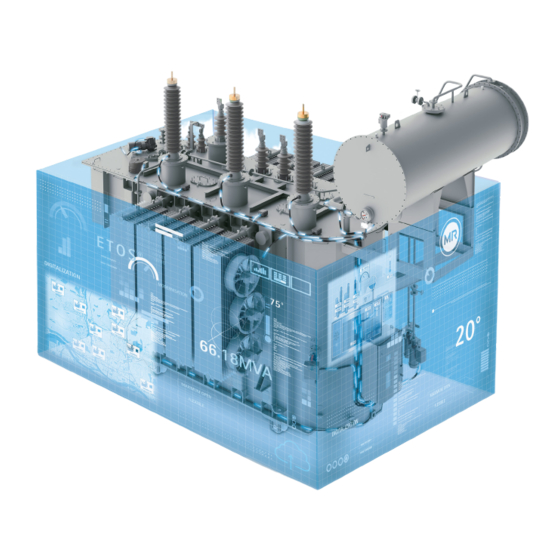

MR ETOS ED Motor Drive Unit Manuals

Manuals and User Guides for MR ETOS ED Motor Drive Unit. We have 1 MR ETOS ED Motor Drive Unit manual available for free PDF download: Operating Instructions Manual

Advertisement

Advertisement