Table of Contents

Advertisement

Quick Links

F

Save This Manual

For Future Reference

owner's

manua

NODEL

NO.

t 13.235140

Serial

Number

Modal

and

serial

numbers

may

be

found

on

a

plata

attached

to your

saw,

at the

side of the Miter Saw arm,,

You should

record both model

and

seria!

number

in a safe

place for future use_

FOR YOUF

READ ALL

INSTRUCTIONS

CAREFULLY

Part No, SP6008

o assembny

o operating

o repair parts

J

Sears,

Roebuck

and

Co.,

Hoffman

Estates,

IL. 60179

U.S.A.

Printed in U.S A.

Advertisement

Table of Contents

Summary of Contents for Craftsman 113.235140

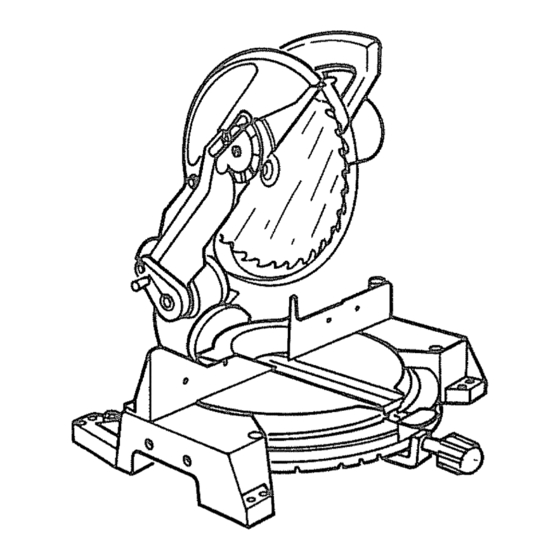

- Page 1 Save This Manual For Future Reference owner's manua NODEL t 13.235140 Serial Number Modal serial numbers found plata attached to your saw, at the side of the Miter Saw arm,, You should record both model seria! number in a safe place for future use_ o assembny FOR YOUF...

-

Page 2: Warranty

FULL ONE YEAR WARRANTY ON CRAFTSMAN BENCHTOP TOOLS If this miter saw fails due to a defect in material or' workmanship within one year' from the date of purchase, RETURN IT TO THE NEAREST SEARS SERVICE CENTER IN THE UNITED STATES, and Sears will repair it, free of charge°... -

Page 3: Before Each Use

° Support t hemitersawsothetableis level a ndthe saw store anything above or near the tool where anyone doesnotrock,. might stand on the tool to reach them. • Bolt or clamp the saw to its support. To avoid injury or death from electrical shock: o Never Stand On Tool. -

Page 4: Dress For Safety

Safety Instructions fen"Miter Saws (continued) ........o Do not wear loose clothing, gloves, neckties or' jewelry Dress For Safety (rings, wrist watches) They can get caught and draw WEAR YOUR you into moving parts. • Wear nonslip footwear. • Tie back long hair_ •... -

Page 5: Whenever Saw Is Running

Let the blade reach full speed before cutting. This will Whenever Saw is Running help avoid thrown workpieces WARNING: Don't allow familiarity (gained from fre- Don't Force Tool. It will do the job better and safer at its quent use of your miter saw) cause a careless mis- designed rate. -

Page 6: Motor Specifications

Motor Specifications and Electrical Requirements The ArC motor used on this tool is an universal non-revers- Power Supply and Motor Specifications ible type, having the following specifications: WARNING: To avoid electrical hazards, fire haz- Max Developed H_P, 3-1/2 ards or' damage to the tool, use proper circuit pro- tection. -

Page 7: Table Of Contents

Motor Safety Protection a.. Motor Is Overloaded-Overloading can occur if you feed too rapidly or make too many start/stops in a 1. Connect this tool to a 120v, 15-amp branch circuit with short time. a 15-amp time delay fuse or circuit breaker Using the b.. -

Page 8: Unpacking And Checking Contents

Unpacking and Checking Contents Tools Needed Combination Square Must be True Straight Edge of Draw Light Board 314" Thick Combination Wrench, Line on Board This Edge Must be 1/4" Hex "L" Wrench Combination Square with #2 Phillips tip (supplied) Along this i_i. _ PI rfectly Straight 314 Socket &... -

Page 9: Getting To Know Your Miter Saw

Getting to Know Your Miter Saw 1,, Warning Label, 2. Lock Pin - The miter saw can be locked in the low- ered position tor compact storage. 3. Miter Lock Knob - The miter lock handle securely locks the miter saw at a desired miter angle, Index points have been provided on right and left for 0, 15 °, 225 °, 30 °... -

Page 10: Assembly

Assembly WARNING: For your own safety, never connect plug to power' source outlet until all assembly steps are complete, and you have read and under'- .Lock Pin stood the safety and operational instructions, Assembling the Lower Blade Guard NOTE: For compact shipment the lower blade guard has been partially disconnected. -

Page 11: Assembling Dust Elbow

4. Find the arbor lock between the upper guard and the miter saw handle Fit 1/4" hex end of combination tool in arbor screw or use 1/2" box end wrench 5., Press the arbor lock and hold it in lirmfy while turning the wrench clockwise.. - Page 12 Ah'gnment (Adjustments) ............... co° e,. owo e, co,, o permanently damaged. Wear' your safety goggles, NOTE: Before this saw is aligned or used, a kerr must be cut into the table insert at 0° bevel. Our Quality Control Audit Procedure requires us to cut through some inserts before they leave our factory..

-

Page 13: Adjust Miter Scale Indicator

Step Two: Blade Square to Fence (Miter Align- ment) WARNING: To avoid injury from unexpected start- ing or electrical shock, do not plug the saw in. The power cord must remain unplugged whenever you are working on the saw. 1..To check blade squareness to fence, lock power head guard in lower position with the lock pin.. -

Page 14: Alignment (Adjustments)

Alignment (Adjustments) (continued) ....,,,, Bevel Pivot Movement/Adjustment 1 Check that miter saw bevels easily by loosening the bevel lock handle and tilting the power head to the left. NOTE: At least one thread of the pivot bolt should stick out past the hex lock nut,. - Page 15 Portable Applications To mount the saw to a 3/4" piece of plywood, use, 4 of the 6, 5/16 bolt holes o_rr the 4 drywall screw holes, The mounting board can then be clamped down to prevent it from tip- ping. Plywood mount also helps pro- tect saw from damage during the rough handling associated...

-

Page 16: Safety Instructions For Basic Saw Operations

Safety instructions for Basic Saw Operations ....Before Each Use inspect your saw. stops by itself. Check the lower guard to see if it closed fully. If it did not, follow the instructions in the Trouble Disconnect The Miter Saw. To avoid injury from acci- Shooting section dental starting, unplug the saw, before changing the... -

Page 17: Dress For Safety

Glasses or goggles not in compliance with ANSI Z87_1 Dress For Safety could seriously hurt you when they break.. WEAR YOUR o Do not wear loose clothing, gloves, neckties or jewelry (rings, wrist watches) They can get caught and draw you into moving parts, •... -

Page 18: Basic Saw Operations

Safety instructions for Basic Saw Operations (continued) Let the blade reach full speed before cutting. This will . Release the switch, and wait for alt moving parts to help avoid a thrown workpiece, stop before moving your hands or raising power head_ Don't Force Tool, It will do the job better and safer at its o If blade doesn't stop within 6 seconds, unplug the saw designed rate Feed the saw into the workpiece only fast... - Page 19 MiterCut Whena mitercut is required, l oosenmiter lockknob, depressthe index spring and movethe saw to the desired angle,Retighten miterlockknob,Movewiththe handle tothe miterangletomakethecut with miter Move feet angle Bevel Cut When a bevel cut is required, loosen bevel lock knob, Tilt the blade to desired bevel angle_ Retighten bevel lock knob, Stand to the left side of the handle to make the cut.,...

- Page 20 Basic Saw Operations (continued) ......... ,..... Compound When a compound cut is required, select the desired bevel and miter positions.. Move with the handle to the miter angle to make the cut. Cutting Bowed Material Before cutting a workpiece, check to make sure it is not bowed, tf it is bowed the workpiece must be positioned Correct and cut as illustrated..

- Page 21 Workpiece Support Long pieces need extra supports. The supports should be placed along the workpiece so the work- piece does not sag and your hand holding the work- piece is positioned 4" or more from the blade path, The support should let the workpiece lay flat on the base and work table during the cutting operation NOTE: When mounted on a large flat surface, the miter saw table is 3 1/2"...

-

Page 22: Helpful Hints When Cutting Compound Miters

Basic Saw Operations (continued) Helpful Hints When Cutting Compound Miters Tips for Cutting Compound Miters on Picture Frames and Boxes A compound miter-is a cut usually requiring both a miter setting and bevel setting A compound miter is used for making frames or boxes that have sloping sides and are wide at one end and narrow at the opposite end. - Page 23 Workpiece standing up, usually cut inverted from ceiling mounted orientation Fixturing: Optional fence mounted crown molding jigs w!_ich locate workplace. See recommended accessories (Table clamp is help- ful). Hand is holding workpiece to fence when the cuts are made All cuts are made at 0° bevel setting and 45 °...

- Page 24 Maintenance and Lubrication Lower Blade Guard Maintenance Do not use the saw without the lower guard The lower' DANGER: Never put lubricants on the blade while it blade guard is attached to the saw for your protection is spinning. Should the lower' guard become damaged, do not use the saw until damaged guard has been replaced..

-

Page 25: Maintenance And Lubrication

Maintenance and Lubrication (continued) ......2, Lubrication of mechanism which pivots lower guard: (see picture on previous page) Use light household oil (sewing machine oil) or a pressurized light spray oil on metal-to-metal or metaHo-plastic guard contact areas as required for smooth, quiet operation. Avoid excess oil, to which sawdust will cling Lubricate the lower... -

Page 26: Lubrication

Troubleshooting Guide Motor Problem Probable Cause Suggested Corrective Action r _'_;,,;;;;;;;, "'"'",,', ,,,_;,; ' i........ Brake does stop l_Brushes not seated or - Inspect/cleanheptace brushes_ See "Mainte- blade within 6 second& nance" section,, lightly sticking 2. Motor brake winding - Use onfy recommended blades/accessories, overheated from use of... -

Page 27: Trouble Shooting Of Brake By Qualified Service Person Only

Wiring Diagram : ..:..:::._..White Field N,O_ Switch 4. Check brake circuit for continuity: remove brush caps Trouble Shooting of brake by qualified and brushes.. Use ohmmeter to check continuity from service person only. brass brush holder to brush holder. If open, locate 1.. -

Page 28: Repair Parts

Repair Parts ..........................Parts List For Craftsman 12" Compound Miter Saw Model No. 113.235140 Figure 1 23 3... - Page 29 Repair Parts ....... Parts List For Craftsman 12" Compound Miter Saw Model No. 113.235140 Figure 1 Always order by part number - not by key number Pa_ No, Part No,, Description Description Blade" Guard Asm 823355 Bolt Table Pivot See Fig. 4...

- Page 30 Repair Parts Parts List For Craftsman 12" Compound Miter Saw Model No. 113.235140 Figure 2 - Arm and Motor Assembly ! WARNING: For your' safety, this miter saw is specially insulated. To avoid electrical shock, fire or injury, use only parts identical to those identified in the parts list, Reassemble exactly as originally assembled.

- Page 31 Repair Parts ..Parts List For Craftsman 12" Compound Miter Saw Model No. 113.235140 Figure 3 - Pivot Assembly Always order by Part Number - Not by Key Number Part No, Description Part No. Description 823260 Pivot 823401 Ring Retaining ....

- Page 32 Repair Parts ....................Parts List For Craftsman 12" Compound Miter Saw Model No. 113.235140 Figure 4...

- Page 33 Repair Parts Parts List For Craftsman 12" Compound Miter Saw Model No. 113.235140 Figure 4 Blade & Blade Guard Asm. :_ Always order by part number - Not by key number Part No. Description Part No, Description 1 823664 823351...

-

Page 34: Notes

Notes .. - Page 35 Notes ............

- Page 36 12 0NCH COMPOUND ITER SAW MODEL NO. For the repair or replacement paris you need 113.235140 Call 7 am - 7 pm, 7 days a week t ,.SO0-366-PART (1-800-366-7278) For in-home major brand repair service Call 24 hours a day, 7 days a week t =S00=4=REPAUR (1-800-473-7247) The model number...