Kuka KR C2 Manuals

Manuals and User Guides for Kuka KR C2. We have 5 Kuka KR C2 manuals available for free PDF download: Operating Instructions Manual, Assembly Instructions Manual, Operating Handbook, User Manual

Kuka KR C2 Operating Instructions Manual (215 pages)

edition 2005

Brand: Kuka

|

Category: Control Systems

|

Size: 12 MB

Table of Contents

-

Purpose11

-

Target Group11

-

Intended Use11

-

Motherboard16

-

Hard Drive18

-

Saferdc26

-

Batteries31

-

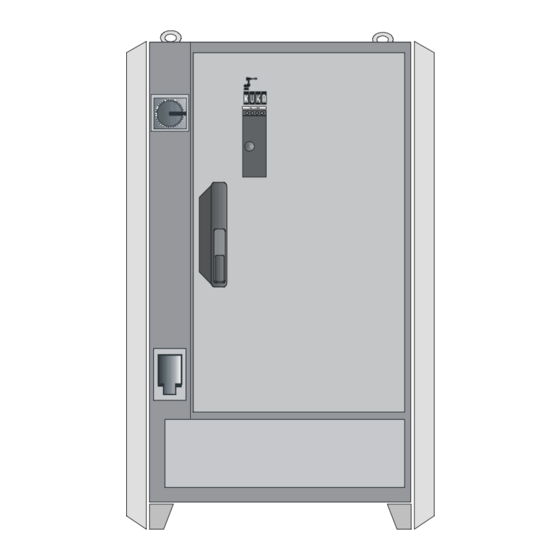

Front View32

-

Rear View33

-

ESC Nodes36

-

Fuses45

-

Mains Filter50

-

Safe KSK XA760

-

Safe KSK XA861

-

Saferdc65

-

Safety73

-

General73

-

Liability73

-

Terms Used75

-

Personnel75

-

Jog Mode83

-

Manual Mode91

-

Simulation92

-

Planning97

-

Interface X11105

-

Transportation117

-

Operation127

-

Coupling the KCP128

-

Maintenance129

-

Repair131

-

Troubleshooting151

-

MFC3 Errors152

-

Checking the KCP153

-

CI3 Bus Board157

-

CI3 Tech Board158

-

Testing the KSD163

-

RDC Table178

-

Drive Bus - KPS182

-

ESC Diagnosis186

-

User Interface186

-

Log File187

-

Troubleshooting189

-

KUKA Service201

Advertisement

Kuka KR C2 Operating Instructions Manual (157 pages)

Table of Contents

-

Motherboard15

-

Hard Drive16

-

Batteries19

-

Front View20

-

Rear View21

-

ESC Nodes24

-

Fuses35

-

Mains Filter38

-

Basic Data47

-

Safety53

-

Description55

-

Jog Mode59

-

Personnel61

-

Start-Up63

-

Programming64

-

Planning65

-

Start-Up79

-

Operation85

-

Maintenance87

-

Repair89

-

Troubleshooting103

-

CI3 Bus Board109

-

CI3 Tech Board110

-

Error Messages115

-

RDC Table123

-

Drive Bus - KPS128

-

ESC Diagnosis132

-

User Interface132

-

Log File133

-

Appendix145

-

KUKA Service147

-

Index153

Kuka KR C2 Operating Handbook (96 pages)

Machine Data

Brand: Kuka

|

Category: Controller

|

Size: 0 MB

Table of Contents

-

-

Tech_Max9

-

Num_Ax10

-

Axis_Type[ ]11

-

Coup_Comp[ ]11

-

Mames[ ]12

-

Robroot13

-

Ersysroot14

-

Pmchannel[ ]18

-

Curr_Max[ ]28

-

Curr_Cal[ ]28

-

Curr_Lim[I]29

-

Curr_Mon[I]29

-

Kps_Curr_Max30

-

Kt_Mot[ ]31

-

Kt0_Mot[ ]31

-

Vel_Cpt1_Ma33

-

Axis_Reso[ ]33

-

Red_Acc_Dyn35

-

Red_Vel_Cpc35

-

Red_Acc_Cpc35

-

Vel_Cp_T135

-

Vel_Cp_Com35

-

Red_Jus_Ueb36

-

Acc_Car_Tool36

-

Acc_Car_Act37

-

Acc_Car_Stop37

-

Warmup_Time39

-

St_Tol_Time40

-

Bounce_Time41

-

Sen_Del[ ]41

-

L_Emt_Max[ ]42

-

G_Vel_Cal42

-

Lg_Ptp[ ]42

-

Lg_Cp[ ]43

-

Tc_Sym43

-

Decel_Mb[]43

-

G_Coe_Cur44

-

G_Vel_Ptp[ ]44

-

G_Vel_Cp[ ]44

-

I_Vel_Ptp[ ]45

-

I_Vel_Cp[ ]45

-

Vel_Filt[ ]46

-

Tm_Con_Vel46

-

Acc_Ma47

-

Vel_Ma47

-

Acc_Ov48

-

Red_T148

-

Def_Flt_Ptp48

-

Def_Flt_Cp48

-

Def_Ov_Jog49

-

Ana_Del_Flt49

-

100 $Seq_Cal49

-

101 $Dir_Cal49

-

110 $Ms_Da54

-

111 $Ffc_Vel55

-

141 $A4_Par69

-

144 $Spindle71

-

155 $Tiroro75

-

156 $Tflwp76

-

157 $Tx3P376

-

160 $Dh_477

-

161 $Dh_577

-

162 $Spin_A78

-

163 $Spin_B78

-

164 $Spin_C78

-

165 $Trp_A78

-

166 $Spc_Kin79

-

Ex_Ax_Num83

-

Ex_Ax_Async84

-

Ex_Kin88

-

Et1_Ax88

-

Et1_Name[ ]89

-

Et1_Ta1Kr89

-

Et1_Ta2A190

-

Et1_Ta3A290

-

Et1_Tfla390

-

Et1_Tpinfl91

Advertisement

Kuka KR C2 User Manual (89 pages)

CONTROL CABINET

Brand: Kuka

|

Category: Controller

|

Size: 1 MB

Table of Contents

-

-

Drives9

-

Stopped Ax19

-

-

System Info41

-

-

Display53

-

Print60

-

Configure68

-

General70

-

Trace Status73

-

Trace Data73

-

Kuka KR C2 Assembly Instructions Manual (106 pages)

Table of Contents

-

Purpose9

-

Target Group10

-

General11

-

Wrist12

-

Arm13

-

Link Arm14

-

Base Frame18

-

General21

-

Safety35

-

General35

-

Liability36

-

Terms Used38

-

Personnel39

-

Manual Mode47

-

Installation57

-

General57

-

Installation69

-

Description73

-

General83

-

Coding85

Advertisement