Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Cornelius Triton 200 HC

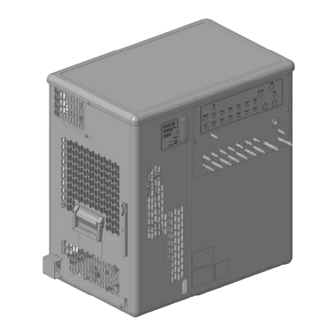

- Page 1 Triton 200 HC...

- Page 2 TRITON 200 HC Manual Operation English Legal notice Manual operation (Original) Document no.: TD1011602EN Undercounter cooler Model range Triton 200 HC Version A Date of issue: 04.07.2019 Revision status: Index 0 Protection notices (in accordance with DIN ISO 16016:2002-5) The reproduction, distribution and utilization of this document as well as the communication of its contents are prohibited, unless expressly permitted.

-

Page 3: Table Of Contents

TRITON 200 HC SAFETY ..............................4 1.1 I ............................4 NTENDED USE 1.2 I ............................4 MPROPER USE 1.3 S ..............................4 TAFF 1.3.1 Operator ............................4 1.3.2 User .............................. 5 1.3.3 Expert ............................5 1.4 P ........................5 RESENTATION OF WARNING 1.5 S... -

Page 4: Safety

By using the unit as intended you will not only protect yourself, but also prevent damage occurring to the unit and its components! The intended use of under counter coolers from the Triton 200 HC (referred to as “unit” in the following) is to refrigerate and convey non-alcoholic beverages and their basic ingredients. CO2 or electric pumps are used as conveying equipment for the brands. -

Page 5: User

1.5.2 Disclaimer of liability and warranties If work is undertaken on the unit which is not described in this document, Cornelius Deutschland GmbH shall not assume any liability for any resulting hazards and damages. The same applies to described work which is partly or not fully performed in compliance with the regulations set out in this document. -

Page 6: Safety Information To Prevent Personal Injury And Equipment Damage

Improperly executed work at the unit will cause dangers to persons and damage to the unit. Have all work at the unit carried out by Cornelius Deutschland GmbH or by a service partner. Warning! Risk of personal injury and equipment damage due to the use of non- approved... -

Page 7: Transport And Packaging

60335-2 – 24). Transport and packaging Choose a suitable packaging when returning the unit itself or one of its components to Cornelius Deutschland GmbH, e.g. for repairs. In particular, make sure that the unit and any components are protected from shock/impact, moisture, dirt and electrostatic discharge (ESD). This will prevent transport damage to the unit and to the components, for which the manufacturer shall assume no liability. -

Page 8: Storage

TRITON 200 HC Storage Avoid excessive temperature fluctuations as condensate may form, which in turn may cause damage to the unit or to the components. The permissible storage temperature is -10 °C to +50 °C. The acclimatization period is 6 hours. -

Page 9: Transport And Packaging

TRITON 200 HC Transport and packaging Choose a suitable packaging when returning the unit itself or one of its components to Cornelius Deutschland GmbH, e.g. for repairs. In particular, make sure that the unit and any components are protected from shock/impact, moisture, dirt and electrostatic discharge (ESD). This will prevent transport damage to the unit and to the components, for which the manufacturer shall assume no liability. -

Page 10: Disposal

TRITON 200 HC Caution! Component damage due to material ageing Material can age due to long storage periods, thereby affecting the material’s properties (e.g. plastics and seals may become brittle). The properties of lubricants may change due to long storage periods. -

Page 11: Installation

TRITON 200 HC Installation The device must be installed by a trained service technician. Please take care, that the socket for the unit is always accessible. There are no user serviceable items inside the equipment. If the power supply cable to the unit is damaged, it has to be replaced by the manufacturer, the service partner or any other qualified person to avoid safety hazard. -

Page 12: Putting Into And Out Of Service

TRITON 200 HC Putting into and out of Service Putting into Service (to be done by expert) Comply with the cleaning regulations defined by law before beginning each operation. Clean the couplings on the container for beverage/syrup every time before you attach them. Connect coupling to container for beverage/syrup. -

Page 13: Putting Out Of Service (To Be Done By Expert)

TRITON 200 HC Check the CO -lines for leaks by closing valve on the CO -cylinder. The inlet pressure indicated on the pressure regulator should not drop. If it does, call a service technician immediately. Do not forget to re- open the CO -cylinder valve afterwards. -

Page 14: Cleaning And Disinfection Directions

TRITON 200 HC Cleaning and Disinfection Directions Cleaning Directions (to be done by operator or experts) Comply with the valid national regulations for cleaning bar equipment at the particular installation site. Clean connection parts and tap fittings in advance whenever making connections or changing the type of beverage. - Page 15 TRITON 200 HC Remark -> Water filters : In case the system is equipped with a water filter, the filter cartridge needs to be removed before doing the cleaning / sanitization and replaced by a blind plug that allows bypassing the filter. Do not use any empty service filter cartridges to flush the sanitizing agent into the system, as this will not allow a proper and consistent level of sanitizing agent in the unit.

- Page 16 TRITON 200 HC A.) Flushing-in of sanitization agent (e.g. P3 Ansep CIP from Ecolab) (to be done by experts) Syrup Lines 1.1) The product lines filled with syrup must first be flushed with water. For this an external water distributor can be used to connect and flush several syrup lines simultaneously.

- Page 17 TRITON 200 HC 2.6) Flood the complete dispense system with the cleaning / sanitizing agent by operating the post-mix valves. Ensure that on all valves clearly visible agent is being drawn. Effect- / working time for the cleaning / sanitizing agent is min. 20 minutes!! In the meantime remove the dispense nozzles from the valves and sanitize them manually by putting them for 20 minutes into sanitizing agent.

- Page 18 TRITON 200 HC 2.6) Dispense sufficiently water from the post-mix valves to ensure that no sanitizing agent is left in the system Depending on the unit type (Over counter dispenser / large soda circuit installation with long python runs, etc.) the amount of water that needs to be dispensed may vary.

-

Page 19: Problems And Troubleshooting

TRITON 200 HC Problems and Troubleshooting Before looking for problems with the dispensing equipment, first check: Is the electricity to the device interrupted? Is the flow of water to the device interrupted? Are the beverage containers empty? Is the CO... -

Page 20: Technical Data

Cooling capacities and output capacity at 24°C ambient temperatures and water or syrup inlet temperatures of 24°C and beverage outlet temperatures of less than 5°C. When Cornelius pythons are used, a cooling loss of 13 kcal/hour per meter length must be included in calculations. -

Page 21: Illustration Of The Triton

TRITON 200 HC Illustration of the Triton 200 HC 11.1 Connections at the Unit 11.2 Flow Chart Comment Still water option is not available for this unit Cornelius Deutschland GmbH Manual operation undercounter cooler Document no: TD1011602EN Triton 200 HC Version A, 04.07.2019, Index 0... -

Page 22: Circuit Diagram

TRITON 200 HC 11.3 Circuit Diagram Cornelius Deutschland GmbH Manual operation undercounter cooler Document no: TD1011602EN Triton 200 HC Version A, 04.07.2019, Index 0 Page 22... -

Page 23: Exploded View / Spare Part List

TRITON 200 HC Exploded View / Spare part list 12.1 Exploded View Cornelius Deutschland GmbH Manual operation undercounter cooler Document no: TD1011602EN Triton 200 HC Version A, 04.07.2019, Index 0 Page 23... -

Page 24: Spare Part List

TRITON 200 HC 12.2 Spare Part List Cornelius Deutschland GmbH Manual operation undercounter cooler Document no: TD1011602EN Triton 200 HC Version A, 04.07.2019, Index 0 Page 24... -

Page 25: Declaration Of Conformity

TRITON 200 HC Declaration of conformity Cornelius Deutschland GmbH Manual operation undercounter cooler Document no: TD1011602EN Triton 200 HC Version A, 04.07.2019, Index 0 Page 25...