Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Matchless 1949 CLUBMAN G3L

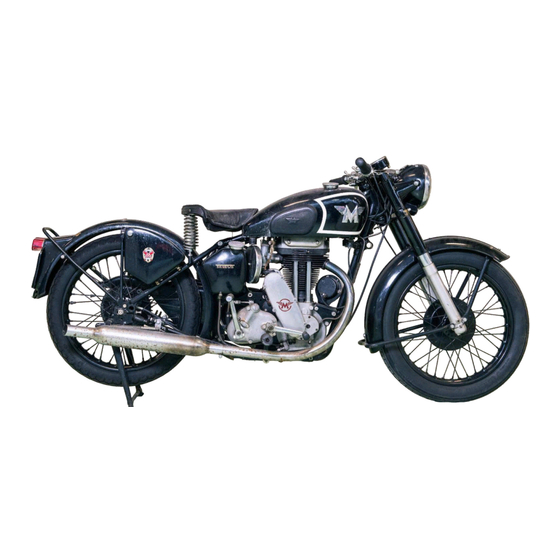

- Page 1 350 c . c. and 500 c.c. CLUBMA N MODELS O.H.V., MA TCHLESS MATCHLESS MOTOR CYCLES PROPRIETORS : ASSOCIATED MOTOR CYCLES LIMITED P L U M S T E A D · LO N D O N · S .E .1 8...

- Page 3 Codes : A.B.C. 5th and 6th Edition ; Bentley's ; and Private Codes All correspondence to :— MATCHLESS MOTOR CYCLES, PLUMSTEAD ROAD, LONDON, S.E.18 Supplied free, upon application, with each new motor cycle. Replacement Copies, 2/6 each EDITIO N CM-7...

- Page 4 We are always pleased to give " MATCHLESS " owners the full benefit of our wide experience in matters relating to motor cycles of our manufacture and in paragraph 113 will be found details of the particulars that should be given us when making such an enquiry.

- Page 5 DATA 1 DATA Description. Models "350" "500" Engine number 350 & 500 Stamped on left-hand side of crankcase. Frame number Stamped on right-hand side of seat lug. 350 & 500 (Below saddle). Cubic Capacity (Actual) 347 Cubic Centimetres. 498 Cubic Centimetres. Cylinder bore Millimetres.

- Page 6 Gear ratios (Touring). 350 Solo. 500 Solo. 500 Sidecar. Engine Sprocket, Engine Sprocket, Engine Sprocket, 21 teeth 19 teeth 18 teeth 5.0 to 1 … … 5.83 to 1 5.4 to 1 6.4 to 1 Third … … 7.0 to 1 7.5 to 1 8.8 to 1 Second...

- Page 7 (k) Spokes. (300 and 500). Front, left side. 5 x" by 8g. by 10g. Butted. Front, right side. 8 8" by 9g. by 11g. Butted. Rear, both sides. 8 8" by 6g. by 9g. Butted. Spoke lengths are measured under the head. (Not overall length).

-

Page 8: Clutch Lever

CONTROLS 2 CONTROLS Throttle twist grip. Twist inwards to open. When fully closed engine should just idle when hot. Air control lever. Pull inwards to increase air supply. Once set, when engine has warmed up, requires no alteration for different road speeds. Should be fully closed to start engine from cold. - Page 9 Before using the machine, sit on the saddle and become familiar with the position and operation of the various controls. Pay particular attention to the gear positions Para. 7 and Illustration 3. Although all the controls are adjustable for position, the only ones that may require alteration to suit the individual taste of the rider are the foot brake pedal (see Para.

- Page 10 DRIVING 3 FUEL At the time of publishing this Instruction Book only one grade of motor fuel is on sale, but it may be that soon the various grades of pre-war petrol will again be available. We recommend the use only of best quality fuel because the small amount of economy that might be considered to accrue by using the cheaper fuels is more than offset by the advantages obtained by using only Number One grades.

- Page 11 STARTING THE ENGINE (a) See that there is sufficient fuel in the petrol tank (b) See that there is sufficient oil in the oil tank. (c) See that the gear pedal is in the neutral position. (See Para. 7). (d) Push inward the hexagonal end of off side petrol tap slide. (e) See that the air control lever is in the fully closed position.

- Page 12 6 STOPPING THE ENGINE To stop the engine, close the throttle, raise the valve lifter lever and keep it raised until the engine has ceased to revolve. 7 ON THE ROAD Having started and warmed up the engine, take the machine off the stand, sit astride it, free the clutch by pulling up the large lever on the left bar and engage the lowest gear.

- Page 13 The exhaust valve lifter is NOT used in normal driving on main and secondary roads. When travelling slowly, such as may occur in traffic or on a hill, and the engine commences to labour, it is then necessary to change to a lower gear. Engine "...

-

Page 14: Oil Pump

Illustration 4 Showing the oil tank with the felt filter in its cylindrical housing and the metal strainer mounted on the entry end of the feed pipe union. Also shows the direction of flow of oil from tank to engine and return flow from engine to tank via the small spout, located so that it can be inspected by removing the tank filler cap (mentioned in Para. - Page 15 LUBRICATION 14 LUBRICANTS TO USE Efficient Iubrication is of vital importance and it is false economy to use cheap oils and greases. We recommend the following lubricants for use in machines of our make :— FOR ENGINE LUBRICATION IN SUMMER : Castrol "Grand P r i x "...

- Page 16 15 FILLING THE GREASE GUN The standard grease gun consists of a barrel having a spring loaded end cap, to which is fixed a centre steel piston in the shape of a long rod. This piston fits into a small cylinder made in one with the screwed top cap, on the end of which is the cupped nozzle that fits over the grease nipples.

- Page 17 16 ENGINE LUBRICATION SYSTEM This is by dry sump system. Oil feeds, by gravity, from the oil tank to the pump in the crankcase. The pump forces oil to various parts, which then drains to the bottom of crankcase sump. The pump then returns oil to the tank. This process is continuous while the engine is revolving.

- Page 18 For access to oil filter :— Unscrew the hexagonal headed cap on top of oil tank and withdraw the dished washer and spring. Then insert a finger in the felt filter and gently raise same until the top end touches the underneath of saddle. Then by encircling the filter with the hand it will be found possible to exert sufficient upward pressure on the flexible saddle top to permit the filter to be completely withdrawn without distortion.

- Page 19 Illustration 6 The inlet valve guide is shown withdrawn as also is the inlet valve stem adjusting screw (with lock nut). (By courtesy of " Motor Cycling ") PLAIN HOLE, TO ACCOMMODATE CYLIN- TAPPED HOLE, ACCOMMODATE DER HEAD RETAINING BOLT. NEEDLE SCREW.

- Page 20 23 GEAR BOX LUBRICATION The gear box must not be entirely filled with oil, and, under normal conditions, the addition of about two ounces of oil every 1,000 miles will be sufficient. Excessive oil will cause leakage. (Correct content 20 fluid ozs. (1 pint) 568 c.c). In no circumstances must heavy grease be used for gear box lubrication.

- Page 21 28 BRAKE PEDAL LUBRICATION Grease nipple in heel of brake foot pedal. Use grease sparingly. 29 SPEEDOMETER LUBRICATION One nipple on top of speedometer gear box attached to rear wheel spindle. Use grease sparingly. No other part of the speedometer (including the driving cable) requires lubrication.

-

Page 22: Gear Box

33 CONTROL LEVER LUBRICATION A drop of engine oil on all moving parts of the handlebar control levers. Also, if the twist grip operation is too tight, indicating dryness, lubricate as follows :— Remove the two screws that retain the two halves of the twist grip body. This will release the grip so that it can be slid off the handlebar. - Page 23 MAINTENANCE SADDLE ADJUSTMENT Saddle adjustment is provided at both front and rear ends. Importance is attached to the desirability of owners selecting the adjustment most to their liking. At the front end the adjustment consists of three evenly spaced positions for the hinge bolt, accessi- ble only upon removal of the petrol tank.

- Page 24 Control levers :— Smear moving parts with engine oil. (7). Brake joints :— Smear yoke end pins at front and rear ends of brake rod and at bottom end of front brake cable with engine oil. (8). QUARTERLY Sparking plug :— Clean and, if necessary, re-set point gap.

- Page 25 EVERY 1,000 MILES Hubs :— The hubs are packed with grease during assembly to lubricate the bearings and prevent the entry of mud and water. A grease nipple is on each hub shell. Inject grease, which must not be excessive in quantity or the surplus may reach the brake and so impair its efficiency.

- Page 26 ENGINE SERVICE 36 ACCESS For almost all service work to the upper parts of the engine, it is necessary, in order to obtain accessibility, first, to remove the petrol tank. The two petrol taps facilitate this operation by removing the need to first drain the tank of petrol. 37 TO REMOVE THE PETROL TANK Disconnect the petrol feed pipe from both petrol taps (use two spanners, one to hold the tap while the union nut is being unscrewed with the other).

- Page 27 38 TO REPLACE THE PETROL TANK Place a metal washer on each support bracket end. Place a thick rubber pad on each metal washer and then another metal washer on each rubber pad. Place the tank in position. Place a thin rubber pad and then a metal washer on each tank fixing bolt and then enter the bolts.

- Page 28 Tighten each bolt in turn bit by bit until all are fully home. On 500 c.c. models replace the engine steady stay. Turn engine over several times to ensure parts have bedded home. Re-fix valve lifter cable. Re-fix rocker box oil pipe union nut using two spanners to ensure that the union screwed into rocker box does not turn while the nut is being tightened.

- Page 29 42 TO REMOVE AND REPLACE THE VALVES Remove the cylinder head. (See Para. 41). Attach the special valve spring compressing tool, Part No. 0I460S, to cylinder head with the two bolts provided (Part No. 41-G3L-M38), see illustration 8A. Then compress the springs by screwing in evenly the two long bolts, the reduced tips of which will engage with the countersink depressions on the valve spring collar.

- Page 30 44 VALVE GRINDING It is advisable to grind in the valves at every decarbonisation. Clean valve stems with very fine emery cloth, using up and down motion with cloth held between thumb and forefinger. Smear the face of each valve, in turn, with valve grinding compound and revolve the valve on its seat in a slight forward and backward direction, at the same time, maintaining slight pressure on the valve head to keep it on its seat.

- Page 31 45 TO REPLACE THE CYLINDER HEAD A gasket is fitted between cylinder head and barrel. The top ends of the push rod cover tubes have rubber gaskets between tubes and head, they are a push fit and metal washers are located between the top edges of the gaskets and the cylinder head recesses.

- Page 32 Note :— The gudgeon is an easy sliding fit in both piston and connecting rod small-end bush. Rings may be removed from a piston by "peeling o f f " with a knife, or by introducing behind the rings three pieces of thin steel spaced at 120° from each other and then sliding off the rings.

- Page 33 Illustration 10 Inlet Camshaft timing marks. When checking the valve timing the tappet clearances must be set to .016" so that the tappets may be well clear of the quietening curves of the camshafts. The timing gears are marked to facilitate their replacement. To re-set the valve timing, by using the marks on the gears, proceed as follows :—...

-

Page 34: Tappet Adjustment

50 TAPPET ADJUSTMENT The top ends of the two long push rods have screwed extensions. These are locked in position by nuts, thereby providing tappet adjustment. The correct tappet clearances, with valves closed and engine cold, is NIL. This means the push rods should be free enough to revolve and, at the same time, there should be no appreciable up and down play. -

Page 35: Contact Breaker

51 TO RE-TIME THE IGNITION The maximum advance is ½". Have available a stout screwdriver, or an old type tyre lever with turned up end, and a bar of metal about ¼" diameter and 5½" long. Before setting the ignition firing point it is essential the magneto contact breaker points are correctly adjusted. - Page 36 52 TO REMOVE AND REPLACE THE OIL PUMP PLUNGER Remove :— Lower end of rocker box oil feed pipe by unscrewing union nut. Both oil pump end caps. Oil pump plunger guide screw with pin. (See Illustration 13, No. 11). Oil pump plunger, by pushing at front and extracting from rear end of its housing.

- Page 37 53 OVERSIZE PARTS AND RE-BORING CYLINDER BARREL Pistons and rings, .020" larger than standard, are available. This degree of oversize is such that it is essential for the cylinder barrel to be re-bored to accommodate it. We can provide that service at prices quoted in the Spares List. On the 350 c.c.

- Page 38 The size of the main jet should not be altered save for some very good reason. See Data, Para. 1 (Sub Para, c), for details of standard jet sizes, throttle valves, chokes and jet taper needles. With the standard setting it is possible to use nearly full air in all conditions, except, perhaps, when the engine is pulling hard up hill or is on full throttle, when some benefit may be obtained by slightly closing the air control.

- Page 39 Illustration 14 Showing details of the pilot jet with its air adjusting screw and the throttle stop screw.

- Page 40 CARBURETTER TUNING INFORMATION Poor idling may be due to :— Air leaks. Either at junction of carburetter and engine, or by reason of badly worn inlet valve stem or guide. Faulty engine valve seatings. Sparking plug faulty, or its points set too closely. Ignition advanced too much.

- Page 41 TRANSMISSION SERVICE 59 THE GEAR BOX The gear box provides four speeds and has a positive foot change, operated by the right foot, and a kick-starter. It is retained to the main frame by being clamped between the two engine rear plates by two bolts.

- Page 42 Second gear. Sliding gear (C) on mainshaft is in mid-way position, i.e., disengaged from gears B and D. Layshaft sliding clutch (W) moves to left and engages with gear F. Power passes through clutch A, to mainshaft T, to mainshaft sliding gear C, to layshaft gear F, to layshaft clutch W.

- Page 43 To remove dynamo chain and back half of chaincase :— Remove the spring lock ring on dynamo sprocket retaining nut. Take away lock washer surrounding dynamo sprocket nut. Apply spanner (RTK-1, included in tool kit) to the two flats on the back of the dynamo sprocket and.

- Page 44 Fit the clutch centre and sprocket by :— Place on the gear box main shaft the thicker of the two clutch sprocket roller bearing retaining washers. Place on the gear box main shaft the clutch sprocket roller bearing ring. With grease, stick in place on the bearing ring the twenty-four clutch sprocket bearing rollers.

- Page 45 Fully tighten the metal band binding screw. Replace, on the brake rod, the knurled adjusting nut, and adjust the rear brake. (See Para. 90). Allow time for the liquid jointing compound to set and then :— Remove inspection cap from the chaincase and pour in engine oil to the level mentioned in Para.

- Page 46 On allowing the clutch handlebar lever to return to its normal position the clutch operating lever becomes " free " and the clutch spring pressure causes the clutch thrust rod D, the steel ball C and the operating plunger B to move to the right. The whole of the clutch spring pressure is thereby transferred to the clutch spring pressure plate F and this forces the steel plates G tightly against the clutch friction plates H so that power, transmitted by the engine to clutch sprocket L, is transferred...

- Page 47 Obtain adjustment of clutch mechanism by (See Illustration 17) :— Remove the two screws 333-X. Take away the cap 328-X. Adjust the sleeve nut 331-X as may be necessary as follows. To increase clearance between clutch operating lever 175-X-4 and operating plunger 330-X, turn sleeve nut in a right-hand, or clockwise, direction.

- Page 48 Note :— The amount of play, or free movement, can easily be discovered by virtue of the greatly increased resistance of the handlebar clutch control lever as the de-clutch- ing action commences. To remove a clutch control cable :— Remove the oil filler cap from the kick-starter case cover. Screw right home the clutch cable adjuster that is located in the back of the kick- starter case.

- Page 49 Note :— Before tightening the rear chain, check the front chain adjustment, and, if attention is necessary, adjust front chain first. Altering the adjustment of the front chain upsets the adjustment of the rear chain. Therefore, after making a front chain adjustment, always check the rear chain adjustment and re-set if necessary.

- Page 50 ENGINE SHOCK ABSORBER The engine shock absorber is a spring device for smoothing out the impulses transmitted by a single cylinder engine. The engine sprocket is a free fit on the driving side flywheel axle. It has, integral with it, a face cam that engages with a similar face cam (shock absorber cam) which is keyed to the driving side flywheel axle by splines.

- Page 51 FRAME & FORK SERVICE 72 STEERING HEAD ADJUSTMENT The steering head frame races are of the floating self-aligning type and have spherical seats. Therefore they do not fit tightly in the head lug. Occasionally test the steering head for correct adjustment by exerting pressure upwards from the extreme ends of the handlebars.' It is particularly important that the adjustment is tested after the first one hundred miles because of the initial settling down that always occurs in that period.

- Page 52 As will be seen, the sliding members operate on steel bushes attached to the bottom ends of the main tubes and also upon bakelite bushes secured to the top ends of the sliders themselves. Above each bakelite bush will be observed an oil seal, provided to overcome any possibility of oil leakage into the spring chamber.

- Page 53 It will thus be gathered that, on the shock movement of the sliders, slight damper action occurs, with a greatly increased damper action on the reverse movement, both actions automatically increasing in effect the more violent the movement. Before concluding this description, it should be mentioned that upon a very violent impact, as a result of which the springs are almost fully compressed, the damping of the upward movement of the sliders is automatically increased by the greatly restricted passage for the displaced oil, due to the lower ends of the inner tubes encircling the...

- Page 54 (c) To remove a fork inner tube (either side) :— First remove the hexagonal bolt at the top of the tube to be removed. Next proceed to remove the fork slider as detailed in Para. 73b. Now loosen the clamping nut on fork crown stud when it should be possible to draw the entire inner tube assembly down through the crown lug.

- Page 55 Fit the fork crown ball race (the odd one of the four races, i.e., the race that does not have a spherical seat) to the fork crown, load the race track with greas e and fill with twenty-eight steel balls (x " diameter). Lay a frame ball race over the steel balls.

- Page 56 Illustration 19...

- Page 57 Name Part No. 014354 FRONT FORK INNER TUBE TOP BOLT. 013631 HANDLEBAR LUG (COMPLETE). L4FF46 FRONT FORK HEAD DOME NUT. STD-236 FRONT FORK HEAD NUT. FRONT FORK SPRING COVER TUBE CAP, TOP. 40-G12M-FF186 FRONT FORK SPRING COVER TUBE LOCATING PLATE (TAPPED 40-GI2M-FFI27 HOLES).

- Page 58 Note :— Great care must be exercised when fitting the oil seal and this is best done by :— Cut a piece of thin foil sheet 4" x 3" and wrap round the screwed end of the inner tube. Then gently slide the seal over the wrapped foil using a rotary motion in the opposite direction to the overlap of the foil and taking particular care to apply the side of seal in which the spring is visible first.

- Page 59 Illustration 20 Fit the inner tube assemblies (b and c) to the front fork crown assembly by :— Take one inner tube assembly, introduce the top end (the internally threaded end) to the fork crown (immaterial if left or right side) and push it upwards till it engages with the handlebar clip lug and then gently force it home.

- Page 60 Proceed as follows :— Lightly tighten nut on left-hand end of front wheel spindle. Fully tighten the four spindle clamping nuts. (Do not over tighten). Fully tighten nut on left-hand end of front wheel spindle. Fit, and tighten, the two brake anchorage bolts. Fully tighten the two screwed slider extensions.

- Page 61 79 TO REMOVE OIL TANK AND BATTERY CARRIER Two studs on the seat tube, one facing to the front, the other facing to the rear, engage with two right-angle stays on the oil tank and two similar stays on the battery carrier and two washers and nuts, fitted to the studs, retain the oil tank and battery carrier in position.

- Page 62 WHEEL, BRAKE & TYRE SERVICE TO REMOVE FRONT WHEEL Prepare by :— Place machine on rear and front stands. Remove :— The split pin, and pin, retaining yoke end of front brake cable to the brake expander lever. Remove the bolts retaining the brake cover plate to the fork slider. Slacken :—...

- Page 63 Illustration 21 REAR HUB (In all relative details the construction of the front and rear hubs is similar). WASHER, SOLID SPINDLE. DISHED CUP, FOR OIL SEAL. NUT, SOLID SPINDLE. FORK END OF FRAME. SPRING CIRCLIP. WASHER, SOLID SPINDLE. RETAINING RING, FOR OIL SEAL. NUT , SOLID SPINDLE.

- Page 64 Re-fit in the reverse order but, before finally tightening the rear wheel spindle nuts, ensure the speedometer gear box is so positioned that the speedometer driving cable can be correctly replaced. When the wheel alignment is correct a piece of thin string stretched taut across both wheels, about four inches from, and parallel to, the ground, should just touch each tyre at both sides of the wheel centres.

- Page 65 Illustration 22 Showing exploded view of hub bearing components. SPRING CIRCLIP. (FITS IN GROOVE CUT FRONT WHEEL SPINDLE, WITH SET OF IN UNTHREADED END OF HUB.) TAPER ROLLERS MOUNTED T W O CAGES. OIL SEAL ASSEMBLY, CONSISTING OF : REAR WHEEL H O L L O W SPINDLE W I T H 1 SPACING RING (11) SET OF TAPER ROLLERS MOUNTED IN 1 OIL SEAL...

- Page 66 Remove :— Adjusting ring. (The lock nut 16 will come away with it). Dished steel washer. Oil seal. Plain steel washer. Turn to opposite end of hub. Remove :— Spring ring fitted just inside the hub end. Plain steel washer. Oil seal, with the spacing collar encircling it.

-

Page 67: Brake Shoe Adjustment

Screw into the hub shell the adjusting ring (5 Illustration 22). Screw the lock nut (6 Illustration 22) on the adjusting ring. Adjust hub bearings by the method described in Para. 83. Inject two fluid ounces of grease into the hub shell. (Through grease nipple in hub barrel). -

Page 68: Brake Pedal Adjustment

Centralise brake shoes by :— Ensure the nut binding the cover plate to the wheel spindle is slightly slack. Place on the brake expander lever a tubular spanner (to increase the leverage), and, while maintaining pressure on the tubular spanner (to expand fully the brake shoes), fully tighten the spindle nut binding the cover plate to spindle. - Page 69 Illustration 24 Showing the rear brake pedal with its adjusting bolt and lock nut. To permanently raise the toe end of the pedal, slacken lock nut (B) and unscrew the adjusting bolt (A). (Check back brake adjustment after). 90 REAR BRAKE ADJUSTMENT Major adjustment of the rear brake shoes is made on the brake thrust pins, as described In Para.

- Page 70 FRONT BRAKE ADJUSTMENT Major adjustment of the front brake shoes is made on the brake thrust collars, as described in Para. 87. Minor adjustment of the front brake shoes is made by altering the position of the knurled cable adjuster on the fork assembly. (Unscrew the brake cable adjuster to "...

- Page 71 93 RIMS AND SPOKES The front and rear rims are 19" by 2½" and accommodate the same size of tyre, but they are not interchangeable because the nipple holes in the front rim are smaller than those in the rear rim. The dimensions of spokes will be found in Para.

- Page 72 96 TYRE FITTING Re-fit inner tube and outer cover by :— Place one edge of cover right into well of rim, with white dots adjacent to valve hole, and, commencing diametrically opposite, and using the hands only, work the cover over the edge of the rim. Replace the valve "...

- Page 73 ELECTRICAL SERVICE 98 ELECTRICAL EQUIPMENT LUCAS electrical equipment is fitted and this comprises three independent electrical circuits, as follows :— (a) IGNITION—Magneto, High-tension W i r e and Sparking Plug. (b) CHARGING—Dynamo, Cut-out Regulator, Ammeter Battery. (c) LIGHTING A N D ACCESSORIES—Lamps, Wires, Switches and Horn.

- Page 74 Illustration 28 Showing component details of Contact Breaker. Lubricate contact breaker cam and tappet by :— Remove contact breaker as described above. Saturate, with a few drops of thin machine oil, the wick mounted in the core of its carrying screw B, Illustration 27. Push out of the contact breaker body the tappet B, Illustration 28, wipe it with a soft cloth, smear it with thin machine oil and then replace it.

- Page 75 Complete service (dismantling, cleaning, lubrication of the armature shaft bearings, etc.) should be entrusted to a Lucas Service Station and should be done about every ten thousand miles. Sparking plug :— The sparking plug has a thread of 14 mm. and the reach is ½". The point gap should be from .020 to .025".

- Page 76 Illustration 30 Showing the panel contain- ing the Lucas Lighting Switch Ammeter removed from the Head Lamp. To remove ammeter :— Remove the panel from top of headlamp by taking away the three retaining screws. Unscrew the ammeter terminal screws A, Illustration 30, and remove the wires. Bend back the four metal tags B, Illustration 30, that secure the ammeter to the panel and the ammeter is then free to be taken away from the panel.

- Page 77 Illustration 31 Lucas Battery. Pour distilled water in each cell to bring the electrolyte level with the tops of the plate separators. Acid must not be added to the electrolyte unless some is accidentally spilled. Should this happen, make loss good with acid diluted to same specific gravity as acid in the cell.

- Page 78 LIGHTING AND ACCESSORIES Headlamp :— A LUCAS type SSU700P headlamp is fitted. It has a panel mounted on its top which carries the main lighting switch and the ammeter together with cable harness. (See Illustration 30). The main bulb is 6v. with double filament each 24w. One filament provides the main driving beam and the other a dipped beam brought into operation by the dipping switch on handlebar as required.

-

Page 79: Wire Connector

Rear lamp:— A Special Lucas type 467/1 rear lamp is fitted. The body with bulb holder, is secured to the rear number plate with two nuts and spring washers. The cover, carrying the red glass, is secured to the body by means of one captive screw. - Page 80 Earth wires :— There are two earth wires, one from the regulator and the second from the negative terminal of the battery. The ends of those wires have sleeve terminals, as described in the above paragraph, and are secured to the seat lug bolt (just below the saddle on the left-hand side) by means of a screw and washer and it is essential the connections are kept clean and the screw must be kept fully tight.

-

Page 81: Wiring Diagram

KEY TO CABLE COLORS BLUE & PURPLE BLUE & BLACK RED & YELLOW RED & BLUE WHITE WHITE & GREEN RED & WHITE RED & GREEN WHITE & BROWN RED & BROWN WHITE & PURPLE RED & BLACK WHITE & BLACK YELLOW GREEN YELLOW &... - Page 82 TOOLS AND SPECIAL EQUIPMENT 102 TOOLS The standard tool kit, issued with each new machine, contains :— 17520 Tool bag. (Not shown in Illustration 35). 38-G3-EQ2 Tyre inflator. W40-G3-TK29 Tyre levers. LTK-15 Pliers. 11024 Gudgeon pin circlip pliers. LTK-13 Screwdriver. LTK-20 Grease gun.

- Page 83 Illustration 35 Description Part Number Description Part Number Grease Gun LTK20 Spanner, Dynamo- RTK1 Pliers LTKI5 Spanner, 3 - Way, .820 x 1.011 x 1.200 RTK3 Circlip Pliers 11024 Spanner, 6" Adjust- Spanner, Light able LTK12 Forged, x" x ¼" Whit.

- Page 84 USEFUL INFORMATION 106 TRACING TROUBLES In the following five paragraphs are particulars of failures and troubles that can occur, together with the probable reasons. These troubles are arranged in the order of their probability. Engine fails to start, or is difficult to start, may be due to :— Throttle opening too large.

- Page 85 Engine overheats may be due to :— Lack of proper lubrication. (Quality or quantity of oil). Faulty sparking plug. Air control to carburetter out of order. Punctured carburetter float. Engine carbonised. Weak valve springs. Pitted valve seats. Worn piston rings. Ignition lever creeps to full retard position.

- Page 86 CLEANING THE MACHINE Do not attempt to rub, or brush, mud off the enamelled surfaces because this will soon destroy the sheen of the enamel. Mud, and other road dirt, should be soaked off with water. The best method is to use a small hose, taking care not to direct water on to the engine, carburetter, magneto and other such parts.

- Page 87 113 CORRESPONDENCE Our routine is organised into different departments, therefore delay cannot be avoided if matters relating to more than one department are contained in one letter. Consequently it is desirable, when communicating with more than one department, to do so on separate sheets, each of which should bear your name and address. In particular, requests for Technical Advice should not be on the same sheets as orders for spare parts.

- Page 88 115 GUARANTEE We give the following guarantee with our motorcycles, motorcycle combinations and sidecars, which is given in place of any implied conditions, warranties or liabilities whatsoever, statutory or otherwise, all such implied conditions, warranties and liabilities being in all cases excluded. statement, description, condition or representation contained in any catalogue, advertisement, leaflet or other publication shall not be construed as enlarging, varying or overriding this guarantee.

- Page 89 The nearest Railway Station is WOOLWICH ARSENAL, SOUTHERN RAILWAY. This Station is five minutes' walk from our Service Depot in Burrage Grove. There is an excellent service of electric trains from Charing Cross, Waterloo, Cannon Street and London Bridge Stations, Southern Railway. Bus services 53, 53a, 54, 75, 99, 122, and 161.

- Page 90 In due course you will receive :— (1) A Registration Book. (Commonly called the " log " book). (2) A Licence Disc. (3) Your insurance certificate. (4) Your invoice. The Registration Book and the Licence Disc will bear the registration numbers that have been allotted to your machine and will also show the date the Road Licence expires.

- Page 91 Illustration 36 Wiring Diagram. (Pictorial.)

- Page 92 FREE SERVICE SCHEME LL new owners of 1949 Models are entitled to one Free Service and Inspection at 500 miles or at latest three months after taking delivery. This Service is arranged by the supplying Dealer to whom the Free Service Voucher must be handed. This Voucher, together with Instruction Manual are supplied by us upon receipt of the signed application card to be found in the tool box upon taking delivery of...

-

Page 93: Table Of Contents

ILLUSTRATIONS Illustrations Page Battery … … … … … … … Brake adjustment, front … … … … … Brake adjustment, rear … … … … … Brake pedal adjustment … … … … … Brake shoe adjustment … … …... - Page 94 INDEX … … … … … … Carburetter Service … … … … … … … … Controls Data … … … … … … … … Driving … … … … … … … … … … … … …...

Need help?

Do you have a question about the 1949 CLUBMAN G3L and is the answer not in the manual?

Questions and answers