Table of Contents

Advertisement

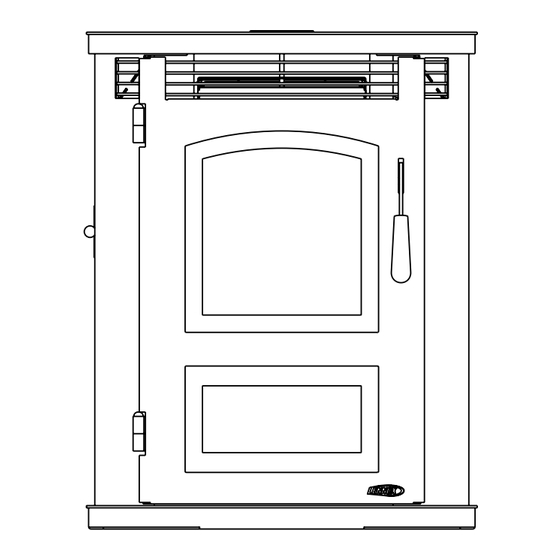

Free-Standing

Pellet Stove

Save These Instructions

For Future Reference

P/N 900116-00, Rev. A, 05/2015

C

US

Report No. 14-200

INSTALLATION AND OPERATION MANUAL

P900116-00

A French manual is available upon request. Order P/N 900117-00.

Ce manuel d'installation est disponible en francais, simplement en faire la demande. Numéro de la pièce

900117-00.

This appliance must be properly installed and operated in order to prevent the possibil-

ity of a house fire. Please read this entire manual before installation and use of this

pellet fuel-burning room heater. Failure to follow these instructions could result

• Hot! Do not touch! The glass and surfaces of this appliance will be

hot during operation and will retain heat for a while after shutting off

the appliance. Severe burns may result.

• Carefully supervise children in the same room as appliance.

• IHP pellet-burning appliances are designed for use as a supplemental

heater. They are not intended for continuous use as a primary heat

source.

in property damage, bodily injury or even death. Contact your local building

or fire officials to obtain a permit and information on any installation

requirements and inspection requirements in your area.

WARNING

Pellet Stove

Model Montage™ 32FS

Advertisement

Table of Contents

Summary of Contents for IronStrike Montage 32FS

- Page 1 INSTALLATION AND OPERATION MANUAL Free-Standing Pellet Stove Save These Instructions For Future Reference P/N 900116-00, Rev. A, 05/2015 Pellet Stove P900116-00 Model Montage™ 32FS A French manual is available upon request. Order P/N 900117-00. Ce manuel d’installation est disponible en francais, simplement en faire la demande. Numéro de la pièce 900117-00.

-

Page 2: Important Safety Information

11. APPROVED FUEL: This appliance is designed specifically IMPORTANT SAFETY AND WARNING for use only with pelletized wood fuels only. This appliance INFORMATION is designed and approved for the burning of wood residue pellets with up to 2% ash content. This appliance is NOT approved to burn cardboard, nut hulls, cherry pits, corn, etc. -

Page 3: Table Of Contents

Listing: The listing laboratory is PFS Corporation and the listing mark is thousands of individuals whose answer to their home heating needs PFS. The report number is 14-200 for model Montage 32FS pellet stove. reflects their concern for aesthetics, efficiency and our environment. -

Page 4: Smoke Detector Recommended

2. Local amendments Smoke Detector Recommended 3. Is a permit required - cost. You may wish to contact your insurance company to ask if they require this. Since there are always several potential sources of fire in any home, we 4. -

Page 5: Selecting A Location

Ventilation Requirements - Provide adequate air for combustion. The fresh SELECTING A LOCATION air requirements of this appliance must be met within the space where it will be installed. Ventilation is essential when using a solid-fuel-burning The design of your home and where you place your stove will determine heater. -

Page 6: Clearances

Rear Wall or Alcove - Clearance to Combustibles Combustible Up to * 6” (153 mm) Rear 6” 6” (153 mm) Top View (153 mm) min. min. Front *NOTE: Refer to pipe Manufacturer's installa- Floor Protector Figure 2 6” (153 mm) tion instructions for minimum pipe clearances. -

Page 7: Installation Tips

INSTALLATION TIPS INSTALLATION TIPS Select Your Installation Type GOOD INSTALLATION * BETTER INSTALLATION BEST INSTALLATION Horizontal Installation Vertical & Horizontal Installation Vertical Installation (Direct Vent - Outside Wall) (Up and Out) (Straight Up) No natural draft. Wind Some natural draft aids venting. Wind Natural draft improves operation and pressures may affect operation pressures may still affect operation... -

Page 8: Manufactured Home Installation

MANUFACTURED HOME INSTALLATION In addition to the standard installation instructions, the following instruc- tions may be required by local, state or federal building codes: • Installation should be in accordance with the Manufactured Home and Safety Standard (HUD), CFR 3280, Part 24. •... -

Page 9: Installation

INSTALLATION Removing Appliance From Pallet 1. After removing the packaging from the stove, lift the hopper lid, and remove all prepackaged items that were shipped in the hopper. Next, open the stove door and remove all prepackaged items. 2. With the stove door open, remove the ash drawer and set aside. Using a 7/16”... - Page 10 • Hot or cold air from ducts. Damper Location and Adjustment NOTE: See Wiring Diagram on Page 29. Damper Air Control Located behind the right side panel on model Montage 32FS. IMPORTANT Adjustment Procedure Using a 1/4" nut driver or socket, loosen the damper setscrew (see If the wall thermostat provided is not used, the Figure 6).

-

Page 11: Venting Requirements

• Horizontal Runs - The maximum total horizontal run must not exceed VENTING REQUIREMENTS 10 feet (3.1 meters). • Horizontal run of pipe requires 1/4” (7 mm) rise per foot. It is recommended that only an IHP dealer install your pellet stove. The •... - Page 12 D. The distance from the bottom of termination to grade is 12” (305 mm) B. Not less than 4 feet (1.2 m) below, 4 feet (1.2 m) horizontally from or minimum unless otherwise specified by the vent manufacturer. This is 1 foot (3.1 m) above any gravity air inlet (door, window, etc.) which flue gases could reenter the dwelling.

- Page 13 Chimney Height Requirements - Site Built Residential Home To pass inspection in nearly any jurisdiction, the chimney must meet both safety and exhaust flow requirements. The (3’ by) 2’ by 10’ rule applies to both masonry and factory-built chimneys The vent termination height required is - USA, 1-foot minimum; Canada 3-feet minimum above the roof penetration point as illustrated below (Ref.

- Page 14 Determining Size Of Pipe To Install To determine what diameter pipe to use in an installation (3” or 4”), first 4 “ Diameter Only find the “equivalent pipe length” using the following guidelines, then plot this number and the altitude on the chart (Figure 13). Fill out the installation chart, and calculate your total equivalent pipe length.

- Page 15 Standard Horizontal Vent Installation 3. Push the stove with pipe attached towards the wall (the pipe will go through the wall thimble). Do not position the back of the stove closer than 2” (51 mm) from the wall (see Clearances, Page 6). Installing Montage™...

- Page 16 Ne pas installer de coudes successifs immédiatement à Wall l’arrière du poêle, quelque soit l’installation. Figure 16 - Montage 32FS, Corner Through the Wall NOTE: Horizontal run of pipe requires 1/4” (7 mm) rise per foot. 2” (51 mm) Minimum...

- Page 17 Standard Vertical Installation Configurations Preferred Installation – Vertical Vent Through the Roof Model: Montage™ 32FS This venting configuration allows for the best stove performance. The This free-standing model may be connected to an existing flue or by vertical pipe promotes natural draft and with the chimney inside the installing listed type “PL”...

-

Page 18: Care And Operation

CARE AND OPERATION Simple Operating Instructions 1. Start FIRST TIME USE 2. Preparation 3. Priming the Auger 5. To Start Your Stove 7. Set stove to desired (Optional) heat setting (heat output a] Check hopper and remove a] Check hopper, and fill with button). - Page 19 Control Board Operation IMPORTANT NOTE: If the fuel feed trim or combustion air trim needs to be adjusted, contact your dealer or qualified technician to calibrate internal software. The trim controls should START BUTTON only be adjusted for the proper flame if all other options did not achieve proper adjustment. It is recommended that the damper be used to fine-tune your stove to your particular fuel The "START"...

- Page 20 Pre-lighting Instructions General Operating Considerations During an initial start-up, or in the case where the hopper has run out of Proper Burn Characteristics: Your flame should be bright yellow under fuel, it will be necessary to prime the auger feed system. normal operations.

- Page 21 Turning Off Your Stove NOTE: Excessive amounts of fly-ash built-up in the UltraGrate™, clinkers in the UltraGrate or leakage of air (if the grate is not properly seated) will starve the fire for air. See Routine Maintenance, on Pages 22 Press the "STOP"...

-

Page 22: Fuel

Wood pellets manufactured to the pellet fuels institute (P.F.I.) certification FUEL standard are available in two grades, Standard and Premium. The primary difference between the two is the ash content of the pellets. CAUTION The P.F.I. specification for standard grade and premium grade residential and commercial pellet fuel is as follows: The use of unapproved, dirty, wet and / or high salt •... - Page 23 Heat Exchange Tubes (Recommended Frequency of 2 days to 2 weeks*) Tube Scraper - Using the hole in the handle of the Grate Scraper Tool Front “grab” the scraper rod as shown in Figure 26. Using the Grate Scraper Tool, pull the rod up and out towards the opening of the firebox. Con- tinue pulling until the Tube Scraper reaches the top of the firebox.

- Page 24 Ash Clean-out Ports (Recommended Frequency of 1 year*)* IMPORTANT NOTES: • ENSURE APPLIANCE IS COLD BEFORE BEGINNING. • FIREBRICK PANEL MUST BE INSTALLED BEFORE OPERATING UNIT. • ASH CLEAN-OUT PORTS MUST BE CLEANED OUT AS PART OF ROUTINE MAINTENANCE. Accessing Ash Clean-Out Ports 1) Open firebox door.

- Page 25 UltraGrate™ (Burn Grate) Ash Pan (Recommended Frequency of 1 – 7 days*) (Recommended Frequency of 2 Days - 2 Weeks*) Inspect the UltraGrate periodically so that the air holes don't clog with ash The ash pan will have to be emptied periodically, depending on amount or clinkers.

- Page 26 Door Rope Gasket Motor Lubrication The condition of the rope gasket around the door and windows should be The blowers are permanently lubricated by the manufacturer. Do not checked periodically and replaced or repaired if necessary. The door gasket apply oil to any part of the blower, doing so may cause damage. does not need to be “tight”...

-

Page 27: Specifications

SPECIFICATIONS - Montage™ 32FS Product Reference Information Cat. No. Model Ship. Weight Ship. Volume H6839 Montage 32FS 285 lb. 22.06 cu. ft. Flue Size 3” (76 mm) Rear Floor Protection Front and Sides: 6”(152 mm) Requirements Back: Up to 6”(152 mm) Hopper Capacity 55 Lbs. -

Page 28: Component Definitions

• Thermal Switch, Low Limit (Ceramic, F140-20F, N/O*) (G)- This "proof COMPONENT DEFINITIONS of fire" switch will close at 140° F and will not open until it reaches a temperature of 120° F. This switch is located on the combustion •... -

Page 29: Wiring Diagram

INTERNATIONAL GRAPHICS & NAMEPLATE, INC. Orange, California NEUT 1-BLU ANENT ACRYLIC ADHESIVE 3-BLK ALTERATIONS 14413 NE 10TH AVE., SU. C WIRE DIAGRAM LABEL - MONTAGE 32FS DATE PREPARED BY / DESCRIPTION: IGNITER ” X 10” & CHKR = FEMALE VANCOUVER, WA 98685... -

Page 30: Troubleshooting

TROUBLESHOOTING QUALIFIED TECHNICIANS ONLY Unplug Appliance Before Performing Any Troubleshooting or Maintenance PROBLEM CAUSE(S) SOLUTIONS ) Lack of maintenance (clean UltraGrate™, clean-out ports, 1. Fire burns with a lazy orange flame. Pellets build up • There is insufficient combustion air. exhaust flow passages, venting system, combustion blower in the and there is excessive glass soot that is difficult to •... - Page 31 TROUBLESHOOTING QUALIFIED TECHNICIANS ONLY Unplug Appliance Before Performing Any Troubleshooting or Maintenance PROBLEM CAUSE(S) SOLUTIONS 4. Blowers will not operate when the ON/OFF start button A) There is no power to the stove. A) Check that the stove is plugged in to the wall is depressed.

-

Page 32: Replacement Parts List & Diagrams

REPLACEMENT PARTS LIST - MONTAGE™ 32FS Contact an IHP dealer to obtain any of these parts. Never use substitute materials. Use of non-approved parts can result in poor performance and safety hazards. DOOR PARTS Item # Cat. No. Description Item # Cat. - Page 33 REPLACEMENT PARTS - MONTAGE™ 32FS Includes 20 feet of thermostat wire NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE...

- Page 34 REPLACEMENT PARTS - MONTAGE™ 32FS NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE...

-

Page 35: Optional Accessories

OPTIONAL ACCESSORIES - MONTAGE™ 32FS Item # Cat. No. Model Description Optional Accessories H6840 MONT-32FS-CONT Contemporary Trim Accessory Kit, Brushed Nickel (775201M) H6841 MONT-32FS-ART Artisan Accessory Trim Kit, Matte Black (775201M) H6842 MONT-32FS-ARCH Arch Accessory Trim Kit, Matte Black (775201M) H6843 MONT-32FS-GOTH Gothic Cast Iron Accessory Kit, Black Paint... - Page 36 NOTES...

-

Page 37: Warranty

THE WARRANTY Innovative Hearth Products ("IHP") Limited Lifetime Warranty warrants your IronStrike™ brand pellet fueled stove or insert ("Product") to be free from defects in materials and workmanship at the time of manufacture. The Product body, heat exchange tubes and ceramic glass carry the Limited Lifetime Warranty. Ceramic glass carries the Limited Lifetime Warranty against thermal breakage only. -

Page 38: Product Reference Information

1508 Elm Hill Pike, Suite 108 See Page 32 through 34 for a complete replacement parts list. Use only Nashville, TN 37210 parts supplied from the manufacturer. visit us at www.IronStrike.us.com Model Number _____________________________________________________ Serial Number _____________________________________________________ Date Installed ______________________________________________________...

Need help?

Do you have a question about the Montage 32FS and is the answer not in the manual?

Questions and answers