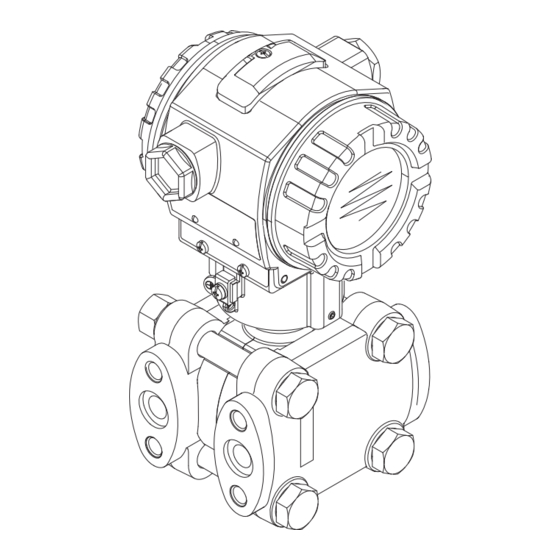

Endress+Hauser Deltabar S FMD78 Operating Instructions Manual

Differential pressure measurement

Hide thumbs

Also See for Deltabar S FMD78:

- Operating instructions manual (238 pages) ,

- Brief operating instructions (52 pages) ,

- Special documentation (40 pages)

Summary of Contents for Endress+Hauser Deltabar S FMD78

- Page 1 Operating Instructions Deltabar S FMD76/77/78, PMD70/75 Differential pressure measurement BA00301P/00/EN/16.14 71254467 valid from Software version: 04.00.zz...

- Page 2 – The documentation is supplied with the – Operation without display device. See cover of the terminal – Description of Quick Setup menus compartment. ® – Operation HistoROM /M-DAT – The documentation can also be found on the documentation CD supplied. Endress+Hauser...

-

Page 3: Table Of Contents

Maintenance....79 Cleaning instructions ..... . . 79 Endress+Hauser... -

Page 4: Safety Instructions

Operating Instructions. The installation regulations, connection values and safety instructions listed in this Ex document must be observed. The documentation number of the related safety instructions is also indicated on the additional nameplate. • Ensure that all personnel are suitably qualified. Endress+Hauser... -

Page 5: Notes On Safety Conventions And Icons

Temperature resistance of the connection cables t >85°C States, that the connection cables must be resistant to a temperature of at least 85 °C (185 °F). Safety instruction For safety instructions refer to the manual for the appropriate instrument version. Endress+Hauser... -

Page 6: Identification

EN 1092-1 Tab. 18. The chemical composition of the two materials can be identical. Aluminium housing (T14/T15) and stainless steel housing (T14) Ser. no.: Order code: Ext. order code: A0016056 Fig. 1: Nameplate Device name Order code (for re-orders) Extended order code (complete) Technical data Serial number (for identification) Address of manufacturer Endress+Hauser... - Page 7 Serial number (for identification) Technical data Approval-specific information and document number for safety instructions or drawing number 2.2.2 Identifying the sensor type See parameter "Sensor Meas.Type" in Operating Instruction BA00303P. The Operating Instruction BA00303P can be found on the supplied documentation CD. Endress+Hauser...

-

Page 8: Scope Of Delivery

The devices comply with the applicable standards and regulations as listed in the EC Declaration of Conformity and thus comply with the statutory requirements of the EC Directives. Endress+Hauser confirms the conformity of the device by affixing to it the CE mark. -

Page 9: Installation

• To ensure optimal readability of the onsite display, it is possible to rotate the housing up to 380°. ä 21, Section 3.3.9 "Rotating the housing". • Endress+Hauser offers a mounting bracket for installing on pipes or walls. ä 19, Section 3.3.7 "Wall and pipe-mounting (optional)". - Page 10 • Mount the Deltabar S below the measuring point. • Mount the condensate traps at the same level as the tapping points and at the same distance to the Deltabar S. • Prior to commissioning, fill the pressure piping to the level of the condensate traps. Endress+Hauser...

- Page 11 • Mount the Deltabar S below the lower measuring connection so that the pressure piping is always filled with liquid. • The negative side is open to atmospheric pressure. • When measuring in media with solid parts, such as dirty liquids, installing separators and drain valves is useful for capturing and removing sediment. Endress+Hauser...

- Page 12 • Always connect the impulse piping of negative side above the maximum level. • When measuring in media with solid parts, such as dirty liquids, installing separators and drain valves is useful for capturing and removing sediment. Endress+Hauser...

- Page 13 (FMD78)". • The ambient temperature should be the same for both capillaries. Note! Level measurement is only ensured between the upper edge of the lower diaphragm seal and the lower edge of the upper diaphragm seal. Endress+Hauser...

- Page 14 Level measurement in a closed container with superimposed steam with FMD76/ FMD77 ➀ – max. ➁ min. ➂ ➃ ➄ P01-FMD76xxx-11-xx-xx-xx-005 Fig. 14: Measuring arrangement for level measurement in a container with superimposed steam with FMD76 Condensate trap Shutoff valve Separator Drain valve Deltabar S, here FMD76 Endress+Hauser...

- Page 15 Differential pressure measurement in liquids with PMD70/PMD75 ➀ ➁ ➁ – ➂ ➃ ➃ ➄ ➄ ➅ P01-PMD75xxx-11-xx-xx-xx-007 Fig. 16: Measuring arrangement for differential pressure measurement in liquids with PMD75 e.g. filter Shutoff valves Deltabar S, here PMD75 Separator Drain valves Three-way valve manifold Endress+Hauser...

- Page 16 • The ambient temperature and length of both capillaries should be the same when using two-sided diaphragm seal systems. • Two diaphragm seals which are the same (e.g. with regard to diameter, material, etc.) should always be used for the negative and positive side (standard delivery). Endress+Hauser...

- Page 17 Vacuum application (FMD78) For applications under vacuum, Endress+Hauser recommends mounting the pressure transmitter underneath the lower diaphragm seal. A vacuum load of the diaphragm seal caused by the presence of filling oil in the capillaries is hereby prevented.

- Page 18 λ 0.04 ≤ • P01-FMD77xxxx-11-xx-xx-xx-000 Fig. 22: Maximum permitted insulation height FMD77 70°C (158°F) Ambient temperature (T Process temperature (T Max. 400°C (752°F), depending on the diaphragm seal filling oil used ( see Technical Information TI00382P Deltabar S) Endress+Hauser...

- Page 19 Installation 3.3.7 Wall and pipe-mounting (optional) Endress+Hauser offers a mounting bracket for installing the device on pipes or walls. A holder with mounting accessories for pipe mounting is included with the device. Note! When using a valve block, the block's dimensions must be taken into account.

- Page 20 Mount the housing on a wall or pipe using the mounting bracket (item 7). When mounting on a pipe, tighten the nuts on the bracket uniformly with a torque of at least 5 Nm (3.69 lbs ft). Mount the cable with a bending radius (r) 120 mm (4.72 in). Endress+Hauser...

-

Page 21: Post-Installation Check

Post-installation check After installing the device, carry out the following checks: • Are all screws firmly tightened? • Are the housing covers screwed down tight? • Are all locking screws and vent valves firmly tightened? Endress+Hauser... -

Page 22: Wiring

Please refer also to Section 4.2.1 "Supply voltage", ä 23. Housing Internal ground terminal External ground terminal Supply voltage, for version in non-hazardous area = 9 to 32 V DC Devices with integrated overvoltage protection are labeled OVP (overvoltage protection) here. Endress+Hauser... -

Page 23: Connecting The Measuring Unit

• Terminals for wire cross-sections: 0.5 to 2.5 mm (20 to 14 AWG) • Outer cable diameter: 5 to 9 mm (0.2 to 0.35 in) Note! For further information on the cable specifications, see Operating Instructions BA00013S "FOUNDATION Fieldbus Overview", FOUNDATION Fieldbus Guideline and IEC 61158-2 (MBP). Endress+Hauser... -

Page 24: Overvoltage Protection (Optional)

• Are all screws firmly tightened? • Are the housing covers screwed down tight? As soon as voltage is applied to the device, the green LED on the electronic insert lights up for a few seconds or the connected onsite display lights up. Endress+Hauser... -

Page 25: Operation

• Option of configuring the display according to individual requirements and preferences, such as alternating display, contrast setting, display of other measured values such as sensor temperature • Comprehensive diagnostic functions (fault and warning message, maximum indicator, etc.) • Rapid and safe commissioning using Quick Setup menus Endress+Hauser... - Page 26 The primary value of the Pressure Transducer Block is increasing. Tendency symbol (decreasing) The primary value of the Pressure Transducer Block is decreasing. Tendency symbol (constant) The primary value of the Pressure Transducer Block has remained constant over the past few minutes. Endress+Hauser...

-

Page 27: Operating Elements

– Operation via FF configuration program: In the Pressure Transducer Block, change the measuring mode by means of the PRIMARY_VALUE_TYPE and LINEARIZATION parameters. – Operation via digital communication: change the measuring mode by means of the MEASURING MODE parameter. Endress+Hauser... - Page 28 Note: For the terms function group, level, selection level, ä 41, Section 5.4.1 – DIP switch 1: for locking/unlocking parameters relevant to the measured value. Factory setting: off (unlocked) – DIP switch 2: for the simulation mode Factory setting: off (simulation mode off) P01-xxxxxxxx-19-xx-xx-xx-134 Endress+Hauser...

-

Page 29: Foundation Fieldbus Interface

– An FF-H1 connecting card is needed for direct connection to a process control system. Note! Further information on FOUNDATION Fieldbus can be found in Operating Instructions BA00013S "FOUNDATION Fieldbus Overview, Installation and Commissioning Guidelines", the FOUNDATION Fieldbus Specification or on the Internet at "http://www. fieldbus.org". Endress+Hauser... - Page 30 You can obtain special configuration and operating programs from various manufacturers for the configuration, such as the FieldCare operating program from Endress+Hauser ä 44, Section 5.5 "FieldCare". These configuration programs make it possible to configure FF functions and all the device-specific parameters.

- Page 31 (PID). Each of these function blocks is used to execute different application functions. The function blocks can be connected by means of an FF configuration program, depending on the automation task. The device thus takes on simple control functions, thereby relieving the workload on the higher-order process control system. Endress+Hauser...

- Page 32 Endress+Hauser Guideline BA00062S. The guideline provides an overview of the standard function blocks that are described in FOUNDATION Fieldbus Specifications FF 890 - 894. It is designed to help operators use the blocks implemented in the Endress+Hauser field devices. Endress+Hauser...

- Page 33 Note! Please note that the links between the blocks are deleted and the FF parameters are reset to the default values following a reset by means of the RESTART parameter in the Resource Block, "Default" option. Endress+Hauser...

- Page 34 Transducer Block Parameter name CHANNEL parameter in the Discrete Output Block Totalizer ("Flow" measuring DP Flow Block TOTALIZER_1_VALUE/ mode) TOTALIZER 1 Overshoot counter for maximum Service Transducer Block COUNTER: P > Pmax set user limit for pressure Factory setting Endress+Hauser...

- Page 35 Configuration error Sensor overpressure Sensor underpressure Sensor overtemperature Sensor undertemperature Process isolating diaphragm broken Diagnostic Transducer Electronic overtemperature DIAGNOSTIC_CODE Block Electronic undertemperature Temperature transmitter override Pressure transmitter override Pmin PROCESS underrun Pmax PROCESS overrun Tmin PROCESS underrun Tmax PROCESS overrun Endress+Hauser...

- Page 36 Deltabar S FMD76/77/78, PMD70/75 with FOUNDATION Fieldbus 5.3.8 Index tables of Endress+Hauser parameters The following tables list the manufacturer-specific device parameters for the Resource Block, the Transducer Blocks and the Analog Input Blocks. For the FF parameters, see either the FF Specification or Operating Instructions BA00303P "Description of Device Functions, Cerabar S/...

- Page 37 7864, 333 EMPTY_HEIGHT_EASY Full calib. level easy Float 7864, 333 FULL_HEIGHT_EASY Full calib. level easy Float 7864, 333 PROCESS_DENSITY_EASY Process density level easy Float 7864, 333 MEASURED_LEVEL_EASY Meas. level easy Float FULL_CALIBRATION_EASY Full calib. level easy Float 7864, 333 Endress+Hauser...

- Page 38 AUTO, OOS, MAN 7864 DISPLAY_MAINLINE_FORMAT Main data format Unsigned8 AUTO, OOS, MAN 7864 DISPLAY_ALTERNATING_VALUES Alternate data Unsigned8 AUTO, OOS, MAN 7864 DISPLAY_CONTRAST Display contrast Unsigned8 AUTO, OOS, MAN 7864 DISPLAY_LANGUAGE Language Unsigned8 AUTO, OOS, MAN 7864 SIL_DIGITS_TEST_STRING Digits set Visible String Endress+Hauser...

- Page 39 Low alarm output discrete 41 DS66 AUTO, OOS, MAN LOLO_ALM_OUT_D Low low alarm output DS66 AUTO, OOS, MAN discrete ALARM_MODE Select alarm mode Unsigned8 AUTO, OOS, MAN ALARM_OUT_D Alarm output discrete DS66 AUTO, OOS, MAN BLOCK_ERR_DESC_1 Block error description Unsigned32 AUTO, OOS, MAN Endress+Hauser...

- Page 40 • Restart (Resource Block) • Troubleshooting information, Config. Error No, Alarm Table (Diagnostic Block) • Peakhold indicator, HistoROM (Service Block) • Sensor Trim (TRD Block) Note! For further information on accessing methods, see the description of the FF configuration program used. Endress+Hauser...

-

Page 41: Local Operation - Onsite Display Connected

The MEASURING MODE parameter is only displayed via the onsite display on the 1st selection level. In FieldCare, the LANGUAGE parameter is displayed in the DISPLAY group and the parameters for configuring the measuring mode are displayed in the Measuring Mode menu see also Section 10.1 "Menu". Endress+Hauser... - Page 42 1. Use the "+" key to change the digit "2" to "3". 2. Press the "E" key to confirm "3". The cursor goes to the next position (highlighted in black). P01-xxxxxxxx-19-xx-xx-en-028 The decimal point is highlighted in black. This means you can now edit this digit. P01-xxxxxxxx-19-xx-xx-en-029 Endress+Hauser...

- Page 43 Using the "E" key, assign the value (3.9 mbar) to the POS. ZERO ADJUST parameter. The device confirms the adjustment and goes back to the parameter, here POS. ZERO ADJUST (see next graphic). P01-xxxxxxxx-19-xx-xx-en-037 Go to the next parameter with "E" . P01-xxxxxxxx-19-xx-xx-en-160 Endress+Hauser...

-

Page 44: Fieldcare

FieldCare is Endress+Hauser's plant asset management tool based on FDT technology. You can use FieldCare to configure all Endress+Hauser devices as well as third-party devices which support the FDT standard. Hardware and software requirements you can find on the internet: www.endress.com ... - Page 45 Using the HistoROM CONTROL parameter, select the "Device HistoROM" option for the data transfer direction. ® Wait approx. 40 seconds. Configuration data are uploaded from the device to the HistoROM M-DAT. The device is not restarted. Disconnect the device from the supply voltage again. Detach the memory module. Endress+Hauser...

-

Page 46: Locking/Unlocking Operation

• Via a DIP switch on the electronic insert, locally on the display. • Via communication e.g. FieldCare. -symbol on the onsite display indicates that operation is locked. Parameters which refer to how the display appears, e.g. LANGUAGE and DISPLAY CONTRAST, can still be altered. Endress+Hauser... - Page 47 2. To lock operation, enter "0" for the parameter. Unlocking operation 1. Operation via FF configuration program: select SWLOCK parameter in the Resource Block. Operation via FieldCare: select INSERT PIN No.parameter. 2. To unlock operation, enter "100" for the parameter. Endress+Hauser...

-

Page 48: Simulation

• Any customer-specific configuration carried out by the factory is not affected by a reset (customer- specific configuration remains). If, after a reset, you wish the parameters to be reset to the factory settings, please contact Endress+Hauser Service. • The OUT Value parameter may have to be rescaled after resetting with code 7864. See also ... - Page 49 (DISPLAY group). – Any simulation which may be running is ended. – The device is restarted. 8888 HistoROM reset The measured value and event buffers are deleted. During the reset, the HistoROM has to be attached to the electronic insert. Endress+Hauser...

- Page 50 – The device is restarted. The table uses the group and parameter names as they appear in FieldCare. See ä 36, Section 5.3.8 "Index tables of Endress+Hauser parameters" for the assignment of the FieldCare parameter names and the FF configuration program.

-

Page 51: Commissioning

If necessary, disable the lock for device operation. ä 46, Section 5.7 "Locking/unlocking operation". Operating is unlocked as standard. If necessary, change the block name. Factory setting: RS_452B481009-xxxxxxxxxxx If necessary, assign a description to the block by means of the TAG_DESC parameter. If necessary, change other parameters as per the requirements. Endress+Hauser... - Page 52 Reporting to the field host system only takes place with alarms with a priority greater than 2. Set the block mode to Auto using the MODE_BLK parameter, TARGET element. For this purpose, the Resource Block must also be set to the "Auto" block mode. Endress+Hauser...

-

Page 53: Selecting The Language And Measuring Mode

Level, mass, volume None Level Easy Height Level, mass, volume, tank content in % None Level Standard Level, mass, volume, tank content in % Level linearized Level Standard Level, mass, volume, tank content in % Level combined Level Standard Endress+Hauser... -

Page 54: Position Adjustment

– The CALIB. OFFSET parameter displays the resulting pressure difference (offset) by which the MEASURED VALUE was corrected. The following applies: CALIB. OFFSET = MEASURED VALUE – POS. INPUT VALUE, here: CALIB. OFFSET= 0.5 mbar (0.0073 psi) – 2.0 mbar (0.029 psi) = – 1.5 mbar (0.022 psi) Factory setting: Endress+Hauser... - Page 55 To correct the MEASURED VALUE to 0.0 mbar, you must enter the value 2.2 here. (The following applies: MEASURED VALUE = MEASURED VALUE – CALIB. OFFSET) – MEASURED VALUE (after entry for calib. offset) = 0.0 mbar Factory setting: Endress+Hauser...

-

Page 56: Flow Measurement

Carry out pos. zero adjustment if the flow can be blocked off. In this case, step 5 is not applicable. ä 58, Section 6.5.3 and ä 54, Section 6.4. Carry out calibration. ä 57, Section 6.5.2 For arrangement with 5 valves Endress+Hauser... - Page 57 – FF, Pressure Transducer Block Table – FF, DP Flow Block Table – FieldCare, POSITION ADJUSTMENT Table – FieldCare, BASIC SETUP Table – FieldCare, EXTENDED SETUP Table – FieldCare, TOTALIZER SETUP Table ä 2, "Overview of documentation" section. Endress+Hauser...

- Page 58 Analog Input Block react to a change in the pressure. pressure. Note! For onsite operation, see also ä 28, Section 5.2.3 "Function of the operating elements – onsite display connected" and ä 41, Section 5.4 "Local operation – onsite display connected". Endress+Hauser...

-

Page 59: Level Measurement

Set measuring point to operation. – – B and 6 are closed. – Axis open. P01-xMD7xxxx-11-xx-xx-xx-003 Carry out calibration. Fig. 38: Open container ä 62, Section 6.6.2. Deltabar S, PMD70 or PMD75 Separator Vent valves on Deltabar S Shutoff valve Drain valve Endress+Hauser... - Page 60 ä 62, Section 6.6.2. Fig. 39: Closed container Deltabar S, PMD70 and PMD75 Three-way valve manifold Separator 1, 2 Drain valves 2, 4 Inlet valves Equalizing valve 6, 7 Vent valve on Deltabar S A, B Shutoff valve Endress+Hauser...

- Page 61 Three-way valve manifold – 2, 4, A and B are open. Separator 1, 5 Drain valves Carry out calibration. 2, 4 Inlet valves ä 62, Section 6.6.2. Equalizing valve 6, 7 Vent valves on Deltabar S A, B Shutoff valves Endress+Hauser...

- Page 62 – Customer-specific units of level, volume and mass, or a linearization table, can only be entered in the "Level standard" level mode. • For a detailed description of the parameters and configuration examples, see Operating Instructions BA00303P "Cerabar S/Deltabar S/ Deltapilot S, Description of Device Functions", ä 2, "Overview of documentation" section. Endress+Hauser...

- Page 63 Instructions BA00303P. not be in direct proportion to the measured pressure. A linearization table must be entered for the 2nd measured variable. The 2nd measured variable is assigned to the 1st mea- sured variable by means of this table. Endress+Hauser...

- Page 64 Primary Value Type Select "Level" option. Select "Level" option. LEVEL SELECTION Level Selection Select level mode. For an overview see ä 63. Select level mode. For an overview see ä 63. GROUP SELECTION Select QUICK SETUP menu. Endress+Hauser...

- Page 65 – LEVEL SELECTION "Level Standard", LEVEL MODE "Linear" and CALIBRATION MODE "Wet" Note! For onsite operation, see also ä 28, Section 5.2.3 "Function of the operating elements – onsite display connected" and ä 41, Section 5.4 "Local operation – onsite display connected". Endress+Hauser...

-

Page 66: Differential Pressure Measurement

Carry out calibration if necessary. ä 67, Section 6.7.2. Deltabar S, PMD70 or PMD75 Three-way valve manifold Separator 1, 5 Drain valves 2, 4 Inlet valves Equalizing valve 6, 7 Vent valves on Deltabar S A, B Shutoff valve For arrangement with 5 valves Endress+Hauser... - Page 67 OUT Value as the onsite display, measured value and the OUT Value of the Analog Input Block react to a change in the of the Analog Input Block react to a change in the pressure. pressure. Endress+Hauser...

-

Page 68: Scaling The Out Parameter

• The L_TYPE, XD_SCALE and OUT_SCALE parameters can only be changed in the OOS block mode. • Make sure that the output scaling of the Pressure Transducer Block SCALE_OUT matches the input scaling of the Analog Input Block XD_SCALE. Endress+Hauser... -

Page 69: Configuring Event Behavior In Accordance With Foundation Fieldbus Specification Ff912 Field Diagnostic Profile

• 132: F>Checksum error in totalizer EEPROM • 133: F>Checksum error in History EEPROM • 135: F>Checksum error in EEPROM FF segment • 728: F>RAM error • 729: F>RAM error • 736: F>RAM error Configuration • Not used Process • Not used Endress+Hauser... - Page 70 • 741: M>TANK HEIGHT (LEVEL_TANK_HEIGHT) out of edit limits • 750: M>Configuration not permitted Process • 730: M>Pmin ALARM WINDOW (PRESSURE_1_USER_LOW_LIMIT) undershot • 731: M>Pmax ALARM WINDOW (PRESSURE_1_USER_HIGH_LIMIT) overshot • 732: M>Tmin ALARM WINDOW (TEMPERATURE_1_USER_LOW_LIMIT) undershot • 733: M>Tmax ALARM WINDOW (TEMPERATURE_1_USER_HIGH_LIMIT) overshot Endress+Hauser...

- Page 71 The Highest Severity / Electronics group contains the events 131: Checksum error in EEPROM: min/max segment, among others. These should no longer be categorized as Failure (F), and should be categorized as Check (C) instead. In the FieldCare navigation window navigate to Expert Field Device Diagnostic Configuration Endress+Hauser...

- Page 72 Status 1 and 2. The mask check box acts as a negative check box, i.e. if a field is selected the associated events are not transmitted on the bus. The Resource Block must be set to the Auto mode to transmit status information on the bus. Endress+Hauser...

- Page 73 Block are used for this purpose. The appropriate bit can then be set from 0 to 1 in the desired assignment parameter. Example Error 115 "Sensor overpressure" should no longer be categorized as Out of Specification (S), and should be categorized as Function (C) instead. In the FieldCare navigation window navigate to Expert Field Device Diagnostic Configuration. Endress+Hauser...

- Page 74 Changing the error category for Sensor overpressure does not affect an error that already exists. The new category is only assigned if this error occurs again after the change has been made. The "Status 1" and "Status 2" tabs indicate whether an event is active. Endress+Hauser...

- Page 75 Deltabar S FMD76/77/78, PMD70/75 with FOUNDATION Fieldbus Commissioning The "Simulation" tab makes it possible to simulate an event. Endress+Hauser...

- Page 76 FieldCare under Expert Field Device Diagnostic Configuration. The mask check box acts as a negative check box, i.e. if a field is selected the associated events are not transmitted on the bus. Endress+Hauser...

- Page 77 • 726: Sensor temperature error-overrange • 727: Sensor pressure error-overrange • 730: LRV user limits exceeded • 731: URV user limits exceeded • 732: LRV-Temp. user limits exceeded • 733: URV-Temp. user limits exceeded • 740: Calculation Overflow, bad configuration Endress+Hauser...

- Page 78 In the FieldCare navigation window navigate to Expert Field Device Diagnostics PV Status Config All the bits of the Status Select Events have the status "Uncertain" in the factory setting. Select the "Bad" option for the "Status Select Event 115" row. Press Enter to confirm your entry. Endress+Hauser...

-

Page 79: Maintenance

Maintenance Deltabar S requires no maintenance. Cleaning instructions • Endress+Hauser offer flushing rings as accessories to clean process isolating diaphragms without taking the transmitters out of the process. For further information please contact your local Endress+Hauser Sales Center. • We recommend you perform CIP (cleaning in place (hot water)) before SIP (sterilization in place (steam)) for pipe diaphragm seals. -

Page 80: Diagnostics And Troubleshooting

• You can see a list of all the active alarms via the Diagnostic code/ACTUAL_ALARM_INFOS parameter. • You can see a list of all the alarms that are no longer active (event log) via the Last Diag. Code/ LAST_ALARM_INFOS parameter. Endress+Hauser... -

Page 81: Diagnostic Information On Local Display

• If the device detects a defect in the onsite display during initialization, special error messages are generated. For the error messages, see ä 81, Section 8.2.2 "Onsite display error messages". • For support and further information, please contact Endress+Hauser Service. • See also Section 8.8, Section 8.9 and Section 8.10. -

Page 82: Diagnostic Event In The Operating Tool

Navigate to the "Diagnostics" menu. The diagnostic event along with text about the event is displayed in the "Actual diagnostics" parameter. On the right in the display area, hover the cursor over the "Actual diagnostics" parameter. A tool tip with remedy information for the diagnostic event appears. Endress+Hauser... -

Page 83: Diagnostic Messages In The Diagnostic Transducer Block (Trddiag)

Pressure, Level, Flow Electronics Failure Other BAD_DEVICE_FAILURE Pressure, Level, Flow Electronics Failure Other BAD_DEVICE_FAILURE Pressure, Level, Flow Electronics Failure Sensor Failure BAD_DEVICE_FAILURE Pressure, Level, Flow Electronics Failure Sensor Failure BAD_DEVICE_FAILURE Pressure, Level, Flow Electronics Failure Other BAD_DEVICE_FAILURE Pressure, Level, Flow Endress+Hauser... - Page 84 Pressure, Level, Flow – STATUS_UNCERTAIN – GOOD Configuration Error Other GOOD Pressure, Level, Flow None Configuration Error Other GOOD Pressure, Level, Flow None Configuration Error Other GOOD Pressure, Level, Flow None Configuration Error Other GOOD Pressure, Level, Flow None Endress+Hauser...

- Page 85 Primary Value(1) Electronics Failure Other STATUS_UNCERTAIN Pressure, Level, Flow Data Integrity Error Other GOOD Pressure, Level, Flow Maximum Pressure(4) Counter P > Pmax(5) Data Integrity Error Other STATUS_UNCERTAIN Pressure, Level, Flow Data Integrity Error Other GOOD Pressure, Level, Flow None Endress+Hauser...

-

Page 86: Overview Of Diagnostic Events

– Briefly disconnect device from the power supply. – Main electronics defect. – Replace main electronics. Alarm F>Measurement error – Fault in the main electronics. – Briefly disconnect device from the power supply. – Main electronics defect. – Replace main electronics. Endress+Hauser... - Page 87 – Electromagnetic effects are – Restart the device. Perform reset error greater than specifications in the (Code 62). technical data. – Block off electromagnetic effects (See Section 9.) or eliminate source of disturbance. – Main electronics defect. – Replace main electronics. Endress+Hauser...

- Page 88 – The sensor was replaced and the – Adjust calibration to suit sensor. customer-specific configuration – Replace sensor with a suitable does not suit the sensor. sensor. – Unsuitable download carried – Check configuration and out. perform download again. Endress+Hauser...

- Page 89 – Perform reset (code 7864) and the configuration of the device recalibrate the device. but the options do not suit one another. For example, if the option "1" (linearization table) was selected for LIN_TYPE and the unit "1347 (m /s)" was selected for PRIMARY_VALUE_UNIT. Endress+Hauser...

- Page 90 HistoROM. – Device reset codes such as 1 or 40864 do not have any effect on the HistoROM. That means that if you perform a reset, the configurations in the HistoROM and in the device can be different. Endress+Hauser...

- Page 91 – Select a device with a suitable SCALE_IN, EU_100/MAX. measuring range. PRESS FLOW. Warning M>Sensor data – Sensor does not suit the device – Replace sensor with a suitable unknown (electronic sensor nameplate). sensor. Device continues measuring. Endress+Hauser...

- Page 92 ( ä 2), TEMPERATURE_1 _SENSOR_LIMIT_LOW/ Tmin SENSOR parameter). – Unsuitable download carried – Check configuration and out. perform download again. – Loose connection at sensor – Wait a short period of time and cable. tighten the connection, or avoid loose connection. Endress+Hauser...

- Page 93 ALARM WINDOW if necessary. (See also Operating Instructions BA00303P, parameter description or these Operating Instructions, ä 2) – Loose connection at sensor – Wait a short period of time and cable. tighten the connection, or avoid loose connection. Endress+Hauser...

- Page 94 (TEMPERATURE_1_ for the TEMPERATURE_1_ – Change value for USER_HIGH_LIMIT) USER_HIGH_LIMIT/Tmax TEMPERATURE_1_ overshot ALARM WINDOW parameter. USER_HIGH_LIMIT/Tmax ALARM WINDOW if necessary. (See also Operating Instructions BA00303P, parameter description or these Operating Instructions, ä 2) Endress+Hauser...

-

Page 95: Response Of Outputs To Errors

• FSAFE_VALUE: 0 Note! The failsafe mode is also activated if the "Out of service" option was selected by means of the MODE_BLK parameter, "Target" element. 1 These parameters are not available by means of the FieldCare operating program. Endress+Hauser... -

Page 96: Confirming Messages

FieldCare: Menu path for ALARM DISPL. TIME and ACK. ALARM MODE: OPERATING MENU DIAGNOSTICS MESSAGES Repair The Endress+Hauser repair concept provides for measuring devices to have a modular design and also that the customer may carry out repairs ä 97 "Spare Parts" on ). Note! •... -

Page 97: Spare Parts

The measuring device must be returned if repairs or a factory calibration are required, or if the wrong measuring device has been ordered or delivered. According to legal regulations, Endress+Hauser, as a ISO-certified company, is required to follow certain procedures when handling returned products that are in contact with process fluids. -

Page 98: Software History

BA301P/00/EN/08.08 BA303P/00/EN/08.08 – FieldCare version 2.15.00 71077522 71076564 BA301P/00/EN/06.09 BA303P/00/EN/06.09 71095421 71095456 BA301P/00/EN/05.10 BA303P/00/EN/05.10 71111781 71111814 BA301P/00/EN/13.11 BA303P/00/EN/13.11 71139766 71139808 BA00301P/00/EN/14.12 BA303P/00/EN/13.11 71161885 71139808 01.2013 04.00.zz FF912 Field Diagnostic Profile Integration BA00301P/00/EN/15.13 BA00303P/00/EN/14.13 71207382 71207399 BA00301P/00/EN/16.14 BA00303P/00/EN/14.13 71254467 71254484 Endress+Hauser... -

Page 99: Technical Data

Menu Note! • The entire menu of Endress+Hauser parameters is depicted on the following pages. Some Endress+Hauser parameters correspond to FF standard parameters. All other FF parameters can only be configured by means of an FF configuration program. (See Operating Instructions BA00303P "Cerabar S/Deltabar S/Deltapilot S, Description of Device Functions"). - Page 100 There are parameters that are only displayed if other parameters are appropriately configured. For example the Customer Unit P/CUSTOMER_UNIT_PRESSURE parameter is only displayed if the "User unit" option was selected for the Press. Eng. Unit/PRESSURE UNIT parameter. These parameters are indicated with a "*". P01-xxxxxxxx-19-xx-xx-en-167 Endress+Hauser...

- Page 101 There are parameters that are only displayed if other parameters are appropriately configured. For example the Customer Unit P/CUSTOMER_UNIT_PRESSURE parameter is only displayed if the "User unit" option was selected for the Press. Eng. Unit/PRESSURE_UNIT parameter. These parameters are indicated with a "*". P01-xxxxxxxx-19-xx-xx-en-149 Endress+Hauser...

- Page 102 There are parameters that are only displayed if other parameters are appropriately configured. For example the Customer Unit H/CUSTOMER_HEIGHT_UNIT parameter is only displayed if the "User unit" option was selected for the Height Unit/HEIGHT_UNIT parameter. These parameters are indicated with a "*". P01-xxxxxxxx-19-xx-xx-en-150 Endress+Hauser...

- Page 103 There are parameters that are only displayed if other parameters are appropriately configured. For example the Tot. 1 User Unit/CUSTOMER_UNIT_TOT_1 parameter is only displayed if the "User unit" option was selected for the Totalizer 1 Unit/TOTALIZER_1_UNIT parameter. These parameters are indicated with a "*". P01-xxxxxxxx-19-xx-xx-en-151 Endress+Hauser...

- Page 104 DEVICE DESIGN. HARDWARE REV. MAT. MEMBRANE SOFTWARE VERSION FILLING FLUID CONFIG RECORDER Tmin SENSOR PCB TEMPERATURE Tmax SENSOR ALLOWED MIN. TEMP SENSOR H/WARE REV. ALLOWED MAX. TEMP DIP STATUS 1) Display via on-site display only 2) Display via FieldCare P01-xxxxxxxx-19-xx-xx-en-152 Endress+Hauser...

- Page 105 PCB COUNT:T > Tmax TOTALIZER 2 PCB MAX. TEMP. TOTAL. 2 OVERFLOW PCB COUNT: T< Tmin PCB MIN. TEMP. RESET PEAKHOLD There are parameters that are only displayed if other parameters are appropriately configured. These parameters are indicated with a "*". P01-xxxxxxxx-19-xx-xx-en-170 Endress+Hauser...

- Page 106 Pressure Flow Level Tank content SIM. PRESSURE SIM. FLOW VALUE SIM. TANK CONT. SIM. ERROR NO. SIM. LEVEL There are parameters that are only displayed if other parameters are appropriately configured. These parameters are indicated with a "*". P01-xxxxxxxx-19-xx-xx-en-154 Endress+Hauser...

- Page 107 Deltabar S FMD76/77/78, PMD70/75 with FOUNDATION Fieldbus Appendix Endress+Hauser...

- Page 108 Appendix Deltabar S FMD76/77/78, PMD70/75 with FOUNDATION Fieldbus Endress+Hauser...

-

Page 109: Index

Level measurement, Quick Setup menu....64 "Level" Quick Setup menu......64 Endress+Hauser... - Page 110 Warnings ........81 Endress+Hauser...

- Page 111 Deltabar S FMD76/77/78, PMD70/75 with FOUNDATION Fieldbus Index Endress+Hauser...

- Page 112 www.endress.com/worldwide BA00301P/00/EN/16.14 71254467 CCS/FM+SGML 9 71254467...