Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Miller Electric 250

- Page 1 Visit our website at www.MillerWelds.com Bobcat 250 Diesel ™ OM-217 455H 2007−05−21 Processes Stick (SMAW) Welding MIG (GMAW) Welding Flux Cored (FCAW) Welding Non-Critical TIG (GTAW) Welding Description Engine Driven Welding Generator File: Engine Drive...

- Page 2 ISO 9001:2000 Quality System Standard. particular model are also provided. Miller Electric manufactures a full line of welders and welding related equipment. For information on other quality Miller products, contact your local Miller distributor to receive the latest full line catalog or individual specification sheets.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING 1-1. Symbol Usage ............... 1-2. - Page 4 TABLE OF CONTENTS SECTION 10 − PARTS LIST ..............10-1.

-

Page 5: Section 1 − Safety Precautions − Read Before Using

DC constant voltage (wire) welder, 2) a DC manual (stick) welder, or 3) an AC welder with reduced open-circuit volt- age. In most situations, use of a DC, constant voltage wire welder is recommended. And, do not work alone! D Disconnect input power or stop engine before installing or servicing this equipment. -

Page 6: Noise Can Damage Hearing

D Do not use welder to thaw frozen pipes. D Remove stick electrode from holder or cut off welding wire at contact tip when not in use. -

Page 7: Engine Hazards

D Do not allow tools to cause sparks when working on a battery. D Do not use welder to charge batteries or jump start vehicles. D Observe correct polarity (+ and −) on batteries. -

Page 8: Additional Symbols For Installation, Operation, And Maintenance

HOT METAL from air arc cutting and gouging can cause fire or explosion. D Do not cut or gouge near flammables. D Watch for fire; keep extinguisher nearby. HOT PARTS can cause burns and injury. D Do not touch hot compressor or air system parts. -

Page 9: California Proposition 65 Warnings

H.F. RADIATION can cause interference. D High-frequency (H.F.) can interfere with radio navigation, safety services, computers, and communications equipment. D Have only qualified persons familiar with electronic equipment perform this installation. D The user is responsible for having a qualified electrician promptly correct any interference problem resulting from the installation. -

Page 10: Section 2 − Consignes De Sécurité − Lire Avant Utilisation

SECTION 2 CONSIGNES DE SÉCURITÉ − LIRE AVANT − Se protéger, ainsi que toute autre personne travaillant sur les lieux, contre les étincelles et le métal chaud. 2-1. Signification des symboles DANGER! − Indique une situation dangereuse qui si on l’évite pas peut donner la mort ou des blessures graves. - Page 11 Une tension DC importante subsiste à l’intérieur des onduleurs après avoir coupé l’alimentation. D Couper l’alimentation du poste et décharger les condensateurs d’entrée comme indiqué dans la Section Maintenance avant de toucher des composants. DES PIÈCES CHAUDES peuvent provoquer des brûlures graves. D Ne pas toucher à...

-

Page 12: Dangers Existant En Relation Avec Le Moteur

D Suivre les recommandations dans OSHA 1910.252(a)(2)(iv) et NFPA 51B pour les travaux à chaud et avoir de la surveillance et un extincteur à proximité. LE BRUIT peut affecter l’ouïe. Le bruit des processus et des équipements peut affec l’ouïe. D Porter des protections approuvés pour les ore les si le niveau sonore est trop élevé. -

Page 13: Dangers Liés À L'air Comprimé

D Dévisser le bouchon légèrement et laisser la vapeur s’échapper avant d’enlever le bouchon. L’utilisation d’un groupe autonome à l’intérieur PEUT VOUS TUER EN QUELQUES MINUTES. D Les fumées d’un groupe autonome contient du monoxyde de carbone. C’est un poison invisi- ble et inodore. - Page 14 LE SURCHAUFFEMENT peut endom- mager le moteur électrique. D Arrêter ou déconnecter l’équipement avant de démarrer ou d’arrêter le moteur. D Ne pas laisser tourner le moteur trop lentement sous risque d’en- dommager le moteur électrique à cause d’une tension et d’une fré- quence trop faibles.

-

Page 15: Proposition Californienne 65 Avertissements

2-6. Proposition californienne 65 Avertissements Les équipements de soudage et de coupage produisent des fumées et des gaz qui contiennent des produits chimiques dont l’État de Californie reconnaît qu’ils provoquent des mal- formations congénitales et, dans certains cas, des cancers. (Code de santé... -

Page 16: Symbol Definitions

4-1. Weld, Power, and Engine Specifications Also see Performance Data in Section 13. Rated Welding Weld Output Welding Mode Range Output 250 A, 25 V, CC/AC 40 − 250 A 100% Duty Cycle 250 A, 25 V, CC/DC 40 − 250 A 100% Duty... -

Page 17: Dimensions, Weights, And Operating Angles

4-2. Dimensions, Weights, and Operating Angles Dimensions 35-1/2 in (902 mm) Height (To Top Of Exhaust) Width 20 in (508 mm) Depth 53 in (1346 mm) 20 in (508 mm) 16-1/2 in (419 mm) 1-3/4 in (44 mm) 6-1/16 in (154 mm) 32-3/4 in (832 mm) 51-3/8 in (1305 mm) 13/32 in (10 mm) Dia. -

Page 18: Section 5 − Installation

SECTION 5 − INSTALLATION 5-1. Installing Welding Generator Movement Do not lift unit from end. Location / Airflow Clearance 18 in (460 mm) 18 in (460 mm) 18 in 18 in (460 mm) (460 mm) Mounting Inadequate support. Do not use flexible mounts. Grounding GND/PE Electrically bond generator frame to... -

Page 19: Installing Exhaust Pipe

804 196-A / Ref. 228 647-A Connect negative (−) cable last. − 804 250-A / Ref 228 647 / Ref. S-0756-D OM-217 455 Page 15... -

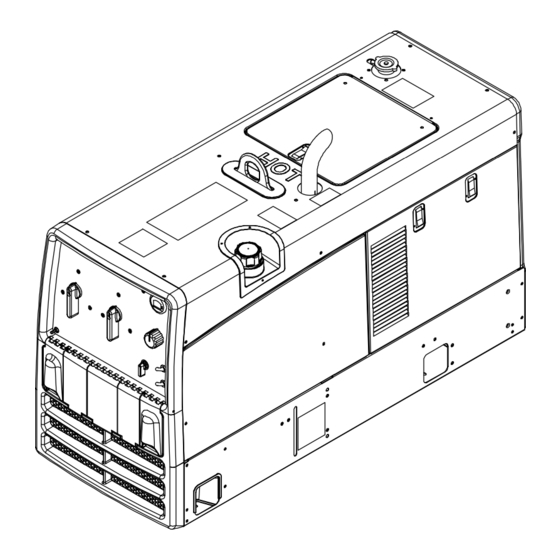

Page 20: Overview And Engine Prestart Checks

A complete Parts List is available at www.MillerWelds.com 5-4. Overview And Engine Prestart Checks Generator Power Receptacles (see Section 7) Weld Output Terminals (see Section 5-5) Operator Controls (see Section 6) Fuel Gauge/Maintenance Display Fuel Filler Cap Exhaust Pipe OM-217 455 Page 16 Radiator Cap Engine Maintenance Label (Inside Door) Oil Fill Cap... -

Page 21: Engine Left Side

Use fuel formulated for cold weather (diesel fuel can gel in cold weather). Contact local fuel supplier for fuel information. Use correct grade oil for cold weather. 804 249-A / 804 250-A OM-217 455 Page 17... -

Page 22: Connecting To Weld Output Terminals

5-5. Connecting to Weld Output Terminals Do not place anything between weld cable terminal and copper bar. Correct Installation OM-217 455 Page 18 Work Weld Output Terminal Electrode Weld Output Terminal Connect work cable to Work terminal. Connect electrode holder cable or electrode weld cable to Electrode ter- minal for Stick and MIG welding. -

Page 23: Selecting Weld Cable Sizes

1/0 (60) 2/0 (70) 3/0 (95) 4/0 (120) 2 ea. 2/0 2/0 (70) 3/0 (95) 4/0 (120) 200 ft 250 ft 300 ft 350 ft (70 m) (90 m) (105 m) 10 − 100% Duty Cycle 3 (30) 2 (35) -

Page 24: Section 6 − Operating The Welding Generator

SECTION 6 − OPERATING THE WELDING GENERATOR 6-1. Engine Control Switches NOTICE − Disconnect equipment from auxil- iary power receptacles during start−up and shutdown. Some equipment can be damaged by changes in frequency as engine rpms change during start-up and shutdown. Engine Control Switch Use switch to start engine, select speed, and stop engine. -

Page 25: Weld Output Controls

6-2. Weld Output Controls Weld Process Selector Switch NOTICE − Do not switch while welding. Use switch to select type of weld output. Wire (GMAW) Welding: Use a positive (+) position for Direct Current Electrode Positive (DCEP) and a negative (−) position for Direct Current Electrode Negative. -

Page 26: Typical Stick Welding Connections And Control Settings

6-3. Typical Stick Welding Connections And Control Settings OM-217 455 Page 22 Stop engine. This section provides general guidelines and may not suit all applications. Typical Settings For 7018 (1/8 in) Electrode: > Set Weld Process Selector switch to + Stick position. >... -

Page 27: Typical Mig Welding Connections And Settings

6-4. Typical MIG Welding Connections And Settings Tools Needed: 3/4 in Work Stop engine. This section provides general guide- lines and may not suit all ap- plications. Typical Control Settings For Short Circuit Transfer Using .035 (ER70S-3) Solid Wire And 75/25 Argon/CO Gas: >... -

Page 28: Typical Mig Connections And Settings Using Weld Control And Spoolgun

6-5. Typical MIG Connections And Settings Using Weld Control And Spoolgun Tools Needed: 3/4 in Work Stop engine. This section provides general guide- lines and may not suit all applications. Typical Settings For 4043 (.035) Aluminum On 1/8 in Material: >... -

Page 29: Section 7 − Operating Auxiliary Equipment

SECTION 7 − OPERATING AUXILIARY EQUIPMENT 7-1. Generator Power Receptacles 803 750-B / Ref. 211 362-A If unit does not have GFCI recep- tacles, use GFCI-protected extension cord. NOTICE − Disconnect equipment from auxil- iary power receptacles during start−up and shutdown. -

Page 30: Simultaneous Weld And Power

7-2. Simultaneous Weld And Power Weld Current in Amperes Total Power in Watts 7-3. Wiring Instructions For Optional 240 Volt, Single-Phase Plug (NEMA 14-50P) Current Available in Amperes 240 V Each 120 V Duplex Receptacle* Receptacle V x A = Watts *One 240 V load or two 120 V loads. -

Page 31: Section 8 − Operating Optional Battery Charger

SECTION 8 − OPERATING OPTIONAL BATTERY CHARGER 8-1. Battery Charge Controls 8-2. Determining Battery Charging Current BATTERY COLD CRANK AMP RATING (CCA) 1000 1500 2000 Have only qualified persons charge batteries. Do not use battery charger for jump starting. NOTICE − D o not use generator power ac re- ceptacles while using optional battery charger. -

Page 32: Battery Charge Cable Connections

8-3. Battery Charge Cable Connections Stop engine. Do not charge a battery which has loose terminals or one showing damage such as a cracked case or cover. Have only qualified persons do bat- tery charging work. Keep cables away from moving parts. -

Page 33: Battery Charging Procedure

8-4. Battery Charging Procedure Stop Engine. Determine Charge Current From Battery CCA Rating And Chart (See Section 8-2). Start Engine. Turn On Battery Charging Switch. Turn Off Battery Charging Switch. Set Charge Voltage Switch To Voltage Of Battery Being Charged (12, 24, Or 36 Volt). NOTICE −... - Page 34 A complete Parts List is available at www.MillerWelds.com Notes Start Your Professional Over 80,000 trained 400 Trade Square East, Troy, Ohio 45373 Welding Career Now! since 1930! 1-800-332-9448 www.welding.org OM-217 455 Page 30...

-

Page 35: Section 9 − Maintenance And Troubleshooting

SECTION 9 − MAINTENANCE AND TROUBLESHOOTING 9-1. Routine Maintenance n = Check Z = Change ........... . Every Hours n Coolant Level... -

Page 36: Maintenance Label And Engine Maintenance Activities

A complete Parts List is available at www.MillerWelds.com 9-2. Maintenance Label And Engine Maintenance Activities Stop engine and let cool. Oil And Fuel Oil Drain Valve Oil Filter Change engine oil and filter according to en- gine manual. NOTICE − Close valve and valve cap before adding oil and running engine. - Page 37 A complete Parts List is available at www.MillerWelds.com 804 197-A / Ref 803 111-A / 227 727 OM-217 455 Page 33...

-

Page 38: Servicing Air Cleaner

9-3. Servicing Air Cleaner Optional Keep nozzle 2 in (51 mm) from element. Blow OM-217 455 Page 34 Inspect aircleaner1 9/02− ST-153 929-B / ST-153 585 / Ref. S-0698-B Stop engine. NOTICE − Do not run engine without air cleaner or with dirty element. Engine damage caused by using a damaged ele- ment is not covered by the warranty. -

Page 39: Adjusting Engine Speed

Retighten nut. If there is no clearance between jam nut and solenoid, loosen the solenoid mount- ing screws and reposition the solenoid as described at the beginning of this section. Ref. 804 250-A / 802 649 OM-217 455 Page 35... - Page 40 Move the solenoid slightly until the link moves freely with solenoid in re- laxed and energized positions. Tighten screws. Tighten jam nut. Go to Step C. Tools Needed: 3/8, 7/16 in 5/32 in Ref. 804 250-A / 802 649...

- Page 41 Weld Speed Jam Nut Adjustment Screw Turn Engine Control switch to Run posi- tion. Loosen nut and turn screw counter- clockwise to increase speed. Turn screw clockwise to decrease speed. Tighten nut. Ref. 804 250-A / 801 963 OM-217 455 Page 37...

-

Page 42: Overload Protection

CB8 protects the engine battery cir- cuit. If CB8 opens, the engine will not crank. CB8 automatically re- sets when the fault is corrected. Replace any open fuses. Close door and/or reinstall cover before operating unit. 804 253-A / Ref 804 250-A... -

Page 43: Troubleshooting Tables

9-6. Troubleshooting Tables A. Welding Trouble Low or no weld output; generator pow- Check control settings. er output okay at ac receptacles. Check weld connections. Check fuse F1, and replace if open (see Section 9-5). Have Factory Authorized Service Agent check brushes, slip rings, integrated rectifiers SR2 and SR3, and main rectifier SR1. - Page 44 Trouble Low power output at ac receptacles. Increase Fine control R1 setting to max. Check fuse F2, and replace if open (see Section 9-5). High power output at ac receptacles. Check engine speed, and adjust if necessary (see Section 9-4). Erratic power output at ac receptacles.

-

Page 45: Section 10 − Parts List

Trouble Battery discharges between uses. Clean top of battery with baking soda and water solution; rinse with clear water. Periodically recharge battery (approximately every 3 months). Replace battery. Check voltage regulator according to engine manual. Engine does not return to idle speed Remove all weld and generator power loads. -

Page 46: Section 11 − Electrical Diagrams

SECTION 11 − ELECTRICAL DIAGRAMS Figure 11-1. Circuit Diagram For Welding Generator OM-217 455 Page 42... - Page 47 228 719-B OM-217 455 Page 43...

- Page 48 Figure 11-2. Circuit Diagram For Welding Generator With Battery Charging Option OM-217 455 Page 44...

- Page 49 231 607-B OM-217 455 Page 45...

-

Page 50: Section 12 − Run-In And Wetstacking

SECTION 12 − RUN-IN AND WETSTACKING 12-1. Run-In And Wetstacking OM-217 455 Page 46 run_in_D722 9/05 Welding Generator Run-in procedures for this engine should not be required. Put unit into regular service. Engine Exhaust Pipe Wetstacking is unburned fuel and oil in the exhaust pipe and occurs if the engine is run too long at light load or idle rpm. -

Page 51: Section 13 − Performance Data

SECTION 13 − PERFORMANCE DATA 13-1. Fuel Consumption Curves 2.00 1.75 1.50 1.25 1.00 0.75 0.50 IDLE 0.25 0.00 2.00 1.75 1.50 1.25 1.00 0.75 0.50 IDLE 0.25 0.00 Weld Fuel Consumption DC WELD AMPERES AT 100% DUTY CYCLE Auxiliary Power Fuel Consumption AUXILARY POWER KW AT 100% DUTY CYCLE On a typical job using 1/8 in 7018 electrodes (125 amps, 20% duty... -

Page 52: Generator Power Curve

OM-217 455 Page 48 AC Amperes At 120 Volts AC Amperes At 240 Volts Continuous Welding 100% Duty Cycle at 250 Amperes The ac generator power curve shows the generator power avail- able in amperes at the receptacles. 226 791-A... -

Page 53: Stick Mode Volt-Ampere Curves

13-4. Stick Mode Volt-Ampere Curves A. CC/DC Stick Mode CC/AC STICK Mode DC Amps AC Amps The volt-ampere curves show the minimum and maximum voltage and amperage output capabilities of the welding generator. Curves of other settings fall between the curves shown. -

Page 54: Mig Mode Volt-Ampere Curve

13-5. MIG Mode Volt-Ampere Curve OM-217 455 Page 50 DC Amps The volt-ampere curves show the minimum and maximum voltage and amperage output capabilities of the welding generator. Curves of other settings fall between the curves shown. 226 794-A... -

Page 55: Section 14 − Generator Power Guidelines

SECTION 14 − GENERATOR POWER GUIDELINES The views in this section are intended to be representative of all engine-driven welding generators. Your unit may differ from those shown. 14-1. Selecting Equipment 14-2. Grounding Generator To Truck Or Trailer Frame GND/PE Generator Power Receptacles −... -

Page 56: Grounding When Supplying Building Systems

14-3. Grounding When Supplying Building Systems 14-4. How Much Power Does Equipment Require? OM-217 455 Page 52 GND/PE VOLTS 115 AMPS Equipment Grounding Terminal Grounding Cable Use #10 AWG or larger insulated copper wire. Ground Device Use ground device as stated in electrical codes. - Page 57 14-5. Approximate Power Requirements For Industrial Motors Industrial Motors Split Phase Capacitor Start-Induction Run Capacitor Start-Capacitor Run Fan Duty 14-6. Approximate Power Requirements For Farm/Home Equipment Farm/Home Equipment Stock Tank De-Icer Grain Cleaner Portable Conveyor Grain Elevator Milk Cooler Milker (Vacuum Pump) FARM DUTY MOTORS Std.

- Page 58 14-7. Approximate Power Requirements For Contractor Equipment Contractor Hand Drill Circular Saw Table Saw Band Saw Bench Grinder Air Compressor Electric Chain Saw Electric Trimmer Electric Cultivator Elec. Hedge Trimmer Flood Lights Submersible Pump Centrifugal Pump Floor Polisher High Pressure Washer 55 gal Drum Mixer Wet &...

-

Page 59: Power Required To Start Motor

14-8. Power Required To Start Motor Motor Start Code KVA/HP 14-9. How Much Power Can Generator Supply? Single-Phase Induction Motor Starting Requirements 10.0 AC MOTOR VOLTS AMPS CODE PHASE 11.2 12.5 Motor Start Code Running Amperage Motor HP Motor Voltage To find starting amperage: Step 1: Find code and use table to find kVA/HP. - Page 60 14-10. Typical Connections To Supply Standby Power Utility Electrical Transfer Switch Service Essential Loads OM-217 455 Page 56 Fused Welding Disconnect Generator Switch Output (If Required) Have only qualified persons perform these connections according to all applicable codes and safety practices. Properly install and ground this equipment according to its Owner’s Manual and na-...

-

Page 61: Selecting Extension Cord (Use Shortest Cord Possible)

10,800 12,000 *Conductor size is based on maximum 2% voltage drop Maximum Allowable Cord Length in ft (m) for Conductor Size (AWG)* 350 (106) 400 (122) 250 (76) 400 (122) 275 (84) 175 (53) 300 (91) 175 (53) 112 (34) -

Page 62: Section 15 − Stick Welding (Smaw) Guidelines

SECTION 15 − STICK WELDING (SMAW) GUIDELINES 15-1. Stick Welding Procedure Tools Needed: OM-217 455 Page 58 Weld current starts when electrode touches work- piece. Weld current can damage electronic parts in vehicles. Disconnect both battery cables before welding on a vehicle. -

Page 63: Electrode And Amperage Selection Chart

15-2. Electrode and Amperage Selection Chart 3/32 6010 5/32 & 3/16 6011 7/32 1/16 5/64 3/32 6013 5/32 3/16 7/32 3/32 5/32 7014 3/16 7/32 3/32 5/32 7018 3/16 7/32 3/32 5/32 7024 3/16 7/32 3/32 Ni-Cl 5/32 3/16 3/32 308L 5/32 15-3. -

Page 64: Poor Weld Bead Characteristics

15-5. Positioning Electrode Holder ° End View of Work Angle ° End View of Work Angle 15-6. Poor Weld Bead Characteristics 15-7. Good Weld Bead Characteristics OM-217 455 Page 60 ° ° ° Side View of Electrode Angle GROOVE WELDS °... -

Page 65: Conditions That Affect Weld Bead Shape

15-8. Conditions That Affect Weld Bead Shape Weld bead shape is affected by electrode angle, arc length, travel speed, and thickness of base metal. Angle Too Small Too Short Slow 15-9. Electrode Movement During Welding Normally, a single stringer bead is satisfactory for most narrow groove weld joints; however, for wide groove weld joints or bridging across gaps, a weave bead or multiple stringer beads work better. -

Page 66: Butt Joints

15-10. Butt Joints 15-11. Lap Joint ° Or Less Single-Layer Fillet Weld 15-12. Tee Joint OM-217 455 Page 62 ° 1/16 in (1.6 mm) ° Or Less Multi-Layer Fillet Weld ° Or Less Tack Welds Prevent edges of joint from drawing together ahead of electrode by tack welding the materials in position be- fore final weld. -

Page 67: Weld Test

15-13. Weld Test 2 To 3 in (51-76 mm) 1/4 in (6.4 mm) 15-14. Troubleshooting − Porosity Possible Causes Arc length too long. Damp electrode. Workpiece dirty. 15-15. Troubleshooting − Excessive Spatter Possible Causes Amperage too high for electrode. Arc length too long or voltage too high. 2 To 3 in (51-76 mm) Porosity −... -

Page 68: Troubleshooting − Incomplete Fusion

15-16. Troubleshooting − Incomplete Fusion Possible Causes Insufficient heat input. Improper welding technique. Workpiece dirty. 15-17. Troubleshooting − Lack Of Penetration Lack of Penetration Good Penetration Possible Causes Improper joint preparation. Improper weld technique. Insufficient heat input. 15-18. Troubleshooting − Excessive Penetration Excessive Penetration Good Penetration Possible Causes... -

Page 69: Troubleshooting − Burn-Through

15-19. Troubleshooting − Burn-Through Possible Causes Excessive heat input. 15-20. Troubleshooting − Waviness Of Bead Possible Causes Unsteady hand. Use two hands. Practice technique. 15-21. Troubleshooting − Distortion Base metal moves in the direction of the weld bead. Possible Causes Excessive heat input. - Page 70 Notes Work like a Pro! Pros weld and cut safely. Read the safety rules at the beginning of this manual.

- Page 71 Warranty Questions? LIMITED WARRANTY − Subject to the terms and conditions Call below, Miller Electric Mfg. Co., Appleton, Wisconsin, warrants to 1-800-4-A-MILLER its original retail purchaser that new Miller equipment sold after the effective date of this limited warranty is free of defects in for your local material and workmanship at the time it is shipped by Miller.

-

Page 72: Owner's Record

For assistance in filing or settling claims, contact your distributor and/or equipment manufacturer’s Transportation Department. © 2007 Miller Electric Mfg. Co. 2007−01 Miller Electric Mfg. Co. An Illinois Tool Works Company 1635 West Spencer Street Appleton, WI 54914 USA International Headquarters−USA...

Need help?

Do you have a question about the 250 and is the answer not in the manual?

Questions and answers

when turning off takes a minute before it shuts off