Table of Contents

Advertisement

Quick Links

Installation & Service Instructions

THE GAS SAFETY (INSTALLATION AND USE) REGULATIONS 1994 (as amended).

'' In your own interest, and that of safety, it is law that all gas appliances are installed by competent persons,

in accordance with the above regulations. Failure to install appliances correctly could lead to prosecution.''

Installation must be in accordance with these installation & Service Instructions and the rules in force.

The polythene bags used for packaging are a potential hazard to babies and young children

LEAVE THESE INSTRUCTIONS WITH THE USER FOR USE ON FUTURE CALLS

For Use With Natural Gas

(G20) Only At 20mbar

For Use in GB & IE

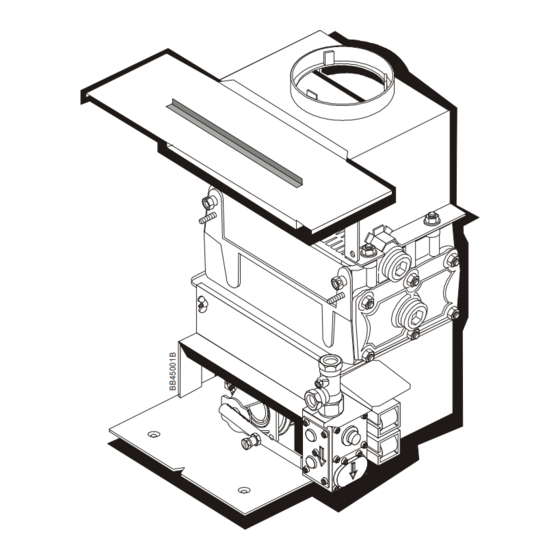

Housewarmer 45 & 55

Gas Fired Electronic Back Boilers

and MUST BE DISPOSED OF IMMEDIATELY.

Potterton Housewarmer 45 - G.C. No. 44 590 18

Potterton Housewarmer 55 - G.C. No. 44 590 19

IMPORTANT

PLEASE READ THIS BOOK

BEFORE INSTALLING,

OPERATING OR SERVICING

THIS APPLIANCE.

Advertisement

Chapters

Table of Contents

Need help?

Do you have a question about the Housewarmer 45 and is the answer not in the manual?

Questions and answers