine. Your engine may have different equipment from that illustrated. 051099-00X00 Figure 4 1 –... -

Page 21: Right Side (Viewed From Flywheel) - 3Ym30(E)

PRODUCT OVERVIEW 12/05 Right Side (Viewed from Left Side (Viewed from Flywheel) Flywheel) - 3YM30(E) - 3YM30(E) Figure 5 and Figure 6 illustrate a typical version of a 3YM30(E) engine. Your engine may have different equipment from that illustrated. 051100-00X00 Figure 6 1 –... -

Page 22: Nameplates

NAMEPLATES The marine gear nameplate (Figure 8) is attached to the marine gear. Check the The nameplates of Yanmar YM series marine gears model, gear ratio, oil used, engines are shown in Figure 7. Check the oil quantity and serial number. -

Page 23: Function Of Major Components

PRODUCT OVERVIEW 12/05 FUNCTION OF MAJOR COMPONENTS Name of Component Function Fuel Filter Removes dirt and water from the fuel. Drain the filter periodically. The filter element should be replaced periodically. The water separator (if equipped) should be drained periodically. See Draining Fuel Filter / Water Separator on page 65. -

Page 24: Control Equipment

PRODUCT OVERVIEW CONTROL EQUIPMENT The equipment in the control room makes remote control operation possible. It consists of the instrument panel, which is connected to the engine by a wire harness, and the remote control handle, which is connected by control cables to the engine control lever and marine gear. - Page 25 PRODUCT OVERVIEW 12/05 Meters Instrument Function Tachometer Shows engine rotation speed. Hourmeter Shows number of operating hours. Can be used as a guide for periodic maintenance checks. The hourmeter is located at the bottom of the tachometer. Panel Lights When the power switch is pushed, the gauges will illuminate for easier viewing. Note: The LCD on the instrument panel show hourmeter, display brightness and battery voltage.

- Page 26 PRODUCT OVERVIEW LCD control (hourmeter, display brightness, battery voltage) You can switch (scroll) between displays Figure 1 by pressing the buttons on the bottom. • Switching screens by pressing the right button (Pressing the left button switches the screens in the opposite direction.) Press the power switch.

- Page 27 PRODUCT OVERVIEW 12/05 Setup Screen Access and Control (Setting the engine speed pulse value for B20/C30 type panel) Use the buttons on the bottom of the LCD Figure 2 display to set the instrument panel. Press the left button to switch between displays.

- Page 28 Alarm buzzer Charge lamp Coolant temperature lamp Engine lubricating oil pressure lamp LCD display Yanmar Full display Hourmeter NOTICE When the warning devices are activated and normal operation is impossible, stop the engine and do not use it until the problem has been solved.

- Page 29 PRODUCT OVERVIEW 12/05 Accessory power output The harness attached to the panel has a terminal where the signal that is synchronized to the panel power supply can be taken off. (Figure 13) ( Refer to the Wiring Diagrams on page 94.) The maximum current of this output terminal is 3 A.

-

Page 30: Single-Handle Remote Control Head

PRODUCT OVERVIEW Single-Handle Remote Control Head Figure 4 0004511 Figure 15 Note: Yanmar recommends the use of 0004504 a single-handle type for the Figure 14 remote control system. If only a Note: Direction of travel will vary two-handle type is available in... -

Page 31: Before You Operate

BEFORE YOU OPERATE INTRODUCTION SAFETY PRECAUTIONS This section of the Operation Manual Before performing any operations within describes the diesel fuel, engine oil and this section, review the Safety section on engine coolant specifications and how to page 5. replenish them. YM Series Operation Manual... -

Page 32: Diesel Fuel

EN590-2009, EN14214. • In the United States, biodiesel fuels must Only use diesel fuels recommended by comply with the American Standard Yanmar for the best engine performance, ASTM D6751 Grade-S15, D7467 Grade to prevent engine damage and to comply B7-S15. - Page 33 BEFORE YOU OPERATE 12/05 • Even biodiesel fuels that comply with a • PAH (polycyclic aromatic hydrocarbons) suitable standard as delivered will content should be below 10% by volume. require additional care and attention to • Do not use Biocide. maintain the quality of the fuel in the equipment or other fuel tanks.

- Page 34 BEFORE YOU OPERATE The fuel outlet should be positioned 20 to 30 mm (0.75 to 1.125 in.) above the bottom of the tank so that only clean fuel is distributed to the engine. Fuel System 0004512 Figure 1 2. Keep the fuel container stationary for several hours to allow any dirt or water to settle to the bottom of the container.

-

Page 35: Filling The Fuel Tank

BEFORE YOU OPERATE 12/05 Filling the Fuel Tank WARNING Before filling fuel tank for the first Fire and Explosion Hazard. time: Never overfill the fuel tank. WARNING 5. Replace the fuel cap and hand-tighten. Fire and Explosion Hazard. Over-tightening the fuel cap will Never refuel with the engine running. -

Page 36: Bleeding The Fuel System

BEFORE YOU OPERATE Bleeding the Fuel System 1. Check the fuel level in the fuel tank. Refill if necessary. The fuel system has an automatic air 2. Open the fuel cock of the fuel tank. bleeding device that purges air from the fuel system. -

Page 37: Engine Oil

Engine Oil Specifications is being operated. See Engine Oil Viscosity Figure 5. NOTICE • Yanmar does not recommend the use of engine oil "additives." Only use the engine oil specified. Other engine oils may affect warranty coverage, cause internal engine components to seize and / or shorten engine life. -

Page 38: Checking The Engine Oil

If you intend to operate your equipment at (Figure 6, (5)) lines on the dipstick. temperatures outside the limits shown, you must consult your authorized Yanmar 5. Add oil if necessary. See Adding Marine dealer or distributor for special Engine Oil on page 32. -

Page 39: Marine Gear Or Sail Drive Oil

BEFORE YOU OPERATE 12/05 MARINE GEAR OR SAIL 1. Make sure the engine is off. Make sure the engine is as level as possible and DRIVE OIL wipe area clean around the marine gear filler port (Figure 7, (2)). Marine Gear Oil Specifications 2. -

Page 40: Engine Coolant

BEFORE YOU OPERATE ENGINE COOLANT Coolant (Closed Cooling System) Engine Coolant Specifications NOTICE Note: In the U.S., LLC is required for Always add LLC to soft water especially the warranty to be valid. when operating in cold weather. Never use •... -

Page 41: Checking And Adding Coolant

BEFORE YOU OPERATE 12/05 Checking and Adding Coolant Figure 2 Figure 1 0004793 Figure 10 1 – Stop Solenoid 2 – Coolant Drain Cock 051169-00X00 3 – Flywheel Housing Figure 8 1. Allow the engine to cool. 1 – Coolant Tank / Heat Exchanger 2 –... - Page 42 BEFORE YOU OPERATE Figure 3 Figure 4 FULL 0004493 054720-00X00 Figure 11 Figure 12 1 – Filler Cap Tabs 1 – Rubber Hose to Coolant Tank 2 – Coolant Filler Cap 2 – FULL Mark 3 – Filler Port Notches 3 –...

-

Page 43: Cranking The Engine

After a long period of no use, reservoir, there may be water or distribute engine oil to each part by air leaks in the cooling system. cranking. Perform in accordance with the Consult authorized Yanmar following procedures before beginning dealer or distributor. operation. 1. Open seacock. - Page 44 BEFORE YOU OPERATE Figure 5 Stop solenoid Push (emergency stop) 006224-01E Figure 13 6. Continue cranking the engine for about 5 seconds, checking for abnormal sounds. If you cannot find any abnormal sounds, push the power switch and turn off the engine. Start switch Power switch 042590-00E00...

-

Page 45: Engine Operation

ENGINE OPERATION INTRODUCTION SAFETY PRECAUTIONS This section of the Operation Manual Before performing any operations within describes the diesel fuel, engine oil and this section, review the Safety section on engine coolant specifications and how to page 5. replenish them. It also describes the daily engine checkout. - Page 46 WARNING fails to display and go out about 3 seconds after the ignition switch is turned on, Fire and Explosion Hazard consult authorized Yanmar Marine dealer Never jump-start the or distributor for service before operating engine. Sparks caused by the engine...

-

Page 47: Starting The Engine

ENGINE OPERATION 12/05 STARTING THE ENGINE 1. Open the seacock (if equipped). • Contact your authorized Yanmar Marine 2. Open the fuel tank cock. engine dealer or distributor if the engine will be operated outside of this standard 3. Put remote control handle in temperature range. -

Page 48: If The Engine Fails To Start

ENGINE OPERATION If the Engine Fails to Start Air Bleeding the Fuel System After Starting Failure Before pushing the start switch again, be sure to confirm that the engine has If the engine does not start after several stopped completely. If an attempt to restart attempts, there may be air in the fuel is made while the engine is running, the system. -

Page 49: After The Engine Has Started

For troubleshooting assistance, see Troubleshooting After Starting on page 75 or Troubleshooting Chart on page 77 . If necessary, consult authorized Yanmar dealer or distributor. YM Series Operation Manual... -

Page 50: Remote Control Handle Operation

ENGINE OPERATION REMOTE CONTROL HANDLE OPERATION Shifting the marine gear while operating at high speed or not pushing the handle fully Acceleration and Deceleration into position (partial engagement) will result in damage to marine gear parts and abnormal wear. 1. Before using the marine gear, be sure to move the throttle handle to a low idle position (less than 1000 min ). -

Page 51: Cautions During Operation

ENGINE OPERATION 12/05 CAUTIONS DURING OPERATION Excessive vibration may cause damage to the engine, marine gear, hull and onboard equipment. In addition, it causes able passenger and crew Engine trouble can arise if the engine is discomfort. operated for a long time under overloaded conditions with the control handle in the full throttle position (maximum engine speed Depending on the hull structure, engine... -

Page 52: Shutting Down The Engine

5 minutes. engine at near maximum engine speed while underway. This will generate higher exhaust temperatures, which will For maximum engine life, Yanmar help clean out hard carbon deposits, recommends that when shutting the maintaining engine performance and engine down, you allow the engine to prolonging the life of the engine. -

Page 53: Emergency Shutdown

ENGINE OPERATION 12/05 Figure 2 Continue to hold the stop switch in until the engine is completely stopped. If the switch is released before the engine has completely stopped, it may restart. If the engine does not shut down, see Emergency Shutdown on page 47 . -

Page 54: Checking The Engine After Operation

ENGINE OPERATION CHECKING THE ENGINE AFTER OPERATION • Check that the power switch is off and that the battery switch (if equipped) is turned to off. • Fill the fuel tank. See Filling the Fuel Tank on page 29. • Close seawater cock(s). •... -

Page 55: Periodic Maintenance

PERIODIC MAINTENANCE INTRODUCTION SAFETY PRECAUTIONS This section of the Operation Manual Before performing any maintenance describes the procedures for proper care procedures within this section, read the and maintenance of the engine. following safety information and review the Safety section on page 5. WARNING Crush Hazard If the engine needs to be... - Page 56 Any • When welding is completed, alterations to this engine may void its reconnect the alternator and engine warranty. Be sure to use Yanmar genuine control unit prior to reconnecting the replacement parts. batteries. Entanglement Hazard...

-

Page 57: Precautions

Yanmar Replacement Parts operating in an enclosed area. All internal combustion engines create Yanmar recommends that you use carbon monoxide gas during operation. genuine Yanmar parts when replacement Accumulation of this gas within an parts are needed. -

Page 58: Tightening Fasteners

PERIODIC MAINTENANCE Tightening Fasteners Use the correct amount of torque when you tighten fasteners on the engine. Applying excessive torque may damage the fastener or component and not enough torque may cause a leak or component failure. he tightening torque in the Standard Torque Chart should be applied only to the bolts with a “7”... -

Page 59: Epa Maintenance Requirements

Compliance with EPA Emission Standards See Inspection and Maintenance of EPA Emission-Related Parts on page 58 for the The 2YM15, 3YM20 and 3YM30E are EPA emission-related parts. Inspection EPA-certified engines. and maintenance procedures not shown in the Inspection and Maintenance of EPA... -

Page 60: Installing Sample Port

PERIODIC MAINTENANCE Installing Sample Port 4. To facilitate insertion and withdrawal of an exhaust sample probe, there should All engines subject to emission standards be no obstructions for at least one and shall be equipped with a connection in the one-half exhaust pipe/stack diameters engine exhaust system that is located perpendicular, i.e., 90 degrees, from... -

Page 61: Periodic Maintenance Schedule

Consult authorized Yanmar Marine dealer or distributor for assistance when checking items marked with a ●. YM Series Operation Manual... - Page 62 PERIODIC MAINTENANCE : Check or Clean : Replace ●: Contact your authorized Yanmar Marine dealer or distributor Periodic Maintenance Interval Every Every Every Every Every Before 1000 Starting hours hours hours hours hours Initial or six or one or one...

- Page 63 PERIODIC MAINTENANCE 12/05 : Check or Clean : Replace ●: Contact your authorized Yanmar Marine dealer or distributor Periodic Maintenance Interval Every Every Every Every Every Before 1000 Starting hours hours hours hours hours Initial or six or one or one...

-

Page 64: Inspection And Maintenance Of Epa Emission-Related Parts

Check turbocharger adjustment (if equipped) Check electronic engine control unit and its associated sensors and actuators (if equipped) Note: The inspection and maintenance items shown above are to be performed at your Yanmar Marine dealer or distributor. YM Series Operation Manual... -

Page 65: Periodic Maintenance Procedures

6. Check the electrical harnesses for Before you head out for the day, make cracks, abrasions, and damaged or sure the Yanmar engine is in good corroded connectors. operating condition. 7. Check hoses for cracks, abrasions, and damaged, loose or corroded clamps. -

Page 66: After Initial 50 Hours Of Operation

PERIODIC MAINTENANCE Checking and Refilling Marine Gear After Initial 50 Hours of Operation Refer to the Operation Manual for the marine gear. Perform the following maintenance after the initial 50 hours of operation. Checking the Battery Electrolyte Level • Draining the Fuel Tank •... - Page 67 PERIODIC MAINTENANCE 12/05 Draining the Fuel Tank WARNING Burn Hazard. If you must drain the engine oil while it is still hot, stay clear of the hot engine oil to avoid being burned. Always wear eye protection. 1. Turn the engine off. 2.

- Page 68 PERIODIC MAINTENANCE Replacing the Engine Oil Filter Element Checking and Adjusting the Alternator V-ribbed belt Tension 1. Turn the engine off. WARNING 2. Turn the engine oil filter Figure 2 counterclockwise with a wrench. Sever Hazard. Perform this check with 3.

- Page 69 Improper adjustment Figure 3 will cause the engine to run noisily, resulting in poor engine performance and engine damage. Consult authorized Yanmar Marine dealer or distributor to adjust the intake / exhaust valve clearance. 0004798 Figure 4 1 –...

- Page 70 Consult your authorized control lever. Yanmar Marine dealer or distributor. Adjusting Clutch Remote Control Cable Figure 4 0004799 Figure 5 1 – Marine Gear 2 –...

-

Page 71: Every 50 Hours Of Operation

PERIODIC MAINTENANCE 12/05 Figure 5 Every 50 Hours of Operation When completing the initial 50 hour maintenance procedures, perform the following procedures every 50 hours thereafter or monthly, whichever comes first. • Draining Fuel Filter / Water Separator • Checking the Battery Electrolyte Level Draining Fuel Filter / Water Separator... - Page 72 PERIODIC MAINTENANCE 5. Be sure to bleed air from the fuel system. See Bleeding the Fuel System on page 30. Never attempt to remove the covers or fill a maintenance-free battery. Checking the Battery Electrolyte Level (Serviceable Batteries Only) 4. If the electrolyte level is lower than the Never operate with insufficient battery minimum fill level (Figure 7, (1)), fill electrolyte.

-

Page 73: Every 100 Hours Of Operation

PERIODIC MAINTENANCE 12/05 Every 100 Hours of Operation Every 150 Hours of Operation Perform the following maintenance every Perform the following maintenance every 100 hours or every 6 months of operation, 150 hours or every year of operation, whichever comes first. whichever comes first. -

Page 74: Every 250 Hours Of Operation

PERIODIC MAINTENANCE Draining the Fuel Tank Every 250 Hours of Operation See Draining the Fuel Tank on page 61. Replacing the Fuel Filter Element Perform the following maintenance every 250 hours or 1 year of operation, WARNING whichever comes first. Fire and Explosion Hazard. - Page 75 5. Apply a thin film of clean diesel fuel to the seawater pump are necessary, consult the sealing surface of the new filter your Yanmar Marine dealer or distributor. gasket. 6. Clean the inside of the housing The seawater pump turns in the direction thoroughly, install the O-ring and as shown in Figure 9.

- Page 76 2. Clean dirt and scale out of the exhaust and seawater passages. 3. If the mixing elbow is damaged, repair or replace it. Consult authorized Yanmar Marine dealer or distributor. 4. Inspect the gasket and replace if necessary. Replace the mixing elbow with a new one every 500 hours or 2 years, whichever comes first, even if no damage is found.

-

Page 77: Every 1000 Hours Of Operation

V-ribbed belt Tension on page 62. 1000 hours or 4 years of operation, whichever comes first. Cleaning the Breather Pipe • Checking the Fuel Injection Timing Consult authorized Yanmar Marine dealer or distributor. • Checking the Fuel Injector Spray Pattern Checking the Wiring Connectors •... - Page 78 • Heat Exchanger 4 – Diaphragm 5 – Rocker Arm Cover • Pressure Cap 6 – Breather Baffle Consult authorized Yanmar Marine dealer 7 – Baffle Plate or distributor. 8 – Intake Silencer (air cleaner) Replacing the Alternator V-ribbed Checking the Diaphragm Assembly...

- Page 79 See Checking and Adjusting the Remote Control Cables on page 63. Adjusting the Propeller Shaft Alignment Consult authorized Yanmar Marine dealer or distributor. Tightening All Major Nuts and Bolts See Tightening Fasteners on page 52 or consult authorized Yanmar Marine dealer or distributor.

- Page 80 PERIODIC MAINTENANCE This Page Intentionally Left Blank YM Series Operation Manual...

-

Page 81: Troubleshooting

TROUBLESHOOTING SAFETY PRECAUTIONS TROUBLESHOOTING AFTER STARTING Before performing any troubleshooting procedures within this section, review the Just after the engine has started, check Safety section on page 5. the following items at a low engine speed: If a problem occurs, stop the engine Is sufficient water being discharged immediately. -

Page 82: Troubleshooting Information

Troubleshooting Chart on page Is there sufficient fuel in the fuel tank? 77 or consult authorized Yanmar Marine dealer or distributor. Refill fuel in advance to avoid running out of fuel. If the tank runs out of fuel, bleed Supply the authorized Yanmar Marine the fuel system. -

Page 83: Troubleshooting Chart

Marine dealer or distributor. Faulty Warning Devices Do not operate the engine if alarm devices are not repaired. See you authorized Yanmar Marine dealer or distributor. Serious accidents may result if abnormalities are not identified due to faulty indicators or alarm. - Page 84 Level on page 60 Cable terminal contact failure. Remove corrosion from terminals. Tighten battery cables. Faulty safety switch device. Consult authorized Yanmar Marine dealer or distributor. Faulty starter switch. Consult authorized Yanmar Marine dealer or distributor. Power lacking due to accessory drive Consult authorized Yanmar being engaged.

-

Page 85: Long-Term Storage

6 months. If it remains unused for longer than this, please contact your authorized 1. Wipe off any dust or oil from the outside Yanmar Marine dealer or distributor. of engine. Before performing any storage procedures 2. Drain water from fuel filters. -

Page 86: Drain Seawater Cooling System

LONG-TERM STORAGE DRAIN SEAWATER COOLING SYSTEM 0004793 Figure 3 1 – Stop Solenoid 2 – Coolant Drain Cock 3 – Flywheel Housing 051170-00X00 Figure 1 Figure 4 1 – Coolant Tank / Heat Exchanger 2 – Seawater Drain Cock Note: The drain cocks are opened 3 –... - Page 87 LONG-TERM STORAGE 12/05 Never drain engine coolant in the cold season or before long storage. If LLC (Long Life Coolant) has not been added to the cooling system, add LLC or drain the coolant from the coolant system after daily use.

- Page 88 LONG-TERM STORAGE This Page Intentionally Left Blank YM Series Operation Manual...

-

Page 89: Specifications

SPECIFICATIONS PRINCIPAL ENGINE SPECIFICATIONS YM Series Operation Manual... -

Page 90: 2Ym15 Engine Specifications

SPECIFICATIONS 2YM15 Engine Specifications Specification 2YM15 Marine Gear Model KM2P-1 SD-20 Pleasure use Type Vertical water cooled 4-cycle diesel engine Combustion System Swirl pre-combustion chamber Air Charging Natural aspiration Number of Cylinders Bore x Stroke 70 mm x 74 mm (2.76 in. x 2.91 in.) Displacement 0.570 L (34.8 cu in.) -

Page 91: 3Ym20 Engine Specifications

SPECIFICATIONS 12/05 3YM20 Engine Specifications Specification 3YM20 Marine Gear Model KM2P-1 SD-20 Pleasure use Type Vertical water cooled 4-cycle diesel engine Combustion System Swirl pre-combustion chamber Air Charging Natural aspiration Number of Cylinders Bore x Stroke 70 mm x 74 mm (2.76 in. x 2.91 in.) Displacement 0.854 L (52.1 cu in.) Continuous... -

Page 92: 3Ym30E Engine Specifications

SPECIFICATIONS 3YM30E Engine Specifications Specification 3YM30E Marine Gear Model KM2P-1 SD-20 Pleasure use Type Vertical water cooled 4-cycle diesel engine Combustion System Swirl pre-combustion chamber Air Charging Natural aspiration Number of Cylinders Bore x Stroke 76 mm x 82 mm (2.99 in. x 3.23 in.) Displacement 1.115 L (68.04 cu in.) Continuous... -

Page 93: 3Ym30 Engine Specifications

SPECIFICATIONS 12/05 3YM30 Engine Specifications Specification 3YM30 Marine Gear Model KM2P-1 SD-20 Pleasure use Type Vertical water cooled 4-cycle diesel engine Combustion System Swirl pre-combustion chamber Air Charging Natural aspiration Number of Cylinders Bore x Stroke 76 mm x 82 mm (2.99 in. x 3.23 in.) Displacement 1.115 L (68.04 cu in.) Continuous... -

Page 94: Marine Gear And Sail Drive Specifications

SPECIFICATIONS Marine Gear and Sail Drive Specifications SD20 Model KM2P-1(S) KM2P-1(G) KM2P-1(GG) (coupled at boat builder) Type Mechanical cone clutch Dog Clutch Reduction Ratio 2.21 / 3.06 2.62 / 3.06 3.22 / 3.06 2.64 / 2.64 (Forward / Reverse) Propeller Speed 1580 / 1140 min 1332 / 1140 min 1083 / 1140 min... -

Page 95: System Diagrams

SYSTEM DIAGRAMS PIPING DIAGRAMS Piping diagrams and wiring diagrams are provided for reference only. Contact your authorized Yanmar Marine dealer or distributor for the most current diagrams. Notation Description Screw Joint (Union) Flange Joint Eye Joint Insertion Joint Drilled Hole... - Page 96 SYSTEM DIAGRAMS Figure 12YM15 with KM2P-1 Marine Gear 1 2 3 4 12 13 16 17 ( 36 ) ( 38 ) ( 37 ) 026475-00X Figure 1 YM Series Operation Manual...

- Page 97 SYSTEM DIAGRAMS 12/05 Unit: mm (in.) 1 – 7.8 x t4.5 Rubber Hose 2 – Check Valve 3 – 7.8 x t4.5 Rubber Hose Detail of part A Detail of part B 4 – 7.8 x t4.5 Rubber Hose 5 – Overflow 6 –...

- Page 98 SYSTEM DIAGRAMS Figure 23YM20 and 3YM30(E) with KM2P-1 Marine Gear 026476-00X Figure 2 YM Series Operation Manual...

- Page 99 SYSTEM DIAGRAMS 12/05 Unit: mm (in.) 1 – PCV 2 – Overflow 3 – Fuel Inlet Detail of part A Detail of part B 4 – Fuel Feed Pump 5 – Fuel Injection Pump 6 – Engine Oil Filter (cartridge type) 7 –...

-

Page 100: Wiring Diagrams

SYSTEM DIAGRAMS WIRING DIAGRAMS Color Coding Black White Blue Red / Black Blue / Black Yellow / White Yellow / Green White / Blue Purple Blue / White Orange White / Brown Allowable Length by Cross Sectional Area of Battery Cable Section of Cable Allowable Length (in. - Page 101 SYSTEM DIAGRAMS 12/05 Figure 32YM15, 3YM20, 3YM30(E) - B20 Type Instrument Panel Figure 3 YM Series Operation Manual...

- Page 102 SYSTEM DIAGRAMS 1 – Instrument panel B20 2 – Alarm lamps (3 to 7) 3 – Engine oil low pressure indicator 4 – Coolant high temperature Indicator 5 – Water in sail drive seal indicator 6 – Battery low charge indicator 7 –...

-

Page 103: Epa Warranty Usa Only

EPA WARRANTY USA ONLY YANMAR CO., LTD. LIMITED EMISSION CONTROL SYSTEM WARRANTY - USA ONLY 2YM15 EPA and CARB 3YM30E EPA and CARB Nameplate Nameplate For Example EMISSION CONTROL INFORMATION EMISSION CONTROL INFORMATION THIS ENGINE COMPLIES WITH U.S.EPA MARINE AND CALIFORNIA OFF-ROAD REGULATIONS FOR 2013 M.Y. -

Page 104: Your Warranty Rights And Obligations

UNITED STATES EPA 40 CFR Part replacement of emission control systems 1042.135 AND SOLD BY YANMAR THAT are Yanmar parts. The owner may elect to ARE INSTALLED IN VESSELS FLAGGED have maintenance, replacement or repair OR REGISTERED IN THE UNITED of the emission control components and STATES. -

Page 105: Warranty Coverage

12/05 Warranty Coverage: Owner’s Responsibility: Repair or replacement of any warranted As the Yanmar Marine engine owner, you parts will be performed at an authorized are responsible for the performance of the Yanmar dealer or distributor. This limited required maintenance listed in your emission control system warranty covers Operation Manual. - Page 106 EPA WARRANTY USA ONLY This Page Intentionally Left Blank YM Series Operation Manual...

-

Page 107: Emission System Warranty

Environmental Protection Agency (EPA) engines are warranted for the periods and Yanmar Co., Ltd. hereafter referred to listed below. If any emission-related part as Yanmar, are pleased to explain the on your engine is found to be defective... - Page 108 Repair or replacement system of the engine as delivered by of any warranted part will be performed at Yanmar to the original retail purchaser. an authorized Yanmar Marine engine Such components may include the dealer or distributor.

- Page 109 You are responsible for initiating the warranty process. You must present your engine to a Yanmar dealer as soon as a problem exists. The warranty repairs should be completed by the dealer as expeditiously as possible.

-

Page 110: Maintenance Log

EMISSION SYSTEM WARRANTY Maintenance Log Stamp or Date Operating Hours Maintenance Performed Dealer Name Signature YM Series Operation Manual... - Page 111 EMISSION SYSTEM WARRANTY 12/05 Stamp or Date Operating Hours Maintenance Performed Dealer Name Signature YM Series Operation Manual...

- Page 112 EMISSION SYSTEM WARRANTY YM Series Operation Manual...

- Page 113 1st edition: November 2007 2nd edition 1st rev.: March 2012 2nd edition 2nd rev.: July 2012 3rd edition: February 2013 3rd edition 1st rev.: June 2013 Issued by: YANMAR CO., LTD. Marine Operations Division Edited by: YANMAR TECHNICAL SERVICE CO., LTD.

- Page 114 0AYMM-G00202...

Need help?

Do you have a question about the 2YM15 and is the answer not in the manual?

Questions and answers