Subscribe to Our Youtube Channel

Summary of Contents for PeerlessBoilers LC Series

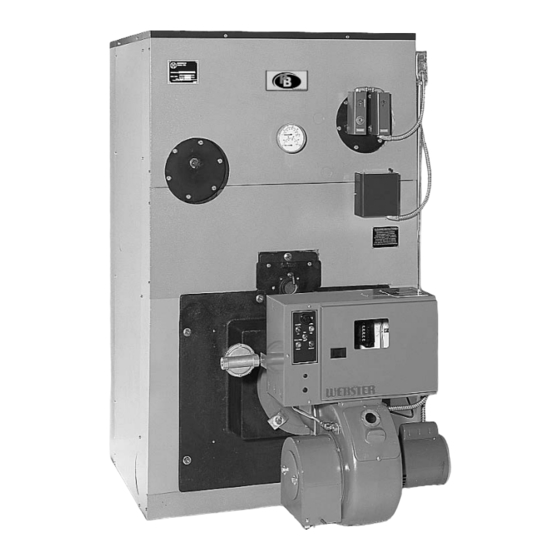

- Page 1 Series LC/LCE Oil, Gas & Gas/Oil Boilers – Water I n s t a l l a t i o n , O p e r a t i o n & M a i n t e n a n c e M a n u a l...

-

Page 2: Table Of Contents

TABLE OF CONTENTS TABLE OF CONTENTS USING THIS MANUAL 5. VENTING A. INSTRUCTION MANUALS ....1 6. INSTALL THE BURNER B. SPECIAL ATTENTION BOXES ... .1 A. -

Page 3: Using This Manual

USING THIS MANUAL USING THIS MANUAL A. INSTRUCTION MANUALS DANGER The Series LC/LCE Installation, Operation & Indicates a condition or hazard which will cause Maintenance Manual is divided into four basic sections: severe personal injury, death or major property 1. Preinstallation (Section 1) damage. -

Page 4: Preinstallation

PREINSTALLATION 1. PREINSTALLATION NOTICE The equipment must be installed in accordance with installation requirements of the authority having jurisdiction or, in the absence of such requirements, to the current edition of the National Fuel Gas Code , ANSI Z223.1/NFPA 54. Where required by the authority having jurisdiction, the installation must conform to American Society of Mechanical Engineers Safety Code for Controls and Safety Devices for Automatically Fired Boilers, ASME CSD-1. -

Page 5: Clearance From Combustible Construction

PREINSTALLATION B. CLEARANCE FROM COMBUSTIBLE D. CHIMNEY OR VENT CONSTRUCTION 1. Inspect the existing chimney or vent system. Make sure it is in good condition. Inspect chimney liner Provide the following minimum clearances to and repair or replace if necessary. combustible construction. -

Page 6: Boiler Setting

PREINSTALLATION Figure 1.4: Foundation Layout 8. Exterior Vents: E. BOILER SETTING a) Insulate sufficiently to ensure adequate draft and 1. If the boiler room floor is not level or if additional to prevent vent damage due to condensation. structural support is needed, provide a good, level 9. -

Page 7: Installation Survey

You can also use this survey to locate system problems which will have to be corrected. To obtain copies of the Water Installation Survey, contact your PB Heat representative or download it from PeerlessBoilers.com. G. PLANNING THE LAYOUT Prepare sketches and notes of the layout to minimize the possibility of interferences with new or existing equipment, piping, venting and wiring. - Page 8 PREINSTALLATION...

- Page 9 PREINSTALLATION...

- Page 10 PREINSTALLATION Table 1.3: Standard and Optional Sections for Knockdown Boilers 50 psig MAWP 80 psig MAWP Sections Standard w/Inspection Tappings No Inspection Tappings w/Inspection Tappings No Inspection Tappings Front Part #/UPC LC-1001 86000 LC-1013 86010 LC-1001-2 86002 LC-1013-2 86012 Plain Interm. Part #/UPC LC-1000 86004...

- Page 11 PREINSTALLATION Table 1.6B: Burner Mounting Plates Boiler Model Model LCE-13 LCE-14 LCE-15 LCE-16 LCE-17 LCE-18 LCE-19 LCE-20 LCE-21 LCE-22 LCE-23 LCE-24 86074* CF2300AKG CF2300AKB 86083* 86083* Beckett CF2500 86074* 86074* Available CF3500AKM 86083* 86083* 86083* CF3500AKL 86080* 86080* 801CRD 86073 86073 Carlin 1050FFD...

-

Page 12: Place The Boiler

PLACE THE BOILER 2. PLACE THE BOILER 2. Remove lifting frame and hardware. A. PACKAGED BOILER 3. Proceed to Section D: Install Coils or Plates 1. Remove crate top and sides. Remove any loose cartons. Remove burner support pedestal and C. -

Page 13: The Sections

PLACE THE BOILER WARNING The sections are heavy and must be supported securely. 10. Lift up the Rear Section and move into position on the steel channels on the boiler foundation. 11. Screw a 3" pipe at least 30 inches long into the lower 3"... - Page 14 PLACE THE BOILER Figure 2.4: Install Additional Sections. Use level on each section as tie rod bolts are drawn up.

- Page 15 PLACE THE BOILER Figure 2.5: Series LC Boiler Assembly – Right Side View...

- Page 16 PLACE THE BOILER Figure 2.6: Series LCE Boiler Assembly – Right Side View...

- Page 17 PLACE THE BOILER 16. To properly assemble LC/LCE sections in the field, 17. Repeat with the remaining sections. the following steps must be followed to ensure that a. Save the LWCO Intermediate with two 1" no damage occurs to the tie rod lugs. A 0-100 ft-lbs tappings (for level control) for use as the section torque wrench is required.

- Page 18 PLACE THE BOILER Figure 2.9: LC/LCE Boiler Section Assembly Sequence...

-

Page 19: Install Coils Or Plates

PLACE THE BOILER D. INSTALL COILS OR PLATES 1. Remove the coil cover plates, gaskets and mounting hardware, located in the Flue Box Carton. 2. Install tankless heaters, if used, in openings #1 and #2. See Figure 2.10 and Table 2.2. 3. -

Page 20: Apply Cleanout Cover Plates

PLACE THE BOILER APPLY CLEANOUT COVER PLATES 1. Apply the Cleanout Cover Plates on the tops of the section joints as shown in Figure 2.11. 2. Pre-assemble a steel flat washer and steel nut on the carriage bolts. Place a carriage bolt into each side of the cleanout opening as shown in the figure. -

Page 21: Install Flue Baffles

PLACE THE BOILER H. INSTALL FLUE BAFFLES INSTALL CHAMBER LINER 1. Remove the Front Cleanout Plate from Front 1. (LCE) Remove Ceramic Fiber Liner from Jacket Section. Carton E. Place the liner on the floor of the combustion chamber. Place the front end of the liner 2. -

Page 22: Pipe The Boiler

PIPE THE BOILER 3. PIPE THE BOILER Lower flow rates (higher temperature rise) are A. PREPARATION acceptable provided the return temperature to the boiler is at least 130°F on gas boilers and 150°F on 1. Make sure the boiler has been pressure tested as oil boilers to prevent condensation of flue gases. - Page 23 PIPE THE BOILER Figure 3.2: LC/LCE Boiler Piping Table 3.1: Boiler Supply and Return Connections & Recommended Header Sizing Suggested Supply Return Connections I=B=R Connections – Top Rear and Side Gross Model @ 20°F Output Size Header Size Header Rise Number Number (Inches)

- Page 24 PIPE THE BOILER b) Temporary low temperature operation is acceptable within limits. For occasional cold start- ups condensation will occur, but will have limited effects. If the system is frequently allowed to cool to room temperature, such as on night set-back systems or energy management systems, cold start-ups will occur often.

-

Page 25: Chilled Water Systems

PIPE THE BOILER control valve and boiler circuit pump piped off of MULTIPLE BOILER INSTALLATIONS the system as a secondary loop. See Figure 3.6 for a single boiler and Figure 3.7 for multiple 1. For multiple boiler installations, piping the boilers in boilers. - Page 26 PIPE THE BOILER Figure 3.6: Piping for Variable Low Temperature Systems, Single Boiler...

- Page 27 PIPE THE BOILER Figure 3.7: Multiple Boiler Piping, System Return Temperature Above 130°F on Gas, 150°F on Oil...

- Page 28 PIPE THE BOILER Figure 3.8: Piping for Variable Low Temperature Systems, Multiple Boilers...

-

Page 29: Assemble The Jacket

ASSEMBLE THE JACKET 4. ASSEMBLE THE JACKET 2. Attach the Middle Front Panel and Lower Front Rail A. PREPARE THE PARTS in the same manner. 1. Collect all the jacket cartons: Jacket Front & Back 3. Position the Jacket Assembly with the front panels Carton plus Jacket Side &... - Page 30 ASSEMBLE THE JACKET Figure 4.2: Jacket Assembly...

-

Page 31: Venting

VENTING 5. VENTING Refer to Chapter 1, Preinstallation, Section D. Chimney or Vent for installation requirements. Refer to Chapter 9, Starting the Boiler, Section C. Run Burner Check Out for damper settings and draft requirements. 6. INSTALL THE BURNER 3. Screw (7) 3/8"-16 x 2 1/4" studs into the holes in the A. - Page 32 INSTALL THE BURNER Figure 6.1: Combustion Chamber Layout – See Table 6.1 for Dimensions Table 6.1: Combustion Chamber Dimensions Chamber Burner Front Plate Extension Past Jacket (Inches) Length Model “A” Gordon- Power Beckett Carlin Webster (Inches) Piatt Flame LC-04 18⁷⁄₈ 6¹⁄₈...

-

Page 33: Connect Fuel Piping

CONNECT FUEL PIPING 7. CONNECT FUEL PIPING A. GENERAL 1. Read the Burner Instruction Manual, supplied with the boiler or with the burner if purchased separately. Review applicable code requirements for burner and fuel piping installations. 2. Install piping to allow removal of burner and access to combustion chamber for cleaning or service. - Page 34 CONNECT FUEL PIPING Table 7.1: Capacity of Gas Supply Pipe in Cubic Feet Per Hour of Natural Gas for Pressure Drop of 0.3 inch Water Column. Pipe Length 1-1/4" 1-1/2" 2" 2-1/2" 3" 4" 6" (Feet) Pipe Pipe Pipe Pipe Pipe Pipe Pipe...

-

Page 35: Install Controls And Trim

INSTALL CONTROLS AND TRIM 8. INSTALL CONTROLS AND TRIM A. INSTALL SAFETY RELIEF VALVE C. INSTALL LOW WATER CUTOFFS 1. Pipe the Safety Relief Valve off of the 2-1/2" tapping 1. See Figure 8.2 for the locations of tappings for probe at the upper left side of the Rear Section. -

Page 36: Pipe Tankless Heaters If Used

INSTALL CONTROLS AND TRIM CAUTION 3. Mount the High Limit Control bulb well in the left side 3/4" tapping of the coil cover plate if a tankless heater is not mounted in the upper right opening The boiler/burner must be electrically grounded in (Position 2). - Page 37 INSTALL CONTROLS AND TRIM Figure 8.2: Control and Pipe Tapping Locations...

- Page 38 INSTALL CONTROLS AND TRIM Figure 8.3: Suggested Piping – Single Tankless Coil Installation Figure 8.4: Suggested Piping – Dual Tankless Coil Installation...

-

Page 39: Starting The Boiler

STARTING THE BOILER 9. STARTING THE BOILER • If automatic fill is used, the system will have A. CHECK THE PIPING to be checked periodically to make sure the antifreeze concentration has not been diluted 1. Water Piping below design level. a) The Boiler must have been hydrostatically tested. -

Page 40: Check Boiler Controls

STARTING THE BOILER 4. Adjust the burner as needed for a CO 2 reading of: 2. Low Water Cutoffs a) Oil burners: CO 2 approximately 12.5% or 1% a) Test probe type controls by using the Push-to-Test less than the level at which the smoke reading Button. -

Page 41: Maintenance

MAINTENANCE 10. MAINTENANCE WARNING Product Safety Information Refractory Ceramic Fiber Product This appliance contains materials made from refractory ceramic fibers (RCF). Airborne RCF, when inhaled, have been classified by the International Agency for Research on Cancer (IARC), as a possible carcinogen to humans. After the RCF materials have been exposed to temperatures above 1800°F (982°C), they can change into crystalline silica, which has been classified by the IARC as carcinogenic to humans. -

Page 42: Placing Boiler In Operation

MAINTENANCE c) Be certain that the boiler and system are refilled WARNING before returning to service. Follow the Instructions in this manual and the Lighting Do not store or allow combustible or flammable Instructions to operate. materials near the boiler. Substantial fire or explosion hazard could result, causing risk of personal injury, d) The system may be filled with a 50% inhibited death or property damage. -

Page 43: Monthly Maintenance

MAINTENANCE d) Remove the Burner and Burner Mounting Plate. E. DAILY MAINTENANCE Remove any scale or soot from the combustion chamber by means of vacuum cleaning or other 1. Inspect the boiler area to make sure the area is free available means. -

Page 44: Boiler Ratings & Dimensions

BOILER RATINGS & DIMENSIONS 11. BOILER RATINGS & DIMENSIONS Table 11.1: Series LC/LCE Boiler Ratings SERIES LC/LCE BOILER RATINGS Gross I=B=R Burner Capacity I=B=R Net Ratings Combustion Efficiency I=B=R Boiler Model Output Boiler Steam Steam Water Number H.P . Sq. Ft. LC-04 16.3 4.75... - Page 45 BOILER RATINGS & DIMENSIONS Figure 11.2: Series LC Dimensional Diagram Figure 11.3: Series LCE Dimensional Diagram...

- Page 46 BOILER RATINGS & DIMENSIONS...

-

Page 47: Repair Parts

REPAIR PARTS 12. REPAIR PARTS Repair parts are available from your installer or by contacting PB Heat, LLC, New Berlinville, PA. Use the Figures and Tables on pages 45-50 to assist in ordering parts. Note: Remember to include boiler model number and serial number when ordering parts. Figure 12.1: Series LC Boiler Assembly... - Page 48 REPAIR PARTS Table 12.1A: Series LC Repair Parts Item Stock Description Part Selection Information Code Front Section See Table 3 for Stock Code – Intermediate Section w/1" Tapping See Table 3 for Stock Code – Intermediate Section See Table 3 for Stock Code –...

- Page 49 REPAIR PARTS Table 12.1B: Series LC Repair Parts (continued) Item Stock Description Part Selection Information Code Top Jacket Panel LC-6004 For Models LC-04 and LC-08 Top Jacket Panel LC6004-1 For Models LC-05, LC-08, LC-09 and LC-10 Top Jacket Panel LC-6004-2 For Models LC-06, LC-10, LC-11 and LC-12 Top Jacket Panel LC-6004-3 For Models LC-07 and LC-12...

-

Page 50: Series Lce Boiler Assembly

REPAIR PARTS Figure 12.2: Series LCE Boiler Assembly... - Page 51 REPAIR PARTS Table 12.2A: Series LCE Repair Parts Item Stock Description Part Selection Information Code Front Section See Table for Stock Code – Top Flue Outlet Intermediate Section – Intermediate Section w/1" Tapping – Intermediate Section – Back Section (Closed Back) 86022 Back Section w/Tankless Coil Opening 86036...

- Page 52 REPAIR PARTS Table 12.2B: Series LCE Repair Parts (continued) Item Stock Description Part Selection Information Code Top Jacket Panel LC-6004-2 For Models LCE-15, -16, -19, -23 & -24 Top Jacket Panel with Flue Opening LC-6022 For All LCE Boilers Rear Top Jacket Panel LC-6006 Top Flue Outlet Plate (14"...

- Page 53 NOTES NOTES...

- Page 54 NOTES...

- Page 55 Series LC/LCE Oil, Gas & Gas/Oil Boilers Water I n s t a l l a t i o n , O p e r a t i o n & M a i n t e n a n c e M a n u a l TO T H E I N S TA L L E R : This manual is the property of the owner and must...

Need help?

Do you have a question about the LC Series and is the answer not in the manual?

Questions and answers