Table of Contents

Troubleshooting

Summary of Contents for Miller Electric Delta-Fab

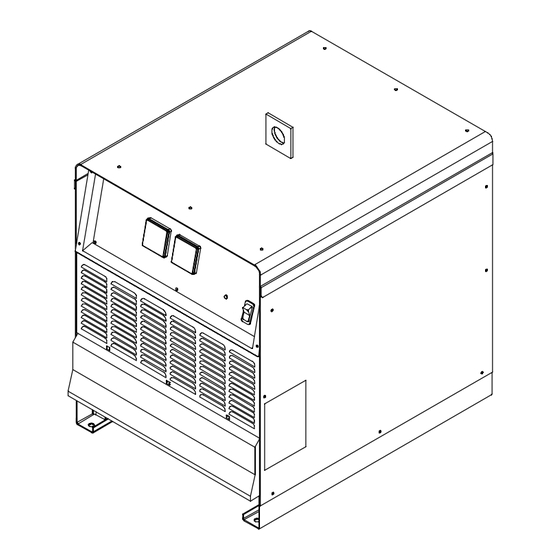

- Page 1 Visit our website at www.MillerWelds.com OM-2241 2006−03 Processes Description Arc Welding Power Source Delta-Fab 209 815H Gas Metal Arc (MIG) Welding Flux Cored (FCAW) Welding Air Carbon Arc Cutting and Gouging File: MIG (GMAW)

- Page 2 ISO 9001:2000 Quality System Standard. particular model are also provided. Miller Electric manufactures a full line of welders and welding related equipment. For information on other quality Miller products, contact your local Miller distributor to receive the latest full line catalog or individual specification sheets.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING 1-1. Symbol Usage ............... . 1-2. - Page 4 Notes...

-

Page 5: Section 1 − Safety Precautions - Read Before Using

DC constant voltage (wire) welder, 2) a DC manual (stick) welder, or 3) an AC welder with reduced open-circuit volt- age. In most situations, use of a DC, constant voltage wire welder is recommended. And, do not work alone! D Disconnect input power or stop engine before installing or servicing this equipment. - Page 6 D Do not use welder to thaw frozen pipes. D Remove stick electrode from holder or cut off welding wire at contact tip when not in use.

-

Page 7: Additional Symbols For Installation, Operation, And Maintenance

1-3. Additional Symbols For Installation, Operation, And Maintenance FIRE OR EXPLOSION hazard. D Do not install or place unit on, over, or near combustible surfaces. D Do not install unit near flammables. D Do not overload building wiring − be sure power supply system is properly sized, rated, and protected to handle this unit. -

Page 8: Principal Safety Standards

1-5. Principal Safety Standards Safety in Welding, Cutting, and Allied Processes, ANSI Standard Z49.1, from Global Engineering Documents (phone: 1-877-413-5184, website: www.global.ihs.com). Recommended Safe Practices for the Preparation for Welding and Cut- ting of Containers and Piping, American Welding Society Standard F4.1 from Global... -

Page 9: Section 2 − Consignes De Sécurité − Lire Avant Utilisation

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT UTILISATION Y Avertissement : se protéger et protéger les autres contre le risque de blessure — lire et respecter ces consignes. 2-1. Symboles utilisés Symbole graphique d’avertissement ! Attention ! Cette pro- cédure comporte des risques possibles ! Les dangers éven- tuels sont représentés par les symboles graphiques joints. - Page 10 LES RAYONS D’ARC peuvent entraî- ner des brûlures aux yeux et à la peau. Le rayonnement de l’arc du procédé de soudage génère des rayons visibles et invisibles intenses (ultraviolets et infrarouges) susceptibles de provo- quer des brûlures dans les yeux et sur la peau. Des étincelles sont projetées pendant le soudage.

-

Page 11: Dangers Supplémentaires En Relation Avec L'installation, Le Fonctionnement Et La Maintenance

2-3. Dangers supplémentaires en relation avec l’installation, le fonctionnement et la maintenance Risque D’INCENDIE OU D’EXPLO- SION. D Ne pas placer l’appareil sur, au-dessus ou à proximité de surfaces inflammables. D Ne pas installer l’appareil à proximité de produits inflammables. D Ne pas surcharger l’installation électrique −... -

Page 12: Principales Normes De Sécurité

2-5. Principales normes de sécurité Safety in Welding, Cutting, and Allied Processes, ANSI Standard Z49.1, de Global Engineering Documents (téléphone : 1-877-413-5184, site In- ternet : www.global.ihs.com). Recommended Safe Practices for the Preparation for Welding and Cut- ting of Containers and Piping, American Welding Society Standard AWS F4.1 de Global Engineering Documents (téléphone : 1-877-413-5184, site Internet : www.global.ihs.com). -

Page 13: Section 3 − Installation

SECTION 3 − INSTALLATION 3-1. Specifications Voltage Range Voltage Range Rated Welding Output 375 A @ 35 Volts DC, 10 − 45 100% Duty Cycle *While idling 3-2. Duty Cycle And Overheating Overheating Amperes Input at Rated Load Output, 60 Hz, Three-Phase 230 V 460 V Max OCV DC... -

Page 14: Volt-Ampere Curves

3-3. Volt-Ampere Curves OM-2241 Page 10 DC Amperes Volt-ampere curves show mini- mum and maximum voltage and amperage output capabilities of unit. Curves of other settings fall be- tween curves shown. 209 811... -

Page 15: Selecting A Location

3-4. Selecting A Location Movement Location And Airflow 3-5. Tipping 18 in (460 mm) Lifting Eye Lifting Forks Use lifting eye or lifting forks to move unit. If using lifting forks, extend forks beyond opposite side of unit. Rating Label (Non CE Models Only) Use rating label to determine input power needs. -

Page 16: Dimensions And Weights

3-6. Dimensions And Weights 3-7. 115 VAC Receptacle And Supplementary Protectors OM-2241 Page 12 4 Holes 4 Holes 801 530 Dimensions Dimensions 30 in (762 mm) including lift eye 23 in (585 mm) 30-1/2 in (775 mm) including strain relief 27-1/2 in (699 mm) 3/4 in (19 mm) 21-1/8 in (537 mm) -

Page 17: Weld Output Terminals And Selecting Cable Sizes

3-8. Weld Output Terminals And Selecting Cable Sizes Y Turn off power before connecting to weld out- put terminals. Welding Amperes Y Do not use worn, dam- aged, undersized, or poorly spliced cables. Negative Stainless Steel/ Aluminum Aluminum All Other Mat ial Materials *Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere. -

Page 18: Remote 14 Receptacle Rc8

3-10. Remote 14 Receptacle RC8 3-11. Remote 14 Receptacle RC8 Information 24 VOLTS AC 24 VOLTS AC REMOTE OUTPUT CONTROL 115 VOLTS AC 115 VOLTS AC REMOTE POWER ON/OFF REMOTE POWER ON/OFF REMOTE VOLTAGE SENSING REMOTE VOLTAGE SENSING * Not Used OM-2241 Page 14 C L N Socket... -

Page 19: Electrical Service Guide

3-12. Electrical Service Guide Input Voltage Input Amperes At Rated Output Max Recommended Standard Fuse Rating In Amperes Time-Delay Normal Operating 3 Min Input Conductor Size In AWG 4 Max Recommended Input Conductor Length In Feet (Meters) Min Grounding Conductor Size In AWG 4 Reference: 2005 National Electrical Code (NEC) 1 Consult factory for circuit breaker applications. -

Page 20: Connecting Input Power

3-14. Connecting Input Power L1 (U) L2 (V) L3 (W) Tools Needed: 3/8 in 3/8 in OM-2241 Page 16 = GND/PE Earth Ground IMPORTANT Input Contactor GND/ PE Earth Ground Y Installation must meet all National and Local Codes − have only quali- fied persons make this installation. -

Page 21: Section 4 − Operation

SECTION 4 − OPERATION 4-1. Controls Voltage Meter Amperage Meter Voltmeter and ammeter display actual output voltage and amperage. SECTION 5 − MAINTENANCE & TROUBLESHOOTING 5-1. Routine Maintenance Y Disconnect input power before maintaining. 3 Months Replace unreadable labels. 6 Months Blow out or vacuum inside. -

Page 22: Fuse F1

5-2. Fuse F1 Tools Needed: 3/8 in 5-3. Short Circuit Shutdown When contact tip is shorted and sticks to workpiece, the unit output falls to a safe operating level. To resume operation, release gun trigger, turn Off unit, and remove contact tip from workpiece. Check contact tip and replace if damaged. Turn On unit to continue operation. -

Page 23: Troubleshooting Table

5-4. Troubleshooting Table Trouble No weld output; unit completely Place line disconnect switch in On position (see Section 3-14). inoperative. Check fuse F1, and replace if necessary (see Section 5-2). Check and replace line fuse(s), if necessary, or reset circuit breaker (see Section 3-14). Check for proper input power connections (see Section 3-14). -

Page 24: Section 6 − Electrical Diagram

SECTION 6 − ELECTRICAL DIAGRAM 218 521-A Figure 6-1. Circuit Diagram OM-2241 Page 20... - Page 25 Notes OM-2241 Page 21...

-

Page 26: Section 7 − Parts List

SECTION 7 − PARTS LIST Hardware is common and not available unless listed. 803 388-B Figure 7-1 Main Assembly OM-2241 Page 22... - Page 27 Item Dia. Part Mkgs....+179 430 ....179 429 ..

- Page 28 Hardware is common and not available unless listed. Item Dia. Part Mkgs....159 863 ... 209 627 .

- Page 29 Item Dia. Part Mkgs. Figure 7-2 Panel, Front w/Components (Fig 7-1 Item 33) (continued) ..PLG2 . . . 185 626 ... 159 522 .

- Page 30 Hardware is common and not available unless listed. Item Dia. Part Mkgs....173 283 ....180 165 .

- Page 31 Warranty Questions? LIMITED WARRANTY − Subject to the terms and conditions Call below, Miller Electric Mfg. Co., Appleton, Wisconsin, warrants to 1-800-4-A-MILLER its original retail purchaser that new Miller equipment sold after the effective date of this limited warranty is free of defects in for your local material and workmanship at the time it is shipped by Miller.

-

Page 32: Owner's Record

File a claim for loss or damage during shipment. For assistance in filing or settling claims, contact your distributor and/or equipment manufacturer’s Transportation Department. 2006 Miller Electric Mfg. Co. 2006−01 Miller Electric Mfg. Co. An Illinois Tool Works Company 1635 West Spencer Street Appleton, WI 54914 USA International Headquarters−USA...

Need help?

Do you have a question about the Delta-Fab and is the answer not in the manual?

Questions and answers