Datamax W-6208 Operator's Manual

W class series

Hide thumbs

Also See for W-6208:

- Programmer's manual (302 pages) ,

- Quick start manual (2 pages) ,

- Quick reference manual (88 pages)

Table of Contents

Advertisement

Quick Links

Operator's Manual

Corporate Headquarters

4501 Parkway Commerce Blvd.

Orlando, Fl 32808

Phone: 407-578-8007

Fax: 407-578-8377

Asia-Pacific

Datamax International

19 Loyang Way

Herbert House

#01-01 CILC Building

12 Elizabeth Way, Pinnacles

Singapore 508724

Harlow, Essex CM19 5FE UK

Phone: +65 542-2611

Phone: +44 1279 772200

Fax: +65 542-3611

Fax: +44 1279 424448

Advertisement

Table of Contents

Summary of Contents for Datamax W-6208

- Page 1 Operator’s Manual Corporate Headquarters 4501 Parkway Commerce Blvd. Orlando, Fl 32808 Phone: 407-578-8007 Fax: 407-578-8377 Asia-Pacific Datamax International 19 Loyang Way Herbert House #01-01 CILC Building 12 Elizabeth Way, Pinnacles Singapore 508724 Harlow, Essex CM19 5FE UK Phone: +65 542-2611...

- Page 3 Information in this document is subject to change without notice and does not represent a commitment on the part of Datamax Barcode Products Corporation. No part of this manual may be reproduced or transmitted in any form or by any means, for any purpose other than the purchaser's personal use, without the expressed written permission of Datamax Corporation.

- Page 5 Agency Compliance and Approvals: UL1950 Information Technology Equipment C22.2 No. 950-M93 Listed EN60950 For 230 Volt Operation (Europe): Use a cord set, marked “HAR,” consisting of a min H05VV-F cord which has a minimum 0.75 square mm diameter conductors, provided with an IEC 320 receptacle and a male plug for the country of installation rated 6A, 250V Für 230 Volt (Europa): Benützen Sie ein Kabel, das mit “HAR”...

- Page 6 Important Safety Instructions: The exclamation point within an equilateral triangle is intended to alert the user to the presence of important operating and maintenance instructions in the literature accompanying this unit. This unit has been carefully designed to provide years of safe, reliable performance.

-

Page 7: Table Of Contents

Printer Overview About the Printer ..............1 1.0.1 Standard Features ..........2 1.0.2 Optional Features ..........2 Option Installation..............4 Getting Started Unpacking the Printer ............5 Media and Ribbon Selection..........7 2.1.1 Print Quality Controls ..........7 Setting Up the Printer Installation ................ - Page 8 4.0.6.1 Soft Reset ..........27 4.0.6.2 Level One Reset........27 4.0.6.3 Level Two Reset........27 The Menu System ............. 28 4.1.1 Entrance and Exit Prompts ......... 29 4.1.2 Media Settings ............ 30 4.1.3 Print Control............31 4.1.4 Printer Options............ 33 4.1.5 System Settings ..........

- Page 9 Troubleshooting Problem Resolution ............75 Fault and Warning Messages ..........79 Hex Dump Mode ............... 85 Printer Specifications General Specifications............87 Media and Ribbon Requirements ........89 Appendix A ASCII Control Code Chart ............91 Appendix B Available Fonts and Bar Codes..........93 Appendix C Module Assignments..............

- Page 10 Warranty Information ........... 113 Glossary ................117 Index ..................121...

-

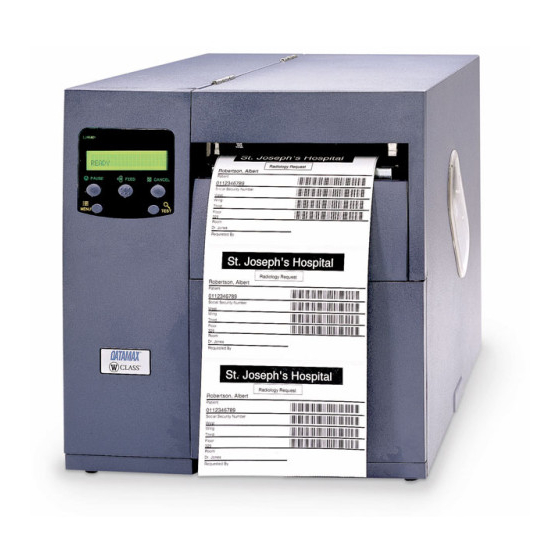

Page 11: About The Printer

If you wish to write custom label programs, a copy of the I & W Class Programmer’s Manual is included on the enclosed Datamax Accessories CD; otherwise, a copy may be downloaded from our web site at http//www.datamaxcorp.com. -

Page 12: Standard Features

Operational 2 X 20 Backlit Liquid Crystal Display and functional keypad CG Triumvirate Scalable font w/AGFA Scalable font engine EFIGS (multi-language display and configuration label support) 203 DPI Printhead (W-6208) 300 DPI Printhead (W-6308 and W-8306) 1.0.2 Optional Features The printer offers the following optional features: Cover Dampener A device to control the closing rate of the cover. - Page 13 Simplified Chinese GB Scalable font Korean Hangul Scalable font ILPC – CG Times Firmware The printer’s firmware can be upgraded to include the Datamax ILPC CG Times font. This supports the Datamax Enhanced Language Code Pages. Internal Rewind (factory installed) A mechanism to rewind printed labels and backing material inside the printer.

-

Page 14: Option Installation

These are internal devices, providing connection to AS/400 and System/3X Twinax host system or 3270-type host system. 1.1 Option Installation This table lists the recommended qualification level for the person installing the options. Contact your dealer or Datamax Technical Support for details. Suggested Experience Level Option Qualified Installer... -

Page 15: Unpacking The Printer

2.0 Unpacking the Printer Inspect the shipping container(s) for damage; if evident, immediately notify the shipping company to report the nature and extent of the damage. The printer has been carefully packaged to avoid damage during transit. In order to operate the printer, you will need to remove the tape and foam placed there for shipment. - Page 16 Inspecting the Printer After removing the printer from the packaging material, check the contents of the package. In addition to this manual, the following items should be included: Printer Power cord Accessories CD Any special or additionally purchased items. Additional Requirements The following items are necessary for generating printed labels.

-

Page 17: Media And Ribbon Selection

The following is a limited overview of media characteristics. For complete information and advice regarding your specific application needs, always consult a qualified media specialist or a Datamax Media Representative. Media Selection – Direct Thermal Consider three important factors when selecting direct thermal stock: The abrasive qualities of the material that covers the thermal reactive layer of the paper. - Page 18 The following table is intended for reference only (for specific application information, consult your media specialist or a Datamax Media Representative). Thermal Transfer Ribbon...

-

Page 19: Installation

3.0 Installation This chapter explains how to connect your printer, and load it with media and ribbon. Note: When connecting the AC Power Cord or data cables to the printer, ensure the Power On/Off Switch is in the ‘Off’ position. Place the printer on a firm, level surface. -

Page 20: Communications

3.0.1 Communications Using a data detection process, the interface selection occurs automatically in the printer. At power-up, the printer begins monitoring the interface ports for activity. When the host transmits data, the printer port detecting this data is set ‘active’ and remains active as long as data flow continues. Once the incoming (received) data flow stops and the Host Timeout Value (see Section 4.1.6) is exceeded, the detection process will be repeated. - Page 21 Serial Port: serial interface supports RS-232C and, equipped, RS-422 communications. The following list of serial port settings is menu-selectable and must match the host computer’s serial port settings; see Section 4.1.6. Baud Rate (serial communication speed) Word Length Word Parity Number of Stop Bits Handshaking Protocol In addition to the port settings, the serial interface cable wiring must have...

-

Page 22: Loading Media

3.1 Loading Media The following section explains the media loading steps. Before beginning, complete these steps: Raise the Access Cover. Rotate the Printhead Latch forward to raise the Printhead Assembly. Slide the Media Guide out away from the frame. Proceed according to the type of media you are using: go to Section 3.1.1 for Roll Media or go to Section 3.1.2 for Fan-... -

Page 23: Roll Media

3.1.1 Roll Media This loading method is for roll type media applications. To load: Slide Roll Media onto the Media Supply Hub until it rests against the Backstop. Route the media as shown below: under the Bouncer Assembly, through the Media Sensor, then out the front of the printer. -

Page 24: Fan-Fold Media

3.1.2 Fan-Fold Media This loading method is for tag and fan-fold type media applications. To load: Bring media in from the Bottom or Rear Fan-Fold Slot and through the printer, as shown below. (If using reflective stock, ensure that the mark is facedown.) Slide the Media Guide over until it rests lightly against the edge of the... -

Page 25: Media Sensor Adjustment

3.2 Media Sensor Adjustment The Media Sensor needs to be positioned so that the printer can detect the presence of media and the top-of-form (except for continuous stock, where the TOF is set through programming; see Label Length, Section 4.1.2). To adjust: With media loaded, as described in Section 3.1.1 or 3.1.2, turn the Media Sensor Adjust Knob clockwise (outward) or counterclockwise (inward) until the Sensor Eye Mark is positioned over the media according to the... -

Page 26: Loading Ribbon

3.3 Loading Ribbon Thermal transfer media requires the use of ribbon. To load: Note: Using a ribbon that is slightly wider than your media (and liner, if any) will help protect against printhead wear. With the access cover raised, remove the J-Hook from the Ribbon Take-Up Hub. -

Page 27: Quick Media Calibration

3.4 Quick Media Calibration When ‘Uncalibrated’ is displayed, follow the Media Sensor Calibration procedure in Section 5.0. At the factory, the printer is calibrated to sense a wide range of media types. Quick Media Calibration fine-tunes the media sensor for your gap, notch or reflective media application (this is not required for continuous media). -

Page 28: Outputting Labels

3.5 Outputting Labels In addition to directly outputting labels from the printer, there are several optional output configurations available. 3.5.1 Rewinding onto the Media Rewind Hub With the Internal Rewind option, the printed labels and backing material can be wound directly onto the Media Rewind Hub. To rewind labels and backing: Load media as described in Section 3.1. -

Page 29: Rewinding Onto A Core

3.5.2 Rewinding onto a Core With the Internal Rewind option, the printed labels and backing material can be wound directly onto Media Cores. To rewind labels and backing onto cores: Load media as described in Section 3.1. Remove the Tear Bar and install the Arc Plate;... -

Page 30: On-Demand Dispensing

3.5.3 On-Demand Dispensing When equipped with the Peel and Present option, labels are dispensed then separated automatically from the liner for immediate application. Load media as described in Section 3.1. Remove the Tear Bar (see pictorial, Section 3.5.1) and attach the Peel Mechanism to the printer using the Thumbscrews. - Page 31 Place the leading edge of the media into the Slot in the hub. Rotate the hub several times to secure the media. Slide the Media Retainer onto the hub; position it just to the edge of the media and tighten the Thumbscrew. Push the Peel Roller Bracket back to its closed position.

- Page 32 W-Class...

-

Page 33: Operation

4.0 Operation The front panel is comprised of three indicator lights, a Liquid Crystal Display and five mode-dependant keys. The selectable modes (Ready, Menu and Quick Test) and the related functions of the keys are detailed below. 4.0.1 Ready Mode: Normal Operation (Ready Light ‘On’) The PAUSE key temporarily suspends printing. -

Page 34: Menu Mode

4.0.2 Menu Mode: Configuration (Ready Light ‘Flashing’) The DOWN ARROW key scrolls to the previous menu item on the same menu level. It also decrements numerical values in most menu selections. The UP ARROW key scrolls to the next menu item. -

Page 35: Quick Test Mode

4.0.3 Quick Test Mode: Print Test Labels Note: The Quick Test Mode functions are disabled while processing data from communications interfaces until the Host Timeout value expires. The DOWN ARROW key scrolls to the previous test function. The UP ARROW key scrolls to the next test function. -

Page 36: Indicator Lights

4.0.4 Indicator Lights ‘On’ indicates that the printer is powered ‘On’ and, after initialization, it indicates the Ready Mode. ‘Slow Flashing’ indicates the Menu Mode. ‘Fast Flashing’ indicates data is being received and processed. ‘On’ indicates a ‘Paused’ condition. ‘Slow Flashing’ indicates a Warning. ‘Fast Flashing’... -

Page 37: Resetting The Printer

4.0.6 Resetting the Printer Depending upon the method used, there are three reset levels possible: 4.0.6.1 Soft Reset To reset the printer and clear any temporary host settings: With the printer ‘On’, press and hold the CANCEL key for approximately four seconds. -

Page 38: The Menu System

4.1 The Menu System Printer operation can be controlled through the user interface, allowing the operator access to these six menu system branches: Media Settings Print Control Printer Options System Settings Communications Diagnostics While in the menu system, the current selection will be indicated with the ‘*’ symbol next to the displayed item on the LCD, and selections designated with the ‘§’... -

Page 39: Entrance And Exit Prompts

4.1.1 Entrance and Exit Prompts With ‘Ready’ displayed on the LCD, press the key to enter the Menu Mode. Note: While in the Menu Mode, the printer will stop processing new DPL (or bitmapped) data. MENU MODE Depending upon the configuration of the printer, the following Entrance and Exit Prompts may be displayed when accessing or leaving the Menu System. -

Page 40: Media Settings

4.1.2 Media Settings MEDIA TYPE Selects the printing method. DIRECT THERMAL For use with heat sensitive media. THERMAL TRANSFER For use with media requiring a ribbon to create an image. SENSOR TYPE Selects the top-of-form (TOF) sensing method for the media. The printer recognizes the TOF by sensing gaps in the media. -

Page 41: Print Control

4.1.3 Print Control Refer to Section 2.1.1 for detailed information on print quality controls. HEAT Controls the ‘burn-time’ of the printhead. 10 (0-30) This is the equivalent of Heat Setting on most label software programs. PRINT SPEED Controls the rate of label movement during the printing process;... - Page 42 Print Control (continued) These factory adjustments independently CUSTOM ADJUSTMENTS change the listed parameters to finely tune the printer and compensate for slight mechanical differences sometimes evident when multiple printers share label formats. In addition, each of the following adjustments has no factory default setting and restoring factory defaults will NOT affect these settings.

-

Page 43: Printer Options

4.1.4 Printer Options MODULES Memory available for user storage of graphics, fonts and label formats. (The physical presence of the respective memory module must be detected to show the function selections for that module in the menu system.) See Appendix C for a listing of all possible modules. - Page 44 Printer Options (continued) CUTTER Used to cut media into separate labels. (The physical presence of a cutter must be detected to show the ENABLE/DISABLE selections.) ENABLED Enables label cutting. DISABLED Disables the cutter. NOT INSTALLED No cutter is detected. GPIO PORT Model dependant option used to interface the printer to an external controlling device (see Appendix D).

-

Page 45: System Settings

4.1.5 System Settings CONFIGURATION FILE Options for storage and recall of printer configuration files. See Appendix F for details. RESTORE AS CURRENT Provides a list of available configuration files. Selecting a file from the list causes a printer reset; afterward, the printer is configured according to the activated file. - Page 46 System Settings (continued) DOUBLE BYTE SYMBOLS When equipped with the ILPC option, this selects the code page used to print double byte fonts unless otherwise specified in DPL; see the I & W Class Programmer’s Manual for details. Japanese Industry Standard SHIFT JIS Shift Japanese Industry Standard Extended UNIX Code...

- Page 47 Datamax authorization to upgrade.) yyyyyy – is a manufacturing date code zzz – is a unique time stamp UPGRADE PRINTER This function is used to upgrade the CODE software feature level of the printer. Datamax authorization is required. W-Class...

- Page 48 System Settings (continued) SET FACTORY DEFAULTS Parameters in this menu listing with the ‘ ’ symbol are the designated defaults. SET FACTORY DEFAULTS Overwrite the current settings with the factory default settings or, if selected, will restore the Factory Setting File. Note: The reset will be automatic.

- Page 49 System Settings (continued) PAUSE MODE When enabled, Pause Mode suspends printing between each label until the PAUSE key is pressed. ENABLED Printer requires operator to press the PAUSE key after each label. DISABLED Printer completes label batch without pausing between labels. Provides the user with the ability to SECURITY password protect all printer settings made...

- Page 50 System Settings (continued) BACK AFTER PRINT When the present distance is set with the cutter, present sensor or GPIO option enabled, this setting determines the timing of the label back up. ENABLED Commands the printer to immediately back up the label after the cut operation, the GPIO start of print signal is received, or the present sensor is clear.

-

Page 51: Communications

4.1.6 Communications Controls the communications settings for SERIAL PORT A Serial Port A. BAUD RATE Determines the serial communication rate. 38400 38400 bits per second 28800 28800 bits per second 19200 19200 bits per second 9600 9600 bits per second 4800 4800 bits per second 2400... - Page 52 Communications (continued) Same as Parallel Port A, for an optional PARALLEL PORT B Ethernet connection. If not present, this displays ‘NOT INSTALLED’ when accessed. Note: If the ‘LOCKED’ message appears when attempting to access the NIC ADAPTER menu, the printer may have active print requests or multiple users may be trying to access these parameters (for example, during simultaneous telenet sessions).

- Page 53 Communications (continued) PROTOCOL The network protocols recognized by the NIC Adapter. This protocol is always supported. Local Area Transport is a DEC VMS network protocol that requires a LAT license number. ENABLED Protocol is enabled by default. DISABLED Ignore LAT protocol. Select this option if LAT is not needed.

- Page 54 Communications (continued) DISCOVERY This is the address discovery method used by the NIC Adapter if a static address is not utilized. If no server for any of the discovery methods is found, the static value specified above is used. Note: For faster NIC Adapter boot times, disable any discovery methods not used.

- Page 55 Communications (continued) HOST SETTINGS Settings which affect all communications with a host. HOST TIMEOUT The number of seconds a communications SEC (1-60) port must be idle before the printer may process data from a different port. This value is also used to “timeout” an image / label format download.

- Page 56 Communications (continued) HEAT COMMAND Allows the user to disable the DPL Heat Command, providing compatibility with other DATAMAX printers. ENABLED Normal printer operating mode. DISABLED DPL Heat Commands are ignored. The heat value is controlled via the menu setting; see Print Control, Section 4.1.3.

-

Page 57: Diagnostics

4.1.7 Diagnostics HEX DUMP MODE Most commonly used for troubleshooting. Prints data and instructions received from the host rather than interpreting them as label formats; see Section 6.2. ENABLE Prints raw ASCII data received from the host rather than executing the commands. DISABLE Executes and prints label formats (normal operating mode). -

Page 58: Display Messages

4.2 Display Messages The printer displays several different types of information (if not in the menu system or Quick Test Mode): User Prompts and Condition Messages (also see Section 4.1.1 for a listing of the Enter / Exit Prompts) Application and Boot Loader Updating Messages (see Section 5.3 and 5.4) Fault and Warning Messages (see Section 6.1) 4.2.1 User Prompts and Condition Messages... - Page 59 User Prompts and Condition Messages (continued) Displayed Message Description Condition(s) The Present Sensor option A label is awaiting is enabled and a label removal. blocks the sensor. Remove the label to continue printing. Normal power-up and Follows the ‘SYSTEM soft reset condition. RESET IN PROGRESS’...

-

Page 60: Quick Test Mode

4.3 Quick Test Mode This section explains the functions of the resident Quick Tests, accessible by pressing the key on the Front Panel. Notes: (1) With the exception of the Configuration Label, all Quick Test labels require 4-inch (102mm) wide media to print the entire format. If using narrower media, change the Label Width setting (Section 4.1.2) to match your media’s width to avoid printing on the platen. -

Page 61: Configuration Label

4.3.2 Configuration Label The Configuration Label provides valuable printer database information, as detailed in Section 4.1. Note: The Configuration Label content can vary with the application version and printer model. To print all information, the media cannot be less than 2 inches wide (51mm) and the Label Width setting must match the media width (see Section 4.1.2). -

Page 62: Quick Ribbon Test Label

4.3.3 Quick Ribbon Test Label The Quick Ribbon Test Label features a compliant picket-fence bar code that can be used to verify thermal transfer and print quality functions. To print a Quick Ribbon Test Label: Press the key. Use the key to scroll to ‘Ribbon Test Label’. -

Page 63: Dot Test Pattern Label

4.3.4 Dot Test Pattern Label The Dot Test Pattern Label features patterns that exercise all of the thermal elements (dots) of the printhead. The resulting label (see examples below) can be an indication of the printhead’s condition. To print a Dot Test Pattern Label: Press the key. -

Page 64: Validation Label

4.3.5 Validation Label The Validation Label is another useful tool for evaluating overall print quality. To generate a Validation Label: Press the key. Use the key to scroll to ‘Validation Label’. Use the key to select a quantity; see Section 4.0.3. Press the key to start printing. -

Page 65: Media Sensor Calibration

5.0 Media Sensor Calibration In addition to the Sensor Type selection, Media Sensor calibration ensures that each label is detected correctly and reliably. Perform calibration when the ‘Uncalibrated’ message is displayed. Two different methods are available to calibrate the printer: Standard and Advanced Entry. 5.0.1 Standard Calibration Standard Calibration is appropriate for most media types. - Page 66 Standard Calibration (continued) Step Operator Action Displayed Message Comment Press the key to See Section 4.1.2 enter the Media Settings for menu layout. menu. Press the Press the and scroll to ‘Sensor key to abort this Calibration’. procedure. Press the key.

- Page 67 Standard Calibration (continued) Step Operator Action Displayed Message Comment Proceed according to This sets the your media type: parameter for the ‘gap’ or ‘mark’ Die-cut stock: strip the Or, for reflective media: value. media from the backing and then reinsert it into Where ‘yyy’...

- Page 68 Standard Calibration (continued) Step Operator Action Displayed Message Comment Observe the display. The calibration was successful. See note below if Or, for reflective media: another message was displayed. Or, for continuous media: 10 Exit upon successful The printer is now calibration: Back out of ready to begin the menu tree by...

-

Page 69: Advanced Entry Calibration

5.0.2 Advanced Entry Calibration Advanced Entry Calibration is the alternate method for special-case media types. The procedure has two parts: 1) You must list the sensor readings for the label and TOF values using different algorithms. 2) From your list the best algorithm is chosen, new readings taken and those values entered. - Page 70 Advanced Entry Calibration (continued) Step Operator Action Displayed Message Comment Press the You are entering to scroll to ‘Advanced Advanced Entry Entry’. Calibration. Press the key. Press the key to abort this procedure. Press the key. You are beginning the Advanced Entry Calibration.

- Page 71 Advanced Entry Calibration (continued) Step Operator Action Displayed Message Comment 11 Proceed according to Where ‘yyy’ is a your media type: numerical value representing the Die-cut stock: strip the Or, for reflective media: current sensor media from the backing reading: useful in and then reinsert it into locating the best the sensor;...

- Page 72 Advanced Entry Calibration (continued) Step Operator Action Displayed Message Comment 12 From the data collected in Both sensor Steps 10 and 11, where readings must both the sensor readings are be above 20. Or, for reflective media: above 20, subtract each Label Value from the corresponding TOF Value.

- Page 73 Advanced Entry Calibration (continued) Step Operator Action Displayed Message Comment 13 Using the key, Selection is select the Gain Number denoted with an determined in Step 12. ‘*’. Press the key to Or, for reflective media: select the setting. Place the media in the Where ‘yyy’...

- Page 74 Advanced Entry Calibration (continued) Step Operator Action Displayed Message Comment 16 Press the key. The selection will flash and Ç Using the or the the display key, set the heading will ‘Paper’ level to the value change to Ç determined in the previous indicate the step.

-

Page 75: Printhead Adjustments

5.1 Printhead Adjustments To ensure consistent print quality over a wide range of media types and dimensions, the printer is equipped with two adjustments: Leveling Cam and Pressure. 5.1.1 Leveling Cam Adjustment The printer features a Leveling Cam to maintain even print whenever using less than full width media. -

Page 76: Pressure Adjustment

In addition, the Adjustment Screws should be turned equally to maintain even pressure distribution. Note: Excessive pressure can reduce the service life of the printhead and platen roller. Contact Datamax Technical Support with any questions regarding this procedure. W-Class... -

Page 77: Maintenance Schedule

5.2 Maintenance Schedule The following list and table detail the recommended items, techniques and schedules to help you safely and effectively clean the printer. Isopropyl alcohol Cotton swabs A clean, lint-free cloth Soft-bristle brush Soapy water / mild detergent Compressed air For your safety and to avoid damaging the printer, turn ‘Off’... -

Page 78: Cleaning The Printhead

5.2.1 Cleaning the Printhead If print quality begins to decline, the typical cause is a dirty printhead. Possible symptoms include non-compliant barcodes, dropouts, streaking and smudging. If this debris is not removed, it may greatly reduce the life of the printhead. To clean the printhead: Turn ‘Off’... -

Page 79: Cleaning The Platen Roller

5.2.2 Cleaning the Platen Roller A platen roller contaminated with grit, label adhesive, or ink can cause a decline in print quality and, in extreme cases, cause labels to stick and wrap around the roller. To clean the platen roller: Turn ‘Off’... -

Page 80: Cleaning Interior And Exterior Surfaces

5.2.3 Cleaning Interior and Exterior Surfaces Interior Surfaces: During operation, dust particles from the media build-up inside the printer. Then, as the media is pulled through the printer, the particles can become attached and cause voids on the printed labels. To prevent this, turn ‘Off’... -

Page 81: Updating From The Ready Mode

5.3.1 Updating from the Ready Mode Update Procedure for Application Version 2.091 or greater Step Displayed Message Operator Action Comment(s) Using the DOS As an example, this would be copy command entered as: (where ‘filename’ copy 4212tb 1.zs lpt1 is the program to be (Where ‘lpt1’... -

Page 82: Updating From The Download Mode

5.3.2 Updating from the Download Mode Required Update Procedure for Application Version 2.08 or earlier* Step Displayed Message Operator Action Comment(s) Press and hold the The Boot Loader version PAUSE and TEST is displayed. keys while turning Note: This information ‘On’... -

Page 83: Possible Problems During An Update

1) Use the Download Mode (see Section 5.3.2). 2) Windows users – try restarting the computer in MS-DOS mode. 3) Use the Datamax Driver by Seagull Scientific – Device Setting / Send File to Printer function. Application Update Error Messages... -

Page 84: Boot Loader Program Updates

5.4 Boot Loader Program Updates The printer stores the Boot Loader Program in Flash memory on the Main PCB. A feature allows updates to this program via the printer’s interface port. Updates ftp://ftp.datamaxcorp.com can be found at If power is lost while ‘Upgrading Software’ is displayed, the printer will become non-functional and must be returned to the factory for programming or the main logic board must be WARNING... -

Page 85: Problem Resolution

The following table lists problems that will not necessarily generate an error message. (For information on displayed messages, see Section 6.1.) If you have questions, or if problems persist, contact a qualified technician or Datamax Technical Support. If experiencing this problem… Try this solution…... - Page 86 If experiencing this problem… Try this solution… Intellifont will not print: Intellifont format is Little/Big Endian specific. The printer uses Big Endian. Refer to your font supplier for information. Light print on the right side The Leveling Cam may be incorrectly (facing the printer) of the adjusted;...

- Page 87 If experiencing this problem… Try this solution… No power (all indicator lights Verify that the AC power cord connection are ‘Off”): has been made at both the outlet and the printer; also, ensure the power switch is ‘On’. Verify that the AC outlet is functioning, or try moving the printer to another AC circuit.

- Page 88 If experiencing this problem… Try this solution… Nothing happens when trying Ensure that the printer is at READY. to print using a software Observe the Front Panel, if the READY program: light does not flash as you send the format check the protocol and port settings between the printer and host.

-

Page 89: Fault And Warning Messages

6.1 Fault and Warning Messages All printer functions are internally monitored. If a problem (Fault) or a potential problem (Warning) is detected, the Error Indicator (see Section 4.0.4) will be illuminated. A corresponding message will be displayed (if not within a branch of the menu system or in Quick Test Mode). - Page 90 Printer Fault Messages (continued) Displayed Message Description Possible Solution(s) The printer has Try cycling the printer power detected a Direct ‘Off’ and ‘On’. If the fault Memory Access does not clear, call for failure. service. Consistently low Press any key to continue. sensor readings Ensure that media was were detected.

- Page 91 Printer Fault Messages (continued) Displayed Message Description Possible Solution(s) Two possible Depending upon the cause: causes: (1) Press the FEED key in an (1) The printer was attempt to identify and then powered-off or clear the related fault reset during a condition;...

- Page 92 Printer Fault Messages (continued) Displayed Message Description Possible Solution(s) Consistently high Press any key to continue. sensor readings Ensure that media was were detected. removed from the media sensor during the appropriate calibration steps; also ensure that no labels are stuck in the media sensor.

- Page 93 Printer Fault Messages (continued) Displayed Message Description Possible Solution(s) The printer could If media is moving: not find the TOF 1) Press the FEED key. It may mark within the be necessary to re-calibrate maximum label the printer; see Section 5.0. length setting or it found a TOF in an 2) The Media Sensor may be...

- Page 94 Warning Messages: Warning Messages are displayed for a period of five seconds. If multiple warnings are detected, the display will reflect the highest priority message. Printer Warning Messages Displayed Message Description Action(s) The printer has Replace the printhead if the detected defective print quality becomes printhead elements.

-

Page 95: Hex Dump Mode

As a final note, many software programs use bit mapping to construct the label, making diagnosis difficult. Contact Datamax Technical Support with any questions. Note: To return to Ready Mode, re-enter the Diagnostics Menu and disable the Hex Dump Mode, exit the menu, then save the changes. - Page 96 W-Class...

-

Page 97: General Specifications

7.0 General Specifications Bar Codes (See the I &W Class Programmer’s Manual for programming details; and see Appendix B for visual samples.) Code 39, Interleaved 2 of 5, Code 128 (subsets A, B and C), Codabar, LOGMARS, UPC-A, UPC-E, UPC 2 & 5 digit addendums, EAN-8, EAN-13, EAN 2 &... -

Page 98: Environmental Requirements

Printing Type: Direct Thermal or Thermal Transfer Print Speed: 2 – 6 IPS (50 – 152.4 mm/second) W-8306 2 – 8 IPS (50 – 203.2 mm/second) W-6208, W-6308 Printhead Resolution: 203 DPI (8 dots/mm) W-6208 300 DPI (11.8 dots/mm) W-6308, W-8306 Nominal Dot Size: .0043”... -

Page 99: Media And Ribbon Requirements

To achieve optimum print quality and maximum printhead life, DATAMAX brand media and ribbons are recommended. These supplies are specially formulated for use in this printer. The use of non-Datamax supplies may affect the print quality, performance, and life of the printer or its components (see the Warranty Statement). - Page 100 Media and Ribbon Requirements (continued) Media Dimensions Maximum Minimum Designator Description media width: W-6208 and W-6308 6.700 2.000 W-8306 9.000 3.000 backing material width: W-6208 and W-6308 6.700 2.000 W-8306 9.000 3.000 gap (or notch) between labels .100 label length 0.500...

-

Page 101: Ascii Control Code Chart

ASCII Control Code Chart Char Char Char Char Ctrl @ ‘ Ctrl A Ctrl B “ Ctrl C Ctrl D Ctrl E Ctrl F & Ctrl G ‘ Ctrl H Ctrl I Ctrl J Ctrl K Ctrl L Ctrl M Ctrl N Ctrl O Ctrl P... - Page 102 ASCII Control Code Chart (continued) Char Char Char Char Ç á Ó ü í ß é ó Ô â ú Ò ä ñ õ à Ñ Õ å ã µ ç ° Ã ê ¿ è ® Ú è Û ï...

-

Page 103: Available Fonts And Bar Codes

Available Fonts and Bar Codes All character fonts and bar codes available with the printer are described in this section. Each font and bar code has a name associated with it for use in programming. Human-readable fonts have numeric names, while bar code fonts have alpha names. - Page 104 The table below lists the font sizes; the numbers indicate the number of dots. Font Height Width Spacing Font 0: 96-character alphanumeric, Font 1: 145-character upper and upper and lower case. lower case alphanumeric with descenders and ascenders. Font 2: 138-character alphanumeric, Font 3: 62-character alphanumeric, upper and lower case.

- Page 105 Font 4: 62-character alphanumeric, Font 5: 62-character alphanumeric, uppercase. uppercase. Font 6: 62-character alphanumeric, uppercase. W-Class...

- Page 106 Font 7: OCR-A, size I. Font 8: OCR-B, size III. Font 9: Internal Triumvirate font. The number in the bar code height field sets the point sizes. Larger point sizes can be obtained by increasing the height and width multipliers. W-Class...

-

Page 107: Bar Code Summary Data

Bar Code Summary Data Bar Code fonts have alpha names (left column in the table below). Uppercase alpha names will print barcodes with human-readable interpretations. Lowercase alpha names will print barcodes only. The table is followed by visual samples. Valid ASCII Characters, Code Type Length Checksum... - Page 108 Bar Code A: Code 3 of 9 Bar Code B: UPC-A Bar Code D: Interleaved 2 of 5 Bar Code C: UPC-E Bar Code E: Code 128 Bar Code F: EAN-13 Bar Code H: Health Industry Bar Code (HBIC) Bar Code G: EAN-8 Bar Code I: Codabar Bar Code J: Interleaved 2 of 5 w/modulo 10 checksum...

- Page 109 Bar Code K: Plessey Bar Code L: Interleaved 2 of 5 w/modulo 10 checksum and shipping bearer bars Bar Code M: 2 Digit UPC addendum Bar Code N: 5 Digit UPC addendum Bar Code p: Postnet Bar Code O: Code 93 Bar Code Q: UCC/EAN Code 128 Bar Code R: UCC/EAN Code 128 KMART NON EDI...

- Page 110 Bar Code T: Telepen Bar Code S: UCC/EAN Code 128 Random Weight Bar Code v: FIM Bar Code u: UPS MaxiCode Bar Code WG: USD-8 Bar Code z: PDF-417 Bar Code W1c: DataMatrix Bar Code W1d: QR Code Bar Code W1z: MicroPDF417 Bar Code W1f: Aztec W-Class...

-

Page 111: Appendix C Module Assignments

*When power is removed from the printer, stored data will be lost. Print Resolutions and Maximum Label Widths Printhead Resolutions and Widths Printhead Maximum Print Width Factory Default Model Resolution Setting Inches Millimeters W-6208 203 dots/inch 6.61 167.89 6.62 (8 dots/mm) W-6308 300 dots/inch 6.40 162.56 6.40 (11.8 dots/mm) -

Page 112: Available Speeds And Default Settings

Available Speeds and Default Settings Printer Speeds and Defaults Speed Range Default Setting Model MMPS MMPS W-6208: Print 51 – 203 Feed 2-10 51 – 254 Reverse 51 – 152 W-6308: Print 51 – 203 Feed 2-10 51 – 254 Reverse 51 –... -

Page 113: Gpio Port

GPIO Port Description With the optional GPIO PCB, the printer can easily be programmed to interface with most applicator devices. The GPIO functions are enabled and configured using the menu system of the printer (see Section 4.1.4). These parameters are stored in non-volatile memory and saved for subsequent power-ups. - Page 114 GPIO Pin Configuration (as viewed from the rear of the printer) External Start of Print Control Connections for an external Start of Print control can be made (1) directly to Pin 8 using a TTL- level input or (2) with an interface circuit similar to the one shown right.

-

Page 115: Menu System Multi-Language Support

Program used during the process to create DPL file. Gemmsgxls.xls** Menu Dictionary Datamax provides these software files and programs. They are available on the Datamax FTP site – ftp:\\ftp.datamaxcorp.com Datamax recommends that the Img2dl.exe and Gemmsgxls.xls files reside in the same directory. - Page 116 Creating a Menu Language: Invoke Excel and open the gemmsglst.xls file. Excel opens the file and the following screen appears. Click the “Enable Macro” box and the following appears: W-Class...

- Page 117 Click On Column J and enter your new language, or modify an existing one. Tips: A) Message Size – When entering new messages, reference the ‘MAX’ column: this is the maximum number of characters allowed for this field. Warnings are displayed when the number of characters is exceeded or when trying to modify the MAX value.

-

Page 118: Advance File Handling Information

C. You may not modify this number. Advance File Handling Information The Standard Datamax Printer leaves the factory with EFIGS loaded into module Y. At this point, Module Y is LOCKED and will only accept additional Language Downloads. After downloading a language update, Module Y is left UNLOCKED until the printer is reset or power is cycled. - Page 119 To restore the factory generated EFIGS image, download the file *832296.01A to the printer. This file is located on the Datamax FTP site. The letter at the end of the file name (e.g., A) specifies the revision. The latest revision will be available on the FTP site.

- Page 120 W-Class...

-

Page 121: Saving A Configuration File

Saving a Configuration File With application version 5.01 and above, the printer can save and restore complete printer settings, including media calibration parameters, as internal Configuration Files. Here are the highlights and restrictions of this feature: Configuration files eliminate the need to repeat the manual steps of a special printer setup, making future changeovers faster and easier. - Page 122 To save a manually entered setup (for example, an application that required an Advanced Entry Calibration before beginning) as a configuration file using the front panel: Step Displayed Message Operator Action Comment(s) You are entering Press the key. ‘Menu Mode’. Use the key can to scroll to ‘System...

- Page 123 Limited Warranty Statement W-Class Printers Printer Datamax warrants* to Purchaser that under normal use and service, the W- Class Printers, (with the exception of the thermal printhead, platen rollers, and belts) purchased hereunder shall be free from defects in material and workmanship for a period of five years (1826 days) or four million (4,000,000) linear inches, whichever comes first, from the date of shipment by Datamax.

- Page 124 This one year (365 days) warranty is valid only if a Datamax - approved thermal label media is used, as defined in the then current Datamax list of approved thermal/thermal transfer media, a copy of which is available from Datamax.

-

Page 125: Limitation Of Liability

Datamax’s products. Limitation of Liability In no event shall Datamax be liable to the purchaser for any indirect, special or consequential damages or lost profits arising out of or relating to Datamax’s products, or the performance or a breach thereof, even if Datamax has been advised of the possibility thereof. - Page 126 W-Class...

- Page 127 alphanumeric Consisting of alphabetic, numeric, punctuation and other symbols. backing material The silicon-coated paper carrier material to which labels with adhesive backing are affixed. Also referred to as “liner”. bar code A representation of alphanumeric information in a pattern of machine-readable marks.

- Page 128 Also referred to as “resolution”. DPL (Datamax Programming Language) programming commands used specifically for control of and label production in Datamax printers. A complete listing of commands can be found in the I & W Class Programmer’s Manual.

- Page 129 label A paper or synthetic printing material, typically with a pressure sensitive adhesive backing. label length The distance from the top of the label to the bottom of the label as it exits the printer. label repeat The distance from the top of one label to the top of the next label.

- Page 130 reverse speed The backward rate of media motion into the printer during tear-off, peel and present and cutting operations for positioning the label at the start of print position. ribbon An extruded polyester tape with several layers of material, one of which is ink-like, used to produce an image on the label.

- Page 131 DPI, 88, 101, 118 DPL, 29, 46, 85, 118 alphanumeric, 117 application program, 37, 70 ASCII, 47, 85, 91, 92 EFIGS, 2, 70, 101, 105 - 109, 118 emulation, 39 bar code, 76, 78, 87, 93, 97 - 100, 117 boot loader, 72 - 74, 117 factory default settings, 27, 28 - 47, 83, burn line, 68, 117...

- Page 132 media quick test mode, 23, 25, 47, 48, 50 - 54, backing material, 7, 16 - 20, 58, 89, 77, 79 90, 117, 118 black mark, 13 - 15, 17, 30, 55 - 64, 80, 81, 83, 90, 117, 119, 120 continuous, 15, 17, 30, 57, 58, 89, ready mode, 23, 24, 26, 48, 70, 71, 85 117, 119...