Vogelsang VX186Q Manuals

Manuals and User Guides for Vogelsang VX186Q. We have 2 Vogelsang VX186Q manuals available for free PDF download: Operating Instructions Manual

Vogelsang VX186Q Operating Instructions Manual (77 pages)

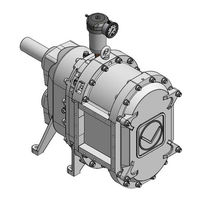

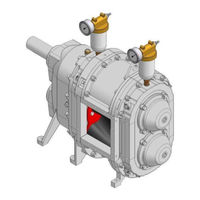

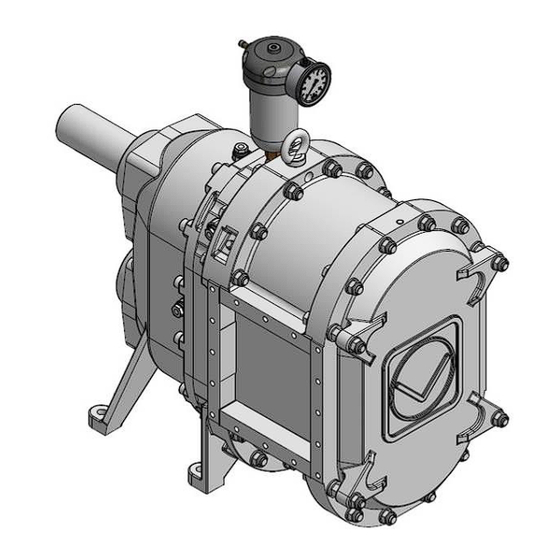

Rotary Lobe Pump

Brand: Vogelsang

|

Category: Water Pump

|

Size: 3 MB

Table of Contents

Advertisement

Vogelsang VX186Q Operating Instructions Manual (61 pages)

Rotary lobe pump

Brand: Vogelsang

|

Category: Water Pump

|

Size: 3 MB

Table of Contents

Advertisement