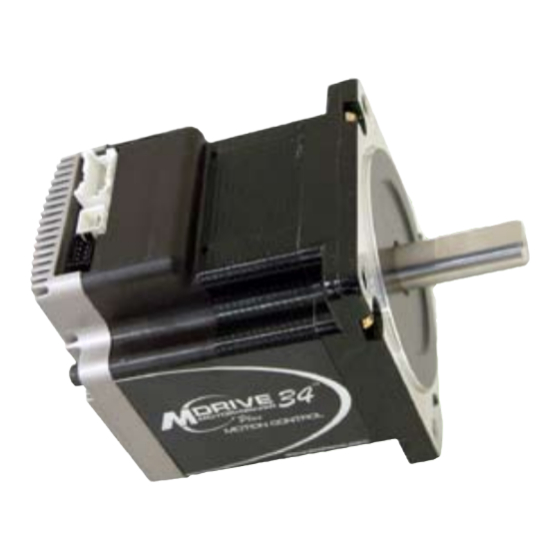

IMS MDrive 34 Plus Series Manuals

Manuals and User Guides for IMS MDrive 34 Plus Series. We have 1 IMS MDrive 34 Plus Series manual available for free PDF download: Hardware Reference Manual

IMS MDrive 34 Plus Series Hardware Reference Manual (84 pages)

Motor+driver motion control

Table of Contents

Advertisement

Advertisement