Advertisement

Quick Links

Owner's

I

Read this manual for complete instructions

Fran_ais (page 25) / Espa_oi (pagina 49)

Contents

2 Important Safety Information

4 What's in the Box?

5 Assembly

6 Proper Use and Functions

7 Pressure Relief Procedure

8 Load Material

9 Getting Material to Flow

10 Practice Spraying

12 Clear the Spray Tip

13 Clean the Spray Gun Filter

14 Clean the Inlet Filter

15 Short Term Storage

16 Cleanup - latex materials

18 Cleanup - oil-based materials

19 Cleaning the Spray Gun Components

20 Long-Term Storage

21 Replacing the Outlet/Inlet Valves

22 Troubleshooting

72 Parts List

76 Warranty

1009

•

Form No. 0504949C

Patent pending

Espa_ol

Advertisement

Summary of Contents for WAGNER PROCOAT 850

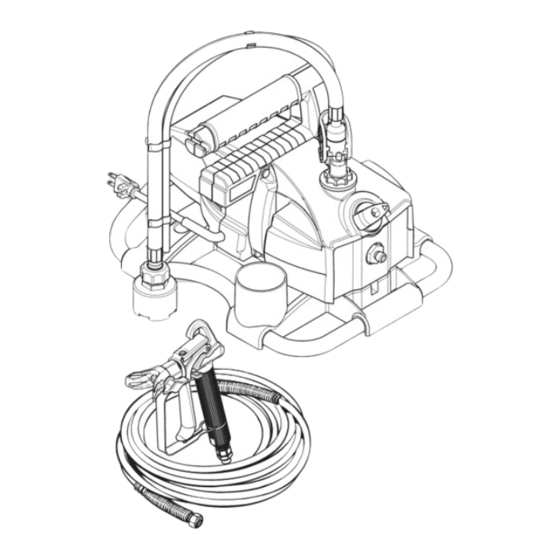

- Page 1 Owner's Read this manual for complete instructions Fran_ais (page 25) / Espa_oi (pagina 49) Contents 14 Clean the Inlet Filter 2 Important Safety Information 4 What's in the Box? 15 Short Term Storage 5 Assembly 16 Cleanup - latex materials 6 Proper Use and Functions 18 Cleanup - oil-based materials 7 Pressure Relief Procedure...

- Page 2 • ALWAYS remove the spray tip before flushing or • Do not smoke in spray area. cleaning the system. • Fire extinguisher must be present and in good • Paint hose can develop leaks from wear, kinking working order. and abuse. A leak can inject material into the skin. •...

- Page 3 The wire with insulation having a thatdonotmeet theminimum s pecifications Wagner Spray Tech accessory extension cords green outer surface with or without yellow stripes is the safety r equirements ofthepump manufacturer.

- Page 4 Pump cleaning adapter* Inlet filter ........Spray Gun / Spray Tip Assembly Connector Spray gun Washer** Catl Wagner Technical Service at: Spray tip seat** 1-800-328-8251 assembly Spray guard ** Saddle seat and washer Register your product online at:...

- Page 5 Youwill need: • Adjustable wrench NOTE: If suction set is difficult Attach the suction set to the pump 2. Remove the plug from inside the as shown. Make sure the conector press onto the pump, lubricate hose fitting and remove the cap on the outlet valve.

- Page 6 Controlsand Functions OH/OFF switch: Spray hose: The ON/OFF switch turns power The spray hose connects the to sprayer on and off. spray gun to the pump. (O=OFF, I=ON) PRIME/SPRAY knob: Spray gun: The PRIME/SPRAY knob directs The spray gun controls the material to the material return Specifications delivery of the material being...

- Page 7 important SafetyWarning accidently spray yourself. The high pressure paint Be careful when handling the spray gun so you don't stream could pierce your skin causing serious injury, if an accident happens see detail procedures in the Safety information section on pages 2=3. See physician immediately and bring this instruction manual.

- Page 8 Youwill need: • The material you plan to spray • Extension cord • Waste bucket 1. Push the red inlet release 2. Unclip the suction hose and return tube. 3. Plug in the sprayer. Turn the PRIME/SPRAY knob to PRIME. Place suction hose into material container (a).

- Page 9 Youwill need: • Scrap material / cardboard • Drop cloths to protect floors and furnishings from overspray Point the spray gun at a piece of scrap material/ 1. Rotate spray tip forward to SPRAY position (a). Unlock the spray gun trigger by turning the trigger lock down (b). cardboard.

- Page 10 Tip: Trigger gun after starting the stroke. Release the trigger before ending the stroke. The spray gun should be moving when the trigger is pulled and released. Overlap each stroke by about 30%. This will ensure Youwill need: an even coating. •...

- Page 11 SprayTechnique Tip: CORRECT Flex your wrist you move in order to CORRECT the surface keep gun parallel to IHCORRECT Start Pull Move Release stroke stroke trigger steadily trigger Spray Pattern Overlap YourStrokes GOODSPRAY PATTERH BAD SPRAY PATTERH:TAILIHG CORRECT See page 12-14...

- Page 12 Note: If spray tip is difficult to rotate, relieve pressure by turning PRIME/ SPRAY knob to PRIME and squeeze trigger while pointing at scrap material/ cardboard. Release trigger Youwill need: and try rotating spray tip again. • Scrap material / cardboard Do not attempt to unclog or clean the tip with your finger.

- Page 13 Youwill need: • Wrench • Warm, soapy water for latex material • Mineral spirits for oil based materials • Replacement spray gun filter (if necessary) 1. Peform the Pressure Relief Pull trigger guard from filter 3. Unscrew the filter housing using a wrench.

- Page 14 Youwill need: • Warm, soapy water for latex material • Mineral spirits for oil based materials 1. Unscrew the inlet filter from the fitting on the end of the 2. Clean the filter using the appropriate cleaning solution suction tube. (warm, soapy water for latex materials, mineral spirits iMPORTANT: Make sure your floors and...

- Page 15 Shutdown This procedure should be used when taking a short term break or when ending your project for the day. if your break is longer than 16 hours follow Cleanup_ instructions, page 16. Youwill need: 1. Peform the Pressure Relief 2.

- Page 16 Cleaningnotes- read before cleaning • When using latex material, clean sprayer and components with warm, soapy water. For oil based material use mineral spirits. Never use mineral spirits with latex materials • NEVER use gasoline to clean sprayer • Dispose of used cleaning solution properly •...

- Page 17 IIS J Remove the inlet filter from Thread pump cleaning 7. Unctip the return tube from the suction tube Turn the water supply to the garden hose on. the suction tube and place adapter onto garden hose. and place it into the waste container. Turn Turn the pump ON.

- Page 18 Follow these steps if you sprayed oil-based materials, or if you sprayed latex materials and do not have a garden hose available. Be sure to use the appropriate cleaning solution for the type of material sprayed. Youwill need: 1. Perform Pressure Relief Procedure Remove the spray tip and 3.

- Page 19 Youwill need: • Soft bristled brush • Light household oil • Warm, soapy water if using latex material • Mineral spirits for oil based material • Wrench Peform the Pressure Relief Pull trigger guard to separate Remove filter from spray gun. Clean Procedure, page 7.

- Page 20 Youwill need: • Light household oil 5 SECONDS • Rags 1. Remove the suction set. 2. Pour approximately 2 ounces of 3. Cover the outlet valve with a rag. Turn light household oil into the pump power ON and let the pump run for five inlet.

- Page 21 Replacement of the outlet valve may be Cleaning or replacing the inlet valve may be necessary if necessary if spray performance remains spray performance remains poor after following steps in poor after following steps in the Fix Spraying the Fix Spraying Problems section.

- Page 22 Test the power supply voltage Replace extension cord The extension cord is damaged or has too low a capacity There is a problem with sprayer motor Take sprayer to Wagner Authorized Service Center Problem B: The sprayer starts but does not draw...

- Page 23 Gun filter housing is loose Tighten handle nterna parts of spray gun are worn or d rty Take sprayer to Wagner Author zed Sew ce Center Problem F: The spray tip assembly leaks The spray tip was assembled incorrectly...

- Page 24 Sprayer,, Puiv6risateur , , Rociador Espa_ol...

- Page 25 item Part No. Quantity Article No de piece Quantite Articulo Pieza No. English - Description Fran_ais - Description EspaSol - Descripci6n Cantidad 0504156 Suction set assembly Ensemble de dispositif d'aspiration Ensamblaje del juego du succi6n 0515454 Spray hose Flexible de pulv_risation Manguera de rociadora 0504164 Outlet valve...

- Page 26 Spray Gun,, Pistolet ,, Pistola Item Part No. Quantity Article No de piece Quantite Articulo Pieza No. Cantidad English - Description Frangais - Description EspaSol - Descripci6n 0501011 Prot_ge-embout Ensamblaje de protecci6n Guard assembly 0501515 Tip, 515 Buse, 515 Boquilla, 515 0515229 Complete gun assembly (Includes Pistotet et ses composants...

- Page 27 English - All spray tips and filters listed below are sold separately. Pa_No. Tip Size* " Part No: Filter Type Filter Color 0501411 0154918 Extrafine Minimum Thin stains, sealers 0501511 0501413 0501513 0154675 Fine Yellow Maximum Thick latex paints, stains 0501415 0501515 Fran_ais - Tous les buses de pulv6risation et de filtres ci-dessous sont vendues s6par6ment.

- Page 28 (at Wagner's option) and return it to you, junto con el comprobante de compra y flete previamente payes, &...