Konica Minolta magicolor 2490MF Service Manual

Hide thumbs

Also See for magicolor 2490MF:

- User manual (226 pages) ,

- Service manual (150 pages) ,

- Reference manual (86 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Konica Minolta magicolor 2490MF

- Page 1 SERVICE MANUAL FIELD SERVICE magicolor 2490MF 2006.07 2006.07 Ver. 1.0 Ver. 1.0...

-

Page 2: Table Of Contents

WARNING INDICATIONS ON THE MACHINE ............S-18 MEASURES TO TAKE IN CASE OF AN ACCIDENT ............S-20 Composition of the service manual ................. C-1 Notation of the service manual ..................C-2 magicolor 2490MF Main Unit General ........................... 1 Maintenance ........................7 Adjustment/Setting......................77 Troubleshooting...................... -

Page 4: Safety And Important Warning Items

IMPORTANT NOTICE Because of possible hazards to an inexperienced person servicing this product as well as the risk of damage to the product, KONICA MINOLTA BUSINESS TECHNOLOGIES, INC. (hereafter called the KMBT) strongly recommends that all servicing be performed only by KMBT-trained service technicians. -

Page 5: Safety Warnings

[1] MODIFICATIONS NOT AUTHORIZED BY KONICA MINOLTA BUSINESS TECHNOLOGIES, INC. KONICA MINOLTA brand products are renowned for their high reliability. This reliability is achieved through high-quality design and a solid service network. Product design is a highly complicated and delicate process where numerous mechanical, physical, and electrical aspects have to be taken into consideration, with the aim of arriving at proper tolerances and safety factors. - Page 6 SAFETY AND IMPORTANT WARNING ITEMS [2] POWER PLUG SELECTION In some countries or areas, the power plug provided with the product may not fit wall outlet used in the area. In that case, it is obligation of customer engineer (hereafter called the CE) to attach appropriate power plug or power cord set in order to connect the product to the supply.

- Page 7 SAFETY AND IMPORTANT WARNING ITEMS [3] CHECKPOINTS WHEN PERFORMING ON-SITE SERVICE KONICA MINOLTA brand products are extensively tested before shipping, to ensure that all applicable safety standards are met, in order to protect the customer and customer engi- neer (hereafter called the CE) from the risk of injury. However, in daily use, any electrical equipment may be subject to parts wear and eventual failure.

- Page 8 SAFETY AND IMPORTANT WARNING ITEMS Power Plug and Cord WARNING • When using the power cord set (inlet type) that came with this product, make sure the connector is securely inserted in the inlet of the product. When securing measure is provided, secure the cord with the fixture properly.

- Page 9 SAFETY AND IMPORTANT WARNING ITEMS Wiring WARNING • Never use multi-plug adapters to plug multiple power cords in the same outlet. If used, the risk of fire exists. • When an extension cord is required, use a specified one. Current that can flow in the extension cord is limited, so using a too long extension cord may result in fire.

- Page 10 SAFETY AND IMPORTANT WARNING ITEMS Ventilation CAUTION • The product generates ozone gas during operation, but it will not be harmful to the human body. If a bad smell of ozone is present in the following cases, ventilate the room. a.

- Page 11 SAFETY AND IMPORTANT WARNING ITEMS Work Performed with the Product Powered On WARNING • Take every care when making adjustments or performing an operation check with the product powered. If you make adjustments or perform an operation check with the external cover detached, you may touch live or high-voltage parts or you may be caught in moving gears or the timing belt, leading to a risk of injury.

- Page 12 SAFETY AND IMPORTANT WARNING ITEMS Safety Checkpoints WARNING • Check electrode units such as a charging corona unit for deterioration and sign of leakage. Current can leak, leading to a risk of trouble or fire. • Before disassembling or adjusting the write unit (P/H unit) incorporating a laser, make sure that the power cord has been disconnected.

-

Page 13: Handling Of Consumables

SAFETY AND IMPORTANT WARNING ITEMS Safety Checkpoints WARNING • Make sure that all screws, components, wiring, connec- tors, etc. that were removed for safety check and mainte- nance have been reinstalled in the original location. (Pay special attention to forgotten connectors, pinched cables, forgotten screws, etc.) A risk of product trouble, electric shock, and fire exists. - Page 14 SAFETY AND IMPORTANT WARNING ITEMS Handling of Service Materials CAUTION • Use only a small amount of cleaner at a time and take care not to spill any liquid. If this happens, immediately wipe it off. A risk of fire exists. •...

-

Page 15: Internal Laser Radiation

SAFETY AND IMPORTANT WARNING ITEMS [4] Laser Safety • This is a digital machine certified as a class 1 laser product. There is no possibility of danger from a laser, provided the machine is serviced according to the instruction in this manual. - Page 16 SAFETY AND IMPORTANT WARNING ITEMS the U.S.A., Canada (CDRH Regulation) • This machine is certified as a Class I Laser product under Radiation Performance Stan- dard according to the Food, Drug and Cosmetic Act of 1990. Compliance is mandatory for Laser products marketed in the United States and is reported to the Center for Devices and Radiological Health (CDRH) of the U.S.

- Page 17 SAFETY AND IMPORTANT WARNING ITEMS Finland, Sweden VARO! • Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättömälle lasersäteilylle. Älä katso säteeseen. LOUKAN 1 LASERLAITE KLASS 1 LASER APPARAT VAROITUS! • Laitteen Käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa käyttäjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle. Puolijohdelaser Laserdiodin suurin teho 10 mW...

-

Page 18: Laser Safety Label

SAFETY AND IMPORTANT WARNING ITEMS Laser Safety Label • A laser safety labels is attached to the outside of the machine as shown below. COMPLIES WITH 21 CFR 1040.10 AND 1040.11 EXCEPT FOR DEVIATIONS PURSUANT TO LASER NOTICE NO.50, DATED JULY 26, 2001. or/and 4139P0E501DA S-15... -

Page 19: Laser Caution Label

SAFETY AND IMPORTANT WARNING ITEMS Laser Caution Label • A laser caution label is attached to the inside of the machine as shown below. 4139P0E503DA S-16... -

Page 20: Precautions For Handling The Laser Equipment

SAFETY AND IMPORTANT WARNING ITEMS Precautions For Handling The Laser Equipment • When laser protective goggles are to be used, select ones with a lens conforming to the above specifications. • When a disassembly job needs to be performed in the laser beam path, such as when working around the printerhead and PC Drum, be sure first to turn the copier OFF. -

Page 21: Warning Indications On The Machine

SAFETY AND IMPORTANT WARNING ITEMS WARNING INDICATIONS ON THE MACHINE Caution labels shown are attached in some areas on/in the machine. When accessing these areas for maintenance, repair, or adjustment, special care should be taken to avoid burns and electric shock. High temperature High voltage 4139P0E504DA... - Page 22 SAFETY AND IMPORTANT WARNING ITEMS High voltage 4139P0E505DA CAUTION: • You may be burned or injured if you touch any area that you are advised not to touch by any caution label. Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot be read, contact our Service Office.

-

Page 23: Measures To Take In Case Of An Accident

MEASURES TO TAKE IN CASE OF AN ACCIDENT MEASURES TO TAKE IN CASE OF AN ACCIDENT 1. If an accident has occurred, the distributor who has been notified first must immediately take emergency measures to provide relief to affected persons and to prevent further damage. -

Page 24: Composition Of The Service Manual

Composition of the service manual This service manual consists of Theory of Operation section and Field Service section to explain the main machine and its corresponding options. Theory of Operation section gives, as information for the CE to get a full understanding of the product, a rough outline of the object and role of each function, the relationship between the electrical system and the mechanical system, and the timing of operation of each part. -

Page 25: Notation Of The Service Manual

Notation of the service manual A. Product name In this manual, each of the products is described as follows: (1) IC board: Standard printer (2) magicolor 2490MF: Main body (3) Microsoft Windows 95: Windows 95 Microsoft Windows 98: Windows 98... - Page 26 SERVICE MANUAL FIELD SERVICE magicolor 2490MF Main Unit 2006.07 Ver. 1.0...

-

Page 27: Revision History

Revision history After publication of this service manual, the parts and mechanism may be subject to change for improvement of their performance. Therefore, the descriptions given in this service manual may not coincide with the actual machine. When any change has been made to the descriptions in the service manual, a revised version will be issued with a revision mark added as required. - Page 28 Field Service Ver. 1.0 Jul. 2006 CONTENTS magicolor 2490MF Main Unit General System configuration....................1 Product specifications ..................... 2 Built-in Controllers ....................4 Fax specifications ....................5 Maintenance Periodic check ......................7 Maintenance parts ....................7 3.1.1 Replacement parts..................7 3.1.2...

- Page 29 Field Service Ver. 1.0 Jul. 2006 5.3.4 Right cover....................32 5.3.5 Paper feed cover..................32 5.3.6 Front cover ....................32 5.3.7 Original glass unit ..................33 5.3.8 Operation board (OPB)................34 5.3.9 Operation key board (OKB) ................ 36 5.3.10 USB board (USB) ..................37 5.3.11 Image processing board (IPB) ..............

- Page 30 Field Service Ver. 1.0 Jul. 2006 Adjustment/Setting How to use the adjustment section ............... 77 Description of the control panel................78 Control panel display ..................78 7.1.1 Main screen ....................78 7.1.2 Toner supply screen ..................78 Menu mode ......................79 Menu mode function tree ..................

- Page 31 Field Service Ver. 1.0 Jul. 2006 8.7.1 MEMORY RX MODE .................. 88 8.7.2 NO. of RINGS ..................... 88 8.7.3 REDUCTION RX ..................88 8.7.4 RX PRINT ....................92 8.7.5 RX MODE ....................92 8.7.6 FOOTER ..................... 92 8.7.7 SELECT TRAY.................... 93 COMM.

- Page 32 Field Service Ver. 1.0 Jul. 2006 8.13.7 DEFAULT SUBJECT ................. 100 8.14 SCANNER SETTING..................101 8.14.1 RESOLUTION................... 101 8.14.2 IMAGE FORMAT..................101 8.14.3 CODING METHOD ................... 101 User service mode ....................102 User service mode function tree............... 102 FAX MAINTENANCE..................103 9.2.1 TX SPEED ....................

- Page 33 Field Service Ver. 1.0 Jul. 2006 10.4.6 TOTAL SCAN .................... 109 10.5 TX/RX RESULT ....................109 10.6 PRINT REPORT....................110 10.6.1 TX RESULT REPORT................110 10.6.2 RX RESULT REPORT ................110 10.6.3 ACTIVITY REPORT.................. 110 10.6.4 MEMORY DATA LIST................110 10.6.5 MEMORY IMAGE PRINT .................

- Page 34 Field Service Ver. 1.0 Jul. 2006 11.4.7 ADF SUB ZOOM..................125 11.4.8 ADF MAIN REGIST .................. 125 11.4.9 ADF SUB REGIST ..................126 11.4.10 DMAX......................126 11.4.11 1st TRANSFER VOLTAGE ................ 126 11.4.12 2nd TRANSFER VOLTAGE............... 126 11.4.13 VPP OFFSET.................... 127 11.4.14 ROHS......................

- Page 35 Field Service Ver. 1.0 Jul. 2006 11.10 FIXED ZOOM CHANGE................... 139 11.11 FACTORY TEST....................139 11.12 CLEAR DATA....................140 11.12.1 SRAM CLEAR ..................140 11.12.2 MEMORY CLEAR..................140 SOFT SWITCH set ..................... 141 12.1 Description ....................... 141 12.2 Default setting....................141 12.2.1 Country for each marketing area ..............

- Page 36 Field Service Ver. 1.0 Jul. 2006 12.3.27 SOFT SWITCH: #27 ................. 189 12.3.28 SOFT SWITCH: #28 ................. 190 12.3.29 SOFT SWITCH: #29 ................. 191 12.3.30 SOFT SWITCH: #30 ................. 192 12.3.31 SOFT SWITCH: #31 ................. 193 12.3.32 SOFT SWITCH: #32 ................. 193 12.3.33 SOFT SWITCH: #33 .................

- Page 37 Field Service Ver. 1.0 Jul. 2006 12.3.64 SOFT SWITCH: #62 ................. 214 12.3.65 SOFT SWITCH: #63 ................. 214 12.3.66 SOFT SWITCH: #64 ................. 215 Fax Protocols ...................... 216 13.1 G3 ECM (G3 Error Correction Mode) ............... 216 13.2 Line control ....................... 217 13.2.1 Procedure of G3 mode communication ............

- Page 38 Field Service Ver. 1.0 Jul. 2006 15.4.12 18H: Heating roller warm-up failure ............242 15.4.13 19H: Abnormally low heating roller temperature ........242 15.4.14 1AH: Abnormally high heating roller temperature ........242 15.4.15 1BH: Faulty thermistor ................242 15.4.16 21H: Faulty OHP sensor ................243 15.4.17 23H: Faulty waste toner near full detection board........

- Page 39 Field Service Ver. 1.0 Jul. 2006 17.2.17 Colored spots.................... 266 17.2.18 Blurred image ................... 267 17.2.19 Blank copy, black copy ................268 17.2.20 Incorrect color image registration ............. 269 17.2.21 Poor fusing performance, offset..............270 17.2.22 Brush effect, blurred image............... 271 17.2.23 Back marking ....................

-

Page 40: Lower Feeder Unit

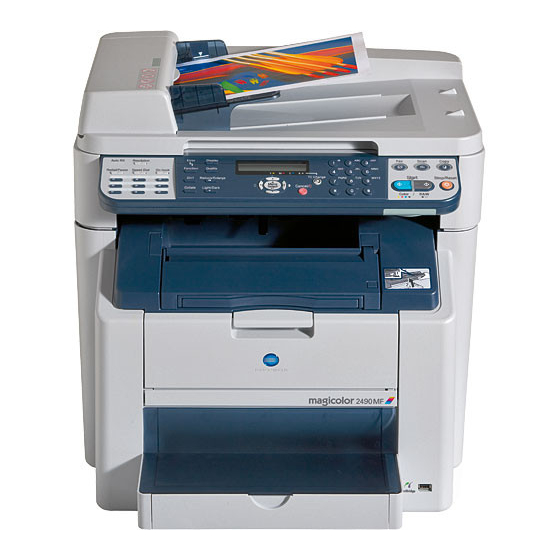

Field Service Ver. 1.0 Jul. 2006 1. System configuration General System configuration Machine Front View 4139T2E562AA magicolor 2490MF Lower Feeder Unit Duplex Option Dust Cover* *: Standard for U.S.A and Europe... -

Page 41: Product Specifications

2. Product specifications Field Service Ver. 1.0 Jul. 2006 Product specifications A. Type Type Desktop Printing system Semiconductor laser and electrostatic image transfer to plain paper Exposure system 2 laser diodes and polygon mirror PC drum type OPC (organic photo conductor) Photoconductor Blade cleaning system cleaning... - Page 42 Field Service Ver. 1.0 Jul. 2006 2. Product specifications B. Functions Average: 45 seconds (100 V area) Warm-up time Average: 49 seconds (200 - 240 V area) (at ambient temperature of 23 °C/73.4 °F and rated source voltage) Plain paper 126.78 mm/second System speed Thick stock...

-

Page 43: Built-In Controllers

2. Product specifications Field Service Ver. 1.0 Jul. 2006 E. Operating Environment 10 °C to 35 °C / 50 °F to 95 °F (with a fluctuation of 10 °C / 18 °F or less per Temperature hour) Humidity 15% to 85% (with a fluctuation of 20% or less per hour) Built-in Controllers Embedded RISC processor 48MHz 128 MB on IPB... -

Page 44: Fax Specifications

Field Service Ver. 1.0 Jul. 2006 2. Product specifications Fax specifications Standard (203 dpi x 98 dpi) Resolution Fine (203 dpi x 196 dpi) Super fine (203 dpi x 392dpi) Standard/Fine/Super fine Halftone level Half tone standard/Half tone fine/Half tone super fine Receive Supported Automatic reduction... - Page 45 2. Product specifications Field Service Ver. 1.0 Jul. 2006 Blank Page...

-

Page 46: Maintenance

Field Service Ver. 1.0 Jul. 2006 3. Periodic check Maintenance Periodic check Maintenance parts • To ensure that the machine produces good prints and to extend its service life, it is recommended that the maintenance jobs described in this schedule be carried out as instructed. •... -

Page 47: Cleaning Parts

3. Periodic check Field Service Ver. 1.0 Jul. 2006 B. Parts to be replaced by service engineers (FRUs) Classifi- Ref. Part name Replacement cycle cation ntity Page about 36,800 Standard print pages about 135,000 Continuous print pages Mono- chrome about 45,000 Image Transfer belt unit 1P/J... -

Page 48: Concept Of Parts Life

Field Service Ver. 1.0 Jul. 2006 3. Periodic check Concept of parts life Max. printed Description Life Value pages/image The period of time during which the main motor is Drum cartridge 4,500 prints energized is counted. Fusing unit The number of printed pages is counted. 120,000 prints 2nd transfer roller The number of printed pages is counted. -

Page 49: Maintenance Procedure

3. Periodic check Field Service Ver. 1.0 Jul. 2006 Maintenance procedure NOTE • The alcohol referred to in the following procedures is isopropyl alcohol. 3.3.1 Paper feed roller A. Cleaning procedure 1. Pull the lever [1] and swing open the IR unit [2]. - Page 50 Field Service Ver. 1.0 Jul. 2006 3. Periodic check 4. Using a soft cloth dampened with alcohol, wipe the pick-up roller [1] clean of dirt. 4139F2C516DA B. Removal procedure 1. Open the top cover. See P.31 2. Remove the drum cartridge. See P.16 NOTE •...

- Page 51 3. Periodic check Field Service Ver. 1.0 Jul. 2006 3. Remove the paper feed roller [1]. 4139F2C517DA...

-

Page 52: Ph Window

Field Service Ver. 1.0 Jul. 2006 3. Periodic check 3.3.2 PH window A. Cleaning procedure 1. Pull the lever [1] and swing open the IR unit [2]. NOTE • Note that the IR unit cannot be swung up with the Auto Document Feeder Unit in its raised position 4139F2C514DA 2. - Page 53 3. Periodic check Field Service Ver. 1.0 Jul. 2006 5. Hold onto the handle [1] of the toner cartridge, pull it and remove the toner cartridge [2]. 4139F2C520DA B. Reinstallation procedure NOTE • Do not let the toner cartridge stand upright or keep it in that upright position.

- Page 54 Field Service Ver. 1.0 Jul. 2006 3. Periodic check 3. Remove the protective cover [1]. 4139fs2504c0 4. Aligning the shaft [1] on both sides of the toner cartridge with the rails in the machine, install the toner car- tridge [2]. 4139F2C521DA 5.

-

Page 55: Drum Cartridge

3. Periodic check Field Service Ver. 1.0 Jul. 2006 3.3.4 Drum cartridge A. Replacement procedure 1. Pull the lever [1] and swing open the IR unit [2]. NOTE • Note that the IR unit cannot be swung up with the Auto Document Feeder Unit in its raised position 4139F2C514DA 2. -

Page 56: Transfer Belt Unit

Field Service Ver. 1.0 Jul. 2006 3. Periodic check 3.3.5 Transfer belt unit A. Replacement procedure 1. Pull the lever [1] and swing open the IR unit [2]. NOTE • Note that the IR unit cannot be swung up with the Auto Document Feeder Unit in its raised position 4139F2C514DA 2. -

Page 57: 2Nd Transfer Roller

3. Periodic check Field Service Ver. 1.0 Jul. 2006 4. Remove two shoulder screws [1]. 5. Remove the transfer belt unit [2]. NOTE • When replacing the transfer belt unit, use care not to touch the sur- face of the belt. A scratchy or dirty belt could result in image problems. - Page 58 Field Service Ver. 1.0 Jul. 2006 3. Periodic check 2. Open the top cover. See P.31 3. Remove the drum cartridge. See P.16 4. Remove the 2nd transfer roller assy [3] as follows. While pushing the levers [2] of the holders [1] located on both sides, pull the holders [1] to the front.

-

Page 59: Fusing Unit

3. Periodic check Field Service Ver. 1.0 Jul. 2006 3.3.7 Fusing unit NOTE • Before replacing the fusing unit, ensure that it has had time to cool down. 1. Remove the rear cover. See P.31 2. Remove the left cover. See P.31 3. - Page 60 Field Service Ver. 1.0 Jul. 2006 3. Periodic check 10. Remove the screw [1]. 11. Disconnect four connectors [2] and remove the power switch [3]. NOTE • At reinstallation, make sure of the correct position of each connector. Color of connector Color of harness White Black Black...

- Page 61 3. Periodic check Field Service Ver. 1.0 Jul. 2006 14. Disconnect two connectors (MPJ2, MPJ3) [1] from the image processing board. 4139F2C662DA 15. Remove nine screws [1] and remove the left frame [2]. 4139F2C537DA 16. Remove two screws [1] and remove the left guide assy [2].

- Page 62 Field Service Ver. 1.0 Jul. 2006 3. Periodic check CAUTION • When the left guide assy is mounted after the fusing unit has been installed, make sure that the harness of the fusing unit is placed under the left guide assy. 4139F2C539DA 17.

- Page 63 3. Periodic check Field Service Ver. 1.0 Jul. 2006 20. Remove two screws [1] and remove the fusing unit [2]. 21. To reinstall, reverse the order of removal. CAUTION • Make sure that the docking gear shaft of the fusing unit fits in the hole of the fusing frame.

-

Page 64: Firmware Upgrade

Field Service Ver. 1.0 Jul. 2006 4. Firmware upgrade Firmware upgrade Controller firmware upgrading 4.1.1 Preparations for firmware upgrading NOTE • Make sure that the scanner driver has been installed in the PC. • Before updating the firmware, print Configuration Page to confirm the current Controller Firmware Version. - Page 65 4. Firmware upgrade Field Service Ver. 1.0 Jul. 2006 8. Firmware updating starts. ERASE FLASH ROM FIREMWARE UPDATE 4139F2E654DA 9. When [Transfer Successfully!] message appears on the screen, click [OK] to close the execution tool. 4139F2E655DA 10. Confirm that [FIRMWARE UPDATE OK] message has been displayed, and turn OFF/ ON the machine's main switch.

-

Page 66: Nic Firmware Upgrading

Field Service Ver. 1.0 Jul. 2006 4. Firmware upgrade NIC firmware upgrading 4.2.1 Preparations for firmware upgrading NOTE • Make sure that the machine's network is correctly connected to the PC. • Before updating the firmware, print Configuration Page to confirm the current NIC Firmware Version. - Page 67 4. Firmware upgrade Field Service Ver. 1.0 Jul. 2006 8. When [Transfer Successfully!] message appears on the screen, click [OK] to close the execution tool. 4139F2E655DA 9. Confirm that [FIRMWARE UPDATE OK] message has been displayed, and turn OFF/ ON the machine's main switch. FIREMWARE UPDATE OK MACHINE POWER OFF/ON 4139F2E656DA...

-

Page 68: Other

Field Service Ver. 1.0 Jul. 2006 5. Other Other Disassembly/adjustment prohibited items A. Black-painted screws • Do not remove or loosen any of the black-painted screws in the field. Any of such screws that has been removed calls for readjustment at reinstallation. B. -

Page 69: Disassembly/Assembly List (Other Parts)

5. Other Field Service Ver. 1.0 Jul. 2006 Disassembly/assembly list (other parts) Section Part name Ref.Page Top cover P.31 Rear cover P.31 Left cover P.31 Exterior parts Right cover P.32 Paper feed cover P.32 Front cover P.32 Original glass unit P.33 Operation board P.34... -

Page 70: Disassembly/Assembly Procedure

Field Service Ver. 1.0 Jul. 2006 5. Other Disassembly/Assembly procedure 5.3.1 Top cover 1. Open the IR unit. 2. Pull the lever and swing open the upper cover [1]. NOTE • Use care not to touch the transfer belt [2]. 4139F2C515DA 5.3.2 Rear cover... -

Page 71: Right Cover

5. Other Field Service Ver. 1.0 Jul. 2006 5.3.4 Right cover 1. Open the IR unit. 2. Remove the rear cover. See P.31 3. Open the top cover. See P.31 4. Remove four screws [1]. 5. Remove the tab [2] and the right cover [3]. -

Page 72: Original Glass Unit

Field Service Ver. 1.0 Jul. 2006 5. Other 5.3.7 Original glass unit 1. Remove the Auto Document Feeder Unit. See P.7 of the Auto Document Feeder Unit service manual. 2. Open the IR unit. NOTE • If the IR unit is to be opened with the Auto Document Feeder Unit removed, do that while pushing the portion [1]. -

Page 73: Operation Board (Opb)

5. Other Field Service Ver. 1.0 Jul. 2006 6. Open the IR unit. 7. Remove two screws [1], IR unit left cover [2], and IR unit right cover [3]. NOTE • To unhook the tab, insert your fin- ger into the hole below the hinge and try to push the cover outward. - Page 74 Field Service Ver. 1.0 Jul. 2006 5. Other 3. Remove three screws [1]. 4. Disconnect two connectors [2] and remove the ground wire [3]. Then, remove the control panel [4]. 4139F2C663DA 5. Disconnect the connector [1]. 6. Remove seven screws [2], two brackets [3], and the operation board [4].

-

Page 75: Operation Key Board (Okb)

5. Other Field Service Ver. 1.0 Jul. 2006 5.3.9 Operation key board (OKB) 1. Open the IR unit. 2. Remove the three caps [1]. 4139F2C613DA 3. Remove three screws [1]. 4. Disconnect two connectors [2] and remove the ground wire [3]. Then, remove the control panel [4]. -

Page 76: Usb Board (Usb)

Field Service Ver. 1.0 Jul. 2006 5. Other 5.3.10 USB board (USB) 1. Remove the right cover. See P.32 2. Remove two screws [1] and discon- nect the connector [2]. Then, remove the USB board assy [3]. 4139F2C615DA 3. Remove two screws [1] and the USB board [2]. - Page 77 5. Other Field Service Ver. 1.0 Jul. 2006 6. Remove five screws [1] and remove the interface metal plate [2]. 4139F2C666DA 7. Remove four wire saddle [1] and dis- connect all connectors from the image processing board [2]. 4139F2C667DA 8. Remove seven screws [1]. 9.

-

Page 78: Printer Control Board (Prcb)

Field Service Ver. 1.0 Jul. 2006 5. Other 5.3.12 Printer control board (PRCB) 1. Remove the rear cover. See P.31 2. Remove the screw [1] and the con- nector protective bracket [2]. 3. Disconnect all connectors and flat cables from the printer control board. 4139F2C549DA 4. -

Page 79: Dc Power Supply 1 (Dcpu1)

5. Other Field Service Ver. 1.0 Jul. 2006 NOTE • When mounting parameter chip (PJ24), align the notches (indicated by “A” in the illustration). 4138fs2544c0 5.3.13 DC power supply 1 (DCPU1) 1. Remove the printer control board. See P.39 2. Remove the image processing board. - Page 80 Field Service Ver. 1.0 Jul. 2006 5. Other 6. Remove nine screws [1] and pull the DC power supply1 assy [2] toward you. NOTE • Do not pull the power unit assy hard, as a number of harnesses are connected to it. 4139F2C559DA 7.

-

Page 81: Dc Power Supply 2 (Dcpu2)

5. Other Field Service Ver. 1.0 Jul. 2006 5.3.14 DC power supply 2 (DCPU2) 1. Remove the left cover. See P.31 2. Remove the screw [1]. 3. Remove two saddles [2] and discon- nect two connectors [3]. Then, remove the DC power supply 2 Assy [4]. -

Page 82: Waste Toner Near Full Detect Board/Led (Wtdtb/Led)

Field Service Ver. 1.0 Jul. 2006 5. Other 3. Remove four screws [1]. 4139F2C561DA 4. Disconnect two connectors [1] and remove the high voltage unit [2]. 4139F2C546DA Precautions for reinstallation of the high voltage unit • Make sure that the high voltage unit fits into the tab [1] at the location shown on the left. -

Page 83: Ncu Board

5. Other Field Service Ver. 1.0 Jul. 2006 3. Remove three tabs [1] and the waste toner near full detect board/LED [2]. 4139F2C597DA 4. Disconnect the connector [2] of the waste toner near full detect board/ LED [1]. 4139F2C598DA 5.3.17 NCU board 1. -

Page 84: Lan Board

Field Service Ver. 1.0 Jul. 2006 5. Other 4. Remove three screws [1] and the NCU board [2]. Then, remove the protection film [3]. NOTE • Make sure to reinstall the protection film. 4139F2C661DA 5.3.18 LAN board 1. Remove the rear cover. See P.31 2. -

Page 85: Scanner Unit

5. Other Field Service Ver. 1.0 Jul. 2006 5.3.19 Scanner unit 1. Remove the original glass unit. See P.33 2. Remove the shaft [1] and belt [2]. 3. Disconnect the flat cable [3], and remove the scanner unit [4]. NOTE •... - Page 86 Field Service Ver. 1.0 Jul. 2006 5. Other 6. Remove the screw [1] and harness holding bracket [2]. 4139F2C590DA 7. Disconnect two flat cables [1] and the connector [2] from the image pro- cessing board. 4139F2C591DA 8. Remove three wire saddle [1]. 9.

- Page 87 5. Other Field Service Ver. 1.0 Jul. 2006 10. Open the IR unit. 11. Remove two screws [1], IR unit left cover [2], and IR unit right cover [3]. NOTE • To unhook the tab, insert your fin- ger into the hole below the hinge and try to push the cover outward.

- Page 88 Field Service Ver. 1.0 Jul. 2006 5. Other 13. Remove the stopper [1] and the IR unit [2]. 4139F2C617DA...

-

Page 89: Ph Unit

5. Other Field Service Ver. 1.0 Jul. 2006 5.3.21 PH unit CAUTION • Do not replace the PH unit while the machine is turned ON. The laser beam that may be emitted can blind you. • Do not attempt to disassemble or adjust the PH unit. The laser beam that may be emitted can blind you. - Page 90 Field Service Ver. 1.0 Jul. 2006 5. Other 8. Remove the speaker. See P.76 9. Remove nine screws [1] and the right frame [2]. 4139F2C563DA 10. Remove the screw [1], bracket [2], and the guide [3]. 4139F2C595DA 11. Remove the wiring saddle [1]. 12.

- Page 91 5. Other Field Service Ver. 1.0 Jul. 2006 13. Disconnect the connector (PJ20) [1] and the flat cable (PJ19) [2] from the printer control board. 4139F2C566DA 14. Disconnect the connector (P3) [1] from the image processing board. 4139F2C674DA 15. Press the rack release lever [1] and then rotate the rack [2] so that the toner cartridge [3] is moved to a position, at which the toner cartridge...

- Page 92 Field Service Ver. 1.0 Jul. 2006 5. Other 16. Hold onto the handle, pull it and remove the toner cartridge [1]. 17. Repeat steps 14 and 15 to remove all toner cartridges. 4139F2C569DA 18. Remove the drum cartridge. See P.16 NOTE •...

- Page 93 5. Other Field Service Ver. 1.0 Jul. 2006 20. Press the rack release lever and turn the rack so that the screw on the PH unit can be accessed through the hole in the machine frame. 21. Remove three screws [1] and the PH unit [2].

-

Page 94: Paper Feed Unit

Field Service Ver. 1.0 Jul. 2006 5. Other 5.3.22 Paper feed unit 1. Remove the rear cover. See P.31 2. Remove the right cover. See P.32 3. Remove the left cover. See P.31 4. Remove the high voltage unit and shield. See steps 1 to 2 of the removal procedure for “Tray1 paper pick-up solenoid (SD1)”... -

Page 95: Main Motor (M1)

5. Other Field Service Ver. 1.0 Jul. 2006 10. Unhook two dowels [1] and remove the paper feed unit [2]. 4139F2C602DA 5.3.23 Main motor (M1) 1. Remove the IR unit. See P.46 2. Remove two screws [1] and the fix- ing base [2]. -

Page 96: Power Supply Cooling Fan Motor (Fm1)

Field Service Ver. 1.0 Jul. 2006 5. Other 4. Remove the speaker. See P.76 5. Remove nine screws [1] and the right frame [2]. 4139F2C563DA 6. Remove four screws [1], disconnect the connector [2], and remove the main motor [3]. 4139F2C578DA 5.3.24 Power supply cooling fan motor (FM1) - Page 97 5. Other Field Service Ver. 1.0 Jul. 2006 3. Remove the screw [1] and the top right cover [2]. 4139F2C562DA 4. Remove the speaker. See P.76 5. Remove nine screws [1] and the right frame [2]. 4139F2C563DA 6. Disconnect the connector (PJ4) [1] from the printer control board.

-

Page 98: Ventilation Fan Motor (Fm2)

Field Service Ver. 1.0 Jul. 2006 5. Other 7. Remove the screw [1], bracket [2], and guide [3]. 4139F2C595DA 8. Remove the wiring saddle [1]. 9. Remove the screw [2] and the har- ness cover [3]. 4139F2C565DA 10. Remove the tab [1] and the power supply cooling fan motor [2]. - Page 99 5. Other Field Service Ver. 1.0 Jul. 2006 3. Remove the screw [1] and the top right cover [2]. 4139F2C562DA 4. Remove the speaker. See P.76 5. Remove nine screws [1] and the right frame [2]. 4139F2C563DA 6. Remove two screws [1] and the bracket [2].

-

Page 100: Fusing Motor (M4)

Field Service Ver. 1.0 Jul. 2006 5. Other 7. Disconnect the connector [1] of the ventilation fan motor and remove the harness from the wiring saddle [2]. 4139F2C575DA 8. Remove five tabs [1] and the ventila- tion fan motor [2]. 4139F2C576DA 5.3.26 Fusing motor (M4) -

Page 101: Developing Motor (M3)

5. Other Field Service Ver. 1.0 Jul. 2006 4. Remove the speaker. See P.76 5. Remove nine screws [1] and the right frame [2]. 4139F2C563DA 6. Remove two screws [1] and discon- nect the connector [2]. 7. Remove the harness from the wiring saddle [3] and remove the fusing motor [4]. - Page 102 Field Service Ver. 1.0 Jul. 2006 5. Other Precautions for reinstallation of the safety switch assy • Check that the switch is actuated with the front cover and the Upper Cover closed. • Make sure that the distance between the switch lever and switch case (with the switch in the actuated position) falls within the specified range.

-

Page 103: Rack Motor (M2)

5. Other Field Service Ver. 1.0 Jul. 2006 5.3.28 Rack motor (M2) 1. Remove the rack drive assy. See steps 1 through 5 of the removal procedure for “developing motor (M3)” on P.62. 2. Remove two screws [1], disconnect the connector [2], and remove the developing motor [3]. -

Page 104: Ir Cooling Fan Motor (Fm3)

Field Service Ver. 1.0 Jul. 2006 5. Other 5. Remove two screws [1] and the scanner motor [2]. 4139F2C630DA 5.3.30 IR cooling fan motor (FM3) 1. Remove the rear cover. See P.31 2. Remove two screws [1] and the IR cooling fan motor cover [2]. -

Page 105: Tray1 Paper Pick-Up Solenoid (Sd1)

5. Other Field Service Ver. 1.0 Jul. 2006 4. Remove two screws [1] and the IR cooling fan motor [2]. 4139F2C620DA 5.3.31 Tray1 paper pick-up solenoid (SD1) 1. Remove the high voltage unit. See P.42 2. Remove the screw [1], unlock the tab [2], and remove the wiring saddle [3]. -

Page 106: Registration Roller Solenoid (Sd2)

Field Service Ver. 1.0 Jul. 2006 5. Other 5.3.32 Registration roller solenoid (SD2) 1. Remove the power supply cooling fan motor. See P.57 2. Remove the tab [1] and the guide [2]. 4139F2C581DA 3. Disconnect the connector [1] and remove the screw [2]. Then, remove the registration roller solenoid [3]. -

Page 107: Pressure/Retraction Solenoid /Cleaning Blade (Sd3)

5. Other Field Service Ver. 1.0 Jul. 2006 5.3.33 Pressure/retraction solenoid /cleaning blade (SD3) 1. Remove the IR unit. See P.46 2. Remove two screws [1] and the fix- ing base [2]. 4139F2C553DA 3. Remove the screw [1] and the top right cover [2]. -

Page 108: Pressure/Retraction Solenoid /2Nd Image Transfer (Sd4)

Field Service Ver. 1.0 Jul. 2006 5. Other 6. Remove the screw [1] and discon- nect the connector [2]. Then, remove the pressure/retraction solenoid/ cleaning blade [3]. 4139F2C584DA 5.3.34 Pressure/retraction solenoid /2nd image transfer (SD4) 1. Remove the power supply cooling fan motor. -

Page 109: Temperature/Humidity Sensor (Tem/Hums)

5. Other Field Service Ver. 1.0 Jul. 2006 5.3.35 Temperature/humidity sensor (TEM/HUMS) 1. Remove the front cover. See P.32 2. Remove the c-clip [1]. 4139F2C621DA 3. Remove the tray 1 [1]. NOTE • Use care not to lose the two springs. -

Page 110: Idc Sensor (Idc)

Field Service Ver. 1.0 Jul. 2006 5. Other 5.3.36 IDC sensor (IDC) 1. Remove the transfer belt unit. See P.17 2. Remove two screws [1] and the IDC sensor protective cover [2]. 4139F2C604DA 3. Disconnect the connector [1] and remove the IDC sensor [2]. 4139F2C603DA 5.3.37 Torque limiter... - Page 111 5. Other Field Service Ver. 1.0 Jul. 2006 B. Reinstallation procedure NOTE • There are five slots provided in the coupling gear [1] of the Paper Feed Clutch. These slots are for adjust- ing the position of the Feed Roller. When the torque limiter [2] is rein- stalled, it is necessary to adjust the position of the coupling gear [1]...

-

Page 112: Inlet Assy

Field Service Ver. 1.0 Jul. 2006 5. Other 5.3.38 Inlet assy 1. Pull the lever [1] and swing open the IR unit [2]. NOTE • Note that the IR unit cannot be swung up with the Auto Document Feeder Unit in its raised position 4139F2C514DA 2. - Page 113 5. Other Field Service Ver. 1.0 Jul. 2006 7. Remove the screw [1]. 8. Disconnect four connectors [2] and remove the Power Switch [3]. NOTE • At reinstallation, make sure of the correct position of each connector. Color of connector Color of harness White Black Black...

- Page 114 Field Service Ver. 1.0 Jul. 2006 5. Other 11. Disconnect two connectors (MPJ2, MPJ3) [1] from the image processing board. 4139F2C662DA 12. Remove nine screws [1] and the left frame [2]. 4139F2C537DA 13. Remove the screw [1] and remove the bracket [2]. 14.

-

Page 115: Speaker (Sp)

5. Other Field Service Ver. 1.0 Jul. 2006 CAUTION • NEVER unplug the faston terminals from the Inlet. If the terminals are unplugged, do not use the inlet assy. Be sure to use a new inlet assy (Inlet + har- nesses) 4139F2C542DA 5.3.39... -

Page 116: Adjustment/Setting

Field Service Ver. 1.0 Jul. 2006 6. How to use the adjustment section Adjustment/Setting How to use the adjustment section • “Adjustment/Setting” contains detailed information on the adjustment items and proce- dures for this machine. • Throughout this “Adjustment/Setting,” the default settings are indicated by “ ”. A. -

Page 117: Description Of The Control Panel

7. Description of the control panel Field Service Ver. 1.0 Jul. 2006 Description of the control panel Control panel display 7.1.1 Main screen 4139F3E506DA Name Description Document type Displays the type of the document currently set. Zoom ratio Displays the zoom ratio currently set. •... -

Page 118: Menu Mode

Field Service Ver. 1.0 Jul. 2006 8. Menu mode Menu mode Menu mode function tree • The press of the Menu/Select key will display the menu of the following functions. • <*>: This function becomes available only when the optional tray2 is mounted on the machine. - Page 119 8. Menu mode Field Service Ver. 1.0 Jul. 2006 Ref. Menu Mode page RX SETTING 1 MEMORY RX MODE P.88 2 NO. of RINGS P.88 3 REDUCTION RX P.88 4 RX PRINT P.92 5 RX MODE P.92 6 FOOTER P.92 7 SELECT TRAY P.93 COMM.

- Page 120 Field Service Ver. 1.0 Jul. 2006 8. Menu mode Ref. Menu Mode page E-MAIL SETTING 1 SENDER NAME P.99 2 E-MAIL ADDRESS P.99 3 SMTP SERVER P.100 4 SMTP PORT NO. P.100 5 SMTP TIMEOUT P.100 6 TEXT INSERT P.100 7 DEFAULT SUBJECT P.100 SCANNER SETTING...

-

Page 121: Machine Setting

8. Menu mode Field Service Ver. 1.0 Jul. 2006 MACHINE SETTING 8.2.1 AUTO PANEL RESET • Sets the period of time after which the initial screen reappears after the last print job is Function received or the last panel key is operated. •... -

Page 122: Buzzer Volume

Field Service Ver. 1.0 Jul. 2006 8. Menu mode 8.2.6 BUZZER VOLUME Function • To set the volume of alarms and the beep sounded when a key is pressed. • The default setting is LOW. Setting/ procedure HIGH “LOW” 8.2.7 INITIAL MODE Function •... -

Page 123: Paper Source Setup

8. Menu mode Field Service Ver. 1.0 Jul. 2006 PAPER SOURCE SETUP 8.3.1 TRAY1 PAPER Function • Sets the type and size of the paper loaded in tray1. • When the type and size of the paper loaded in tray1 have been changed •... -

Page 124: Copy Setting

Field Service Ver. 1.0 Jul. 2006 8. Menu mode COPY SETTING 8.4.1 MODE Function • Sets the type of document used. • When the type of document has been changed • The default setting is MIX. “MIX” TEXT PHOTO Setting/ procedure MIX: Mix manual density TEXT: Text auto density, Text manual density... -

Page 125: Paper Priority

8. Menu mode Field Service Ver. 1.0 Jul. 2006 8.4.6 PAPER PRIORITY Function • Selects the priority tray. • To change the priority tray • The default setting is TRAY1. Setting/ “TRAY1” TRAY2 procedure NOTE • [*NOT AVAILABLE*] is displayed if tray2 is not mounted in the machine. FAX REGISTRATION 8.5.1 ONE-TOUCH DIAL... -

Page 126: Tx Setting

Field Service Ver. 1.0 Jul. 2006 8. Menu mode TX SETTING 8.6.1 SCAN DENSITY • This function can be used to set the default scanning contrast level to one of three set- Function tings between [LIGHT] and [DARK]. • For dark-colored paper (media), select a setting towards [LIGHT]. For faint or colored text, select a setting toward [DARK]. -

Page 127: Rx Setting

8. Menu mode Field Service Ver. 1.0 Jul. 2006 RX SETTING 8.7.1 MEMORY RX MODE Function • This function can be used to set whether to allow [ON] memory reception or not [OFF]. In cases when confidential faxes are being received, the received document can be stored in the memory and printed at a specified time or when memory reception is set to [OFF]. - Page 128 Field Service Ver. 1.0 Jul. 2006 8. Menu mode (1) Reduction print mode • It reduces (only the FD direction) and prints so that receiving data will in a recording paper. Recording Footer Length of received image Printing paper size Less than 289 mm 1 page with 100% 290 mm to 385 mm...

- Page 129 8. Menu mode Field Service Ver. 1.0 Jul. 2006 (2) 100% RX mode • All receiving data is divided into 2 pages or more, and is printed. Recording Footer Length of received image Printing paper size Less than 289 mm 1 page 290 mm to 570 mm Divide into 2 pages...

- Page 130 Field Service Ver. 1.0 Jul. 2006 8. Menu mode (3) Cut mode • The data that is larger than 1-page record area is cut and not recorded (to 24 mm). Recording Footer Length of received image Printing paper size Less than 289 mm 1 page 290 mm to 313 mm Print into 1 page.

-

Page 131: Rx Print

8. Menu mode Field Service Ver. 1.0 Jul. 2006 Recording Footer Length of received image Printing paper size Less than 347 mm 1 page 348 mm to 371 mm Print into 1 page. 1 mm to 24 mm of end is cut. 372 mm to 686 mm Divide into 2 pages 687 mm to 710 mm... -

Page 132: Select Tray

Field Service Ver. 1.0 Jul. 2006 8. Menu mode (1) Attaching footer print When footer is selected ON, it is printed at the end of printable area. 4 mm line area from the end of printable area is kept for printing footer. It should be attached on footer area regardless of image length. -

Page 133: Comm. Setting

8. Menu mode Field Service Ver. 1.0 Jul. 2006 COMM. SETTING 8.8.1 TEL LINE TYPE Function • This function can be used to specify the dialing system. If this function is not correctly set to the type of dialing system used, faxes cannot be sent. Select the correct setting after checking which type of dialing system is used by your telephone line. -

Page 134: Reporting

Field Service Ver. 1.0 Jul. 2006 8. Menu mode REPORTING 8.9.1 ACTIVITY REPORT Function • Every 60 transmissions/receptions, a report can be printed to show the results of the transmissions/receptions. This function can be used to set whether the report is printed automatically when the 60th transmission/ reception is reached. -

Page 135: User Setting

8. Menu mode Field Service Ver. 1.0 Jul. 2006 8.10 USER SETTING 8.10.1 FAX PTT SETTING Function • Sets the country where this machine is installed. • To change the country where this machine is installed. • The default setting is USA. “USA”... -

Page 136: User Fax No

Field Service Ver. 1.0 Jul. 2006 8. Menu mode 8.10.5 USER FAX NO. Function • Enter user fax number. • The specified number is printed in the header of sent faxes. Setting/ • Max. 20 digits. procedure • The characters which can be inputted are “numbers from 0 to 9”, “Space”, “+” and “-.” 8.10.6 USER NAME Function... -

Page 137: N-Up Layout

8. Menu mode Field Service Ver. 1.0 Jul. 2006 8.11.3 N-UP LAYOUT Function • Sets the number of images printed on one page for camera direct photo printing. • To specify the number of camera direct photo printing images to be printed on each sheet. -

Page 138: Gateway

8.13 E-MAIL SETTING 8.13.1 SENDER NAME Function • This function is used to specify the sender’s name. Setting/ • The default setting is “magicolor 2490MF”. procedure • Up to 20 characters can be entered for the sender name. 8.13.2 E-MAIL ADDRESS Function •... -

Page 139: Smtp Server

8. Menu mode Field Service Ver. 1.0 Jul. 2006 8.13.3 SMTP SERVER Function • This function is used to enter the IP address or host name of an SMTP server. NOTE • Please consult customer’s network administrator for information about the IP address to use. -

Page 140: Scanner Setting

Field Service Ver. 1.0 Jul. 2006 8. Menu mode 8.14 SCANNER SETTING 8.14.1 RESOLUTION Function • The default settings for resolution used by the scan to e-mail and scan to server (FTP) functions can be specified. • The default setting is “300 x 300”. Setting/ procedure 150 x 150... -

Page 141: User Service Mode

9. User service mode Field Service Ver. 1.0 Jul. 2006 User service mode User service mode function tree A. Procedure 1. On the initial screen, press the Menu/Select key to call [MACHINE SETTING] to the screen. 2. Keep on pressing key over two seconds. -

Page 142: Fax Maintenance

Field Service Ver. 1.0 Jul. 2006 9. User service mode FAX MAINTENANCE 9.2.1 TX SPEED Function • Transmit start speed setting. Choose the mode from among the following. • The default setting is “V.34 33600”. “V.34”: “33600”, 31200, 28800, 26400, 24000, 21600, 19200, 16800 Setting/ V.17: 14400, 12000, 9600, 7200 procedure... -

Page 143: Cng Level

9. User service mode Field Service Ver. 1.0 Jul. 2006 9.2.6 CNG LEVEL Function • Calling tone output level. • The default setting is “-11 dBm”. Setting/ procedure -17 to -12 dBm “-11 dBm” -10 to -2 dBm 9.2.7 CED LEVEL Function •... -

Page 144: Toner Empty Report

Field Service Ver. 1.0 Jul. 2006 9. User service mode 9.2.10 TONER EMPTY REPORT Function • Select to generate a report to a specific destination when toner empty status occurs in the engine. • The default setting is “OFF”. Generate a report to report destination. “OFF”: Not to generate report. -

Page 145: Sru Usage

9. User service mode Field Service Ver. 1.0 Jul. 2006 SRU USAGE 9.3.1 TRANSFER BELT Function • Displays the remaining life of the transfer belt. • To check the remaining life of the maintenance service parts. 9.3.2 FUSER UNIT Function •... -

Page 146: Transfer Roller

Field Service Ver. 1.0 Jul. 2006 9. User service mode 9.4.3 TRANSFER ROLLER • Resets the counter value of the transfer roller. Function • Executes the image stabilization sequence. • To reset the transfer roller counter after the transfer roller is replaced. 1. -

Page 147: Display Mode

10. Display mode Field Service Ver. 1.0 Jul. 2006 10. Display mode 10.1 Display function tree • Pressing the Display key will display the menu of the following functions. Ref. DISPLAY page TONER REMAINING P.108 TOTAL PAGE B/W COPY P.109 COLOR COPY P.109 B/W PRINT... -

Page 148: Total Page

Field Service Ver. 1.0 Jul. 2006 10. Display mode 10.4 TOTAL PAGE 10.4.1 B/W COPY Function • Displays the number of monochrome copies made. • When checking the number of monochrome copies made 10.4.2 COLOR COPY Function • Displays the number of color copies made. •... -

Page 149: Print Report

10. Display mode Field Service Ver. 1.0 Jul. 2006 10.6 PRINT REPORT 10.6.1 TX RESULT REPORT Function • The [SESSION], [FUNCTION], [NO.], [DESTINATION STATION], [DATE], [TIME], [PAGE], [DURATION], [MODE], and [RESULT] are printed. 1. Press the Display key, then the key three times. -

Page 150: One-Touch List

Field Service Ver. 1.0 Jul. 2006 10. Display mode 10.6.6 ONE-TOUCH LIST Function • The recipients programmed in the one-touch dial keys are printed in numerical order of the keys. 1. Press the Display key, then the key three times. Setting/ 2. -

Page 151: Demo Page

10. Display mode Field Service Ver. 1.0 Jul. 2006 10.6.11 DEMO PAGE Function • Prints the demo page. 1. Press the Display key, then the key three times. Setting/ 2. Check that the [PRINT REPORT] screen appears, and then press the Menu Select key. procedure 3. -

Page 152: Service Mode

Field Service Ver. 1.0 Jul. 2006 11. SERVICE MODE 11. SERVICE MODE 11.1 SERVICE MODE entry procedure NOTE • Ensure appropriate security for the Service Mode entry procedure. It should NEVER be given to any unauthorized person. A. Procedure 1. On the initial screen, press the Menu/Select key to call [MACHINE SETTING] to the screen. - Page 153 11. SERVICE MODE Field Service Ver. 1.0 Jul. 2006 Ref. SERVICE MODE page 2. ADJUST PRN MAIN REGIST P.119 PRN SUB REGIST P.120 CCD MAIN ZOOM P.121 CCD SUB ZOOM P.122 CCD MAIN REGIST P.123 CCD SUB REGIST P.124 ADF SUB ZOOM P.125 ADF MAIN REGIST P.125...

- Page 154 Field Service Ver. 1.0 Jul. 2006 11. SERVICE MODE Ref. SERVICE MODE page 4. DISPLAY MAIN F/W VER. P.129 ENGINE F/W VER. P.129 NIC F/W VER. P.129 MAIN RAM SIZE P.129 SERIAL NO. P.129 BB CPLD VER. P.129 NAND CODE VER. P.129 5.

-

Page 155: Service's Choice

11. SERVICE MODE Field Service Ver. 1.0 Jul. 2006 11.3 SERVICE’S CHOICE 11.3.1 TX SPEED Function • Transmit start speed setting. Choose the mode from among the following. • The default setting is “V.34 33600”. “V.34”: “33600”, 31200, 28800, 26400, 24000, 21600, 19200, 16800 Setting/ V.17: 14400, 12000, 9600, 7200 procedure... -

Page 156: Cng Level

Field Service Ver. 1.0 Jul. 2006 11. SERVICE MODE 11.3.6 CNG LEVEL Function • Calling tone output level. • The default setting is “-11 dBm”. Setting/ procedure -17 to -12 dBm “-11 dBm” -10 to -2 dBm 11.3.7 CED LEVEL Function •... -

Page 157: Toner Empty Report

11. SERVICE MODE Field Service Ver. 1.0 Jul. 2006 11.3.10 TONER EMPTY REPORT Function • Select to generate a report to a specific destination when toner empty status occurs in the engine. • The default setting is “OFF”. Generate a report to report destination. “OFF”: Not to generate report. -

Page 158: Adjust

Field Service Ver. 1.0 Jul. 2006 11. SERVICE MODE 11.4 ADJUST 11.4.1 PRN MAIN REGIST Function • To vary and adjust the print start position in the main scanning direction. • If the image on the copy deviates in the main scan direction •... -

Page 159: Prn Sub Regist

11. SERVICE MODE Field Service Ver. 1.0 Jul. 2006 11.4.2 PRN SUB REGIST Function • To vary and adjust the print start position in the sub-scanning direction. • If the image on the copy deviates in the sub scan direction •... -

Page 160: Ccd Main Zoom

Field Service Ver. 1.0 Jul. 2006 11. SERVICE MODE 11.4.3 CCD MAIN ZOOM • To adjust for variations in the accuracy of IR parts and their mounting accuracy by Function varying the scanning zoom ratio in the main scanning direction. •... -

Page 161: Ccd Sub Zoom

11. SERVICE MODE Field Service Ver. 1.0 Jul. 2006 11.4.4 CCD SUB ZOOM • To adjust for variations in the accuracy of IR parts and their mounting accuracy by Function varying the scanning zoom ratio in the sub-scanning direction. • When the Scanner unit has been replaced NOTE •... -

Page 162: Ccd Main Regist

Field Service Ver. 1.0 Jul. 2006 11. SERVICE MODE 11.4.5 CCD MAIN REGIST • To adjust for variations in the accuracy of IR parts and their mounting accuracy by vary- Function ing the scanning start position in the main scanning direction. •... -

Page 163: Ccd Sub Regist

11. SERVICE MODE Field Service Ver. 1.0 Jul. 2006 11.4.6 CCD SUB REGIST • To adjust for variations in the accuracy of IR parts and their mounting accuracy by Function varying the scanning start position in the sub-scanning direction. • When the original glass is replaced. •... -

Page 164: Adf Sub Zoom

Field Service Ver. 1.0 Jul. 2006 11. SERVICE MODE 11.4.7 ADF SUB ZOOM • To adjust for variations in the accuracy of all parts and their mounting accuracy by vary- Function ing the scanning zoom ratio in the sub-scanning direction when using the Automatic Document Feeder. -

Page 165: Adf Sub Regist

11. SERVICE MODE Field Service Ver. 1.0 Jul. 2006 11.4.9 ADF SUB REGIST • To adjust for variations in the accuracy of all parts and their mounting accuracy by vary- Function ing the scanning start position in the sub-scanning direction when using the Automatic Document Feeder. -

Page 166: Vpp Offset

Field Service Ver. 1.0 Jul. 2006 11. SERVICE MODE 11.4.13 VPP OFFSET • Optimizes the image by varying the output value of the developing bias when an image Function problem occurs due to the atmospheric pressure at high altitudes. • To adjust the developing when an image problem (uneven density) occurs in an environ- ment of low atmospheric pressure in places such as at high altitudes. -

Page 167: Counter

11. SERVICE MODE Field Service Ver. 1.0 Jul. 2006 11.5 COUNTER 11.5.1 TOTAL PRINT A. MONO COPY Function • Displays the number of monochrome copies made. • When checking the number of monochrome copies made B. COLOR COPY Function • Displays the number of color copies made. •... -

Page 168: Display

Field Service Ver. 1.0 Jul. 2006 11. SERVICE MODE 11.6 DISPLAY 11.6.1 MAIN F/W VER. Function • Displays the version of the controller firmware. • When upgrading the firmware • When the image processing board has been replaced with a new one 11.6.2 ENGINE F/W VER. -

Page 169: Function

11. SERVICE MODE Field Service Ver. 1.0 Jul. 2006 11.7 FUNCTION 11.7.1 PAPER FEED TEST • To check the paper feeding in the paper take-up/transport sections without printing on Function the paper. • When a paper misfeed occurs 1. Select the paper tray. 2. -

Page 170: Adf Feed Test

Field Service Ver. 1.0 Jul. 2006 11. SERVICE MODE 11.7.3 ADF FEED TEST • To check the paper feeding in the paper take-up/transport sections in the Automatic Function Document Feeder. • When a document misfeed occurs 1. Load paper into the Automatic Document Feeder. Setting/ 2. -

Page 171: Fax Res. Copy Test

11. SERVICE MODE Field Service Ver. 1.0 Jul. 2006 11.7.6 FAX RES. COPY TEST Function • Fax resolution copy test • To check whether the encoding/ decoding process is correct Setting/ • The paper source is fixed to Tray1. (Tray cannot be changed.) procedure •... -

Page 172: Soft Switch

Field Service Ver. 1.0 Jul. 2006 11. SERVICE MODE 11.8 SOFT SWITCH • Refer to the chapter of soft switch for the explanation of soft switch. See P.141 SERVICE MODE 6. SOFT SWITCH 6. SOFT SWITCH #01=10000000 Bit No. 1 2 3 4 5 6 7 8 4139F3E529DA 11.8.1 KEY DEFINITION FOR SOFT SWITCH... - Page 173 11. SERVICE MODE Field Service Ver. 1.0 Jul. 2006 (1) SERVICE DATA LIST (example) SERVICE DATA LIST NAME : DATE :JUN. 05. 2006 13:58 --SOFT SWITCH – SW01-SW16 SW17-SW32 SW33-SW48 SW49-SW64 --COMMUNICATION HISTORY & COUNTER – 000001: ECM RX TIME 000000: ECM TX TIME 000008: G3 RX TIME 000000: G3 RX PAGE...

- Page 174 Field Service Ver. 1.0 Jul. 2006 11. SERVICE MODE (2) ERROR LOG HISTORY LIST (example) • The following table is the error log history. The table keeps the last 40 records only. ERROR LOG HISTORY LIST Index Error Maker Tele. 0001 :00A0 4230...

-

Page 175: Error Code List

11. SERVICE MODE Field Service Ver. 1.0 Jul. 2006 11.9.2 ERROR CODE LIST Function • Print error code (CODE) and error occurrence time (ERROR TIMES). 1. Enter the [SERVICE MODE]. Setting/ 2. Select [REPORT] and press the Menu Select key. procedure 3. -

Page 176: Protocol List

Field Service Ver. 1.0 Jul. 2006 11. SERVICE MODE 11.9.3 T.30 PROTOCOL LIST Function Print out T.30 or V8 protocol after communication. • SESSION: Session number • FUNCTION: Function Name • DESTINATION STATION: Destination Name/Tel. No. • DATE/TIME: Communication Date & Time •... - Page 177 11. SERVICE MODE Field Service Ver. 1.0 Jul. 2006 (2) V.34 Communication (example) PROTOCOL MONITOR REPORT NAME:TMFP TEL :886 3 4733507 DATE:JUN.10.2006 12:10 SESSION FUNCTION NO. DESTINATION STATION DATE TIME PAGE DURATION MODE RESULT 0001 001 ABC OCT.27 17:19 00h00min03s ECM 22345678901234567890 DATA V.8 PROTOCOL DUMP...

-

Page 178: Fixed Zoom Change

Field Service Ver. 1.0 Jul. 2006 11. SERVICE MODE 11.10 FIXED ZOOM CHANGE Function • The fixed zoom ratios can be changed. 1. Enter the [SERVICE MODE]. Setting/ 2. Select [FIXED ZOOM CHANGE] and press the Menu Select key. procedure 3. -

Page 179: Clear Data

11. SERVICE MODE Field Service Ver. 1.0 Jul. 2006 11.12 CLEAR DATA 11.12.1 SRAM CLEAR To clear the settings for the functions listed at the right and return the functions to their Function default settings. The following items are cleared (initialization). •... -

Page 180: Soft Switch Set

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12. SOFT SWITCH set 12.1 Description This machine is equipped with totally 64 soft switches that are used for fax adjustment in order to conform to the standard of each country. The default setting is changeable. -

Page 181: Soft Switch List

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.2.2 Soft switch list Soft Switch No. Bit No. Designation Page No. V.34 CI signal byte number P.168 Time between phase C to phase D signal in V.17 Header TX selection open to user P.169 Transmit MCF signal level criteria Sent N.G page... - Page 182 Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set Soft Switch No. Bit No. Designation Page No. ECM mode capability V.34 fall back counter for V.34 TX Send CTC after 4th PPR P.178 Send EOR after lowest speed TCF transmission timing after DCS signal MR capability for G3 Delay time between transaction Super fine printing capability for receiving...

- Page 183 12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 Soft Switch No. Bit No. Designation Page No. 8/7/6/5 Time to dial after dial tone on the line P.190 4/3/2/1 CED duration time within calling period 5/4/3/2/1 Time To Dial after seize the line when dial tone detection P.191 Pause Delay Time Within Digits P.192...

- Page 184 Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set Soft Switch No. Bit No. Designation Page No. Reserved P.202 Close network P.203 Daylight savings timer RX print mode Default TX mode P.203 Header for FAX TX Print model name on top of TX page if name not register RX mode P.204 Footer...

-

Page 185: Default Soft Switch Setting For Each Market Area

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.2.3 Default soft switch setting for each market area A. Market area 1 Marketing area United Kingdom Argentina Australia Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0... - Page 186 Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set Marketing area United Kingdom Argentina Australia Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 1 1 1 1 0 0 0 0 1 1 1 1 0 0 0 0 1 1 1 1 0 0 0 0 1 1 1 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0...

- Page 187 12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 B. Market area 2 Marketing area Austria Belgium Brazil Canada Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 1 1 0 0 0 1 1 0 1 1 0 0 0 1 1 0 1 1 0 0 0 0 1 0 1 1 0 0 0 0 1...

- Page 188 Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set Marketing area Austria Belgium Brazil Canada Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0...

- Page 189 12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 C. Market area 3 Marketing area China Czech Denmark Europe Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 1 1 0 0 0 0 1 0 1 1 0 0 0 0 1 0 1 1 0 0 0 1 1 0 1 1 0 0 0 1 1...

- Page 190 Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set Marketing area China Czech Denmark Europe Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0...

- Page 191 12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 D. Market area 4 Marketing area Finland France Germany Greece Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 1 1 0 0 0 1 1 0 1 1 0 0 0 1 1 0 1 1 0 0 0 1 1 0 1 1 0 0 0 1 1...

- Page 192 Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set Marketing area Finland France Germany Greece Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0...

- Page 193 12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 E. Market area 5 Marketing area Hong Kong Hungary Ireland Israel Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 1 1 0 0 0 0 1 0 1 1 0 0 0 1 1 0 1 1 0 0 0 1 1 0 1 1 0 0 0 0 1...

- Page 194 Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set Marketing area Hong Kong Hungary Ireland Israel Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0...

- Page 195 12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 F. Market area 6 Marketing area Italy Japan Korea Malaysia Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 1 1 0 0 0 1 1 0 1 1 0 0 0 0 1 0 1 1 0 0 0 0 1 0 1 1 0 0 0 0 1...

- Page 196 Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set Marketing area Italy Japan Korea Malaysia Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0...

- Page 197 12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 G. Market area 7 Marketing area Mexico Netherlands New Zealand Norway Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 1 1 0 0 0 0 1 0 1 1 0 0 0 1 1 0 1 1 0 0 0 1 1 0 1 1 0 0 0 1 1...

- Page 198 Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set Marketing area Mexico Netherlands New Zealand Norway Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0...

- Page 199 12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 H. Market area 8 Marketing area Philippines Poland Portugal Russia Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 1 1 0 0 0 0 1 0 1 1 0 0 0 0 1 0 1 1 0 0 0 1 1 0 1 1 0 0 0 0 1...

- Page 200 Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set Marketing area Philippines Poland Portugal Russia Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0...

- Page 201 12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 Market area 9 Marketing area Saudi Arabia Singapore Slovakia South Africa Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 1 1 0 0 0 0 1 0 1 1 0 0 0 0 1 0 1 1 0 0 0 0 1 0 1 1 0 0 0 0 1...

- Page 202 Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set Marketing area Saudi Arabia Singapore Slovakia South Africa Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0...

- Page 203 12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 J. Market area 10 Marketing area Spain Sweden Switzerland Taiwan Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 1 1 0 0 0 1 1 0 1 1 0 0 0 1 1 0 1 1 0 0 0 1 1 0 1 1 0 0 0 0 1...

- Page 204 Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set Marketing area Spain Sweden Switzerland Taiwan Soft Switch No. Bit No. Bit No. Bit No. Bit No. 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0...

- Page 205 12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 K. Market area 11 Marketing area Turkey Soft Switch No. Bit No. 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 1 1 0 0 0 1 1 0 0 1 1 0 0 0 0 0 1 0 1 0 0 1 1...

- Page 206 Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set Marketing area Turkey Soft Switch No. Bit No. 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0...

-

Page 207: Soft Switch Definition

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3 Soft switch definition 12.3.1 SOFT SWITCH: #01 Initial Bit No. Designation Function Setting Reserved Reserved Byte 9 bytes 30 bytes 15 bytes 60 bytes number V.34 CI signal byte number Bit No. -

Page 208: Soft Switch: #02

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.2 SOFT SWITCH: #02 Initial Setting Bit No. Designation Function Time between phase 70 ms C to phase D signal in 120 ms 180 ms 60 ms Insensitivity V.17 Bit No. 8 Example: Image Bit No. -

Page 209: Soft Switch: #03

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.3 SOFT SWITCH: #03 Initial Setting Bit No. Designation Function 1: Yes Send out NSF frame with station ID 0: No 0: No any limitation Number of Pause within phone number 1: Max. -

Page 210: Soft Switch: #04

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.4 SOFT SWITCH: #04 Initial Setting Bit No. Designation Function Reserved Reserved 0: No Visible alarm for RTN 1: Yes - display message while sending / receiving signal RTN signal (RTN= Retrain Negative). 0: No Audible alarm for RTN signal... -

Page 211: Soft Switch: #05

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.5 SOFT SWITCH: #05 Initial Setting Bit No. Designation Function ON:100 ON: 70 Timing ON: 70 ON: 90 OFF:140 OFF70 OFF: 140 OFF: 90 Push Button ON/OFF (ms) Timing (PB) Bit No. -

Page 212: Soft Switch: #06

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.6 SOFT SWITCH: #06 Initial Setting Bit No. Designation Function Timing 50 ms 100 ms 150 ms 800 ms Ring on time to ignore (ms) ring off time at 1st Bit No. -

Page 213: Soft Switch: #07

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.7 SOFT SWITCH: #07 Initial Setting Bit No. Designation Function 0: Disable Dial tone or busy tone detection 1: Enable - Detect dial tone before dial 0: PSTN PSTN/PBX setting 1: PBX - Select PBX line type 0: Not to detect dial tone before pre-fix number PBX dial tone detect... -

Page 214: Soft Switch: #08

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.8 SOFT SWITCH: #08 Initial Setting Bit No. Designation Function 1: (Normal, Fine)=(6,12) continue error line Sending RTN signal level 0: (Normal, Fine)=(12,24) continue error line 0: Not to detect Detect busy tone after dialing 1: Detect busy tone after dialing... -

Page 215: Soft Switch: #09

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.9 SOFT SWITCH: #09 Initial Setting Bit No. Designation Function Ringer frequency 10 to 75 20 to 57.5 20 to 75 10 to 75 Ringer frequency range (Hz) detection Bit No. 8 Bit No. -

Page 216: Soft Switch: #10

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.10 SOFT SWITCH: #10 Initial Setting Bit No. Designation Function 0: Not to Print Print out RTN page 1: Print Out RTN page report after transaction for TX/ report RX RTN signal 0: Print “OK”... -

Page 217: Soft Switch: #11

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.11 SOFT SWITCH: #11 Initial Setting Bit No. Designation Function Reserved Reserved 0: No Detect dial tone after pre-fix number 1: Yes 0: Yes Pulse dial allowed to select 1: Not allowed 0: Not to display Protocol signal Dis- play mode... -

Page 218: Soft Switch: #13

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.13 SOFT SWITCH: #13 Initial Setting Bit No. Designation Function 0: Yes MR capability for G3 1: No Description (sec) Delay time between Bit No. 7 transaction Bit No. 6 0: No Super fine printing capability for receiving... -

Page 219: Soft Switch: #14

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.14 SOFT SWITCH: #14 Initial Setting Bit No. Designation Function Reserved Reserved 1: Up to 128 KB Memory size level To 0: Base on system configuration Reserved Reserved Timer (ms) 80 100 120 140 160 Time between V.34 Bit No. -

Page 220: Soft Switch: #16

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.16 SOFT SWITCH: #16 Initial Setting Bit No. Designation Function Reserved Reserved Coding JBIG method Fax communication coding method Bit No. 2 Bit No. 1 12.3.17 SOFT SWITCH: #17 Initial Setting Bit No. -

Page 221: Soft Switch: #18

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.18 SOFT SWITCH: #18 Initial Setting Bit No. Designation Function Reserved Reserved Definition Level1 Level2 Level3 Level4 G3 mode training Bit No. 6 quality level Bit No. 5 Counter Redefine re-dial Bit No. -

Page 222: Soft Switch: #19

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.19 SOFT SWITCH: #19 Initial Setting Bit No. Designation Function Level (dBm) -17 -16 -15 -14 -13 -12 Bit No. 8 Bit No. 7 Bit No. 6 Bit No. 5 CNG signal level Level (dBm) -9 Bit No. -

Page 223: Soft Switch: #20

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.20 SOFT SWITCH: #20 Initial Setting Bit No. Designation Function Reserved Reserved Interval (min) 1 2 3 4 5 6 7 8 9 10 11 Bit No. 5 0 0 0 0 0 0 0 0 0 Bit No. -

Page 224: Soft Switch: #21

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.21 SOFT SWITCH: #21 Initial Setting Bit No. Designation Function 0: Not to send NSS signal for self mode in TX mode NSS signal before 1: Send NSS signal if remote side is same model Duration (unit=sec) CNG sending duration Bit No. -

Page 225: Soft Switch: #22

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.22 SOFT SWITCH: #22 Initial Setting Bit No. Designation Function 1: Check busy tone within dial tone detection Detect busy tone before dial 0: Not to check 1: Yes - Check dial tone after dialing Regard dial tone as busy tone after dialing 0: No... -

Page 226: Soft Switch: #24

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.24 SOFT SWITCH: #24 Initial Setting Bit No. Designation Function Reserved Reserved 12.3.25 SOFT SWITCH: #25 Initial Bit No. Designation Function Setting Reserved Reserved Flash time (ms) Flash key time in ON Bit No. -

Page 227: Soft Switch: #26

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.26 SOFT SWITCH: #26 Initial Setting Bit No. Designation Function Time (unit=sec) Dial tone detection time before discon- Bit No. 8 nected Bit No. 7 Level (dBm) 0 -1 -2 -3 -4 -5 -6 -7 -8 -9 -10 Bit No. -

Page 228: Soft Switch: #27

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.27 SOFT SWITCH: #27 Initial Setting Bit No. Designation Function Reserved Reserved Level (dBm) Bit No. 4 Bit No. 3 Bit No. 2 Bit No. 1 Immunity for Dial Tone receiver Level (dBm) -8 -13 -14 -15... -

Page 229: Soft Switch: #28

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.28 SOFT SWITCH: #28 Initial Setting Bit No. Designation Function Time (msec) 100 200 300 400 500 600 700 Bit No. 8 Bit No. 7 Bit No. 6 Bit No. 5 Time to dial after dial tone on the line Time (msec) 800 900... -

Page 230: Soft Switch: #29

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.29 SOFT SWITCH: #29 Initial Setting Bit No. Designation Function Reserved Reserved Time (sec) 0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 Bit No. 5 Bit No. 4 Bit No. -

Page 231: Soft Switch: #30

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.30 SOFT SWITCH: #30 Initial Setting Bit No. Designation Function Pause Delay Time Time (sec) Within Digits Bit No. 8 Ex. 002Pxxxxxx Bit No. 7 Level (dBm) 0 -1 -2 -3 -4 -5 -6 -7 -8 -9 -10 Bit No. -

Page 232: Soft Switch: #31

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.31 SOFT SWITCH: #31 Initial Setting Bit No. Designation Function Reserved Reserved 12.3.32 SOFT SWITCH: #32 Initial Bit No. Designation Function Setting Reserved Reserved... -

Page 233: Soft Switch: #33

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.33 SOFT SWITCH: #33 Initial Setting Bit No. Designation Function Reserved Reserved 0: off V.17 Echo protection tone 1: On 0: Off V.29 Echo protection tone 1: On Compromise equalize 0: No enable (CEQ) in the 1: Yes... -

Page 234: Soft Switch: #35

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.35 SOFT SWITCH: #35 Initial Bit No. Designation Function Setting Time (ms) 1000 2000 Dial tone table switch Bit No. 8 time Bit No. 7 Dial tone frequency See Bit No. 1 to 3 upper range index Frequency 375 to 462... -

Page 235: Soft Switch: #36

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.36 SOFT SWITCH: #36 Initial Setting Bit No. Designation Function Re-dial attempts con- 0: No any limitation tinue fail counter (Using for detect line 1: limit up to bit 1 to 4 problem error) Reserved Reserved... -

Page 236: Soft Switch: #37

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.37 SOFT SWITCH: #37 Initial Setting Bit No. Designation Function 0: V.34 Polling TX type for V.34 modem 1: V.17 0: Yes - skip V.34 handshaking with remote side Auto dial learning for V.34 modem 1: No - retry from V.8 handshake RX start symbol rate... -

Page 237: Soft Switch: #38

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.38 SOFT SWITCH: #38 Initial Setting Bit No. Designation Function Fine tune of 33.6 1: Yes kbps/ 31.2 kbps receiving speed for 0: No - modem default setting V.34 modem 0: Reset Set/Reset V.34 trans- mit level deviation... -

Page 238: Soft Switch: #39

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.39 SOFT SWITCH: #39 Initial Setting Bit No. Designation Function 1: Yes Disable V.34 TX for V.34 modem 0: No 1: Yes Disable V.34 RX for V.34 modem 0: No Flags number Flags number in FSK Bit No. -

Page 239: Soft Switch: #40

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.40 SOFT SWITCH: #40 Initial Setting Bit No. Designation Function V.17 V.17 V.17 V.17 Speed (bps) 14400 12200 9600 7200 Bit No. 8 Bit No. 7 Bit No. 6 Bit No. 5 V.29 V.29 V.27... -

Page 240: Soft Switch: #41

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.41 SOFT SWITCH: #41 Initial Setting Bit No. Designation Function V.17 V.17 V.17 V.17 Speed (bps) 14400 12200 9600 7200 Bit No. 8 Bit No. 7 Bit No. 6 Bit No. 5 V.29 V.29 V.27... -

Page 241: Soft Switch: #42

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.42 SOFT SWITCH: #42 Initial Setting Bit No. Designation Function Reserved Reserved 12.3.43 SOFT SWITCH: #43 Initial Bit No. Designation Function Setting Reserved Reserved 12.3.44 SOFT SWITCH: #44 Initial Setting Bit No. -

Page 242: Soft Switch: #45

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.45 SOFT SWITCH: #45 Initial Setting Bit No. Designation Function Reserved Reserved 0: Off Close network 1: On Reserved Reserved 12.3.46 SOFT SWITCH: #46 Initial Bit No. Designation Function Setting 0: No Daylight savings timer 1: Yes... -

Page 243: Soft Switch: #47

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.47 SOFT SWITCH: #47 Initial Setting Bit No. Designation Function Reserved Reserved 0: Auto RX mode RX mode 1: Manual RX mode 0: Off Footer 1: On - Print footer information at each of received page Reserved Reserved •... -

Page 244: Soft Switch: #49

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.49 SOFT SWITCH: #49 Initial Setting Bit No. Designation Function Reserved Reserved 0: Base on RX RESULT REPORT setting Print RX Mailbox Report method 1: Always printing 0: Re-dial again Re-dial method if Comm. -

Page 245: Soft Switch: #51

12. SOFT SWITCH set Field Service Ver. 1.0 Jul. 2006 12.3.51 SOFT SWITCH: #51 Initial Setting Bit No. Designation Function Reserved Reserved Print report Print report Not to Description for each while reporting T30 monitor report print used transaction error selection Bit No. -

Page 246: Soft Switch: #53

Field Service Ver. 1.0 Jul. 2006 12. SOFT SWITCH set 12.3.53 SOFT SWITCH: #53 Initial Setting Bit No. Designation Function Reserved Reserved 12.3.54 SOFT SWITCH: #54 Initial Bit No. Designation Function Setting 0: Digits format Report Date/Time type 1: Alpha numeric format When bit No.8 is “1”. -

Page 247: Soft Switch: #55