Summary of Contents for Miller Welding

- Page 1 Robot PAW Interface Visit our website at www.Miller- Welds.com OM-169 510 June 1995 Processes Plasma Arc (PAW) Welding Description Automatic Welding...

- Page 3 Considerations About Welding And The Effects Of Low Frequency Electric And NOTE Magnetic Fields The following is a quotation from the General Conclusions Section of the U.S. Congress, Office of Technology Assessment, Biological Effects of Power Frequency Electric & Magnetic Fields –...

- Page 5 Read and follow safety information in the Plasma Weld- ing Console Owner’s Manual and Welding Torch Own- er’s Manual, as well as the other Owner’s Manuals for this system, to ensure the safe installation and operation of the Plasma Arc Welding system.

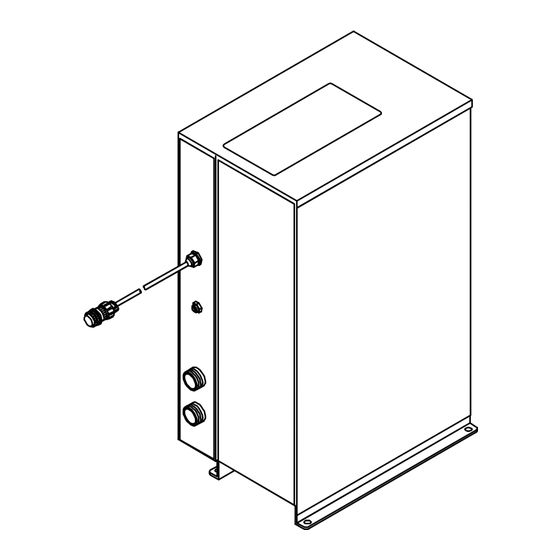

- Page 6 IMPORTANT: When installing or operating plasma arc welding equipment, refer to the Plasma Welding Con- sole Owner’s Manual and Welding Torch Owner’s Manual for specific precautionary information that ap- plies to this equipment. 3-1. FIELD INSTALLATION INSTRUCTIONS FOR PAW INTERFACE PANEL TO COMPUTER IN- TERFACE (Figure 3-1 And Figure 3-2) WARNING: ELECTRIC SHOCK can kill.

- Page 7 Robot Arm Shock Sensor Leads Insulator Shock Sensor Plate Welding Gun Body Torch Mounting Bracket Torch Clamp Mounting Bracket Clamp ST-800 733 Figure 3-3. MRH Shock Sensor Unit Assembly And Installation Output Hub L-Bracket Bracket Insulating Block Shock Sensor Leads...

- Page 8 The Pilot mode switch on the WC 100B console pro- vides a selection for the pilot arc mode of operation. If plasma arc welding is performed with the switch in the NORMAL position, the optional shield sleeving should be installed on the torch cable.

- Page 9 TORCH AND TORCH CABLE INSTALLATION TO ROBOT (Figure 3-3 Thru Figure 3-11) WARNING: ELECTRIC SHOCK can kill. Do not touch live electrical parts. Shut down robot and welding power source, and disconnect input power employing lock- out/tagging procedures before inspecting or installing.

- Page 10 ELECTRIC SHOCK can kill. ELECTROSTATIC DISCHARGE (ESD) can damage circuit boards. Do not touch live electrical parts. Shut down welding power source and Robot Control, and disconnect input power employ- ing lockout/tagging procedures before in- specting high-frequency filter. Lockout/tagging procedures consist of padlock-...

- Page 11 Welding Body Figure 3-8. Welding Gun/Torch Shock Sensor Leads r. Connect plug on end of cord to filter box recep- tacle. s. Connect friction connectors or plug on remain- ing end of cord to shock sensor leads or recep- tacle at shock sensor.

- Page 12 TB1 (IN) ESTOP ESTOP ESTOP SHOCK SHOCK INCOM INCOM LAMP AUTO TEACH ST#1 ST#2 ST#3 STOP SV. ON SV. ON Figure 3-9. Function Control Terminal Block TB1 On Interlock Board Inside Robot Control OM-169 510 Page 8 Terminal Block TB1 CN47 Interlock Board...

- Page 13 MRH 3-5. GROUND (Figure 3-10 And Figure 3-11) IMPORTANT: If welding power source is equipped with a plastic case, only one ground cable is necessary for connecting to robot base. See Figure 3-10 or Figure 3-11 and install three sup-...

- Page 14 (see Section 3-8). Route remaining end of the last ground cable to the welding power source. Connect ground cable to welding power source case unless welding power source is equipped with a plastic case, then no connection is necessary.

- Page 15 TIONS (Figure 3-1, Figure 3-10, Figure 3-11) WARNING: ELECTRIC SHOCK can kill. Do not touch live electrical parts. Shut down robot and welding power source, and disconnect input power employing lock- out/tagging procedures before inspecting or installing. Lockout/tagging procedures consist of padlock-...

- Page 16 This button starts shielding gas flow when the Run/Set switch on the WC 100B welding panel is in the Set posi- tion. When the switch is in Run position, pressing the button starts shielding gas flow and 5 seconds later plasma gas flows and the pilot arc ignites.

- Page 17 I-bar is used for adjusting torch position and for position recovery after a robot crash. Mount plasma arc welding torch, install tip gauge, and follow mounting ad- justment procedures according to instructions in Sec- tion 4 – System Set Up in the robot Owner’s Manual.

- Page 18 4-4. SYSTEM SETUP FOR MRH Set welding power source specifications in user parameters for the Plasma Arc Welding (PAW) process according to the following instructions. Turn on Robot Control input power by placing the power switch handle on the Robot Control cabinet door in the...

- Page 19 O F F S E N S O R C – S Press F4 key for the W–CHARA function to set welding characteristics. F I L E A L L O T key for additional functions to appear on the display.

- Page 20 A X I S M L 4 T E A C H S E R V O O F F R E G I S T D I F Y Use the INCREMENT LECT key to select GTAW-300 by setting a wire size selection. A X I S M L 4 T E A C H...

- Page 21 T E A C H S E R V O O F F Use the numerical keys to amperage to the maximum current output of the welding power source. P O W E R S O U R C E...

- Page 22 A X I S M L 4 T E A C H S E R V O O F F Press the RECORD RECORD A X I S M L 4 T E A C H S E R V O O F F Use the INCREMENT LECT key to change the scaling of the amperage and reference voltage.

- Page 23 Press the RECORD RECORD T E A C H M O D E S E R V O O F F S E N S O R C – S Check settings of weld characteristics as follows: a. Press the F4 key to select the W–CHARA function.

- Page 24 A X I S M L 4 T E A C H S E R V O O F F Press the RESET key. RESET T E A C H M O D E S E R V O O F F S E N S O R C –...

- Page 25 SECTION 5 – ELECTRICAL DIAGRAMS SC-169 456 Figure 5-1. Circuit Diagram For Robot PAW System OM-169 510 Page 21...

- Page 26 SB-169 458 Figure 5-2. Circuit Diagram For Robot PAW Interface Panel SB-169 459-A Figure 5-3. Wiring Diagram For Robot PAW Interface Panel OM-169 510 Page 22...

- Page 27 SA-146 608-A Figure 5-4. Circuit Diagram For High-Frequency Filter SA-146 609-B Figure 5-5. Wiring Diagram For High-Frequency Filter OM-169 510 Page 23...

- Page 28 É É É É É É É É Frequency (HF) É É É É É É Figure 6-1. High Frequency In Plasma Arc Welding (PAW) 50 ft (15 m) Figure 6-2. Sources Of High-Frequency Radiation From Incorrect Installation OM-169 510 Page 24 É...

- Page 29 Ground All Metal Objects And All Wiring In Welding Zone Using #12 AWG Wire Plasma Arc Welding Power Source Ground metal machine case, line discon- nect device, input supply, and workpiece (if required). Center Point Of Welding Zone Midpoint between high-frequency source and welding torch.

- Page 30 Dia. Part Mkgs. Spectrum Interface CR10,11 052 964 RELAY, encl 24VDC DPDT ..169 465 DIODE, w/leads ..169 467 DIODE, w/leads ..113 333 SWITCH, PB MC NO SPST PC10...

- Page 31 169 454 TIP GAGE ..171 042 SHIELD, plasma welding torch ... 143 352 CLAMP, cable ...

- Page 32 Notes...

Need help?

Do you have a question about the Welding and is the answer not in the manual?

Questions and answers