Table of Contents

Advertisement

Quick Links

2017 Lennox Industries Inc.

©

Dallas, Texas, USA

Guidelines for Air Handler Control Field Replacement (16B27)

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal

injury or loss of life. Installation and service must be

performed by a licensed professional HVAC installer or

equivalent, service agency, or the gas supplier.

CAUTION

As with any mechanical equipment, contact with sharp

sheet metal edges can result in personal injury. Take

care while handling this equipment and wear gloves and

protective clothing.

WARNING

Electric Shock Hazard! - Disconnect all

power supplies before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

WARNING

Electrostatic discharge can affect

electronic components. Take care

during unit installation and service to

protect the unit's electronic controls.

ELECTROSTATIC

Precautions will help to avoid control

DISCHARGE

exposure to electrostatic discharge

(ESD)

by putting the unit, the control and the

Precautions and

technician at the same electrostatic

Procedures

potential. Touch hand and all tools

on an unpainted unit surface before

performing any service procedure to

neutralize electrostatic charge.

CONTROLS

KITS AND ACCESSORIES

506461-03

11/2017

Supersedes 506461-02

AIR HANDLER CONTROL FIELD

Table of Contents

Shipping and Packing List ..............................2

General .............................................................2

Installation ........................................................2

For All Applications ............................................................ 2

For Non-Communicating Applications Only ....................... 2

Field Control Wiring ........................................5

Control and Sensor Connection Requirements ................. 7

Discharge Sensor (DAT) .................................................... 7

Outdoor Air Sensor (OAS) ................................................. 7

Indoor Blower Signal 6-Pin Connector (P7)....................... 7

Air Handler Control 9-Pin Connector (P8) ......................... 7

Air Handler Control Button and Display ........8

Push Button ....................................................................... 8

Seven-Segment Display .................................................... 8

Air Handler Jumpers ..................................... 11

Delay Profile 1 ................................................................ 12

Delay Profile 2 ................................................................. 12

Delay Profile 3 ................................................................. 12

Delay Profile 4 ................................................................. 12

Seven-Segment Display .................................................. 12

Target CFM Tables .........................................13

Unit Operating Sequences ............................17

Configuring Unit ............................................19

Checkout ......................................................................... 19

Unit Size Code................................................................. 20

Electric Heat .................................................................... 21

EvenHeat Operation ........................................................ 22

REPLACEMENT KIT

Advertisement

Table of Contents

Summary of Contents for Lennox 16B27

-

Page 1: Table Of Contents

AIR HANDLER CONTROL FIELD 506461-03 Dallas, Texas, USA 11/2017 REPLACEMENT KIT Supersedes 506461-02 Guidelines for Air Handler Control Field Replacement (16B27) Table of Contents WARNING Shipping and Packing List ......2 Improper installation, adjustment, alteration, service General .............2 or maintenance can cause property damage, personal injury or loss of life. -

Page 2: Shipping And Packing List

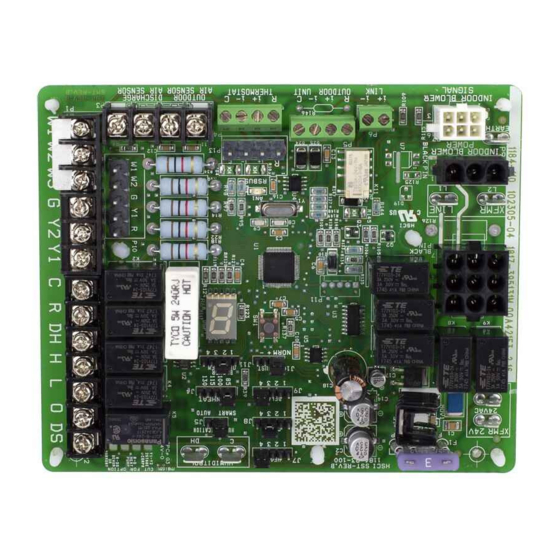

Shipping and Packing List Check package contents for shipping damage. Consult CONTROL BOX last carrier immediately if damage is found. 1 – Control 1 – Wiring diagram (537202-02) 1 – Jumper, Link Guide and Diagnostic Code Sheet General CONTROL BOARD This document provides general guidelines on field re- CONTROL MOUNTING placement of air handler control and unit configuration. - Page 3 The unit will operate based on jumper and link settings on ® control system operation if configuration settings in the iComfort the control. All setting changes must be done at the control ® thermostat are not available. The Lennox iComfort thermostat board. The Lennox ComfortSense ® 7500 thermostat may be must be used in communicating applications.

- Page 4 (Non-Communicating) CBA38MV, CBX32MV & CBX40UHV 1−STG COMPRESSOR 2−STG COMPRESSOR JUMPER & LINK GUIDE DO NOT CUT CUT LINK COOLING MODE HEATING MODE BLOWER SPEED BLOWER SPEED (COOLING & HP MODE) (ELECTRIC HT MODE) A/C UNIT HEAT PUMP UNIT HIGH DO NOT CUT CUT LINK HIGH SPEED...

-

Page 5: Field Control Wiring

Field Control Wiring Figure 4. CBA38MV, CBX32 and CBX40 Air Handler Unit Typical Wiring Diagram Page 5... - Page 6 DETAIL A THE AIR HANDLER CONTROL (AHC) HAS TWO NOTE - Due to varying duct designs SCREW TERMINALS MARKED DISCHARGE AIR SENSOR. THE SENSOR IS REQUIRED FOR and airflow conditions, relocation of the EVENHEAT OPERATION, IS FIELD-MOUNTED discharge sensor may be required to AND MUST BE ORDERED SEPARATELY insure accurate sensing.

-

Page 7: Control And Sensor Connection Requirements

Lennox Catalog # 88K38. 24VAC command (ground) (oAs) 24VAC utdoor ensor This is a two screw terminal for connection to a Lennox RSbus data high connection Outdoor Unit X2658 outdoor temperature sensor. RSbus data low connection (p7) ndoor... -

Page 8: Air Handler Control Button And Display

Table 6. AHC Configuration, Test and Error Recall Air Handler Control Button and Display (Fault and Lockout) Function IMPORTANT NOTE – AHC MUST BE IN IDLE MODE Single Before changing any clippable links or jumper settings, Character Action make sure the motor has completely stopped. Any LED Display changes will not take place while the motor is running. - Page 9 Table 7. Seven-Segment Status Display Operation Description Idle Mode: Decimal point blinks at 1 Hz (0.5 second on, 0.5 second off). Display OFF. Decimal point blinks at 1 Hz Soft Disabled Top & Bottom horizontal line and decimal point blink at 1 Hz (0.5 second on, 0.5 sec- Top &...

- Page 10 Table 8. AHC Configuration, Test and Error Recall (Fault and Lockout) Function ERROR CODE RECALL MODE (NOTE — CONTROL MUST BE IN IDLE MODE) To enter Error Code Recall function — PUSH and HOLD button until solid E appears, then RELEASE button. Control will Solid display up to ten error codes stored in memory.

-

Page 11: Air Handler Jumpers

Table 9. AHC Single Character Display — Error Codes (Communicating and Non-Communicating) Error Codes Status of Air Handler E 3Y8 Relay Y2 failure. Heat call with non-configured or mis-configured electric heat. Check for proper configuring under Configuring Electric Heat Stag- E 350 E 351 Heat section / Stage 1 failed (Pilot relay contacts did not close or the relay coil in electric heat did not energize) -

Page 12: Delay Profile 1

4. Adjust - Used to select the indoor blower CFM Heating – Heat Pump only: adjustment value by placing the jumper in appropriate position. • If NORM is selected, indoor blower runs at normal 100% CFM 100% CFM speeds. 30 sec 45 SEC. -

Page 13: Target Cfm Tables

First stage cooling air volume is 70% of COOL speed setting. Continuous fan speed is approximately 28%, 38%, 70% and 100% (Jumper selectable) of the same second-stage COOL speed selected, minimum 250 cfm. Lennox iHarmony Zoning System applications - minimum blower speed is 250 cfm. - Page 14 First stage cooling air volume is 70% of COOL speed setting. Continuous fan speed is approximately 28%, 38%, 70% and 100% (Jumper selectable) of the same second-stage COOL speed selected, minimum 450 cfm. Lennox iHarmony Zoning System applications - minimum blower speed is 450 cfm.

- Page 15 First stage cooling air volume is 70% of COOL speed setting. Continuous fan speed is approximately 28%, 38%, 70% and 100% (Jumper selectable) of the same second-stage COOL speed selected, minimum 380 cfm. Lennox iHarmony Zoning System applications - minimum blower speed is 380 cfm.

- Page 16 First stage cooling air volume is 70% of COOL speed setting. Continuous fan speed is approximately 28%, 38%, 70% and 100% (Jumper selectable) of the same second-stage COOL speed selected, minimum 250 cfm. Lennox iHarmony Zoning System applications - minimum blower speed is 250 cfm.

-

Page 17: Unit Operating Sequences

First stage cooling air volume is 70% of COOL speed setting. Continuous fan speed is approximately 28%, 38%, 70% and 100% (Jumper selectable) of the same second-stage COOL speed selected, minimum 450 cfm. Lennox iHarmony Zoning System applications - minimum blower speed is 450 cfm. - Page 18 Table 11. Air Handler with ComfortSense 7500 Thermostat and Two-Stage Outdoor Unit Operating Sequence Operating Sequence System Demand System Response Thermostat Demand Relative Humidity System Handler Step Compressor Comments Condition Status (COOL) No Call for Dehumidification Normal Operation Acceptable 24 VAC Compressor and indoor air - Y1 handler follow thermostat...

-

Page 19: Configuring Unit

Configuring Unit This section identifies the requirements for configuring the air handler in non-communicating mode for unit size, heat mode selection and EvenHeat. For communicating configuration see the iComfort installation instruction. ® heckout Air Handler AIR HANDLER CONTROL (AHC) Control Checkout Power-up- Unit Size Code (Number or letter) displayed PUSH represents unit size code (air handler model size and capacity). -

Page 20: Unit Size Code

Con guring Unit Size Codes (Model Number) Power-up — Unit Size Code (number or letter) displayed represents unit size code (air handler model size and capacity). If three horizontal bars display, then Air Handler Control (AHC) does not recognize unit size code. AHC in IDLE mode (No heating, cooling or indoor fan operation) To enter unit size code... -

Page 21: Electric Heat

lectric Con guring/Detecting Electric Heat Sections IMPORTANT — When connected to an iComfort thermostat, all jumper settings can be made during con guration of the system in the thermostat. After all electric heat installations, the Auto Detect function in the control will detect how much electric heat is available. That information will be sent to the Smart Hub, along with all the other air handler parameters. -

Page 22: Evenheat Operation

perAtion INPUTS OUTPUTS Target Discharge Air Target Discharge Air Target Discharge Air Room Thermostat Demand Temperature Set at 85ºF Temperature Set at 100ºF Temperature Set at 115ºF/130ºF Heat Pump First + First Electric Heat Pump First Stage Heat Pump First Stage Heat Section (H1) Heat Pump First and Second Stage + First Electric Heat Section (H1) +... - Page 23 EVENHEAT Operation Note 1 Activation delay 120 seconds if one heat stage is or deactivated 150 seconds if more than one stage is activated or deactivated. Start Timer Delay (Note 1) Change in Heat Activate Y2 demand from room thermostat? Delay Timer Delay Timer Finished or last...

- Page 24 Page 24...