Table of Contents

Troubleshooting

Summary of Contents for Miller Electric M-10 Gun

- Page 1 Visit our website at www.MillerWelds.com Millermatic DVI And M-10 Gun OM-1330 220 237H 2007−02 Processes MIG (GMAW) Welding Flux Cored (FCAW) Welding Description Arc Welding Power Source and Wire Feeder File: MIG (GMAW)

- Page 2 ISO 9001:2000 Quality System Standard. particular model are also provided. Miller Electric manufactures a full line of welders and welding related equipment. For information on other quality Miller products, contact your local Miller distributor to receive the latest full line catalog or individual specification sheets.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING 1-1. Symbol Usage ............... . 1-2. - Page 4 TABLE OF CONTENTS SECTION 8 − MIG WELDING (GMAW) GUIDELINES 8-1. Typical MIG Process Connections 8-2. Typical MIG Process Control Settings 8-3. Holding And Positioning Welding Gun 8-4. Conditions That Affect Weld Bead Shape 8-5. Gun Movement During Welding 8-6. Poor Weld Bead Characteristics 8-7.

-

Page 5: Section 1 − Safety Precautions - Read Before Using

DC constant voltage (wire) welder, 2) a DC manual (stick) welder, or 3) an AC welder with reduced open-circuit volt- age. In most situations, use of a DC, constant voltage wire welder is recommended. And, do not work alone! D Disconnect input power or stop engine before installing or servicing this equipment. - Page 6 D Do not use welder to thaw frozen pipes. D Remove stick electrode from holder or cut off welding wire at contact tip when not in use.

-

Page 7: Additional Symbols For Installation, Operation, And Maintenance

1-3. Additional Symbols For Installation, Operation, And Maintenance FIRE OR EXPLOSION hazard. D Do not install or place unit on, over, or near combustible surfaces. D Do not install unit near flammables. D Do not overload building wiring − be sure power supply system is properly sized, rated, and protected to handle this unit. -

Page 8: Principal Safety Standards

1-5. Principal Safety Standards Safety in Welding, Cutting, and Allied Processes, ANSI Standard Z49.1, from Global Engineering Documents (phone: 1-877-413-5184, website: www.global.ihs.com). Recommended Safe Practices for the Preparation for Welding and Cut- ting of Containers and Piping, American Welding Society Standard F4.1 from Global... -

Page 9: Section 2 − Consignes De Sécurité − Lire Avant Utilisation

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT UTILISATION Y Avertissement : se protéger et protéger les autres contre le risque de blessure — lire et respecter ces consignes. 2-1. Symboles utilisés Symbole graphique d’avertissement ! Attention ! Cette pro- cédure comporte des risques possibles ! Les dangers éven- tuels sont représentés par les symboles graphiques joints. - Page 10 LES RAYONS D’ARC peuvent entraî- ner des brûlures aux yeux et à la peau. Le rayonnement de l’arc du procédé de soudage génère des rayons visibles et invisibles intenses (ultraviolets et infrarouges) susceptibles de provo- quer des brûlures dans les yeux et sur la peau. Des étincelles sont projetées pendant le soudage.

-

Page 11: Dangers Supplémentaires En Relation Avec L'installation, Le Fonctionnement Et La Maintenance

2-3. Dangers supplémentaires en relation avec l’installation, le fonctionnement et la maintenance Risque D’INCENDIE OU D’EXPLO- SION. D Ne pas placer l’appareil sur, au-dessus ou à proximité de surfaces inflammables. D Ne pas installer l’appareil à proximité de produits inflammables. D Ne pas surcharger l’installation électrique −... -

Page 12: Principales Normes De Sécurité

2-5. Principales normes de sécurité Safety in Welding, Cutting, and Allied Processes, ANSI Standard Z49.1, de Global Engineering Documents (téléphone : 1-877-413-5184, site In- ternet : www.global.ihs.com). Recommended Safe Practices for the Preparation for Welding and Cut- ting of Containers and Piping, American Welding Society Standard AWS F4.1 de Global Engineering Documents (téléphone : 1-877-413-5184, site Internet : www.global.ihs.com). -

Page 13: Section 3 − Definitions

SECTION 3 − DEFINITIONS 3-1. Symbols And Definitions Wire Feed Volts Gas Metal Arc Welding (GMAW) Voltage Input SECTION 4 − INSTALLATION 4-1. Specifications A. 115 VAC Rated Welding Amperage Range Output 90 A @ 18.0 Volts DC, 20% 90 A @ 18.0 Volts DC, 20% 30 −... -

Page 14: Duty Cycle And Overheating

4-2. Duty Cycle And Overheating A. 115 VAC 2 Minutes Welding B. 230 VAC 4 Minutes Welding Overheating OM-1330 Page 10 20% duty cycle at 90 amps 8 Minutes Resting 40% duty cycle at 150 amps 6 Minutes Resting Minutes Duty Cycle is percentage of 10 minutes that unit can weld at rated load without overheating. -

Page 15: Volt-Ampere Curves

4-3. Volt-Ampere Curves 4-4. MIG Welding Gun Duty Cycle And Overheating CAUTION WELDING LONGER THAN RATED DUTY CYCLE can damage gun and void warranty. • Do not weld at rated load longer than shown below. • Using gasless flux cored wire reduces gun duty cycle. Definition 100% Duty Cycle At 100 Amperes Minutes... -

Page 16: Connecting To Weld Output Terminals

4-5. Connecting To Weld Output Terminals Tools Needed: 3/4 in (19 mm) Y Turn off power before connecting to weld output terminals. Y Failure to properly connect weld cables may cause excessive heat and start a fire, or damage your ma- chine. -

Page 17: Installing Welding Gun

4-7. Installing Welding Gun 4-8. Setting Gun Polarity For Wire Type Changing Polarity Wire Drive Assembly Lead Positive Terminal Shown as shipped − Electrode Positive (DCEP): For solid steel, stainless steel, aluminum, or flux core with gas wires (GMAW). Electrode Negative (DCEN): Reverse lead connections at terminals from that shown above for gasless flux core wires (FCAW). -

Page 18: Installing Gas Supply

4-9. Installing Gas Supply Argon Gas Or Mixed Gas Tools Needed: 1-1/8, 5/8 in OM-1330 Page 14 DO NOT use Argon/Mixed gas regulator/flowmeter with CO shielding gas. See Parts List for optional gas regulator/flowmeter. Rear Panel Obtain gas cylinders and chain to running gear, wall, other... -

Page 19: Installing Mig Wire Spool And Adjusting Hub Tension

4-10. Installing MIG Wire Spool and Adjusting Hub Tension Installing 1 Or 2 lb Wire Spool Spindle Remove these components from spindle. Tools Needed: Use compression spring with 8 in (200 mm) spools. Spindle Install these components onto spindle. Order extra spring Part No. -

Page 20: Connecting 1-Phase Input Power For 230 Vac

4-11. Connecting 1-Phase Input Power For 230 VAC 230 VAC, 1 Tools Needed: OM-1330 Page 16 =GND/PE Earth Ground Y Installation must meet National and Local Codes − have only qualified persons make this installation. Y Disconnect and lockout/tagout input power before connecting input conductors from unit. -

Page 21: Electrical Service Guide For 230 Vac

4-12. Electrical Service Guide For 230 VAC Input Voltage Input Amperes At Rated Output Max Recommended Standard Fuse Rating In Amperes Min Input Conductor Size In AWG Max Recommended Input Conductor Length In Feet (Meters) Min Grounding Conductor Size In AWG Reference: 2005 National Electrical Code (NEC) (including article 630) 1 Choose a circuit breaker with time-current curves comparable to a Time Delay Fuse. -

Page 22: Selecting A Location And Connecting Input Power

4-14. Selecting A Location And Connecting Input Power 18 in (457 mm) of space for airflow Y Do not move or operate unit where it could tip. Y Special installation may be required where gasoline or volatile liquids are present − see NEC Article 511 or CEC Section 20. -

Page 23: Threading Welding Wire

4-15. Threading Welding Wire Open pressure assembly. Tighten Close and tighten pressure assembly, and let go of wire. Press gun trigger until wire comes out of gun. Reinstall contact tip and nozzle Hold wire tightly to keep it from unraveling. 6 in (150 mm) Pull and hold wire;... -

Page 24: Installing Diverter Valve And Switch For Optional Spool Gun

4-16. Installing Diverter Valve And Switch For Optional Spool Gun Tools Needed: 1/4 in 9/16 in Y Turn Off unit, and disconnect input power. Disconnect and remove MIG (GMAW) welding gun, if applicable. Input End Of Existing Gas Hose Output End Of Existing Gas Hose Spool Gun Gas Hose Gas Diverter Valve To install diverter valve, cut existing gas... -

Page 25: Connecting An Optional Spool Gun

4-17. Connecting An Optional Spool Gun If a MIG gun is connected to the unit, remove it before connecting spool gun. Diverter Valve If spool gun gas hose is equipped with a pre-installed barbed fitting, cut off fitting from end of hose. Connect spool gun gas hose to diverter valve barbed fitting (see Section 4-16). -

Page 26: Section 5 − Operation

SECTION 5 − OPERATION 5-1. Controls Voltage Control Positions 4, 5, and 6 are for 230 volts ac input only. Set Voltage control according to the parameter chart for good starting point. Turn control clockwise to increase voltage. OM-1330 Page 22 Wire Speed Control Set Wire Speed control according to the parameter chart. - Page 27 Notes OM-1330 Page 23...

-

Page 28: Weld Parameter Chart

5-2. Weld Parameter Chart OM-1330 Page 24... - Page 29 220 493-A OM-1330 Page 25...

-

Page 30: Section 6 − Maintenance &Troubleshooting

SECTION 6 − MAINTENANCE &TROUBLESHOOTING 6-1. Routine Maintenance 3 Months Replace unreadable labels Clean and tighten weld terminals 6 Months Blow out or vacuum inside. 6-2. Supplementary Protector CB1 OM-1330 Page 26 Y Disconnect power before maintaining. Repair or replace cracked weld cable Remove drive roll and carrier. -

Page 31: Unit Overload

6-3. Unit Overload Thermostats TP1 in rectifier SR1 and TP2 in stabilizer Z1 protect the unit from damage due to overheating. If TP1 and/or TP2 opens welding output will shut off. Wait several minutes before trying to weld. Supplementary protector CB2 (Power switch) protects transformer T1 from overload. If CB2 opens, unit power will shut off. -

Page 32: Aligning Drive Rolls And Wire Guide

6-6. Aligning Drive Rolls and Wire Guide Tools Needed: 6-7. Removing Knob From Front Panel OM-1330 Page 28 Correct Incorrect Y Turn Off power. View is from top of drive rolls looking down with pressure assembly open. Drive Roll Securing Nut Drive Roll Wire Guide Welding Wire... -

Page 33: Cleaning Or Replacing Gun Liner

6-8. Cleaning Or Replacing Gun Liner 1/2 in Lay gun cable out straight before installing new liner. Y Disconnect gun from unit. Head Tube Remove nozzle, contact tip, adapter, gas diffuser, and wire outlet guide. Blow out gun casing. Tools Needed: 3/8 in Remove liner. -

Page 34: Replacing Switch And/Or Head Tube

6-9. Replacing Switch And/Or Head Tube Remove handle locking nut. Secure head tube in vice. Install existing shock washer onto new head tube. Hand-tighten head tube into connector cable. Tools Needed: 3/4 in OM-1330 Page 30 Y Disconnect gun first. Remove switch housing. -

Page 35: Troubleshooting

6-10. Troubleshooting Welding Trouble No weld output; wire does not feed. Secure power cord plug in receptacle (see Section 4-14). Check power switch/supplementary protector, and reset if necessary. If supplementary protector is not tripped, replace power switch. Check supplementary protector CB1, and reset if necessary (see Section 6-2). Replace building line fuse or reset circuit breaker if open (see Section 4-14). -

Page 36: Section 7 − Electrical Diagram

SECTION 7 − ELECTRICAL DIAGRAM Figure 7-1. Welding Power Source Circuit Diagram OM-1330 Page 32... - Page 37 220 197-E OM-1330 Page 33...

-

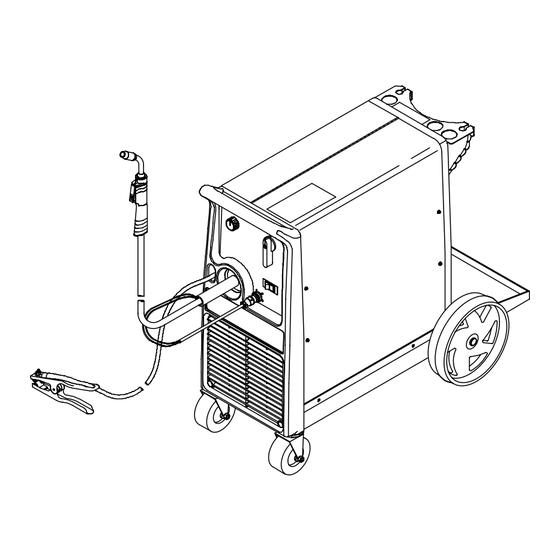

Page 38: Section 8 − Mig Welding (Gmaw) Guidelines

SECTION 8 − MIG WELDING (GMAW) GUIDELINES 8-1. Typical MIG Process Connections Regulator/ Flowmeter Hose OM-1330 Page 34 Shielding Supply Wire Feeder/ Power Source Work Clamp Y Weld current can damage electronic parts in vehicles. Disconnect both battery cables before welding on a vehicle. -

Page 39: Typical Mig Process Control Settings

8-2. Typical MIG Process Control Settings NOTE These settings are guidelines only. Material and wire type, joint design, fitup, position, shielding gas, etc. affect settings. Test welds to be sure they comply to specifications. Material thickness determines weld parameters. .035 in Wire Recommendation Size... -

Page 40: Holding And Positioning Welding Gun

8-3. Holding And Positioning Welding Gun NOTE Welding wire is energized when gun trigger is pressed. Before lowering helmet and pressing trigger, be sure wire is no more than 1/2 in (13 mm) past end of nozzle, and tip of wire is positioned correctly on seam. °... -

Page 41: Conditions That Affect Weld Bead Shape

8-4. Conditions That Affect Weld Bead Shape NOTE Weld bead shape depends on gun angle, direction of travel, electrode extension (stickout), travel speed, thickness of base metal, wire feed speed (weld current), and voltage. Short Short FILLET WELD ELECTRODE EXTENSIONS (STICKOUT) Slow °... -

Page 42: Gun Movement During Welding

8-5. Gun Movement During Welding NOTE Normally, a single stringer bead is satisfactory for most narrow groove weld joints; however, for wide groove weld joints or bridging across gaps, a weave bead or multiple stringer beads works better. 8-6. Poor Weld Bead Characteristics 8-7. -

Page 43: Troubleshooting − Excessive Spatter

8-8. Troubleshooting − Excessive Spatter Possible Causes Wire feed speed too high. Voltage too high. Electrode extension (stickout) too long. Workpiece dirty. Insufficient shielding gas at welding arc. Dirty welding wire. 8-9. Troubleshooting − Porosity Possible Causes Insufficient shielding gas at welding arc. Wrong gas. -

Page 44: Troubleshooting − Lack Of Penetration

8-11. Troubleshooting − Lack Of Penetration Lack of Penetration Good Penetration Possible Causes Improper joint preparation. Improper weld technique. Insufficient heat input. Incorrect polarity. 8-12. Troubleshooting − Incomplete Fusion Possible Causes Workpiece dirty. Insufficient heat input. Improper welding technique. 8-13. Troubleshooting − Burn-Through Possible Causes Excessive heat input. -

Page 45: Troubleshooting − Waviness Of Bead

8-14. Troubleshooting − Waviness Of Bead Possible Causes Welding wire extends too far out of nozzle. Unsteady hand. 8-15. Troubleshooting − Distortion Base metal moves in the direction of the weld bead. Possible Causes Excessive heat input. Waviness Of Bead − weld metal that is not parallel and does not cover joint formed by base metal. -

Page 46: Common Mig Shielding Gases

8-16. Common MIG Shielding Gases This is a general chart for common gases and where they are used. Many different combinations (mixtures) of shielding gases have been developed over the years. The most commonly used shielding gases are listed in the following table. - Page 47 Problem Probable Cause Wire slipping in drive rolls. Welding arc not stable. Wrong size gun liner or contact tip. Incorrect voltage setting for selected wire feed speed on welding power source. Loose connections at the gun weld cable or work cable. Check and tighten all connections. Gun in poor shape or loose connection inside gun.

-

Page 48: Section 9 − Parts List

SECTION 9 − PARTS LIST Hardware is common and not available unless listed. Ref. 803 864-E Figure 9-1. Main Assembly OM-1330 Page 44... - Page 49 PANEL,FRONT ....Fig 9-6 M-10 GUN 12 FT .030-.035 ... . . 196328 CABLE,WORK 10’ NO 3 W/CLAMP (INCLUDING) .

- Page 50 OM-1330 Page 46 Figure 9-2. Baffle, Center w/Components Hardware is common and not available unless listed. 803 865-C...

- Page 51 Item Dia. Part Mkgs. Figure 9-2. Baffle, Center w/Components (Fig 9-1 Item 1) ......SPOOL HUB ASSEMBLY (INCLUDING) .

- Page 52 Hardware is common and not available unless listed. Item Dia. Part Mkgs. Figure 9-3. Panel, Rear w/Components (Fig 9-1 Item 2) ... . . 049399 NUT, 312−18 PUSH ON .63D .07H STL .

- Page 53 Hardware is common and not available unless listed. Item Dia. Part Mkgs. Figure 9-4. Panel, Front w/Components (Fig 9-1 Item 18) ... . . 220079 LABEL,NAMEPLATE MILLERMATIC DVI ..

- Page 54 Item Dia. Part Mkgs. Figure 9-5. Wire Drive And Gears (Fig 9-2 Item 18) 204857 ... . . 602009 SCREW,.250-20 x 1.25 soc hd gr 8 ... . . 172075 CARRIER,DRIVE ROLL W/COMPONENTS .

- Page 55 Item Part Figure 9-6. M-10 Gun (Fig 9-1 Item 19 ) ....169 715 ....

-

Page 56: Drive Roll And Wire Guide Kits

Item Dia. Part Mkgs. 207 642 ....186420 ....195539 . - Page 57 Notes...

- Page 58 Notes...

- Page 59 Warranty Questions? LIMITED WARRANTY − Subject to the terms and conditions Call below, Miller Electric Mfg. Co., Appleton, Wisconsin, warrants to 1-800-4-A-MILLER its original retail purchaser that new Miller equipment sold after the effective date of this limited warranty is free of defects in for your local material and workmanship at the time it is shipped by Miller.

-

Page 60: Owner's Record

For assistance in filing or settling claims, contact your distributor and/or equipment manufacturer’s Transportation Department. © 2007 Miller Electric Mfg. Co. 2007−01 Miller Electric Mfg. Co. An Illinois Tool Works Company 1635 West Spencer Street Appleton, WI 54914 USA International Headquarters−USA...

Need help?

Do you have a question about the M-10 Gun and is the answer not in the manual?

Questions and answers