Table of Contents

Advertisement

Do not use this equipment before reading this manual!

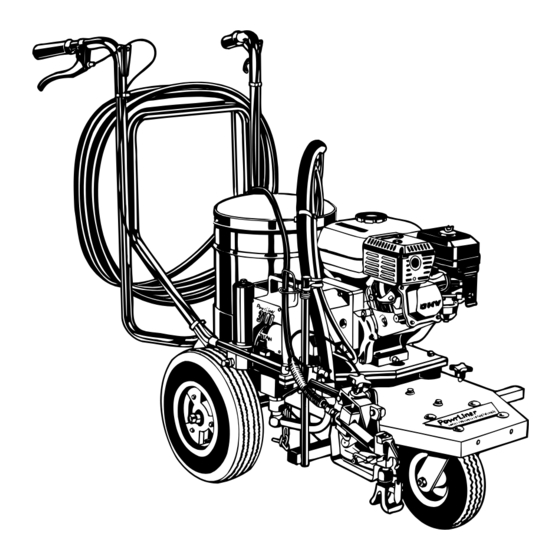

PowrLiner 3100

Model Number:

Pump Complete 759-300

Printed in the U. S. A.

®

Owner's Manual

For professional use only

NOTE: This manual contains important warnings

and instructions. Please read and retain for

reference.

0999 © 1999 Titan Tool Inc. All rights reserved. Form No. 313-1246

REV C

Advertisement

Table of Contents

Summary of Contents for Titan PowerLiner 3100

- Page 1 PowrLiner 3100 Model Number: NOTE: This manual contains important warnings Pump Complete 759-300 and instructions. Please read and retain for reference. Printed in the U. S. A. 0999 © 1999 Titan Tool Inc. All rights reserved. Form No. 313-1246 REV C...

-

Page 2: Table Of Contents

1/4" Mx1/4"F Swivel Union ..490-005 8 oz individual......700-925 1/4" Mx3/8"F Swivel Union ..490-032 1 qt individual......700-926 Retaining Nut Adapter ....490-007 8 oz, case of 12 .....700-911 High Pressure Fl. Gauge ..730-394 1 qt, case of 12.....700-912 © Titan Tool Inc. All rights reserved. ¤... -

Page 3: General Repairs/Service

Weekly: Remove the cover of the air filter and clean the Canada 1-800-565-8665 element. Replace the element if necessary. If operating in Fax 1-905-856-8496 an unusually dusty environment, check the filter daily and replace if necessary. © Titan Tool Inc. All rights reserved. ¤... -

Page 4: Maintenance/Service Record

COMPANY NAME Titan Tool is in the business of designing and manufacturing spray systems and accessories that make today’s Painting Professional become more efficient and profitable. We feel that if you accurately track the maintenance of your equipment on this chart it will improve the performance of this valuable tool to help you get the most out of your investment. -

Page 5: Warnings

11) NEVER alter or modify any part of this equipment; doing so could cause it to malfunction. 12) NEVER leave equipment unattended. Keep away from children or anyone not familiar with the operation of airless equipment. ¤ © Titan Tool Inc. All rights reserved. -

Page 6: Aviso (En Español)

11) JAMAS altere o modifique parte alguna de este equipo, ya que ello puede causar deficiencias de funcionamiento. 12) JAMAS deje al equipo solo. Manténgalo fuera del alcance de los niños o de cualquier persona no familiarizada con la operación de equipo sin aire. ¤ © Titan Tool Inc. All rights reserved. -

Page 7: Attention (En Français)

11) N´altérez ou ne modifiez JAMAIS une partie quelconque de cet appareil, ce qui pourrait causer des défaillances. 12) Ne laissez JAMAIS le matériel sans surveillance. Gardez-le hors de portée des enfants et de toute personne inexpérimentée quant à l’usage de matériel sans air. ¤ © Titan Tool Inc. All rights reserved. -

Page 8: Notice: Fire Or Explosion Hazards

ELECTRIC MOTOR The electric motors used by TITAN are not explosion proof. Therefore, it is essential to keep the working area around the pump well ventilated. Additionally, the pump itself should be a minimum of 25' (7,5) from the spray area. - Page 9 MOTEUR ÉLECTRIQUE Les moteurs électriques utilisés par TITAN ne sont pas protégés contre les explosions. Il est donc essentiel d'as- surer une bonne ventilation de la zone de travail et des environs de la pompe. Il est également important de main- tenir la pompe à...

- Page 10 DICHLOROMOETHANE FLUOROCARBON SOLVENTS: Methyl iodide Monochlorobenzene Dichlorofluoromethane Ethyl iodide Orthodichlorobenzene Trichlorofluoromethane Propyl iodide Perchloroethylene BROMINATED SOLVENTS: CHLORINATED SOLVENTS: TRICHLOROETHANE Ethylene dibromide Carbon tetrachloride Trichloroethylene Methylene chlorobromide Chloroform Monochlorotoluene Methyl bromine Ethylene dichloride © Titan Tool Inc. All rights reserved. ¤...

-

Page 11: Startup Procedure

Step 11: Turn sprayer on and rotate the pressure relief prime valve to the spray position. Step 12: Test on cardboard to check spray pattern. Adjust pressure just until the spray from gun is completely atomized. © Titan Tool Inc. All rights reserved. ¤... -

Page 12: Application Techniques

The spray tip is in the shape of an arrow. It should face to maintain correct spray pattern. always point at your work. If you are spraying a curb, aim spray tip at the top corner of the curb. © Titan Tool Inc. All rights reserved. ¤... -

Page 13: Cleaning Procedure

Curbs ......645-1706 amount of mineral spirits or TITAN LS- 10 solution through pump. This will General Painting . -

Page 14: Flushing Specifications

2. Spray tip too big or worn 2. Change or replace 3. Excessive pressure 3. Decrease pressure and engine speed 1. Worn out packings 1. Replace Paint leaks into oil cup © Titan Tool Inc. All rights reserved. ¤... -

Page 15: Parts Drawings And Repair Information

Screw ............4 756-154 Screw ............2 759-004 Frame, Base..........1 313-1245 Label Powrliner 3100 ......1 313-174 Label Warning .........1 424-281 Caster (includes item 67) ......1 866-004 Washer ............4 866-210 Nut............4 424-280 Wheel (only) ..........1 © Titan Tool Inc. All rights reserved. ¤... -

Page 16: Replacement Labels

When transporting a unit with a gas engine, make sure to shut fuel off. Figure 5 Replacement Labels Part # Description Quantity 759-040 Front Plate (front cover label)......1 313-1245 PowrLiner 3100..........1 313-191 Warning Label (in English) ......1 313-201 Warning/Attention Label (in French)...1 © Titan Tool Inc. All rights reserved. ¤... - Page 17 © Titan Tool Inc. All rights reserved. ¤...

-

Page 18: Engine Assembly

Clutch Plate ........1 763-550 Bushing (Incl. #74)......1 763-566 Screw ..........2 700-652 Screw ..........6 755-117 Engine Assembly (includes items 1-7, 11, & 14)..1 750-018 Screw ..........2 730-184 Electrical Connector......1 755-150 Clutch Plate & Bushing....1 © Titan Tool Inc. All rights reserved. ¤... -

Page 19: Maintenance

Always unplug the necessary. sprayer before servicing! Replacement elements can be purchased from your local TITAN Caution: For detailed engine maintenance and specifica- Dealer. tions, refer to the separate engine manual supplied. -

Page 20: Gear Box Assembly

Rubber Boot........1 730-360 Crank Shaft........1 761-192 Insulator Plate........1 730-088 Thrust Washer ........ 1 700-791 Safety Plate ........1 700-688 Thrust Washer ........ 1 730-172 Clutch Seal ........1 730-167 Output Pinion Ass’y ......1 © Titan Tool Inc. All rights reserved. ¤... -

Page 21: Clutch Rotor & Gear Repair

3. Remove the two screws #57. 7. Reinstall the Cover Plate and Insulator with Warning 4. Reassemble in reverse order. Refer to the Wiring Label facing out. Diagram for the correct placement of the wires. © Titan Tool Inc. All rights reserved. ¤... -

Page 22: Filter Block Assembly

1/4-20 UN Screw ......2 700-699 Fitting ..........1 702-305 Filter HSG Assembly .......1 (excludes items 3, 4, 5, & 27) Optional PTFE O-Ring (not shown) 1 700-897 700-890 Bypass O-Ring Tool (not shown) ..1 Figure 8 © Titan Tool Inc. All rights reserved. ¤... -

Page 23: Pressure Switch

Figure 9 For more detail, part number information and assem- 9. IMPORTANT: If Handle #18 rotates 360° check Pin on bly drawings at larger scale, please see the SGX-20 Cam #16. Professional Airless Gun Owner’s Manual (#313-001). © Titan Tool Inc. All rights reserved. ¤... -

Page 24: Fluid Section Assembly

Syphon Assembly (items 341–345).......1 756-111 Bypass Assembly ......1 756-110 Syphon Assembly (includes item 345) ......1 700-742 Hose Tie Wrap.........1 700-805 Inlet Screen........1 700-900 30 Mesh Inlet Screen (optional, not shown) .......1 755-135 Clip...........1 © Titan Tool Inc. All rights reserved. ¤... -

Page 25: Pump Repair

18. Reattach Retainer #301 and make sure that the upper guide Seat Service and Repair #302 is cleaned and undamaged. The design of Titan's Epic Fluid Section allows access to the 19. Insert pump housing items #301–#307 into a vise, leaving inlet and outlet valves and seat without completely enough room to slide piston through bottom of pump disassembling the Fluid Section. -

Page 26: Equipment Job History

Equipment Job History In order to help you track the superior performance of your Titan Sprayer we recommend you keep this log for your records. We feel you may find it useful for gauging on-site performance, invoicing or overtime and your estimator's reference. -

Page 27: Specifications

.021 w/2 guns Honda engine 3500 759-351 (w/ 2 guns) ** Hose length depends on material being sprayed, hose diameter and tip size. *** DP-30 supplied with 25' of hose and a Profit Gun. © Titan Tool Inc. All rights reserved. ¤... -

Page 28: Warranty

TITAN Warranty for the PowrLiner 3100 Titan Tool, Inc., (“Titan”) warrants that at the time of delivery to the THERE IS NO OTHER EXPRESS WARRANTY. TITAN HEREBY DISCLAIMS ANY AND ALL IMPLIED WARRANTIES INCLUDING, original purchaser for use (“End User”), the equipment covered by this warranty is free from defects in material and workmanship.

Need help?

Do you have a question about the PowerLiner 3100 and is the answer not in the manual?

Questions and answers