Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Endress+Hauser Liquiphant M/S with electronic Insert FEL56

- Page 1 Products Solutions Services SD01521F/00/EN/04.19 71433131 2019-03-05 Special Documentation Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Functional Safety Manual [E x ia ] [E x ia ] Point level measuring system...

-

Page 2: Table Of Contents

Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Table of contents Declaration of conformity ..... 3 General ........4 Other safety-related characteristic values . -

Page 3: Declaration Of Conformity

Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Declaration of conformity A0025774 Endress+Hauser... -

Page 4: General

Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N A0025775 General The components can be operated as different versions: • Version I (→ 6) One Liquiphant for the direct activation of a NAMUR switching unit (e.g. transmitter, safety- related PLC) via the NAMUR interface according to EN 50227 (DIN 19234; NAMUR) or IEC 60947-5-6. -

Page 5: Other Safety-Related Characteristic Values

Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N • Version IV (→ 9) Two Liquiphant devices with a 3-channel Nivotester, switching contacts are switched in series • Version V (→ 11) Three Liquiphant devices with a 3-channel Nivotester, all channels are used, evaluation is performed in a safety-related PLC, for example •... - Page 6 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Specific functional safety parameters: Version I: Liquiphant M/S Characteristics as per IEC Value 61508 Safety function Example Wiring scheme A Other safety equipment e.g. actuator/safety-related PLC Device type Mode of operation...

- Page 7 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Version II: Liquiphant M/S; 1-channel Nivotester FTL325N Characteristics as per IEC Value 61508 Safety function Example Wiring scheme A Other safety equipment e.g. actuator/safety-related PLC Device type Mode of operation Low demand mode...

- Page 8 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Version III: Liquiphant M/S; 3-channel Nivotester FTL325N, CH2 and CH3 in series Characteristics as per IEC Value 61508 Safety function Example Wiring scheme (1oo2) A Other safety equipment e.g. actuator/safety-related PLC B Possibility 1 C Possibility 2;...

- Page 9 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Version IV: 2 Liquiphant M/S; 3-channel Nivotester FTL325N Characteristics as per IEC Value 61508 Safety function Example Wiring scheme (1oo3) A Other safety equipment e.g. actuator/safety-related PLC B Possibility 1 C Possibility 2; 1oo3 assessment...

- Page 10 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N The failure rates are based on an analysis in accordance with DIN EN 61508-6: 2011-02, Table D.4, "Using the β-factor to calculate the probability of failure in an E/E/PE safety-related system due to common cause failures".

- Page 11 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Version V: 3 Liquiphant M/S; 3-channel Nivotester FTL325N Characteristics as per IEC Value 61508 Safety function Example Wiring scheme (2oo3) A Other safety equipment e.g. actuator/safety-related PLC; 2oo3 assessment Device type...

- Page 12 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N The failure rates are based on an analysis in accordance with DIN EN 61508-6: 2011-02, Table D.4, "Using the β-factor to calculate the probability of failure in an E/E/PE safety-related system due to common cause failures".

-

Page 13: Useful Lifetime Of Electrical Components

Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Version VI: Liquiphant M/S; 3-channel Nivotester FTL325N Characteristics as per IEC Value 61508 Safety function Example A0027836 Wiring scheme ∆s A Other safety equipment e.g. actuator/safety-related PLC Δs level control (not SIL) -

Page 14: Certificate

Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Certificate A0028061 Endress+Hauser... -

Page 15: Document Information

Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Document information Document function The document is part of the Operating Instructions and serves as a reference for application-specific parameters and notes. • General information about functional safety: SIL • General information about SIL is available: In the Download Area of the Endress+Hauser Internet site: www.de.endress.com/SIL... -

Page 16: Supplementary Device Documentation

Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Supplementary device Liquiphant M FTL50, FTL50H, FTL51, FTL51H, FTL51C documentation Documentation Comment Technical Information: The documentation is available on the Internet: • TI00328F/00 (FTL50, FTL50H, FTL51, FTL51H) → www.endress.com • TI00347F/00 (FTL51C) Operating Instructions: •... - Page 17 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Nivotester FTL325N Documentation Comment Technical Information: The documentation is available on the Internet: TI00353F/00 → www.endress.com Operating Instructions: • The document is provided with the device. • KA00170F/00 (1-channel) • The documentation is available on the Internet: •...

-

Page 18: Permitted Devices Types

Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Permitted devices types The details pertaining to functional safety in this manual relate to the device versions listed below and are valid as of the specified firmware and hardware versions. Unless otherwise specified, all the following versions can also be used for protective systems. -

Page 19: Sil Label On The Nameplate

Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Valid device versions for safety-related use: Nivotester FTL325N Ordering feature Designation Option Approval • G ATEX II 3(1)G Ex nC/A [ia] IIC T4, SIL, IECEx Zone 2 • H ATEX II (1)GD [EEx ia] IIC, WHG, SIL, IECEx [Ex ia] IIC •... -

Page 20: Safety Function

Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Safety function Definition of the safety The measuring system' s safety functions are: function • Maximum point level monitoring (overfill protection) • Minimum point level monitoring (dry run protection) For information on the choice of operating mode (MIN or MAX detection), see → 23. - Page 21 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N ρ [g/cm³] 1.000 0.100 0.010 0.001 ±0 +120 +180 +240 +300 [°C] +140 +248 +356 +464 +527 [°F] A0026840 1.1 Liquiphant M; density switch position 0.7 g/cm³ 1.2 Liquiphant S; density switch position 0.7 g/cm³...

- Page 22 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Wall distance The distance between the tuning fork of the device and the wall of the vessel containing medium (e.g. tank, pipe) must be at least 10 mm (0.39 in). Corrosion The device may only be used in media to which the wetted parts used are resistant.

-

Page 23: Use In Safety Instrumented Systems

Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Use in safety instrumented systems Device behavior during Behavior of device during power-up operation The behavior of the device during power-up is described in the relevant Operating Instructions (→ 16). - Page 24 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Mode of operation Switch on the operating mode at the left switch: Mode of operation Function Switch position MAX safety MIN safety Bottom Ex ia H 2.2 ... 2.8 mA 0.6 ... 1.0 mA –...

- Page 25 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Density Set the density at the right switch: Liquid density Function Switch position Comment >0.7 kg/dm³ >0.7 Standard setting; (See A in the graphic below) Always use if possible >0.5 kg/dm³...

- Page 26 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Configuring the Nivotester Switch Channel 1 Fault Channel 2 Fault Channel 3 Fault MODE message message message Version 1 H = High With Not applicable 2.1 to 5.5 mA None H = High...

-

Page 27: Proof-Testing

Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N < 1 > 2 [E x ia ] < 1 > 2 A0026107 2 Operating and display element, 3-channel Nivotester FTL325N DIL switch for channel 1: failure current signal 2.1 mA / 1.2 mA (1), fault on/off position (2) Light emitting diodes (LEDs) Switch for functions: Δs, e.g. - Page 28 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Procedure of the proof-test START Output signal Status „OK“ for status „OK“ at the sensor Output signal Establish Proof test has failed for demand mode demand mode Output signal Establish for status „OK“...

- Page 29 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Version II to VI Mode of operation Approach the level Version II to VI, test sequence Version II to VI, test sequence Remove and immerse in a medium of MIN detection (→ 32) MAX detection (→...

- Page 30 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Version I, test sequence A, MIN detection • Approach the level or • Remove and immerse in a medium of similar density and viscosity Step 1 Raise the level or immerse the tuning fork of the sensor that has been removed into the medium until the tuning fork is fully covered.

- Page 31 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Version I, test sequence A, MAX detection • Approach the level or • Remove and immerse in a medium of similar density and viscosity Step 1 Lower the level or remove the tuning fork of the sensor that has been removed out of the medium until the tuning fork is completely free.

- Page 32 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Version II to VI, test sequence A, MIN detection • Approach the level or • Remove and immerse in a medium of similar density and viscosity Step 1 Raise the level or immerse the tuning fork of the sensor that has been removed into the medium until the tuning fork is fully covered.

- Page 33 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Version II to VI, test sequence A, MAX detection • Approach the level or • Remove and immerse in a medium of similar density and viscosity Step 1 Lower the level or remove the tuning fork of the sensor that has been removed out of the medium until the tuning fork is completely free.

- Page 34 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N test sequence B Activate simulation by pressing the test button on the Nivotester. Step 1 ‣ Check the status of the safety contacts. Version Terminal Closed Not applicable Closed Closed Closed...

- Page 35 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N General, test sequence C Check the switch point under reference operating conditions. NOTICE The test sequence can only be performed if the following conditions are met: ‣ Uncoated fork (FTL50, FTL51, FTL50H or FTL51H) ‣...

- Page 36 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Check the current at terminal 2. After immersing the fork (plus a response time of approx. 1 s), the current must be between 2.2 to 2.8 mA. If the current is outside the specified tolerance, a fault has occurred in the safety path. The proof test has not been passed and must be aborted.

- Page 37 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Version Terminal Closed Not applicable Closed Closed Closed 22+23 Not applicable Closed Closed Closed Not applicable 26+27 Not applicable Closed Closed Closed Not applicable If one or more safety contacts are open, a fault has occurred in the safety path. The proof test has not been passed and must be aborted.

-

Page 38: Life Cycle

KA00620F/00 Additional country-specific regulations and tests must be observed. In the event of failure of a SIL-labeled Endress+Hauser device, which has been operated in a protection function, the "Declaration of Contamination and Cleaning" with the corresponding note "Used as SIL device in protective system" must be enclosed when the defective device is returned. -

Page 39: Modification

Modifications to devices with SIL capability onsite at the user' s plant are possible following approval by the Endress+Hauser manufacturing center. In this case, the modifications must be performed and documented by an Endress+Hauser service technician. Modifications to devices with SIL capability by the user are not permitted. -

Page 40: Appendix

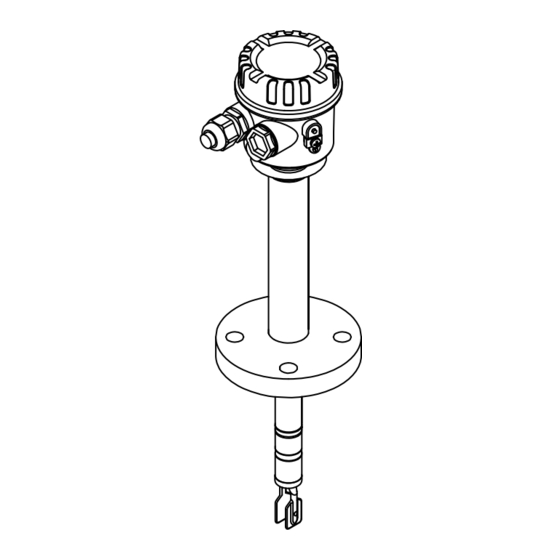

Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Appendix Structure of the measuring System components system The measuring system' s devices are displayed in the following diagram (example): [E x ia ] [E x ia ] A0025771 Liquiphant M/S... - Page 41 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N A0026065 3 Dimensions: mm (in) Installation from above Installation from below Installation from the side For information about the switch point under reference operating conditions, please refer to the Technical Information, → 16.

-

Page 42: Commissioning Or Proof Test Report

Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Commissioning or Report for version I proof test report System-specific data Company Measuring point/TAG no. Facility Device type/Order code Serial no. Liquiphant Name Date Signature Operating mode, density range and version (please tick appropriate box) - Page 43 Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N Report for versions II to VI System-specific data Company Measuring point/TAG no. Facility Device type/Order code Serial no. Liquiphant(en) Serial no. Nivotester Name Date Signature Operating mode, density range and version (please tick appropriate box)

-

Page 44: Further Information

Liquiphant M/S with electronic insert FEL56 + Nivotester FTL325N System-specific data Conclusion Passed Failed Only for Liquiphant with electronic insert FEL58 + Nivotester FLT325N. For restrictions and immersion depths, see → 35 Not applicable as channel is not used.