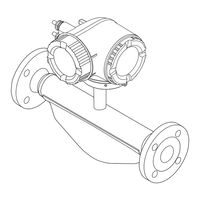

Endress+Hauser Proline Promass E 300 Manuals

Manuals and User Guides for Endress+Hauser Proline Promass E 300. We have 2 Endress+Hauser Proline Promass E 300 manuals available for free PDF download: Operating Instructions Manual

Endress+Hauser Proline Promass E 300 Operating Instructions Manual (244 pages)

Coriolis Flowmeter EtherNet/IP

Brand: Endress+Hauser

|

Category: Measuring Instruments

|

Size: 8 MB

Table of Contents

-

Symbols6

-

Security11

-

Mounting21

-

Requirements40

-

Relay Output43

-

Status Input43

-

Display Area51

-

Editing View55

-

Text Editor55

-

Requirements63

-

Logging on67

-

Function Row67

-

Logging out69

-

Fieldcare73

-

Devicecare74

-

Block Model76

-

Endress+Hauser133

-

Simulation142

-

Operation149

-

Density152

-

Temperature152

-

Concentration152

-

Ctl154

-

Cpl154

-

Ctpl154

-

Output Values162

-

Transmitter172

-

Maintenance199

-

Maintenance Work199

-

Repair200

-

General Notes200

-

Spare Parts200

-

Return200

-

Disposal201

-

Accessories202

-

For the Sensor203

-

Technical Data205

-

Application205

-

Input206

-

Output209

-

Output Signal209

-

Power Supply215

-

Flow Values217

-

Mounting220

-

Environment220

-

Process221

-

Flow Limit222

-

Index237

Advertisement

Endress+Hauser Proline Promass E 300 Operating Instructions Manual (264 pages)

Coriolis flowmeter PROFINET

Brand: Endress+Hauser

|

Category: Measuring Instruments

|

Size: 10 MB

Table of Contents

-

Symbols6

-

Security12

-

Installation22

-

Requirements40

-

Display51

-

Editing View54

-

Code60

-

Logging on65

-

Logging out67

-

Fieldcare71

-

Devicecare72

-

Interface95

-

Switch Output102

-

Simulation134

-

Switch139

-

Operation141

-

Totalizer143

-

Output Values145

-

Conditions147

-

Diodes154

-

Transmitter154

-

Diagnostic List215

-

Maintenance222

-

Repair223

-

General Notes223

-

Spare Parts223

-

Return223

-

Disposal224

-

Accessories225

-

For the Sensor226

-

Technical Data228

-

Application228

-

Input229

-

Output232

-

Power Supply237

-

Installation242

-

Environment242

-

Process243

-

Index259

Advertisement

Related Products

- Endress+Hauser Proline Promass E 300 HART

- Endress+Hauser Proline Promass E 200

- Endress+Hauser Proline Promass E 100

- Endress+Hauser Analytik Jena multi EA 5000

- Endress+Hauser Analytik Jena multi EA 5100

- Endress+Hauser Liquiline To Go Ex CYM291

- Endress+Hauser Endress+Hauser

- Endress+Hauser Proline Promass E 500 PROFINET

- Endress+Hauser Proline Prosonic Flow E 100 HART

- Endress+Hauser Proline Promass E TB2 HART