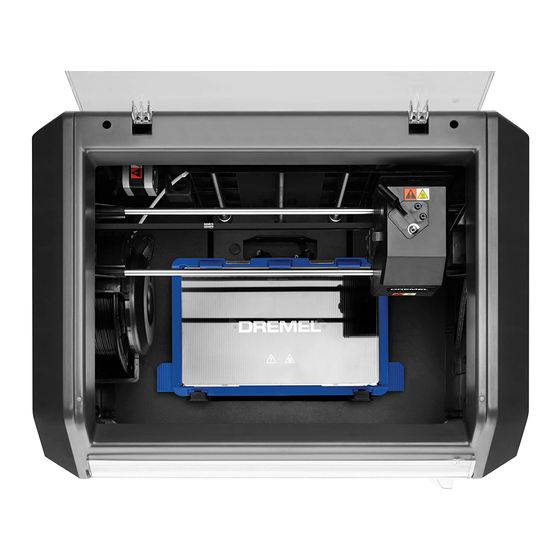

Dremel DIGILAB 3D45 Manual

Unclog extruder

Hide thumbs

Also See for DIGILAB 3D45:

- Original instructions manual (396 pages) ,

- Operating and safety instructions manual (112 pages) ,

- Operating/safety instructions manual (37 pages)

Advertisement

Quick Links

Read the Dremel 3D45 manual and

these instructions before unclogged

the extruder in your Dremel 3D45. Failure to comply with

the warnings and instructions may result in fire, equip-

ment damage, property damage, or personal injury.

Always unplug Dremel 3D45 from its power before per-

forming any service procedures. Failure to do so may re-

sult in personal injury and equipment damage.

Use only Dremel approved materials and components.

Use of object materials, or 3D objects other than Dremel

approved object materials and genuine Dremel components

may void warranty.

Repairs on the Dremel 3D45 may require the use of special

tools (pulling devices and bearing press). Authorized repair

centers have trained repair technicians and equipment

necessary to perform these repairs.

This document will outline the steps necessary to clear a

clog in the heatsink tube assembly caused by the filament

bulging up inside the tube. If the filament becomes clogged,

neither loading nor unloading will be possible. Tube clogging

can occur by either using an old filament that's kept in the

open for a longer duration or from 3rd party filaments with

lower transition temperatures.

Tools Required:

• Unclog tool

• Brush

• Scissors

• Pliers

• 2mm Hex bit or Hex wrench (Allen key)

• 2.5mm Hex bit or Hex wrench (Allen key)

• T10 Torx bit or screwdriver (no longer than 4 inches).

3D45 Unclog Extruder

PRE-SERVICE PREPARATION

For the location of the repair center near you, please call

1-844-4DRML3D (1-844-437-6533) Monday thru Friday,

8AM to 6PM CST. Or, look on our web site at

www.Dremel3D.com and follow the link for 'Support'.

CONTINENTAL UNITED STATES

Dremel Service Center

4915 21st Street

Racine, WI 53406

Phone: 1-844-4DRML3D

Preventative Measures:

In order to help avoid clogging please follow the recommen-

dations below.

1. Only use Dremel filament.

2. Always unload the filament from the printer when not in

use.

3. Always wait for the extruder to cool down see thermome-

ter icon on screen empty.

4. Store your filament in a dry environment with a desiccant

bag and clip the free end of the filament to the two holes

in the spool to prevent filament getting tangled or brittle-

ness.

Please call Dremel service center for help in unclogging

your extruder.

CANADA

Giles Tool Agency

47 Granger Ave,

Scarborough, ON

M1K 3K9, Canada

Phone:1-416-287-3000

West Coast Tool

4008 Myrtle Street

Burnaby, B.C. V5C 4G2

Phone: 1-604-873-5394

Advertisement

Summary of Contents for Dremel DIGILAB 3D45

- Page 1 Dremel components West Coast Tool may void warranty. 4008 Myrtle Street Repairs on the Dremel 3D45 may require the use of special Burnaby, B.C. V5C 4G2 Phone: 1-604-873-5394 tools (pulling devices and bearing press). Authorized repair centers have trained repair technicians and equipment necessary to perform these repairs.

- Page 2 SERVICE A) Purge Filament: 1. Pre-heat the extruder, go to Tools/Pre-heat. Wait until the extruder reaches the recommended temperature for your filament then click on purge when the icons turns green. Check for filament extruding. If there is no filament coming out your nozzle, please go to the next step.

- Page 3 D) Check for Clogs in Stepper Motor: b. Remove screw located on the right side of the hole using the T10 Torx screwdriver. The first picture below Use proper anti-static precautions shows the location of the screw, the second picture a when performing this replacement.

- Page 4 3. Removing the Extruder Motor. 4. Cleaning the stepper gear. There might be filament residue in your stepper motor gear, use your brush to clean the a. Disconnect the white extruder terminal block from the gear of the stepper motor. extruder connector as shown in the picture below.