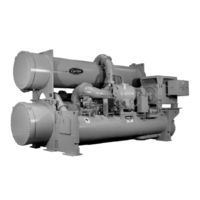

Carrier 19EX Series Manuals

Manuals and User Guides for Carrier 19EX Series. We have 3 Carrier 19EX Series manuals available for free PDF download: Start-Up, Operation And Maintenance Instructions Manual, Start Up & Operation Manual, Product Data

Carrier 19EX Series Start-Up, Operation And Maintenance Instructions Manual (437 pages)

50/60 Hz Centrifugal Liquid Chillers with HFC-134a

Table of Contents

Advertisement

Carrier 19EX Series Start Up & Operation Manual (116 pages)

Centrifugal Liquid Chillers 50/60 Hz with HFC-134a

Table of Contents

Carrier 19EX Series Product Data (37 pages)

Hermetic Centrifugal 50/60 Hz 800 to 1400 Nominal Tons (2810 to 4920 kW)

Table of Contents

Advertisement

Advertisement