GEDA 300 Z Manuals

Manuals and User Guides for GEDA 300 Z. We have 4 GEDA 300 Z manuals available for free PDF download: Assembly And Operating Manual, Operating Manual

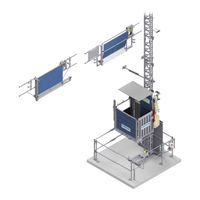

GEDA 300 Z Assembly And Operating Manual (128 pages)

Construction hoist for material transport

Brand: GEDA

|

Category: Lifting Systems

|

Size: 8 MB

Table of Contents

-

Safe Working12

-

Intended Use16

-

Improper Use17

-

Emissions25

-

Speeds27

-

Heights27

-

Mast28

-

Transport31

-

Assembly33

-

Substructure35

-

Stop Bars54

-

Installation54

-

Operation59

-

Cordon66

-

Equipment76

-

Accessories80

-

Spindle80

-

Cleaning87

-

Inspections88

-

Gearboxes95

-

Gearwheels98

-

Function Tests101

-

Fault Table105

-

Rectify Fault107

-

Repair114

-

Disassembly115

-

Disposal116

Advertisement

GEDA 300 Z Operating Manual (101 pages)

Construction Hoist / Transport Platform For loads and persons

Brand: GEDA

|

Category: Lifting Systems

|

Size: 2 MB

Table of Contents

-

Guide7

-

Images7

-

Imprint11

-

Machine12

-

Manufacturer12

-

Speeds14

-

Drives14

-

Emissions14

-

Mast Section15

-

Mast16

-

Foundation16

-

Electrics25

-

Tests26

-

Proper Use27

-

Energies29

-

Emergency29

-

Warranty30

-

Operator34

-

Cleaning42

-

Car Control46

-

Safety Stop54

-

Safety Gear54

-

Roof56

-

Cold Package60

-

Cleaning66

-

Assembly67

-

Disassembly81

-

Maintenance82

-

Drive Pinion88

-

Gear Rack88

-

Motor Brake90

-

Safety Gear91

-

Fault Table94

GEDA 300 Z Operating Manual (104 pages)

Construction Hoist/Transport Platform

Brand: GEDA

|

Category: Industrial Equipment

|

Size: 7 MB

Table of Contents

-

Patents14

-

Intended Use16

-

Improper Use18

-

Emissions27

-

Speeds30

-

Heights30

-

Mast31

-

Operation37

-

Cordon43

-

Controls61

-

Equipment78

-

Roofs78

-

Accessories84

-

Cold Package85

-

Fault Table90

-

Repair101

-

Disposal102

Advertisement

GEDA 300 Z Assembly And Operating Manual (92 pages)

Rack and pinion hoist For loads

Brand: GEDA

|

Category: Lifting Systems

|

Size: 4 MB

Table of Contents

-

Proper Use10

-

Improper Use11

-

Checks19

-

Static Test21

-

Spindle33

-

Foundation44

-

Transport46

-

Installation47

-

Operation61

-

Ramp63

-

Repairs80

Advertisement