Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Exmark Navigator NAV20KC

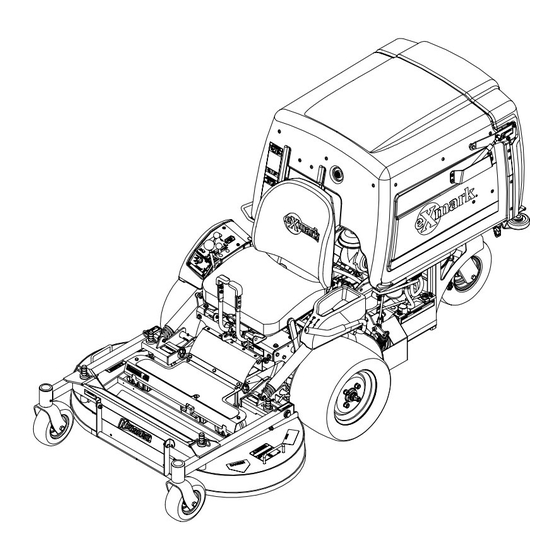

- Page 1 For Serial Nos. 510,000 & Higher Part No. 103-8573 Rev. B...

- Page 2 POTENTIAL HAZARD ♦ This product is a piece of power equipment. WHAT CAN HAPPEN ♦ Failure to follow safe operating practices can result in serious operator injury or even death. HOW TO AVOID THE HAZARD ♦ Keep all shields, guards, and safety devices (especially the grass discharge system) in place and in proper working condition.

- Page 3 3. Exmark being unable to ship the part and the Exmark parts order is received by 3:00 p.m., central time, Exmark pays for the part and freight. 4. If the part does not arrive overnight due to the shipper (UPS), the shipper pays for the freight and Exmark pays for the part.

- Page 4 If additional information is needed, or should you require trained mechanic service, contact your authorized Exmark equipment dealer or distributor. All Exmark equipment dealers and distributors are kept informed of the latest methods of servicing and are equipped to provide prompt and efficient service in the field or at their service stations.

-

Page 5: Table Of Contents

1. SAFETY Safety Alert Symbol ... 1 Training ... 1 Preparation... 1-3 Operation ... 4-6 Maintenance & Storage ... 6-7 Safety Signs ... 8-10 2. SPECIFICATIONS Model Number ... 10 Engine ... 10 Fuel System ... 10 Electrical System ... 10-11 Operator Controls... -

Page 6: Safety Alert Symbol

MAY result in minor or moderate injury. 1.2 TRAINING 1.2.1 Regard the Exmark mower as a piece of power equipment and teach this regard to all who operate this unit. 1.2.2 Read the instructions carefully. Familiarize yourself with the controls and the proper use of the equipment. - Page 7 1.3.4 Thoroughly inspect the area where the equipment is to be used and remove all stones, sticks, wires, bones, and other foreign objects which may damage the equipment or cause personal injury to the operator or bystanders. POTENTIAL HAZARD ♦ Engine exhaust contains carbon monoxide, which is an odorless deadly poison.

- Page 8 DANGER POTENTIAL HAZARD ♦ In certain conditions gasoline is extremely flammable and highly explosive. WHAT CAN HAPPEN ♦ A static charge can ignite gasoline vapors. A fire or explosion from gasoline can burn you, others, and cause property damage. HOW TO AVOID THE HAZARD ♦...

-

Page 9: Operation

1.4 OPERATION Although hazard control and accident prevention are partially dependent upon the design and configuration of the equipment, these factors are also dependent upon the awareness, concern, prudence, and proper training of the personnel involved in the operation, transport, maintenance, and storage of the equipment. It is essential that all Operator Safety Mechanisms be connected and in operating condition prior to use for mowing. - Page 10 POTENTIAL HAZARD ♦ Mowing on wet grass or steep slopes can cause sliding and loss of control. WHAT CAN HAPPEN ♦ Wheels dropping over edges, ditches, steep banks, or water can cause rollovers, which may result in serious injury, death or drowning. HOW TO AVOID THE HAZARD ♦...

-

Page 11: Maintenance & Storage

1.4.7 Never operate the mower with damaged guards, shields, or covers. Always have safety shields, guards, switches, and other devices in place and in proper working condition. 1.4.8 DO NOT change the engine governor settings or overspeed the engine. Operating an engine at excessive speed may increase the hazard of personal injury. - Page 12 1.5.3 Allowing batteries to stand for an extended period of time without recharging them will result in reduced performance and service life. To preserve optimum battery performance and life, recharge batteries in storage when the open circuit voltage drops to 12.4 volts. Note: To prevent damage due to freezing, battery should be fully charged before putting away for winter storage.

-

Page 13: Safety Signs

When new components are installed, be sure that current safety signs are affixed to the replaced components. 1.6.4 New safety signs may be obtained from Exmark Mfg. Co. Inc. 1.6.5 Safety signs may be affixed by peeling off the backing to expose the adhesive surface. - Page 14 LOCATION: Molded into front of hopper PART NO. 103-8611 LOCATION: On Pump Plate, Above Relays WARNING SURFACE 65-2690 PART NO. 65-2690 LOCATION: - On Frame LH side in Front of Exhaust Cutout - On Frame RH side behind Exhaust Cutout PART NO.

-

Page 15: Specifications

Charging Capacity: 15 amps 2.4.3 Battery Type: BCI Group U1 2.4.4 Battery Voltage: 12 Volt 2.4.5 Polarity: Negative Ground PART NO. 103-9032 LOCATION: On Back of Seat PART NO. 103-9034 LOCATION: On Rear of LH Drive Wheel Fender NAV20KC, NAV27KC - 10 -... -

Page 16: Operator Controls

2.4.6 Safety Interlock System: PTO must be disengaged, brake engaged, and speed control lever in neutral position to start engine. (It is not necessary for the operator to be in the seat to start the engine.) Operator must be in seat when PTO is engaged, brake is disengaged, or speed control lever is moved out of neutral or engine will stop. -

Page 17: Tires

2.8 TIRES Pneumatic (Air-Filled) Quantity Tread Size Ply Rating Pressure 2.9 MOWER DECK (Sold Separately) 2.9.1 Models Discharge Cutting Width 2.9.2 Deck Drive: Clutching belt on horizontal engine shaft. Dual “A” section hexagon belt with spring tensioned idler to jackshaft and blower. Heavy-duty cast iron, spiral bevel gearbox is final drive to blades. -

Page 18: Install Drive Wheels

3.2.1 Check the voltage of the battery with a digital voltmeter. Locate the voltage reading of the battery in the table below and charge the battery for the recommended time interval to bring the charge up to a full charge of 12.6 volts or greater. IMPORTANT: Make sure the negative battery cables are disconnected and the battery charger used for charging the battery has an output of 16 volts and 7 amps or less to avoid damaging the battery (see the following chart for... -

Page 19: Service Hydraulic Oil

3.6 SERVICE HYDRAULIC OIL The machine is shipped with hydraulic oil in the reservoir. Run the machine for approximately 15 minutes to allow any extra air to purge out of the hydraulic system. Check hydraulic reservoir and if necessary fill the reservoir to the appropriate level with Mobil 1 15W-50 synthetic motor oil. - Page 20 Run unit at 3/4 speed for at least 5 minutes to bring hydraulic oil up to operating temperature. Stop machine and wait for all moving parts to stop. Engage park brake. Tilt seat forward to gain access to the tracking knob. Rotate the knob towards the right to steer right and rotate towards the left to steer left.

-

Page 21: Pre-Start

With a 7/16 wrench, turn both valves one turn counter-clockwise to release drive system. Turn clockwise to reset system. DO NOT overtighten. DO NOT tow machine. 4.2 PRE-START 4.2.1 Fill fuel tank. For best results use only clean, fresh regular grade unleaded gasoline with an octane rating of 87 or higher. - Page 22 POTENTIAL HAZARD ♦ An uncovered discharge opening will allow objects to be thrown in an operator’s or bystander’s direction. Also, contact with the blade could occur. WHAT CAN HAPPEN ♦ Thrown objects or blade contact can cause serious injury or death. HOW TO AVOID THE HAZARD ♦...

-

Page 23: Transporting

DISABLING HOPPER AUTO DOOR OPEN 4.3.7 Clearing Hopper Screen: a) Screen may be removed by firmly lifting screen handles. See Figure 3. b) Pull screen towards the back to remove. Gently tap debris from the screen as needed. c) Excessive build-up on the screen can cause the blower to plug. NOTE: In conditions where the screen clogs quickly, the front removable screen panel can be turned and reinstalled under the primary screen to allow free air flow from the hopper. - Page 24 POTENTIAL HAZARD ♦ This unit does not have proper turn signals, lights, reflective markings, or a slow moving vehicle emblem. These items are required to drive on a public street or roadway. WHAT CAN HAPPEN ♦ Driving on a street or roadway without such equipment is dangerous and can lead to accidents causing personal injury.

-

Page 25: Maintenance & Adjustments

5. MAINTENANCE & ADJUSTMENTS POTENTIAL HAZARD ♦ While maintenance or adjustments are being made, someone could start the engine. WHAT CAN HAPPEN ♦ Accidental starting of the engine could seriously injure you or other bystanders. HOW TO AVOID THE HAZARD ♦... - Page 26 Check the voltage of the battery with a digital voltmeter. Locate the voltage reading of the battery in the table below and charge the battery for the recommended time interval to bring the charge up to a full charge of 12.6 volts or greater.

- Page 27 1/2 second has elapsed. NOTE: If machine does not pass any of these tests, do not operate. Contact your authorized EXMARK SERVICE DEALER. IMPORTANT: It is essential that operator safety mechanisms be connected and in proper operating condition prior to use for mowing.

- Page 28 5.1.8 Check hydraulic oil level: Service Interval: 40 hr. Stop engine and wait for all moving parts to stop. Tilt hopper up. Clean area around hydraulic reservoir cap and remove cap. Oil level should be to the top of the baffle inside the tank. If not, add oil. Use only Mobil 1 15W-50 synthetic motor oil.

- Page 29 Pack the bearings with a NGLI grade #1 multi-purpose grease. Insert (1) bearing, (1) new seal into the wheel. NOTE: Seals (Exmark PN 103-0063) must be replaced. If the axle assembly has had both spacer nuts removed (or broken loose), apply a thread locking adhesive to (1) spacer nut and thread onto the axle with the wrench flats facing outward.

- Page 30 5.1.14 Lubricate hopper actuator: Service Interval: 160 hrs. a) Stop engine, wait for all moving parts to stop, and remove key. b) Raise hopper and locate actuator on right hand side of mainframe. c) Lubricate switch actuator rod with spray type lubricant or light oil. 5.1.15 Lubricate the pivot bushings (locations shown in Figure 5): Service Interval: 160 hrs.

- Page 31 Change hydraulic system filter: Service Interval: After First 250 hrs. NOTE: Use only Exmark Part No.109-0071 for summer use above 32° F (0°C) or Part No. 1-523541 for winter use below 32° F (0°C). Stop engine, wait for all moving parts to stop, and remove key.

-

Page 32: Adjustments

5.1.22 Wheel Hub – slotted nut torque specification Service Interval: 500 hrs When tightening the slotted nut on the wheel motor tapered shaft: Torque the slotted nut to 125 ft-lbs (169 N-m). NOTE: Do not use antisieze on wheel hub. 5.1.23 Fuel Tank –... - Page 33 Engage the PTO lever. Loosen the jam nuts and adjust linkage as shown in Figure 9 until the pointer is aligned with the tension arm as shown. PTO BELT REPLACEMENT Tighten jam nuts and disengage PTO lever. Re-engage PTO lever and check pointer alignment.

- Page 34 5.2.5 Adjust Seat Switch If necessary, adjust the seat actuator rod length to where the machine will shut off when the operator raises off the seat (with brake disengaged or PTO engaged) but will continue to run with operator in seat (a slight shift in weight should not shut machine off).

- Page 35 THROTTLE TENSION 5.2.8 Adjust Speed Control Lever Tension Stop engine, wait for all moving parts to stop, and remove key. Tension in speed control lever can be adjusted by adjusting the tightness of the lever pivot bolt, which is located under the seat near the speed control lever.

- Page 36 CAUTION POTENTIAL HAZARD ♦ Raising the mower deck for service or maintenance relying solely on mechanical or hydraulic jacks could be dangerous. WHAT CAN HAPPEN ♦ The mechanical or hydraulic jacks may not be enough support or may malfunction allowing the unit to fall, which could cause injury.

- Page 37 TRACKING ADJUSTMENT Move the steering levers to the reverse position. While applying slight pressure to the levers, allow the steering levers to return to neutral. The wheels must stop turning (or slightly creep in reverse). Stop engine and wait for all moving parts to stop. Remove jumper wire from wire harness connector and plug connector into seat switch.

- Page 38 Lift the seat and locate the pump control springs. To increase responsiveness, increase spring tension by hooking the rear spring anchor directly to the anchor bolt. To decrease responsiveness, hook the rear spring anchor to the anchor tab. NOTE: Be sure both springs maintain the same adjustment. STEERING CONTROL LEVER RESPONSE ADJUSTMENT 5.2.11 Tracking Adjustment: See Section 4.1.3 for adjustment.

- Page 39 Tighten the 4 engine mounting bolts and 4 jackshaft mounting bolts. Check alignment after tightening. Re-install pump belt tension spring. Swing fuel tank in and re-install tank mounting nuts. m) Complete Pump Drive Pulley Alignment Section 5.2.13. 5.2.13 Pump Drive Pulley Alignment Pump drive pulley alignment is necessary for any of the following conditions: •...

-

Page 40: Waste Disposal

Door Opening: Locate the hopper door cables. Loosen the jam nut next to the yoke at the end of the hopper door cable/shaft assembly on each side and rotate the shaft until the rear door has a clearance of 1/8”-3/8”. See Figure 22. Verify the cables are pulled equally tight on each side. -

Page 41: Mercury Switch Disposal

Return the switch to your Exmark dealer if it is faulty and is being replaced or if the unit containing the switch is no longer operating and is being scrapped. If the switch is damaged or broken open use extreme caution in handling. -

Page 42: Troubleshooting

NOTE: After carefully checking the above steps, attempt to start the engine. If it does not start, contact your authorized Exmark service dealer. IMPORTANT: It is essential that all operator safety mechanisms be connected and in proper operating condition prior to mower use. - Page 43 ENGINE TROUBLESHOOTING TABLE IMPROPER PROBLEM FUEL FUEL FUEL LINE Will not start Hard starting Stops suddenly Lacks power Operates erratically Knocks or pings Skips or misfires Backfires Overheats High fuel consumption FAULTY DIRT IN DIRTY AIR ENGINE SPARK FILTER OVERLOADED PLUG - 38 - BLOCKED...

-

Page 44: Electrical Diagram

8. ELECTRICAL DIAGRAM - 39 -... -

Page 45: Hydraulic Diagram

HYDRAULIC DIAGRAM - 40 -... -

Page 46: Warranty

Company, pursuant to an agreement between them, jointly warrant on the terms and conditions herein, that we will repair, replace or adjust any part manufactured by Exmark and found by us (in the exercise of our reasonable discretion) to be defective in factory materials or workmanship for a period of two years. - Page 48 CUSTOM RIDE SEAT SUSPENSION SYSTEM ROLL OVER PROTECTION SYSTEM (ROPS) ULTRA VAC COLLECTION SYSTEM ULTRA VAC QUICK DISPOSAL SYSTEM WALK BEHIND ACCESSORIES ©2005 EXMARK MFG. CO. INC. INDUSTRIAL PARK BOX 808 BEATRICE, NE 68310 ALL RIGHTS RESERVED LINE OF ACCESSORIES RIDING ACCESSORIES...