Summary of Contents for Metrologic StratosS MS2220

- Page 1 METROLOGIC INSTRUMENTS, INC. ™ MS2220 Stratos S Scanner / Avery Scale Installation and User’s Guide...

- Page 2 Copyright © 2006 by Metrologic Instruments, Inc. All rights reserved. No part of this work may be reproduced, transmitted, or stored in any form or by any means without prior written consent, except by reviewer, who may quote brief passages in a review, or provided for in the Copyright Act of 1976.

-

Page 3: Table Of Contents

Optional Accessories... 2 Optional Remote Scale Display... 3 Dimensions... 3 Control Panel... 3 Replacement Parts... 4 General Precautions... 5 MS2220 Scanner/Avery Scale Design Specifications ... 6 ODEL HARACTERISTICS MS2220 Scanner/Avery Scale ... 8 Components ... 8 Dimensions ... 10 Connector Panel... 10 Caution and Serial Number Labels... - Page 4 ABLE OF ONTENTS CANNER PERATION Scan Zone... 29 IR Activation Area (IR LED Output) ... 31 Indicator Descriptions... 32 Audible ... 32 Visual ... 33 Failure ... 34 Diagnostic Indicator Display; Error Codes... 35 Power Save Modes ... 38 Beeper Options and Button Functions... 39 Beeper Tone and Volume Control ...

- Page 5 ABLE OF ONTENTS CANNER AND ABLE ERMINATIONS Scanner Pinout Connections ... 69 Cable Connector Configurations ... 71 EGULATORY OMPLIANCE Safety ... 73 EMC ... 74 Weights & Measures ... 75 ... 76 IMITED ARRANTY ... 77 ATENTS ... 78 NDEX...

-

Page 7: Introduction

NTRODUCTION ANUAL COPE This guide provides an overview of the MS2220 StratosS scanner/Avery scale operation with detailed information about setup ® ® and installation. Adobe Acrobat versions of the user's manuals are also available for download from the Metrologic website (www.metrologic.com). -

Page 8: Optional Accessories

NTRODUCTION PTIONAL CCESSORIES Part # RS232 Interface Cable 57-57210x-N-3 Straight, 3.7 m (12') Cord with Short Strain Relief 57-57212x-N-3 IBM 46xx Port 9 Cable, Straight 3.7 m (12') Cord OCIA Interface Cable 57-57016x-N-3 Straight, 3.7 m (12') Cord with Short Strain Relief USB Full Speed Communication Cable, 57-57201x-N-3 Straight 4.0 m (13') Cord, Type A (Non-Locking) Connector... -

Page 9: Optional Remote Scale Display

CCESSORIES Part # Optional Remote Scale Display 46-00248 Remote Scale Display for use with MS2000 lb. Scanner/Scales 46-00249 Remote Scale Display for use with MS2000 kg Scanner/Scales Specifications are subject to change without notice. Figure 2. Optional Remote Scale Display Controls (46-00248 lb, 46-00249 kg) -

Page 10: Replacement Parts

NTRODUCTION EPLACEMENT ARTS Part # Window types (Diamonex and Sapphire) are not interchangeable due to laser safety and/or scanner performance differences. Caution To change window type, the scanner must be returned to the manufacturer for reconfiguration. 46-00232 Vertical Window 46-00233... -

Page 11: General Precautions

NTRODUCTION ENERAL RECAUTIONS The following are some general precautions to remember when handling your MS2220 Scanner/Avery Scale. the unit upside down with the platter in place. RESS on the window in the replacement platter or the vertical window frame. LATTER... -

Page 12: Ms2220 Scanner/Avery Scale Design Specifications

NTRODUCTION MS2220 S CANNER VERY CALE Operational Light Source: VLD 650 nm Peak Laser Power: <1.5 mW Maximum IR LED Output: 50μW per IEC 60825-1 measurement procedure Horizontal Depth of Field: 0 mm - 152 mm (0”- 6”) for 0.33 mm (13 mil) Bar Code Vertical Depth of Field: 0 mm - 216 mm (0”- 8.5”) for 0.33 mm (13 mil) Bar Code Scan Speed:... - Page 13 NTRODUCTION MS2220 S CANNER VERY CALE Scale Capacities Capacity: kg unit Minimum Increment: kg unit Maximum Static Weight: kg unit Adjustments required: Calibration is required for scaled units. Electrical Voltage Supply: 2A @ +5.2V / 1A @ +12V Operating Power: 11.9 Watts Standby Power: 3.25 Watts...

-

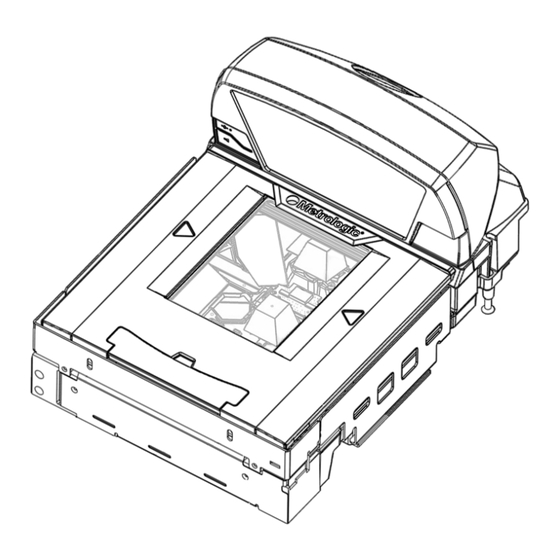

Page 14: Base Model Characteristics

ODEL HARACTERISTICS MS2220 Scanner/Avery Scale Components Figure 7. MS2220 Components... - Page 15 Location of Scale Shipping Hardware (see page 15) Leveling Bubble for Scale Arms Diagnostic Indicator Display (see page 35 for Error Codes) Interface, Aux Scanner and EAS Connectors ( see page 10 ) Power and Scale Connectors ( see page 10 ) Leveling Feet Scanner/Scale label information can be found on page 11.

-

Page 16: Dimensions

ODEL HARACTERISTICS MS2220 Scanner/Avery Scale Dimensions Figure 8. MS2220 Dimensions Specifications are subject to change without notice. Connector Panel Figure 9. MS2220 Connector Panel... -

Page 17: Caution And Serial Number Labels

Caution and Serial Number Labels Figure 10. MS2220 Label Locations (Top) and Examples (Bottom) Caution: To maintain compliance with applicable standards, all circuits connected to the scanner must meet the requirements for SELV (Safety Extra Low Voltage) according to EN/IEC 60950-1. -

Page 18: Installation

EQUIREMENTS Before installing your StratosS scanner/Avery scale, please consider the following items. Vertical Clearance A minimum clearance height of 5.25" from the checkout counter surface is needed for the vertical 'hood' on all of the scanner models. Ventilation and Spacing All StratosS models have a die-cast housing to dissipate heat allowing the unit to operate without a ventilation fan. -

Page 19: Service Access

In what direction are the packages flowing? Most checkout counters are designed for left-handed takeaway. If the operator is facing the vertical window of the scanner, packages flow from the operator's right to left. The packages are in queue on the conveyor to the right and the bagging is to the left. -

Page 20: Unpacking The Unit

• Product Manuals • Power Supply • Communication Cables Lift the scanner out of the shipping box by gripping the bottom of the unit on both sides. Important! Do not lift the unit out of the box by gripping the sides of the platter. -

Page 21: Ms2220 Package Warning

NIT IN THE OUNTER Before starting to mount the StratosS determine: • the scanner's orientation in reference to the operator and the direction of package flow, • the mounting method that provides the most stability for the scanner and •... -

Page 22: Ms2220 Mounting Diagram

NSTALLATION NSTALLING THE NIT IN THE OUNTER MS2220 Mounting Diagram Figure 16. MS2220 Mounting Diagram Specifications are subject to change without notice. -

Page 23: Cable Installation (Interface Specific)

Steps 4 and 5 are for dual cable interfaces where the scale and the scanner connect to the host with their own separate communication cables. Skip to step 6 for a single cable interface where the scale and scanner connect to the host with a single cable. - Page 24 NSTALLATION ABLE NSTALLATION NTERFACE RS232 11. Configure the StratosS to match the host system’s RS232 parameters. Refer to the MetroSelect Configuration Guide ( Mode (scan the recall defaults bar code first). Refer to the MS2xxx Stratos Series Configuration Addendum ( cable configuration bar codes.

-

Page 25: Full Speed Usb

Steps 4 and 5 are for dual cable interfaces where the scale and the scanner connect to the host with their own separate communication cables. Skip to step 6 for a single cable interface where the scale and scanner connect to the host with a single cable. -

Page 26: Ibm Oem

Communication Defaults bar code listed in step 10 must be scanned before scanning one of these barcodes or this feature will not work properly. PECIFIC 00-02034x) under Scanner Configuration Bar Codes: Single Cable Protocols for MLPN 00-02034x) under Scanner Configuration Bar Codes: Dual Cable Scanner... - Page 27 NSTALLATION ABLE NSTALLATION NTERFACE PECIFIC PEED xx** Specifies international connection. See the Base Kit Components and Optional Accessories section of this guide for a complete listing. See Power Source caution statement located on page 11 of this manual. Figure 18. USB Cable Installation Schematic...

-

Page 28: Ibm 46Xx

Steps 4 and 5 are for dual cable interfaces where the scale and the scanner connect to the host with their own separate communication cables. Skip to step 6 for a single cable interface where the scale and scanner connect to the host with a single cable. - Page 29 See Power Source caution statement located on page 11 of this manual. PECIFIC 00-02034x) under Scanner Configuration Bar Codes: Single Cable Protocols for MLPN Generation 46xx. 00-02034x) under Scanner Configuration Bar Codes: Dual Cable Scanner MLPN Generation 46xx and IBM OEM Full Speed USB.

-

Page 30: Ocia

Steps 4 and 5 are for dual cable interfaces where the scale and the scanner connect to the host with their own separate communication cables. Skip to step 6 for a single cable interface where the scale and scanner connect to the host with a single cable. - Page 31 NSTALLATION ABLE NSTALLATION NTERFACE OCIA 10. Configure the StratosS to match the host system’s OCIA parameters. Refer to the MetroSelect Configuration Guide ( OCIA parameters. Refer to the MS2xxx Stratos Series Configuration Addendum ( cable configuration bar codes. xx** Specifies international connection. See the Base Kit Components and Optional Accessories section of this guide for a complete listing.

- Page 32 NSTALLATION ECONDARY The following steps describe how to properly install the cables between a secondary Metrologic scanner and the StratosS. The StratosS and the secondary scanner must then be configured to communicate properly. Cable installation alone does not guarantee that the StratosS will communicate properly with the host system and secondary scanner.

-

Page 33: Cable Installation (Secondary Metrologic Scanner)

NSTALLATION ABLE NSTALLATION ECONDARY ETROLOGIC CANNER † See Aux power notes on page 26 See Power Source caution statement located on page 11 of this manual. Figure 21. Secondary Scanner Cable Installation Schematic... -

Page 34: Eas Deactivation

NSTALLATION EAS D EACTIVATION SW1 and SW2 are the switch banks inside the Checkpoint device that set the deactivation range. The following is a list of Checkpoint recommended switch bank settings. Base Model Checkpoint Recommended Switch Bank Settings MS2220 SW1 & SW2 switches 1 and 6 set to ON All StratosS models have a connector labeled EAS In on the bottom of the unit. -

Page 35: Scanner Operation Scan Zone

CANNER PERATION Figure 24. Checker-Side (13 mil) Figure 25. Horizontal Left/Right (13 mil) Specifications are subject to change without notice... - Page 36 CANNER PERATION Figure 26. Horizontal Direct (13 mil) Figure 27. Vertical Direct (13 mil) Specifications are subject to change without notice...

-

Page 37: Ir Activation Area (Ir Led Output)

OFF after a configured period of non-use then turns the motor OFF after thirty-minute intervals. Any movement detected by the IR in the activation area, shown below, will cause the scanner to exit the power save mode. -

Page 38: Indicator Descriptions

When the scanner successfully reads a bar code, the white LED will flash and the scanner beeps once (if configured to do so). If the scanner does not beep once and the white light does not flash, then the bar code has not been successfully read. -

Page 39: Visual

Steady Blue and Single White Flash When the scanner successfully reads a bar code, the white LED will flash and the scanner will beep once. If the white LED does not flash or the scanner does not beep once, then the bar code has not been successfully read. -

Page 40: Failure

Flashing Blue and One Razzberry Tone This indicates that the scanner has experienced a laser subsystem failure. The scanner will try up to 3 times to correct the failure condition. If the laser subsystem continues to fail, that subsystem (horizontal or vertical) will be shut down and an error indication will be shown on the Diagnostic Indicator Display. -

Page 41: Diagnostic Indicator Display; Error Codes

The following is a list of possible error codes and their meanings. Some errors will require immediate scanner maintenance. RROR Reserved RAM ERROR – The scanner’s Random Access Memory (RAM) is tested as faulty. Return the unit for repair at an authorized service center. PROGRAM ERROR – The scanner’s software program is failing. Return the unit for repair. - Page 42 “break” signal constantly and continuous attempts are made to enter MetroSet configuration mode. A short on the RX Data line can cause this condition. It can also be the result of a laptop in power save mode. The scanner will abort attempts to enter configuration mode after a short timeout.

- Page 43 MOTOR #2 (HORIZONTAL) ERROR – The motor in the horizontal scanning subsystem denotes a failure. The scanner will try three times to correct the motor operation. If the motor error persists, the horizontal scanning subsystem will be shut down and this error code will remain on the Diagnostic Indicators.

-

Page 44: Power Save Modes

Turns the laser OFF after a configured period of non-use. The motor continues to spin allowing for a faster “wake” up time. Any movement detected by the IR will “wake” the scanner from the Laser Off power save mode (see Figure 28 on page 31). -

Page 45: Beeper Options And Button Functions

This feature is configuration dependant. Refer to the MetroSelect Configuration Guide (MLPN 00-02407x) under Scanner Operation: Power Save Modes to enable this feature. Waking the Unit from All Power Save Modes The next button depression will awaken the scanner for normal operation. -

Page 46: Startup

TARTUP When the scanner first receives power the white LED will flash, the blue LED will turn on and the scanner will beep once (the white LED will remain on for the duration of the beep). The scanner is now ready to scan. -

Page 47: Scale Operation Scale Zeroing

After the unit has been officially calibrated (see page 42) the scale can be re-zeroed by pressing the scale zeroing button on either the unit or on the remote display stand. When the scale is at zero the amber LED will be illuminated. Figure 35. The scale zero button on scanner/scale. Figure 36. The scale zero button on the remote display. -

Page 48: Calibration

The certification of the weighing mechanism of the scale version of this scanner is subject to federal, state and local Weights and Measures statutes and regulations and can only be performed by authorized government agencies and/or their duly registered agents. -

Page 49: Priming The Scale For Calibration (Lbs. & Kg)

Priming the Scale for Calibration (lbs. or kg) Prime the scale before starting either method of calibration. Calibrate the scanner/scale after the unit is installed in the checkout countertop. It is important to use the correct certified (lb. or kg.) field weight set when calibrating the scale. -

Page 50: Scale Calibration Procedure (Lbs. & Kg) With Remote Display

If this is a currently installed scanner/scale in need of calibration, cut and remove the calibration switch cover seal. If this is a new installation, cut and remove the factory-applied adhesive seal. - Page 51 (►)(►) while the display flashes all characters. The remote display should read CAL 1. Reinstall the platter onto the scanner/scale. Check the platter to ensure that it is seated properly and nothing is interfering with its freedom to move.

- Page 52 CALE PERATION ALIBRATION Scale Calibration Procedure (lbs. or kg) with Remote Display Make sure there is no load on the scale platter. Calibrate a zero load. Press the right arrow (►) button once when the remote display reads CAL 1 and there is no load on the scale platter.

- Page 53 CALE PERATION ALIBRATION Scale Calibration Procedure (lbs. or kg) with Remote Display 12. Remove the remaining half load from the scale then press clear (C). The message done will flash briefly on the display. 13. Exit calibration mode. Press and hold the test button for at least 3 seconds then release. With no load on the scale the display should read 0.00 lb.

-

Page 54: Bar Code Calibration Procedure Without Remote Display

The following calibration procedure can be used when the remote scale display is not present. This procedure requires that the scanner/scale have a software serial number of 15001, or greater. The beeper volume switch is used to advance to the next stage of calibration and the LED display notifies the operator which ‘calibration stage’... - Page 55 Reinstall the platter and power up the unit. Enter bar code calibration mode. Use the vertical window to scan the following bar code. The scanner will beep once as it enters the bar code calibration mode and the calibration utility will start.

- Page 56 CALE PERATION ALIBRATION Bar Code Calibration Procedure without Remote Display Make sure there is no load on the scale platter. The white LEDs will be used to indicate the current step in the calibration process. Calibrate a zero load. The white LEDs will blink once periodically. Wait 8 to 10 seconds for scale stability then press the beeper volume switch one time.

- Page 57 13. Calibration is now complete. The scanner will automatically restart, and beep one time, in 5 seconds. 14. In order to use the scale in the normal operating mode, the unit must be powered down and the scale program switch returned to the run position.

-

Page 58: Calibration Verification

CALE PERATION ALIBRATION ERIFICATION U.S. Pounds (lbs.) The following tests verify if the scale's Calibration is accurate. For Kilograms see instructions starting on page 53. The following tests are based on a 2-digit accuracy setting for pounds. Increasing Load Test Shift Test Decreasing Load Test Return to Zero Test... -

Page 59: Kilograms (Kg)

CALE PERATION ALIBRATION ERIFICATION Kilograms (kg) The following tests verify if the scale's Calibration is accurate. For US Pounds see instructions starting on page 52. The following tests are based on a 3-digit accuracy setting for kilograms. Increasing Load Test Shift Test Decreasing Load Test Return to Zero Test... -

Page 60: Security Seal Installation

ECURITY NSTALLATION The certification of the weighing mechanism of the scale version of this scanner is subject to federal, state and local Weights and Measures statutes and regulations and can only be performed by authorized government agencies and/or their duly registered agents. Each time the scale or weighing mechanism is calibrated, it should be properly sealed with a paper seal or a wire seal prior to being placed into service in commerce. -

Page 61: Wire Security Seal (Conversion Kit 46-00239)

CALE PERATION ECURITY NSTALLATION Wire Security Seal (Seal Conversion Kit 46-00239) Temporarily remove the platter and place it in a safe location. Install the calibration switch/button cover. Secure the cover in place with the flat head Phillips screw provided. Thread the wire through the hole in the tab that protrudes through the calibration switch/button cover Continue to thread the wire through the wire lock at the other end forming a loop (see Figure 66). -

Page 62: Maintenance

AINTENANCE ORIZONTAL INDOW EPLACEMENT Figure 67. Platter/Horizontal Scan Window Replacement * See replacement parts on page 4. -

Page 63: Vertical Scan Window Replacement

For the glass window: Spray glass cleaner onto lint free, non-abrasive cleaning cloth. Gently wipe the scanner window. For the inner plastic window: Use mild soap and water with lint free, non-abrasive cleaning cloth. Gently wipe the scanner window. -

Page 64: Troubleshooting

Check the transformer, outlet and the power strip. Make sure the power cable is plugged into the scanner. The host system cannot supply enough current to power the MS2220 series scanner. Use the power supply included with the scanner. Contact a Metrologic service representative, if the unit will not hold the configuration. - Page 65 XON/XOFF or D/E, verify that the host cable and host are supporting the handshaking properly. Verify that the scanner’s data format matches that required by the host. Make sure that the scanner is connected to the proper host port. The type of printer and/or the printer settings could be the problem.

- Page 66 Check to make sure that the baud rate and parity of the scanner and the communication port match and the program is looking for RS232 data. Check that the scanner and the host are configured for the same interface. Add some intercharacter delay to the transmitted output by using the MetroSelect Configuration Guide ( 02407x).

-

Page 67: Rs232 Demonstration Program

This program is for demonstration purposes only. It is only intended to prove that cabling is correct, the com port is working, and the scanner is working. If the bar code data displays on the screen while using this program, it only demonstrates that the hardware interface and scanner are working. -

Page 68: Default Settings Communication Parameters

Many functions of the scanner can be "configured" - that is, enabled or disabled. The scanner is shipped from the factory pre- configured to a set of default conditions. The default parameter of the scanner has an asterisk ( * ) in the charts on the following pages. - Page 69 EFAULT ETTINGS OMMUNICATION ARAMETERS ARAMETER RSS Expanded Enable Expanded ID “]e0” RSS Limited Enable RSS Limited ID “]e0” RSS Limited App ID “01” RSS Limited Check Digit DTS/SIEMENS DTS/NIXDORF NCR F NCR S Beeper Tone Beep Transmit Sequence Beeper Volume Power-Up Disable Good Scan Beep Communication Timeout Razzberry Tone on Timeout...

- Page 70 EFAULT ETTINGS OMMUNICATION ARAMETERS ARAMETER Dual Action Power Save Mode #1 Dual Action Power Save Mode #2 Same Symbol Rescan Timeout: 500 msecs Configurable in 50 msec steps (MAX 6.35 seconds) Intercharacter Delay Configurable in 1 msec steps (MAX 255 msecs) Number of Scan Buffers UPC GTIN-14 Format EAN-8 Enable...

- Page 71 EFAULT ETTINGS OMMUNICATION ARAMETERS ARAMETER Transmit UK Plessey Check Digit EAN 128 Enable Enable French Pharma Enable Matrix 2 of 5 Check Digit Enable Hong Kong 2 of 5 Enable Alpha Telepen Telepen Convert Lead ‘^L’ to ‘E’ Enable Code 11 Check Digit Parity Baud Rate 8 Data Bits...

- Page 72 EFAULT ETTINGS OMMUNICATION ARAMETERS ARAMETER Recv “i” = Transmit Scanner ID Byte STX Prefix TAB Prefix Metrologic Prefix UPC Prefix ETX Suffix TAB Suffix Carriage Return Suffix Line Feed Suffix UPC Suffix Transmit LRC Start LRC on 1st Byte Start LRC on 2nd Byte ‘c’...

- Page 73 EFAULT ETTINGS OMMUNICATION ARAMETERS ARAMETER Two Digit Redundancy Five Digit Redundancy Enable Coupon Code 128 Transmit Coupon ‘]C1’ Group Separator Coupon Code Can Begin with ’4’ Enable EAN-99 Coupon Code Bookland Supplements French 378/379 Supplements German 434/439 Supplements Convert Bookland to ISBN Bookland 979 Supplements Convert 979 to ISBN Convert 290 to ISBN...

- Page 74 EFAULT ETTINGS OMMUNICATION ARAMETERS Default settings for “Aux” interface The secondary scanner and the MS2220 series always communicates via RS232. Data is relayed to the host via various primary interfaces ARAMETER Aux Baud Rate Aux Parity Aux Data Bits Aux Stop Bits...

-

Page 75: Scanner And Cable Terminations

ABLE ERMINATIONS CANNER INOUT ONNECTIONS The MS2220 Series scanner interfaces terminate to 10-pin modular jacks located on the bottom of the units. The serial number label indicates the model number of the scanner. Function EAS In EAS Out Scale RS232 to Host... - Page 76 CANNER AND ABLE ERMINATIONS CANNER INOUT ONNECTIONS Scanner to Host, IBM 46xx Function Signal Ground Reserved for RS232 Interface Reserved for RS232 Interface Reserved for RS232 Interface Reserved for RS232 Interface Reserved for RS232 Interface No Connect Reserved for RS232 Interface...

-

Page 77: Cable Connector Configurations

R Data Return Clock Out Signal Ground OCIA Clock In Return / Clock Out Return Clock In No Connect ** All signals are referenced from the StratosS scanner. Specifications are subject to change without notice. 57-57210x-N-3 57-57227x-N-3 57-57227x-N-3 9-Pin D-Type Connector Locking,... - Page 78 * This configuration cable was designed to be used with the StratosS auxiliary connector only. ** All signals are referenced from the StratosS scanner. † All signals are referenced from the auxiliary / secondary scanner. Specifications are subject to change without notice.

-

Page 79: Regulatory Compliance

Under no circumstances should the customer attempt to service the laser scanner. Never attempt to look at the laser beam, even if the scanner appears to be nonfunctional. Never open the scanner in an attempt to look into the device. -

Page 80: Emc

Class A Devices The following is applicable when the scanner cable is greater in length than 3 meters (9.8 feet) when fully extended: Les instructions ci-dessous s’appliquent aux cables de scanner dépassant 3 métres (9.8 pieds) de long en extension maximale: Folgendes trifft zu, wenn das Scannerkabel länger als 3 Meter ist:... -

Page 81: Weights & Measures

Class B Devices The following is applicable when the scanner cable is less than 3 meters (9.8 feet) in length when fully extended: Les instructions ci-dessous s’appliquent aux cables de scanner ne dépassant pas 3 métres (9.8 pieds) de long en extension maximale: Folgendes trifft zu, wenn das Scannerkabel kürzer als 3 Meter ist:... -

Page 82: Limited Warranty

EXCEED THE ACTUAL AMOUNT PAID TO METROLOGIC FOR THE PRODUCT. METROLOGIC RESERVES THE RIGHT TO MAKE ANY CHANGES TO THE PRODUCT DESCRIBED HEREIN. ORPORATE EADQUARTERS ORTH MERICA Metrologic Instruments, Inc. 90 Coles Rd. Blackwood, NJ 08012-4683 Customer Service Department Tel: 1-800-ID-METRO Fax: 856-228-6673 Email: info@metrologic.com... -

Page 83: Patents

ATENTS Patent Information This METROLOGIC product may be covered by, but not limited to, one or more of the following U.S. Patents: U.S. Patent No.; 5,343,027; 5,627,359; 5,686,717; 5,789,731; 5,828,049; 6,029,894; 6,209,789; 6,299,065; 6,345,505; 6,422,467; 6,481,625; 6,494,377; 6,814,292; 6,830,190; 6,874,690; 6,918,540; 6,951,304; No license right or sublicense is granted, either expressly or by implication, estoppel, or otherwise, under any METROLOGIC or third party intellectual property rights (whether or not such third party rights are licensed to METROLOGIC), including any third party patent listed above, except for an implied license only for the normal intended use of the specific equipment,... -

Page 84: Index

NDEX AC ... see power amber LED ...see indicators application ...35, 61 audible...see indicators AUX...9, 60, 69 beep ...see indicators blue LED ...see indicators button calibration ...43, 45 display ...41, 46, 47 multi-function ...9, 39 scale zero ...9, 41 test...47 tone ...9, 39 volume...9, 39 cable...12, 13, 58, 59, 60... -

Page 85: Scan Zone

12 scale capacity...7 scan pattern ...6 scan speed...6 scan zone...29–30 scanner pinouts...69–72 seal...2, 44, 48, 54 secondary scanner ...26, 27 SELV ...17–25 shipping hardware ...15 specifications...6–7 storage ...7 switch ...9, 28 cover...44, 48, 54 test ...3, 40, 42–55 button ...47 tone ... - Page 88 December 2006 Printed in the USA 0 0 - 0 2 0 3 5 C...

Need help?

Do you have a question about the StratosS MS2220 and is the answer not in the manual?

Questions and answers