Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

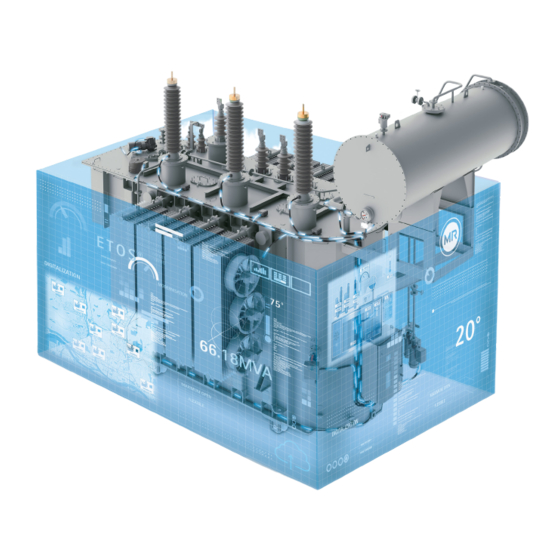

Summary of Contents for MR ETOS ED

- Page 1 Motor-drive unit ® ETOS Operating Instructions 6385142/08 EN...

- Page 2 © All rights reserved by Maschinenfabrik Reinhausen Dissemination and reproduction of this document and use and disclosure of its content are strictly prohibited unless expressly permitted. Infringements will result in liability for compensation. All rights reserved in the event of the granting of patents, utility models or designs.

-

Page 3: Table Of Contents

Table of contents Table of contents Introduction........................ 12 Manufacturer............................. 12 Completeness........................... 12 Safekeeping............................ 12 Notation conventions ........................ 12 1.4.1 Hazard communication system ........................... 12 1.4.2 Information system.............................. 14 1.4.3 Instruction system ............................... 14 1.4.4 Typographic conventions ............................ 15 Safety.......................... 16 Appropriate use .......................... 16 Fundamental safety instructions ....................... - Page 4 Connecting the ISM® assemblies .................... 70 6.4.1 Cable recommendation (ISM® assemblies)...................... 70 6.4.2 Information about connecting serial interfaces RS232 and RS485.............. 71 6.4.3 Notes on connecting to the MR sensor bus ...................... 73 6.4.4 Information about connecting analog sensors .................... 78 6.4.5 Electromagnetic compatibility.......................... 81 6.4.6 Connecting cables to the system periphery ...................... 84...

- Page 5 Table of contents 7.2.3 Checking tripping of motor protective switch....................... 91 7.2.4 Checking functional reliability.......................... 92 Tests on the transformer........................ 92 7.3.1 High-voltage tests on the transformer ......................... 92 7.3.2 Dielectric tests on transformer wiring ........................ 93 Transporting transformer to the operating site.................. 93 Commissioning the transformer at the operating site ...............

- Page 6 Table of contents 9.8.5 Configuring Modbus (optional) .......................... 131 9.8.6 Configuring DNP3 (optional) .......................... 133 9.8.7 Configuring GOOSE (optional).......................... 135 9.8.8 Configure data points (optional) ........................ 140 9.8.9 Display status of the SCADA connection ...................... 147 Name plate ............................. 148 9.9.1 Enter the name plate data.......................... 148 9.9.2 Displaying the name plate.......................... 149 9.10...

- Page 7 Table of contents 9.18 Transformer data .......................... 196 9.18.1 Setting transformer data............................ 197 9.18.2 Circuit examples for voltage transformers and current transformers .............. 199 9.19 Measurement.......................... 212 9.19.1 UI measuring channels ............................. 212 9.19.2 Control variable .............................. 213 9.19.3 Regulation mode ............................... 213 9.19.4 Display power factor negative ........................... 213 9.20 Line drop compensation .........................

- Page 8 Displaying the measured value trend of the oil level and dehydrating breather (optional)........ 273 9.27 Dissolved gas analysis (optional) .................... 273 9.27.1 Configuring DGA monitoring .......................... 274 9.27.2 Displaying measured values .......................... 277 9.28 MR sensor bus.......................... 282 9.28.1 Configuring MR sensor bus.......................... 283 9.28.2 Managing sensors............................. 284 9.28.3 Function assignment ............................ 286 9.28.4 Defining the sensors ............................ 286...

- Page 9 Table of contents 9.31.4 Displaying maintenance overview........................ 303 9.31.5 Displaying the maintenance logbook ........................ 303 9.31.6 Suppressing a maintenance event........................ 305 9.32 Torque monitoring (optional)...................... 306 9.32.1 Tap-change ranges (windows) M1...M8...................... 306 9.32.2 Types of tap-change operations........................ 306 9.32.3 Limit values ............................... 307 9.32.4 Tap-change supervisory control........................ 308 9.32.5 Evaluated and unevaluated tap-change operations.................. 308 9.32.6...

- Page 10 Table of contents Fault elimination ...................... 349 10.1 Safety instructions .......................... 349 10.2 General information ........................ 349 10.3 Fault in the environment of the motor-drive unit ................ 350 10.4 Fault in the motor-drive unit when the switching operation has not ended........ 350 10.5 Fault in the motor-drive unit after the switching operation is ended correctly.........

- Page 11 Table of contents 14.5.7 AIO 8 analog inputs and outputs........................ 389 14.5.8 CPU (central processing unit) I ......................... 390 14.5.9 System networking............................ 392 14.5.10 Ambient conditions............................ 394 14.5.11 Standards and directives........................... 394 Glossary .......................... 397 List of key words ...................... 399 ® Maschinenfabrik Reinhausen GmbH 2020 6385142/08 EN ETOS...

-

Page 12: Introduction

1 Introduction 1 Introduction This technical file contains detailed descriptions on the safe and proper in- stallation, connection, commissioning and monitoring of the product. It also includes safety instructions and general information about the prod- uct. This technical file is intended solely for specially trained and authorized per- sonnel. - Page 13 1 Introduction 1.4.1.1 Warning relating to section Warnings relating to sections refer to entire chapters or sections, sub-sec- tions or several paragraphs within this technical file. Warnings relating to sections use the following format: Type of danger! WARNING Source of the danger and outcome. ►...

-

Page 14: Information System

1 Introduction Pictogram Definition Warning of combustible substances Warning of danger of tipping Warning of danger of crushing Table 2: Pictograms used in warning notices 1.4.2 Information system Information is designed to simplify and improve understanding of particular procedures. In this technical file it is laid out as follows: Important information. -

Page 15: Typographic Conventions

1 Introduction Aim of action ü Requirements (optional). 1. Step 1. ð Result of step (optional). 2. Step 2. ð Result of step (optional). ð Result of action (optional). 1.4.4 Typographic conventions Typographic convention Purpose Example UPPERCASE Operating controls, switches ON/OFF [Brackets] PC keyboard... -

Page 16: Safety

2 Safety 2 Safety ▪ Read this technical file through to familiarize yourself with the product. ▪ This technical file is a part of the product. ▪ Read and observe the safety instructions provided in this chapter. ▪ Read and observe the warnings in this technical file in order to avoid func- tion-related dangers. -

Page 17: Fundamental Safety Instructions

2 Safety ▪ The provided hand crank is for activating the motor-drive unit during in- stallation and tests in the transformer plant or during maintenance tasks if the transformer has been disconnected. ▪ For details about using the hand crank in emergency operation when the transformer is energized, refer to the "Operation"... - Page 18 2 Safety Invisible laser radiation Looking directly into the beam or the reflected beam can cause eye damage. The beam is emitted at the optical connections or at the end of the fiber-optic cables connected to them on the assemblies. Read the chapter "Technical Data"...

- Page 19 2 Safety Explosion protection Highly flammable or explosive gases, vapors and dusts can cause serious explosions and fire. This increases the danger to life and limb. ▪ Do not install, operate or perform maintenance work on the product in ar- eas where a risk of explosion is present.

-

Page 20: Personnel Qualification

2 Safety 2.3 Personnel qualification The person responsible for assembly, commissioning, operation, mainte- nance and inspection must ensure that the personnel are sufficiently quali- fied. Electrically skilled person The electrically skilled person has a technical qualification and therefore has the required knowledge and experience, and is also conversant with the ap- plicable standards and regulations. -

Page 21: Personal Protective Equipment

2 Safety 2.4 Personal protective equipment Personal protective equipment must be worn during work to minimize risks to health. ▪ Always wear the personal protective equipment required for the job at hand. ▪ Never wear damaged personal protective equipment. ▪ Observe information about personal protective equipment provided in the work area. -

Page 22: Security

3 IT security 3 IT security Observe the following recommendations to operate the product safely. General ▪ Ensure that only authorized personnel have access to the device. ▪ Only use the device within an ESP (electronic security perimeter). Do not connect the device to the Internet in an unprotected state. - Page 23 3 IT security Interfaces The device uses the following interfaces for communication: Figure 1: ETH1.1 interface on the OT1205 assembly Interface Protocol Port Description ETH1.1 FTP service access ETH1.1 Web visualization ETH1.1 SSL-protected web visualization ETH1.1 SSL-protected FTP service access ETH1.1 8080 Web visualization (alternative port) ETH1.1...

- Page 24 ETH 2.x (only for MR service) ETH 2.x HTTP for web-based visualization ETH 2.x HTTPS for web-based visualization ETH 2.x FTPS (only for MR service) ETH 2.x 8080 HTTP for web-based visualization ETH 2.x 8081 HTTPS for web-based visualization ETH 2.x SNMP Table 6: Interfaces and open ports of the CPU assembly...

- Page 25 3 IT security The device uses the following cipher suites for a TLS-secured connection: Key exchange Authentication Encryption Key length Operating Hash func- mode tion ECDHE WITH SHA265 ECDHE ECDSA SHA256 ECDH SHA256 SHA384 Table 7: Cipher suite Not available with TLS version >= 1.2 The device uses the SHA256 hash function to save passwords.

-

Page 26: Product Description

4 Product description 4 Product description 4.1 Scope of delivery The motor-drive unit is packaged with protection against moisture and is de- livered as follows: ▪ Motor-drive unit ▪ Product documentation Please note the following: 1. Check the shipment for completeness on the basis of the shipping docu- ments. - Page 27 4 Product description – Motor-drive unit status (motor protective switch, motor is running) – Tap position display – Optional: Status of protective devices (Buchholz relay, protective relay, pressure relief device) ▪ ETOS® ED digital ready – Maintenance interval calculation – Tap-change statistics of on-load tap-changer –...

-

Page 28: Variants

– Relative moisture in oil – Monitoring of the absolute values and rates of increase – Optional: Rogers, Duval, Dörnenburg and IEC 60599 analyses ▪ MR sensor bus ▪ Calculation of the transformer overload capability (emergency operation) 4.4 Variants The ISM® assemblies are installed as follows (figures show swing frame in-... -

Page 29: Etos® Ed Xl

4 Product description With display S41P S13A S13B X20:1...49 AVR STATUS X1:272 ALARM INIT REMOTE ENTER ...313 2 4 6 2 4 6 AVR AUTO TEST PROG AVR MANUAL 24V DC BACK ETH 1 ETH 2.1 ETH 2.2 X1:80...248 S38M A13.1 1...4 S40M... -

Page 30: Design

4 Product description With display S10A S26A S27A S62P S13A S61P S13B S118 DIO 42-20 INIT S7 ETH 1 A18.1 A18.2 CPU II UI 3 AIO 4 AIO 4 UI 5 BEM 1 BES 1 VI 4 INIT 2 4 6 2 4 6 TEST PROG... - Page 31 4 Product description Components not described here in detail are described in the motor-drive unit's technical data. Figure 7: Design 1 Door of the control cabinet 2 Viewing window for indication field 3 Eyebolt 4 Indication field 5 Transmission-gear cover plate 6 Output shaft 7 Hand crank aperture with hand 8 Hand lamp...

-

Page 32: Indication Field

4 Product description 4.5.1 Indication field A clear indication field is fitted in the motor-drive unit. The pointer and opera- tions counter are mechanically driven and indicate the tap-change operation sequence and operating position of the motor-drive unit. The reset wheel on the operations counter is sealed at the factory. -

Page 33: Position Transmitter Equipment

4 Product description 4.5.4 Position transmitter equipment NOTICE Damage to the on-load tap-changer and motor-drive unit! Damage to on-load tap-changer and motor-drive unit due to incorrect use of position transmitter equipment. ► Only circuits stated in the chapter Technical data for position transmitter equipment [►Section 14.3, Page 380] may be connected to the position transmitter module connections. -

Page 34: Ambient Temperature Sensor

4 Product description The touch-protected transmission-gear cover plate features an opening for the hand crank used in manual mode. Transmission-gear cover plate 4.5.6 Ambient temperature sensor The device is equipped with a temperature sensor for recording the ambient temperature. The temperature sensor is on the bottom of the protective housing. -

Page 35: Ism Assemblies

4 Product description 4.5.7 ISM assemblies Depending on the order, the device is either designed as a 19-inch plug-in housing or supplied as individual components for assembly on a cap rail. The individual device assemblies are described in the following section. Figure 10: 19-inch plug-in housing (OT1205) Figure 11: Individual components for assembly on a cap rail 4.5.7.1 Power supply... - Page 36 4 Product description 4.5.7.2 CPU (central processing unit) I The CPU I assembly is the central processing unit for the device. It contains the following interfaces: ▪ Internal system interface RS232 (COM1) ▪ Serial interface RS232/485 (COM2) ▪ 3x Ethernet (ETH1, ETH 2.1, ETH 2.2) ▪...

- Page 37 4 Product description The UI 3 assembly is used for measuring 3-phase voltage and current. Figure 14: UI 3 assembly Warning of a danger point. Read the information given in the product oper- ating instructions. Warning of dangerous electrical voltage. This assembly is protected via double insulation or reinforced insulation. Table 8: Safety-relevant symbols on the assembly 4.5.7.4 UI 5-4 voltage measurement and current measurement The UI 5-4 assembly is used for measuring 3-phase voltage and current.

- Page 38 4 Product description Warning of a danger point. Read the information given in the product oper- ating instructions. Warning of dangerous electrical voltage. This assembly is protected via double insulation or reinforced insulation. Table 9: Safety-relevant symbols on the assembly 4.5.7.5 Digital inputs and outputs The assemblies DIO 28-15 and DIO 42-20 (HL) provide you with a number of digital inputs and outputs that differs based on the version: ▪...

- Page 39 4 Product description In accordance with the device configuration, the AIO assembly supports one of the following signal types: Input Output Voltage Current Voltage Current 0...10 V 0...20 mA 0...10 V 0...20 mA 4...20 mA 4...20 mA Resistance measurement (such as PT100, resistor contact series) Table 11: Signal types supported by the AIO assembly Figure 17: AIO 4 assembly 4.5.7.7 Analog inputs and outputs (AIO 8)

- Page 40 4 Product description Figure 18: AIO 8 assembly 4.5.7.8 Media converter The MC 2-2 assembly is a media converter, which converts 2 electrical con- nections (RJ45) to one fiber-optic cable connection each. Each is converted independently of the other. The following interfaces are available: ▪...

-

Page 41: Nameplate

4 Product description 4.5.7.9 Media converter with managed switch The assembly SW 3-3 is a media converter with managed switch. It com- bines two independent functions and provides you with the following inter- faces: ▪ A media converter converts an electric connection (RJ45) into a fiber-optic cable connection –... -

Page 42: Protective Devices

4 Product description Inside: ETOS® ED L, ETOS® ED L-S and ETOS® ED XL Figure 21: Nameplate in the control cabinet 1 Nameplate Outside: ETOS® ED XL Figure 22: Nameplate on the control cabinet door 1 Nameplate 4.7 Protective devices The following protective devices are fitted in the motor-drive unit: ▪... -

Page 43: Safety Markings

4 Product description 4.8 Safety markings The following safety markings are used on the product: Figure 23: Overview of safety markings 1 Warning of rotating parts 2 Warning of dangerous electrical voltage 3 Warning of hot surface 4 Read the documentation 4.9 Emergency operation during switching blocking (X100 bridge) The monitoring function of the on-load tap-changer is only active when the... -

Page 44: Visualization

4 Product description NOTICE Damage to the transformer and/or on-load tap-changer If the Blocking active event is present in the monitoring system, then the cause of the event has to be analyzed before activating emergency opera- tion. Performing additional tap-change operations on the motor-drive unit without analyzing the cause may lead to on-load tap-changer and/or trans- former damage. - Page 45 4 Product description If the device does not have one of the optional functions, this will be indi- cated in the main screen via a small padlock Depending on the device configuration, the main screen displays the schematic representation of a transformer for network applications or a transformer for industrial applications.

- Page 46 4 Product description Figure 26: Apparent power, oil level, and ambient temperature 1 Asset intelligence 2 Total apparent power 3 Ambient temperature 4 Oil level (transformer on left, on- load tap-changer on right) Figure 27: On-load tap-changer and motor-drive unit 1 OLTC oil temperature 2 Current tap position 3 Voltage regulator 4 Tap-change operation statistics...

- Page 47 4 Product description 4.10.1.2 Transformer for industrial applications Figure 28: Transformer data 1 DGA (status) 2 Top-oil temperature 3 Hot-spot temperature 4 Cooling system (status) 5 Load current an load voltage of the 6 Transformer name phases L1, L2, L3 (high-voltage side) Figure 29: Apparent power, oil level, and ambient temperature 1 Asset intelligence...

- Page 48 4 Product description Figure 30: On-load tap-changer and motor-drive unit 1 OLTC oil temperature 2 Current tap position 3 Voltage regulator 4 Tap-change operation statistics 5 OLTC status message (collective message) ® ETOS 6385142/08 EN Maschinenfabrik Reinhausen GmbH 2020...

-

Page 49: Additional Operating Controls And Display Elements When Using The Mcontrol Touch Panel (Optional)

4 Product description 4.10.2 Additional operating controls and display elements when using the MControl touch panel (optional) If you are using the device with the optionally available MControl touch panel, additional operating controls and display elements are displayed on the left edge of the screen. Depending on the device configuration, a variety of keys are available: Figure 31: Additional display elements and operating controls Status... - Page 50 4 Product description User rights and user roles The device is equipped with a rights system and a roles system. The display and access rights to device settings or events can therefore be controlled at the user level. You can configure the rights system and roles system to meet your require- ments.

- Page 51 4 Product description In these operating instructions, the path for navigating to a parameter is al- ways shown in an abridged form: Go to Settings > Parameters > System > Time synchronization. Setting parameters There are various ways to configure the settings, depending on the parame- ter.

- Page 52 4 Product description Entering a value To enter a value, proceed as follows: 1. Use the rotary knob to select the value field and press the key. ð If operating via the front panel, the numerical keypad appears. Figure 33: Entering a value 2.

- Page 53 4 Product description Parameter search You can use the quick search function in the parameter menu to search for a parameter. Enter the name of the desired parameter in the Search entry field. Figure 35: Quick search Expert mode The device has an expert mode for entering the parameters. You can enter the parameters directly on the overview screen of the respective menu in this mode.

- Page 54 4 Product description Hiding/showing parameters Depending on how you set the parameters, the device will hide or show ad- ditional parameters related to this function. ® ETOS 6385142/08 EN Maschinenfabrik Reinhausen GmbH 2020...

-

Page 55: Packaging, Transport And Storage

5 Packaging, transport and storage 5 Packaging, transport and storage 5.1 Packaging The products are sometimes supplied with sealed packaging and sometimes in a dry state, depending on requirements. Sealed packaging surrounds the packaged goods with plastic foil on all sides. -

Page 56: Markings

5 Packaging, transport and storage 5.1.2 Markings The packaging bears a signature with instructions for safe transport and cor- rect storage. The following symbols apply to the shipment of non-hazardous goods. Adherence to these symbols is mandatory. Protect against Fragile Attach lifting Center of mass moisture... -

Page 57: Storage Of Shipments

5 Packaging, transport and storage Visible damage If external transport damage is found upon receipt of the shipment, proceed as follows: ▪ Immediately record the identified transport damage in the shipping docu- ments and have this countersigned by the carrier. ▪... -

Page 58: Unpacking Shipments And Checking For Transportation Damages

5 Packaging, transport and storage When selecting and setting up the storage location, ensure the following: ▪ Protect stored goods against moisture (flooding, water from melting snow and ice), dirt, pests such as rats, mice, termites and so on, and against unauthorized access. - Page 59 5 Packaging, transport and storage ▪ WARNING! Serious injuries and damage to the control cabinet due to falling load. Attach the lifting gear such that the cable angle is always less than 45° in relation to the vertical. Figure 37: Maximum permissible cable angle for the lifting-gear limit stop of the control cabinet ▪...

-

Page 60: Mounting

6.1 Attaching the control cabinet to the transformer The control cabinet has four fixing attachments on the rear to secure it. 1. Attach four stud bolts (not supplied by MR) to the transformer tank. Figure 38: Fastening the stud bolts A 675±2 B 500±2... - Page 61 6 Mounting 2. For control cabinets with vibration damper: Attach the inner bracket to the control cabinet. Attach the outer bracket to the transformer wall. The com- plete contact surfaces of the brackets must be in contact. 1 Bracket contact surfaces 3.

- Page 62 6 Mounting NOTICE! Damage to the control cabinet due to mechanical tension. Se- cure the control cabinet without subjecting it to mechanical tension. Figure 40: Securing the drive 5. Connect the grounding cable to the control cabinet and the transformer tank, holding it against the control cabinet using a wrench (wrench size 36).

-

Page 63: Mounting Drive Shafts And Bevel Gear

6 Mounting 6.2 Mounting drive shafts and bevel gear The process of mounting the drive shafts and bevel gear is described in the installation and commissioning instructions for the on-load tap-changer / de- energized tap-changer. 6.3 Centering on-load tap-changer and motor-drive unit Danger of death or severe injury! WARNING Danger of death or severe injury due to motor-drive unit starting up by acci-... - Page 64 6 Mounting drive unit and the on-load tap-changer / de-energized tap-changer match. Otherwise damage to the on-load tap-changer and transformer may re- sult. Figure 42: Adjustment position 2. Attach the hand crank in the motor-drive unit to the shaft end located in the upper cover plate.

- Page 65 6 Mounting 3. Turn the hand crank clockwise until the diverter switch operation begins. When turning the hand crank, observe the tap-change indicator, which mechanically reflects the progress of the tap-change operation. Figure 44: Turning the hand crank 4. Once the diverter switch operation begins, continue to turn in the same di- rection while counting the tap-change indicator sections required for the pointer to reach the mid-position of the area marked in gray on the tap- change indicator.

- Page 66 6 Mounting in the same direction (example: 8-2=6) to complete the tap-change opera- tion. Then turn in the opposite direction until the pointer is in the mid-posi- tion of the area marked in gray on the tap-change indicator. Figure 46: Completing the diverter switch operation 6.

- Page 67 6 Mounting 7. Once the diverter switch operation begins, continue to turn in the same di- rection while counting the tap-change indicator sections required for the pointer to reach the mid-position of the area marked in gray on the tap- change indicator.

- Page 68 6 Mounting Also take numbers after the decimal point into account. 10. If the correction value |C| is less than 0.5 tap-change indicator sections, no further action is required. Refer to item 18 for how to proceed next. 11. Use the hand crank to crank in the direction in which the determined value A or B was higher (example: counter-clockwise, because B >...

- Page 69 6 Mounting 13. Uncouple the motor-drive unit and vertical drive shaft by removing the coupling brackets. After uncoupling, do not turn the drive shaft any fur- ther. Figure 50: Uncoupling the motor-drive unit and drive shaft 14. Operate the motor-drive unit using the hand crank in the same direction, continuing by C tap-change indicator sections on the tap-change indica- tor (example: 1.5 tap-change indicator sections).

-

Page 70: Connecting The Ism® Assemblies

6 Mounting tions, turn another 8 A tap-change indicator sections in the same direc- tion (example: 8-4=4) to complete the tap-change operation. Then turn in the opposite direction until the indicator is in the mid-position of the area marked in gray on the tap-change indicator. Check the coupling again as described previously. -

Page 71: Information About Connecting Serial Interfaces Rs232 And Rs485

6 Mounting Cable Assembly Cable type Conductor Conductor Max. length cross-section material Voltage measurement UI 1, UI 3, UI 5-4 Shielded 2.5 mm² Copper Current measurement UI 1, UI 3, UI 5-4 Unshielded 4 mm² Copper Signal inputs DIO 28-15, Shielded 1.5 mm Copper 400 m (<25 Ω/km) DIO 42-20 Signal outputs* DIO 28-15, Shielded 1.5 mm Copper... - Page 72 6 Mounting RS232 (D-SUB 9-pole) For connecting the device via the RS232 interface (COM2), use a data cable with the following structure: Figure 52: RS232 data cable (9-pole) RS485 (D-SUB 9-pole) To connect the device via the RS485 interface (COM2), use a data cable with the following structure: Figure 53: RS485 data cable ®...

-

Page 73: Notes On Connecting To The Mr Sensor Bus

MR sensor bus. ▪ The MR sensor bus uses Modbus in a 2-wire configuration (2W). The 4- wire configuration (4W) is not supported. ▪ You must connect the sensors via a shielded line with 3 conductors (D0, D1, Common). - Page 74 CPU-COM2 Com. (C) D0 (A) D1 (B) Sensor 1 Com. (C) D0 (A) D1 (B) Sensor x Com. (C) D0 (A) 120 Ω D1 (B) Figure 55: MR sensor bus ® ETOS 6385142/08 EN Maschinenfabrik Reinhausen GmbH 2020...

- Page 75 If you would like to use an MSENSE® DGA sensor, you must connect the sensor to the MR sensor bus in accordance with the following connection ex- amples. If the MSENSE® DGA sensor is the only bus device or the last bus device, you must use a terminating resistor (120 Ω, 0.5 W).

- Page 76 The EPT303 FO sensor module contains a terminating resistor. If you would like to use the EPT303 FO sensor together with other sensor types on an MR sensor bus, then we recommend connecting the EPT303 FO sensor to the end of the bus.

- Page 77 6 Mounting 6.4.3.3 MESSKO® MTRAB® 2.5 If you would like to use a MESSKO® MTRAB® 2.5 sensor, you must con- nect the sensor to the RS485 plug terminals on the sensor bus. CPU-COM2 Com. (C) D0 (A) D1 (B) MTRAB 2.5 D+ | Rx+ D- | Rx- Shield...

-

Page 78: Information About Connecting Analog Sensors

6 Mounting 6.4.3.4 MSENSE®-FO ECU-I/S If you would like to use an MSENSE®-FO ECU-I or ECU-S sensor, you must connect the sensor to the RS485 plug terminals on the sensor bus. Use a shielding clamp to apply the shield to the cable. If the MSENSE®-FO sensor is the only bus device or the last bus device, you must use a terminating re- sistor (120 Ω, 0.5 W). - Page 79 6 Mounting The AIO assembly has a separate plug connector for each channel (input or output). The plugs are assigned as follows: Figure 63: Plug assignment of the AIO module (illustration using module AIO 4 as an example) Interface Description I OUT (+): Current output + I/U IN (+) U OUT (+): Voltage input +, current input +, voltage output + I/U IN (-): Voltage input -, current in-...

- Page 80 6 Mounting 4...20 mA sensor You must connect a 4...20 mA sensor to the pins . You must also connect the supplied bridge to the pins , and 4...20 mA signal source I OUT (+) I/U IN (+) U OUT (+) I/U IN (-) I/U OUT (+) Figure 64: Connection example for a 4...20 mA sensor...

-

Page 81: Electromagnetic Compatibility

6 Mounting 6.4.5 Electromagnetic compatibility The device has been developed in accordance with applicable EMC stan- dards. The following points must be noted in order to maintain the EMC standards. 6.4.5.1 Wiring requirement of installation site Note the following when selecting the installation site: ▪... - Page 82 6 Mounting ▪ For signal transmission, use shielded lines with individual conductors (out- going conductor / return conductor) twisted in pairs. ▪ Connect full surface of shielding (360º) to device or to a nearby grounding bar. Using single conductors may limit the effectiveness of the shielding. Con- nect close-fitting shielding to cover all areas.

- Page 83 6 Mounting 6.4.5.4 Information about shielding the CAN bus In order for the CAN bus to operate faultlessly, you have to connect the shielding using one of the following variants. If you are not able to use any of the variants detailed below, we recommend using fiber-optic cables. Fiber- optic cables decouple the devices and are not sensitive to electromagnetic interference (surge and burst).

-

Page 84: Connecting Cables To The System Periphery

6 Mounting 6.4.5.5 Information about shielding the cables for analog signals In order to correctly record the analog signals, you must place the cable screening in the motor-drive unit on the grounding bar. The cable shielding should only be removed just prior to connecting, to ensure that the section with unshielded cables is kept as short as possible. - Page 85 6 Mounting 2. Crimp stranded wires with wire end sleeves. 3. Guide the cables into the corresponding plug terminals and fasten them using a screwdriver. Figure 70: Example: Plug for voltage measurement Figure 71: Example: Plug for current measurement 4. Insert the plug into the associated slots and lock or screw the plug in place.

-

Page 86: Mounting Terminating Resistor Of Can Bus

6 Mounting 6.4.8 Mounting terminating resistor of CAN bus If you want to operate the device in parallel operation, you need to mount a 120 Ω terminating resistor at both ends of the CAN bus. Use the plug con- nector with terminating resistor provided as an option. Figure 72: Terminating resistor of CAN bus 6.5 Connecting the motor-drive unit WARNING... -

Page 87: Cable Recommendation

6 Mounting Suitable equipment includes isolating devices in accordance with IEC 60947-1 and IEC60947-3 (e.g. circuit breaker). When selecting the circuit breaker type, the properties of the relevant circuits (voltage, maximum cur- rents) must be observed. The following should also be noted during installa- tion: ▪... -

Page 88: Electrical Connection

6 Mounting Circuit Function Type Material Cross wiring between motor- Power supply Unshielded, separate cable Copper drive units Tap-change supervisory con- Shielded Copper trol Pulse circuit, raise/lower Shielded Copper Tripping circuit Q1-Off Shielded Copper Table 15: Recommendation for connection cables 6.5.2 Electrical connection The voltage supply for the motor-drive unit must be able to provide 5…7 times the nominal operating current of the motor-drive unit for one second. -

Page 89: Commissioning

7 Commissioning 7 Commissioning 7.1 Starting up motor-drive unit Preparation 1. Make sure that the motor-drive unit is connected as shown in the connec- tion diagram provided. 2. Ensure that all protective conductors are connected correctly. 3. Ensure that the preliminary fuse is selectively configured for the protective devices in the motor-drive unit. -

Page 90: Tests On Motor-Drive Unit

► Ensure that the motor-drive unit and on-load tap-changer/de-energized tap-changer are correctly coupled and that they are in the same tap posi- tion for each operating position. Please contact Maschinenfabrik Reinhausen GmbH (MR) if any aspect of the tests is not clear. 7.2.1 Checking correct electric switch-off 1. -

Page 91: Checking Mechanical And Electric End Stop Of On-Load Tap-Changer/De-Energized Tap-Changer And Motor-Drive Unit

7 Commissioning 7.2.2 Checking mechanical and electric end stop of on-load tap- changer/de-energized tap-changer and motor-drive unit 1. Press the S3 control switch to switch the motor-drive unit to the second- to-last operating position. Figure 73: S3 control switch 2. Open the motor-drive unit door and switch off the motor protective switch Q1 (position O). -

Page 92: Checking Functional Reliability

The device is fully mounted and can be configured. The actions required for this are described in the following chapter. 7.3 Tests on the transformer Please contact Maschinenfabrik Reinhausen GmbH (MR) if any aspect of the tests is not clear. 7.3.1 High-voltage tests on the transformer... -

Page 93: Dielectric Tests On Transformer Wiring

4. Do not actuate an on-load tap-changer which is uncoupled and do not turn its drive shaft. 5. Transport the drive to the installation site in the MR delivery packaging. 6. Fit drive and drive shaft to transformer at the installation site. -

Page 94: Visualization

7 Commissioning NOTICE Damage to the on-load tap-changer and motor-drive unit! Damage to on-load tap-changer and motor-drive unit due to incorrect use of position transmitter equipment. ► Only circuits stated in the chapter Technical data for position transmitter equipment [►Section 14.3, Page 380] may be connected to the position transmitter module connections. - Page 95 7 Commissioning To establish a connection, proceed as follows: 1. Connect the PC and device using an Ethernet cable (RJ45 plug) via the ETH2.1 or ETH2.2 interface. Figure 74: Establishing a connection via the ETH2.1 or ETH2.2 interface 2. Assign a unique IP address to the PC. This IP address must be in the same subnet as the device (e.g.

- Page 96 7 Commissioning ETH1.1 interface To establish a connection via the ETH1.1 interface, proceed as follows: 1. Connect the PC and the device via the front interface using an Ethernet cable (RJ45 plug). Figure 75: Establishing a connection via the front interface 2.

-

Page 97: Setting The Language

7 Commissioning To connect via the ETH2.2 interface, proceed as follows: 1. Connect the PC and device using an Ethernet cable (RJ45 plug) via the ETH2.2 interface. Figure 76: Establishing a connection via the ETH2.2 interface on the back 2. Assign a unique IP address to the PC in the same subnet as the device (e.g. -

Page 98: Setting Date And Time

7 Commissioning 4. Restart the device to apply the changed language setting. 7.6.3 Setting date and time You can set the date and time in the following ways: ▪ Manually ▪ Time synchronization via control system (SCADA) ▪ Time synchronization via SNTP time server If you are using a control system, the device automatically synchronizes the date and time with the control system. -

Page 99: Checking Measured Values And Status Of Digital Inputs And Outputs

7 Commissioning 2. Go to Settings > Commissioning wizard. Figure 78: Calling up the commissioning wizard 3. Press the Next button to launch the commissioning wizard. 4. Follow the on-screen instructions. Once you have entered all of the parameters relevant to commissioning, continue with the function test. - Page 100 7 Commissioning 3. If the temperatures do not match, use the connection diagram to check the wiring. Check configuration of the analog inputs [►Section 9.29, Page 292]. Check the function of the temperature sensors. ® ETOS 6385142/08 EN Maschinenfabrik Reinhausen GmbH 2020...

-

Page 101: Operation

8 Operation 8 Operation 8.1 Operating the motor-drive unit remotely Activate the motor-drive unit remotely during normal operation. You can initiate activation via a single control impulse, for example via the optional "Automatic voltage regulation AVR basic/pro" function package. This adjustment operation is always completed regardless of any other con- trol impulses issued during the tap-change operation. -

Page 102: Operating The Motor-Drive Unit With The Hand Crank

8 Operation 8.3 Operating the motor-drive unit with the hand crank WARNING Danger of explosion! Unauthorized operation of the motor-drive unit with the hand crank may re- sult in death or serious injury. ► Never operate the motor-drive unit electrically or with the hand crank be- fore the transformer has been disconnected if you think there may be a fault in the transformer or on-load tap-changer / de-energized tap- changer. - Page 103 8 Operation 3. Insert the hand crank mounted in the motor-drive unit into the hand crank aperture in the upper cover plate. ð The built-in hand crank interlock switch interrupts the motor circuit at two poles. The control circuit will not be interrupted. NOTICE! Damage to the on-load tap-changer due to tap-change opera- tion not being completed correctly.

-

Page 104: Visualization

9 Visualization 9 Visualization The ETOS® ED motor-drive unit is equipped with web-based visualization. This enables you to configure the device with a computer and to display measured values. System requirements To access the web-based visualization, you need a PC with an HTML5-ca- pable browser. - Page 105 9 Visualization To establish a connection, proceed as follows: 1. Connect the PC and device using an Ethernet cable (RJ45 plug) via the ETH2.1 or ETH2.2 interface. Figure 79: Establishing a connection via the ETH2.1 or ETH2.2 interface 2. Assign a unique IP address to the PC. This IP address must be in the same subnet as the device (e.g.

- Page 106 9 Visualization ETH1.1 interface To establish a connection via the ETH1.1 interface, proceed as follows: 1. Connect the PC and the device via the front interface using an Ethernet cable (RJ45 plug). Figure 80: Establishing a connection via the front interface 2.

-

Page 107: General

9 Visualization To connect via the ETH2.2 interface, proceed as follows: 1. Connect the PC and device using an Ethernet cable (RJ45 plug) via the ETH2.2 interface. Figure 81: Establishing a connection via the ETH2.2 interface on the back 2. Assign a unique IP address to the PC in the same subnet as the device (e.g. -

Page 108: Setting General Device Functions

9 Visualization 9.2.1 Setting general device functions You can set general device functions with the following parameters. Settings Parameters General Name Value Home Language English Commissioning wizard Auto-logout Events Time until auto-logout 15.0 min Measured value display Primary values Transformer name Transformer Remote behavior Hardware and SCADA... -

Page 109: Set Up Automatic Logout

9 Visualization Remote behavior You can use this parameter to select the behavior of the device in remote operating mode. Depending on the device configuration, you can set the re- mote behavior as follows: ▪ Through the visualization (optional) ▪ By setting the digital inputs (optional) You can select the following settings: Setting Description... -

Page 110: Activating/Deactivating Service User Access

9 Visualization Settings Parameters General Name Value Home Language English Commissioning wizard Auto-logout Events Time until auto-logout 15.0 min Measured value display Primary values Transformer name Transformer Remote behavior Hardware and SCADA Information USB interface Service user access activation Activated SNMP Agent Recorder CHANGE REBOOT... -

Page 111: Configuring The Network

9 Visualization Settings Parameters General Name Value Home Language English Commissioning wizard Auto-logout Events Time until auto-logout 15.0 min Measured value display Primary values Transformer name Transformer Remote behavior Hardware and SCADA Information USB interface Service user access activation Activated SNMP Agent Recorder CHANGE REBOOT... - Page 112 9 Visualization You can only set the parameters for ETH 2.2 if the device is equipped with the optional interface for visualization. Settings Parameters Network ...ngs Name Value Home IP address Eth 1 192.168.10.254 Subnet mask Eth 1 255.255.255.0 Gateway address Eth 1 0.0.0.0 IP address Eth 2.2 192.0.1.230...

- Page 113 9 Visualization Visualization release You can use this parameter to set the interfaces via which you can access the visualization: ▪ Only ETH 2.x ▪ ETH 1 and ETH 2.x You can only set this parameter if the device is equipped with the optional control system connection via Ethernet (TCP/IP) and the optional interface for visualization.

-

Page 114: Mqtt

9 Visualization 9.4 MQTT You can activate and configure the MQTT message protocol in this menu point. To do so, you must connect the device to an MQTT server (Broker) via Ethernet via the ETH 1 or ETH2.x interface on the CPU assembly. Note that the device will only send messages (publish). - Page 115 9 Visualization Broker address If you use a URL address, you can use this parameter to enter the domain name of the MQTT server (broker). Otherwise, you can enter the IP address of the MQTT server. Broker port You can use this parameter to set the port of the MQTT server (broker). The following ports are used as standard: ▪...

-

Page 116: Setting The Device Time

9 Visualization 9.5 Setting the device time You can set the the device time manually or automatically via an SNTP time server. The device must be connected to a time server via Ethernet for this purpose. You can operate SNTP and PTP at the same time. In this case, the PTP time is queried in slave operation. -

Page 117: Time Synchronization Via Ptp

9 Visualization Synchronization interval You can use this parameter to set the interval at which the device is to call up the time from the time server. Automatic daylight saving / standard time You can use this parameter to activate the automatic switchover between daylight saving time and standard time. -

Page 118: Configuring Syslog

9 Visualization PTP hops You can use this parameter to enter the number of network sections be- tween master and slave. You can set up to 16 hops. PTP version You can use this parameter to select the PTP version. ▪... - Page 119 9 Visualization Syslog standard You can use this parameter to adjust the transmission process and the for- mat for the syslog messages. You can select the following options: Standard Transport Message format RFC 5425 (recom- RFC 5424 mended) RFC 5426 RFC 6587 RFC 3164 RFC 3164 Table 24: Syslog standard If you use the standard RFC 5245 (TLS), you have to import the root certifi- cate and the client certificate with the corresponding key to the syslog...

-

Page 120: Setting The Screensaver

9 Visualization Severity level Description Notice state Notice Information state Info Debug state Debug Table 25: Severity levels 9.7 Setting the screensaver In order to increase the service life of the display on the front panel of the device, you can activate and set a screensaver. The following functions are available for this purpose: ▪... -

Page 121: Scada

9 Visualization Screensaver waiting time You can use this parameter to set the screensaver waiting time. Dimming When you activate this function, the device reduces the brightness of the display when the adjustable waiting time has expired if no key is pressed. The device then switches back to full brightness when you subsequently press any key. -

Page 122: Configuring Iec 61850 (Optional)

9 Visualization 9.8.1 Configuring IEC 61850 (optional) If you want to use the IEC 61850 control system protocol, you must set the following parameters. Also refer to the section Configuring the network [►Section 9.3, Page 111]. Settings Parameters IEC 61850 Name Value Home... - Page 123 9 Visualization 9.8.1.1 Downloading an ICD file You can download the ICD file from the device via the Import/Export Man- ager [►Section 9.36, Page 324]. To do this, you have to establish an Ether- net connection between the device and your PC. 9.8.1.2 Importing CID/SCD file (optional) Note the following definitions for importing a CID file or SCD file.

-

Page 124: Configuring Iec 60870-5-101 (Optional)

9 Visualization 9.8.2 Configuring IEC 60870-5-101 (optional) If you want to use the IEC 60870-5-101 control system protocol, you must set the following parameters. Settings Parameters IEC 60870-5-101 Name Value Home Serial interface RS232 Baud rate 9600 Transmission procedure Unbalanced Events Number of link address octets Link address... - Page 125 9 Visualization Transmission procedure You can use this parameter to set the transmission procedure. You can se- lect the following options: ▪ Unbalanced transmission ▪ Balanced transmission Number of link address octets You can use this parameter to set how many octets are provided for the link address.

- Page 126 9 Visualization ASDU single character confirmation You can use this parameter to set whether a confirmation is to be sent as single characters instead of as a complete message. Single character confir- mation is only possible for requesting data of class 2 (Class 2 Request). RES bit test You can use this parameter to set whether the device is to check the RES bit (Reserved Bit) in the control field.

-

Page 127: Configuring Iec 60870-5-103 (Optional)

9 Visualization Reference time You can use this parameter to set which time is to be transmitted by the con- trol system. The device uses this information for time synchronization [►Section 9.5, Page 116]. You can select the following options: Option Description Local... - Page 128 9 Visualization Baud rate You can use this parameter to set the serial interface's baud rate. You can select the following options: ▪ 9600 baud ▪ 19200 baud ▪ 38400 baud ▪ 57600 baud ▪ 115200 baud ASDU address You can use this parameter to set the address of the ASDU. Number of data bits You can use this parameter to set the number of databits.

-

Page 129: Configuring Iec 60870-5-104 (Optional)

9 Visualization Reference time You can use this parameter to set which time is to be transmitted by the con- trol system. The device uses this information for time synchronization [►Section 9.5, Page 116]. You can select the following options: Option Description Local... - Page 130 9 Visualization ASDU address You can use this parameter to set the address of the ASDU. ASDU sequence optimization With this parameter, you can set which method is to be used for optimizing the ASDU types. The standard enables optimization in order to be able to transfer multiple value changes in a telegram in a sequence of ascending in- formation object addresses.

-

Page 131: Configuring Modbus (Optional)

9 Visualization Note that all SCADA clients communicate with the device on an equal basis, because the device does not prioritize commands. If you transmit com- mands from several SCADA clients to the device at the same time, the de- vice will execute the last transmitted command. - Page 132 9 Visualization Maximum TCP connections You can use this parameter to set the maximum number of TCP connec- tions. TCP Keepalive You can use this parameter to activate/deactivate the "TCP Keepalive" func- tion. Serial interface You can use this parameter to select the serial interface for data transmis- sion.

-

Page 133: Configuring Dnp3 (Optional)

9 Visualization 9.8.6 Configuring DNP3 (optional) If you would like to use the DNP3 control system protocol, you must set the parameters listed below. Also refer to the section Configuring the network [►Section 9.3, Page 111] if you want to use the DNP3 via TCP. Settings Parameters DNP3... - Page 134 9 Visualization Baud rate You can use this parameter to set the serial interface's baud rate. You can select the following options: ▪ 9600 baud ▪ 19200 baud ▪ 38400 baud ▪ 57600 baud ▪ 115200 baud 9.8.6.2 Device address You can use this parameter to set the device link address.

-

Page 135: Configuring Goose (Optional)

▪ The maximum number of usable GSEControl elements is defined in TEM- PLATE.icd under Services GOOSE. You cannot adjust this value. ▪ The shortest repeat time is defined in Private Element type="MR- MINTIME-GOOSE". You cannot adjust this value. ®... - Page 136 9 Visualization Example: Configuration To configure the device as a GOOSE publisher, you have to call up the vi- sualization via a PC. You must have a parameter configurator or administra- tor user role. To configure the device as a GOOSE publisher, proceed as follows: 1.

- Page 137 9 Visualization 5. Select the PC or USB option, select the SCD/CID file, and select Trans- fer. Figure 97: Importing an SCD/ICD file 6. Select the desired IED with the configuration that is to be imported and select Accept to start the import. Figure 98: Selecting an IED 7.

- Page 138 DataSet and GSE block. The referenced DataSet may contain data ob- jects (DO) or data attributes (DA). The maximum number of usable data points per GOOSE message is defined in Private Element type="MR-MAX- GOOSE-SUBSCRIBER-FCDA". You cannot adjust this value.

- Page 139 9 Visualization To configure the device as a GOOSE subscriber, proceed as follows: ü The SCD file for your system with all required IEDs has been imported. 1. Go to Settings > Mapping. ð The list of functions available on the device appears. Figure 99: Overview of device functions available 2.

-

Page 140: Configure Data Points (Optional)

9 Visualization Deleting a configuration If necessary, you can delete the data point configuration. To do so, proceed as follows: 1. Go to Settings > Mapping. 2. Select the desired function. 3. Press the Delete button to delete the configuration. 9.8.8 Configure data points (optional) You can use the optional "Configure data points"... - Page 141 9 Visualization Column Description Modifiable Setting range Threshold value for measured values. The data point is 0...32,768 only transferred again if the change of value is greater than the threshold value. ▪ If you enter the value 0, no threshold value is active. ▪...

- Page 142 9 Visualization 9.8.8.2 Configuring IEC 60870-5-103 data points You can adjust the following data point properties for the IEC 60870-5-103 control system protocol: Column Description Modifiable Setting range Active You can use the checkbox to set whether the data point is Active/inactive to be transferred via the control system protocol or not.

- Page 143 9 Visualization Proceed as follows to configure the data points: 1. Go to Settings > Data point configuration. 2. Adjust the data points as required. 3. Press the Accept button to adopt the modified list of data points. 4. Restart the device to activate the modified list of data points. 9.8.8.3 Configuring IEC 60870-5-104 data points You can adjust the following data point properties for the IEC 60870-5-104 control system protocol:...

- Page 144 9 Visualization Figure 103: Configuring IEC 60870-5-104 data points Proceed as follows to configure the data points: 1. Go to Settings > Data point configuration. 2. Adjust the data points as required. 3. Press the Accept button to adopt the modified list of data points. 4.

- Page 145 9 Visualization Figure 104: Configuring Modbus data points Proceed as follows to configure the data points: 1. Go to Settings > Data point configuration. 2. Adjust the data points as required. 3. Press the Accept button to adopt the modified list of data points. 4.

- Page 146 9 Visualization Column Description Modifiable Setting range PREFSTATICVAR For a data point of class 0 (Static), you can define the fol- 0...6 lowing variation depending on the object group: ▪ BI: 1, 2 ▪ BO: 2 ▪ AI: 2, 4 ▪...

-

Page 147: Display Status Of The Scada Connection

9 Visualization 2. Adjust the data points as required. 3. Press the Accept button to adopt the modified list of data points. 4. Restart the device to activate the modified list of data points. 9.8.8.6 Resetting the data point configuration to factory settings If you want to reset the data point configuration to factory settings, proceed as follows: 1. -

Page 148: Name Plate

9 Visualization Figure 106: Communication ► Go to Home > Communication. 9.9 Name plate You can enter the data of the name plates, the on-load tap-changer and the motor-drive unit and display it later. 9.9.1 Enter the name plate data You can enter the name plate data for the transformer, the on-load tap- changer and the motor-drive unit. -

Page 149: Displaying The Name Plate

9 Visualization 9.9.2 Displaying the name plate You can display the nameplate data for the transformer, on-load tap- changer, and motor-drive unit. Figure 108: Nameplate ► Go to Information > System > Nameplate. 9.10 Linking signals and events The device enables you to link digital inputs (GPI) and control system com- mands (SCADA) with device functions, digital outputs (GPO), and control system messages. -

Page 150: Linking Functions

9 Visualization You can link the event messages with device functions, digital outputs, and control system messages. You can also link all other event messages (e.g. Undervoltage U<) with digital outputs and control system messages. Corre- sponding parameters, for which you need to enter the relevant event num- ber, are provided for this purpose. -

Page 151: Linking Digital Outputs

9 Visualization 9.10.2 Linking digital outputs You can link each event with a digital output. The device provides a maxi- mum of 20 digital outputs for this purpose. When you link a digital output to an event, the device issues a signal to this output if the event occurs. The signal persists until the event stops. -

Page 152: Cooling System Control (Optional)

9 Visualization Settings Parameters Link messages Name Value Home Generic SCADA status message 1 Generic SCADA status message 2 Generic SCADA status message 3 Events Generic SCADA status message 4 Generic SCADA status message 5 Generic SCADA status message 6 Generic SCADA status message 7 Information Generic SCADA status message 8... -

Page 153: Configuring Cooling Stages

9 Visualization 9.11.1 Configuring cooling stages To control the cooling system, you have to set the following parameters for each cooling group: Settings Parameters Control, c...p 1 Name Value Home Activate Switch-on input variable Hot-spot temperature Switch-off input variable Top-oil temperature Events Switching point 60°C... - Page 154 9 Visualization ▪ Ambient temperature ▪ Lower oil temperature ▪ OLTC oil temperature ▪ Generic temperature Switch off input variable You can use this parameter to set which measured temperature value is to be used to switch off the cooling stage. You can select the following options: ▪...

-

Page 155: Set The Operating Mode

9 Visualization Active if error You can use this parameter to set whether the device is to activate the cool- ing stage in the event of an error (fail-safe mode). The following types of er- ror are recognized: ▪ The input signal for the temperature is in an impermissible range (e.g. ca- ble break, sensor defective) ▪... - Page 156 9 Visualization Once the switch-on delay has elapsed, the cooling stages are activated. To limit the inrush current of the cooling stages, they are activated one after an- other with a delay time of 60 seconds. Settings Parameters Cooling ...rol Name Value Home Operating mode...

-

Page 157: Configuring Periodic Mode

9 Visualization Load-dependent mode: Overrun time You can use this parameter to set the time period for which the cooling stages remain switched on when the transformer load current returns to a value below the set switching point. 9.11.5 Configuring periodic mode Periodic mode is used to prevent the bearings of the cooling stages from seizing up as a result of long idle periods. -

Page 158: Configuring Alternating Mode

9 Visualization Periodic mode: Switch-on delay You can use this parameter to set the time period after which the cooling stages are to be switched back on again. 9.11.6 Configuring alternating mode If the transformer is equipped with several similar cooling stages, you can run the stages in alternating mode. -

Page 159: Configuring The Frequency-Based Cooling System Control

9 Visualization Alternating mode: Change interval You can use this parameter to set the time period after which the cooling stage is to be changed. 9.11.7 Configuring the frequency-based cooling system control The optional frequency-based cooling system control function lets you con- trol the fans in a cooling system using the frequency. - Page 160 9 Visualization The following diagrams show an example of a graph of the fan speeds based on the top-oil temperature according to the set parameters. θ θ °C θ Top oil Figure 116: Fan speed based on the top-oil temperature n Fan speed θ...

- Page 161 9 Visualization The following diagrams show an example of a graph of the fan speeds based on the load factor according to the set parameters. Load factor Figure 117: Fan speed based on load factor n Fan speed θ Top-oil temperature Top-oil Minimum fan speed Maximum fan speed...

-

Page 162: Displaying Status Of Cooling Stages

9 Visualization Min. fan run time after error You can use this parameter to set how long the fans are to continue running if an error occurs in the cooling system control. The fans run at full power for this duration. Minimum fan speed You can use this parameter to set the minimum fan speed. -

Page 163: Cooling System Monitoring (Optional)

9 Visualization Figure 119: Status of cooling stages ► Go to Information > Cooling system > Cooling system control. 9.12 Cooling system monitoring (optional) With the optional cooling monitoring function, you can monitor the cooling system of a transformer. 9.12.1 Setting the cooling system monitoring function You can set the general cooling system monitoring functions with the follow- ing parameters. -

Page 164: Cooling Efficiency Monitoring (Optional)

9 Visualization 4. Press the Accept button to save the modified parameter. Run-in time evaluation You can use this parameter to set the length of time a cooling stage has to be active before the device performs an evaluation of the values to be moni- tored for the "Cooling system flow monitoring"... -

Page 165: Cooling System Flow Monitoring (Optional)

9 Visualization 1. Go to Settings > Parameters > Cooling system > Cooling efficiency monitoring. 2. Select the desired parameter. 3. Set the parameter. 4. Press the Accept button to save the modified parameter. Transformer short-circuit losses You can use this parameter to set the transformer short-circuit losses (cop- per losses) P for calculating the thermal resistance of the cooling system. - Page 166 9 Visualization ▪ Pressure ▪ Flow rate ▪ Pump current consumption Water Cooling stage 1 Cooling stage 2 0.96 bar 1.10 bar 0.96 bar 1.10 bar 3.6 m³/h 3.9 m³/h 3.6 m³/h 3.6 m³/h 45°C 8°C 47°C 8°C 38°C 14°C 41°C 15°C Figure 123: Cooling system flow monitoring values 9.12.3.1 Setting the cooling system flow monitoring function You can set the following limit values for the cooling media oil and water re- spectively for monitoring the cooling system flow:...

- Page 167 9 Visualization Behavior If the measured value is higher than the upper limit (> or >>) or lower than the lower limit (< or <<), the device triggers an event message. Figure 124: Monitoring, cooling stage 1 1. Go to Settings > Parameters > Cooling system > Cooling stage 1/2 monitoring.

- Page 168 9 Visualization Oil pressure You can use these parameters to set the limit values for the permissible pressure of the oil circuit. You can set two lower limit values for each cooling stage. Oil flow You can use these parameters to set the limit values for the permissible flow rate of the oil circuit.

-

Page 169: Control Of The Motor-Drive Unit (Optional)

9 Visualization 9.12.3.2 Displaying the cooling system flow You can display the temporal progression of the measured values of the cooling system flow monitoring over the last 10 days. Figure 125: Cooling system flow ► Go to Information > Cooling system > Cooling stage 1/2. 9.13 Control of the motor-drive unit (optional) The following parameters let you configure control of the motor-drive unit. -

Page 170: Setting The Switching Pulse For Controlling The Motor-Drive Unit

9 Visualization 9.13.1 Setting the switching pulse for controlling the motor-drive unit You can use the parameters Switching pulse type, Switching pulse time and Switching pulse pause to adapt the device switching pulse to the require- ments of the motor-drive unit controller. 1. -

Page 171: Setting Motor Runtime Monitoring

9 Visualization Figure 127: Switching pulse time and switching pulse pause 1 Switching pulse time 2 Switching pulse pause Switching pulse time You can use this parameter to set the maximum duration of the switching pulse. The switching pulse resets after the switching pulse time has elapsed or if the device receives the Motor running signal beforehand or the tap posi- tion is changed. -

Page 172: Setting The Switching Direction

9 Visualization 3. Set the parameter. 4. Press the Accept button to save the modified parameter. Motor runtime You can use this parameter to set the motor runtime. Motor runtime monitoring You can use this parameter to activate or deactivate motor runtime monitor- ing. -

Page 173: Drive Overview

9 Visualization Q switching direction (optional) You can use this parameter to set the switching direction for reactive power regulation. You can use this to adjust the behavior of the device based on how your on-load tap-changer and motor-drive unit are configured. You can select the following options: Setting Meaning... -

Page 174: Regulation

9 Visualization ▪ Internal temperature of the motor-drive unit (optional) ▪ Next maintenance (optional) Figure 128: Drive overview 1 Tap position 2 Tap-change indicator section (SSE) 3 Operation counter 4 Operating mode 5 Switching blocking 6 Motor protective switch 7 Door open/closed 8 Temperatures 9 Next maintenance ►... - Page 175 9 Visualization Settings Parameters Control Name Value Home Control variable Voltage Response to SCADA disconnection No reaction SCADA disconnection delay time 5 s Events Information Recorder CHANGE REBOOT admin 23.09.2020 09:23 Settings Figure 129: Regulation 1. Go to Settings > Parameters > On-load tap-changer regulator > Regu- lation.

-

Page 176: Setting Control Variable (Optional)

9 Visualization 9.15.2 Setting control variable (optional) If the device is equipped with the optional reactive power regulation function, you can set which control variable the device is to regulate. Settings Parameters Control Name Value Home Control variable Voltage Response to SCADA disconnection No reaction SCADA disconnection delay time 5 s... -

Page 177: Voltage Regulation (Optional)

9 Visualization 9.16 Voltage regulation (optional) All of the parameters required for the voltage regulation are described in this section. Settings Parameters Voltage re...ion Name Value Home Desired value 1 100 V Desired value 2 100 V Desired value 3 100 V Events Selecting a desired value Desired value 1 Bandwidth... - Page 178 9 Visualization 3. Press the Accept button to save the modified parameter. Selecting a desired value You can use this parameter to select the desired value used for control. 1. Go to Settings > Parameters > Grid > Control > Select desired value. 2.

- Page 179 9 Visualization 9.16.1.4 Analog setting of the desired value With the analog setting of the desired value, the desired value for the auto- matic voltage regulation can be variably adapted using an analog signal (e.g. 4...20 mA). Desired value Max. Min.

- Page 180 9 Visualization 3. Press the Accept button to save the modified parameter. 9.16.1.5 Step-by-step setting of the desired value For the step-by-step setting of the desired value, you can increase or de- crease the desired value for the automatic voltage regulation by an ad- justable step width using digital inputs or control system commands.

- Page 181 9 Visualization Parameter Function Settings (see diagram below) : Desired value at 0 active Set desired value is activated when measured active 100.00 V power power is 0 MW. : Active power at max. de- Set maximum active power value above which the 20.0 MW sired value power-dependent desired value is to attain the maxi-...

- Page 182 9 Visualization Response to value falling below active power P If the measured active power P falls below the set parameter P , the meas value U is adopted as the desired value. Response to a measured active power P = 0 MW: meas If the measured active power P...

- Page 183 9 Visualization 2. Select the option you want. 3. Press the Accept button to save the modified parameter. TDSC Umax/Umin You can use these parameters to set the maximum and minimum desired value. The maximum or minimum desired value is activated when the mea- sured active power reaches the set minimum or maximum active power.

- Page 184 9 Visualization Depending on whether positive or negative active power is measured, the desired value calculation is based on 2 linear equations (see example in dia- gram below). Parameter Function Settings (see diagram below) : Maximum desired value Maximum set desired value is activated when P 103.0 V exceeded.

- Page 185 9 Visualization Response to active power P being exceeded If the measured active power P exceeds the set parameter P , the value meas is adopted as the desired value. Response to value falling below active power P If the measured active power P falls below the set parameter P , the meas...

- Page 186 9 Visualization If you activate TDSC, the line drop compensation (R&X compensation or Z compensation) function is deactivated. To activate/deactivate TDSC using parameters, proceed as follows: 1. Go to Settings > Parameters > Control > Activate TDSC. 2. Select the option you want. 3.

- Page 187 9 Visualization The following outputs are available to you as an option: ▪ Desired value setting faulty: The device issues a signal if the BCD code for the desired value setting is invalid. ▪ Desired value active: The device issues a signal if desired value setting via BCD is active.

- Page 188 9 Visualization Desired BCD input value 76 V 77 V 78 V 79 V 80 V 81 V 82 V 83 V 84 V 85 V 86 V 87 V 88 V 89 V 90 V 91 V 92 V 93 V 94 V 95 V...

- Page 189 9 Visualization Desired BCD input value 111 V 112 V 113 V 114 V 115 V 116 V 117 V 118 V 119 V 120 V 121 V 122 V 123 V 124 V 125 V 126 V 127 V 128 V 129 V 130 V...

- Page 190 9 Visualization Bandwidth You can use this parameter to set the maximum permissible deviation of the measured voltage U from the desired value U actual desired In order to set the correct value, the transformer step voltage and nominal voltage must be known. Note that a large bandwidth will result in a large control deviation.

- Page 191 9 Visualization change command is issued after expiration of the set delay time T1. The on-load tap-changer carries out a tap-change in a raise or lower direction to return to the tolerance bandwidth. Figure 135: Behavior of the control function with delay time T1 1 Upper limit of bandwidth 4 Set delay time T1 2 Desired value...

- Page 192 9 Visualization Behavior with delay times If the control variable deviates from the set bandwidth for a long period T1 and T2 , a control impulse is output to the motor-drive unit after the set delay time . If the control variable is still outside the bandwidth, delay time T2 starts to count down.

-

Page 193: Reactive Power Regulation (Optional)

9 Visualization 9.17 Reactive power regulation (optional) All of the parameters required for reactive power regulation are described in this section. Settings Parameters Reactive p...ion Name Value Home Desired value 0 var Bandwidth 0 var Delay time T1 40 s Events Time response T1 Linear Activate delay time T2 Delay time T2... - Page 194 9 Visualization change command is issued after expiration of the set delay time T1. The on-load tap-changer carries out a tap-change in a raise or lower direction to return to the tolerance bandwidth. Figure 138: Behavior of the control function with delay time T1 1 Upper limit of bandwidth 4 Set delay time T1 2 Desired value...

- Page 195 9 Visualization the device responds faster to large voltage changes in the grid. Regulation accuracy improves as a result but the frequency of tap-changes increases too. Figure 139: Diagram for integral time response ΔU/B Control deviation "ΔU" as % of desired value in relation to the set band- width "B"...

-

Page 196: Transformer Data

9 Visualization starts to count down. Once delay time T2 is complete, a control impulse is again issued to the motor-drive unit for the tap change to return to the tol- erance bandwidth. Figure 140: Behavior of the regulation function with delay times T1 and T2 1 Upper limit of bandwidth 4 Set delay times T1 and T2. -

Page 197: Setting Transformer Data

9 Visualization 9.18.1 Setting transformer data You can use the following parameters to set the transformer data. Also note the Examples for standard circuits for current transformers and voltage transformers [►Section 9.18.2, Page 199]. Settings Parameters Transfor...ata Name Value Home Primary transformer voltage 100 kV Secondary transformer voltage... - Page 198 9 Visualization Secondary transformer current You can use this parameter to set the secondary current of the current trans- former. You can select the following options: ▪ 0.2 A ▪ 1 A ▪ 5 A If you use the optional function "Hot-spot calculation on 3 different windings (W1, W2, W3)", this parameter setting applies to all 3 windings.

- Page 199 9 Visualization 9.18.2 Circuit examples for voltage transformers and current transformers Below you will find different examples of circuits for voltage transformers and current transformers and the corresponding settings. 9.18.2.1 1-phase measurement Circuit 1-A ▪ The voltage transformer VT is connected to the phase conductor and neu- tral conductor.

- Page 200 9 Visualization ▪ The voltage transformer VT is connected to the phase conductor L1 and the neutral conductor. ▪ The current transformer CT is looped into the phase conductor L1. ▪ The voltage U and current I are in phase. ▪...

- Page 201 9 Visualization Circuit 1-D ▪ The voltage transformer VT is connected to the phase conductors L1 and ▪ The current transformer CT is looped into the phase conductor L3. ▪ The current I is ahead of voltage U by 90°. This corresponds to a phase shift of -90°.

- Page 202 9 Visualization If you use this circuit, set the device as follows: Parameters Option Voltage-transformer circuit 3 Ph differential voltage Current-transformer circuit 3 Ph phase current Phase angle correction 30° Table 53: Circuit 1-E Circuit 1-F ▪ The voltage transformer VT is connected to the phase conductors L1 and ▪...

- Page 203 9 Visualization 9.18.2.2 3-phase measurement Circuit 3-A l1 k2 l2 k3 ▪ Three-phase measurement. ▪ The voltage transformers are connected between the phases. ▪ The current lags behind the voltage by 30°. If you use this circuit, set the device as follows: Parameters Option Voltage-transformer circuit...

- Page 204 9 Visualization Parameters Option Voltage-transformer circuit Current-transformer circuit Phase angle correction 0° UI measuring channels 3-phase measurement (channels 1, 2, 3) Measurement mode Phase-neutral Table 56: Circuit 3-B Only use the circuits 3-C, 3-D and 3-E on symmetrical grids. Otherwise the device will calculate incorrect performance values.

- Page 205 9 Visualization Circuit 3-D l1 k2 l2 k3 ▪ Three-phase voltage measurement, single-phase current measurement. ▪ The voltage transformers are connected between the phases. ▪ The current transformer is connected to phase L2. Parameters Option Voltage-transformer circuit Current-transformer circuit Phase angle correction -150°...

- Page 206 9 Visualization Parameters Option UI measuring channels 3-ph. voltage, 1-ph. current Measurement mode Phase-phase Table 59: Circuit 3-E Circuit 3-F l1 k2 l2 k3 ▪ Three-phase voltage measurement, single-phase current measurement. ▪ The voltage transformers are connected between the phase and neutral conductor.

- Page 207 9 Visualization ▪ Three-phase voltage measurement, single-phase current measurement. ▪ The voltage transformers are connected between the phase and neutral conductor. ▪ The current transformer is connected to phase L2. Parameters Option Voltage-transformer circuit 3 Ph phase voltage Current-transformer circuit 3 Ph phase current Phase angle correction -120°...

- Page 208 9 Visualization Only use these circuits in symmetrical grids. Note that you must always take the W1 voltage and current measurements on the low-voltage side of the transformer. ▪ W1: Voltage measurement and current measurement for the power calcu- lation and hot-spot calculation on winding 1 ▪...

- Page 209 9 Visualization Parameters Option UI measuring channels 3-ph. voltage, 1-ph. current Measurement mode Phase-neutral Table 63: Circuit S-1 Circuit S-2 l1 k2 l2 k3 If you use this circuit, set the device as follows: Parameters Option Voltage-transformer circuit 3 Ph phase voltage Current-transformer circuit 3 Ph phase current Current-transformer circuit W2...

- Page 210 9 Visualization Circuit S-3 l1 k2 l2 k3 If you use this circuit, set the device as follows: Parameters Option Voltage-transformer circuit Current-transformer circuit 3 Ph phase current Current-transformer circuit W2 Phase current Current-transformer circuit W3 Phase current Phase angle correction 0°...

- Page 211 9 Visualization Circuit S-4 l1 k2 l2 k3 If you use this circuit, set the device as follows: Parameters Option Voltage-transformer circuit 3 Ph differential voltage Current-transformer circuit 3 Ph phase current Current-transformer circuit W2 Phase current Current-transformer circuit W3 Phase current Phase angle correction -30°...

-

Page 212: Measurement

9 Visualization 9.19 Measurement You can use the following parameters to configure the measurement of cur- rent and voltage. Settings Parameters Measurement Name Value Home Regulation mode Single-phase Control variable L1/N or L1/L2 UI measuring channels 3-phase measurem.: Ch. 1,2,3 Events Information Recorder... -

Page 213: Control Variable

9 Visualization 9.19.2 Control variable If you are measuring the voltage and current with the 3-phase UI 3 measur- ing module and using the "single-phase" regulation mode, this parameter can be used to select the phase used for voltage regulation. You can select the following options: ▪... -

Page 214: Line Drop Compensation

9 Visualization 9.20 Line drop compensation You can use the compensation function to compensate for the load-depen- dent voltage drop between the transformer and consumer. The device pro- vides 2 methods of compensation for this purpose: ▪ R&X compensation ▪ Z compensation 9.20.1 R&X compensation R&X compensation can compensate for voltage losses on the lines and therefore ensure correct voltage at the load. - Page 215 9 Visualization Settings Parameters Compensation Name Value Home Compensation method R & X compensation Ohmic resistance load 0.0 Ohm/m Inductive resistance load 0.0 Ohm/m Events Length of line 0.00 m Voltage increase 0.0 % Voltage limit value 0.0 % Information Recorder CHANGE REBOOT admin 03.02.2020 08:09 Settings Figure 145: Compensation 1.

-

Page 216: Parallel Operation (Optional)

9 Visualization To use Z compensation, you need to calculate the voltage increase (ΔU) tak- ing the current into account. Use the following formula for this purpose: × k Load ΔU = × × 100 % Load ∆U Voltage increase Load current in A Transformer voltage at current I I Nominal current of current-trans- former connection in A... -

Page 217: Parallel Operation Methods

9 Visualization ▪ Maximum deviation of short-circuit voltages (U ) for transformers con- nected in parallel < 10% ▪ Same number of switching groups ▪ For parallel operation with CAN communication: Current transformers with the same rated values must be used for all devices operating in parallel 9.21.1 Parallel operation methods You can undertake parallel operation with various parallel operation meth- ods. - Page 218 9 Visualization For the tap synchronization parallel operation method, you have to set the following parameters: Parameter Auto Master Follower Activate parallel operation Parallel operation method Auto. tap syn- Master Follower chronization CAN bus address Circul. reactive current Optional, if master/follower current blocking is active blocking limit Master/follower current blocking...

- Page 219 9 Visualization The circulating reactive current is calculated from the transformer currents and their phase angles. The voltage regulators in the parallel operation group share this information via CAN bus. An extra control deviation propor- tional to circulating reactive current is added to the independently regulating voltage regulators as a correction for the control deviation determined on the basis of the measurement voltage.