Table of Contents

Advertisement

Quick Links

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thought-

ful operation on your part. DO

NOT INSTALL, OPERATE OR

REPAIR THIS EQUIPMENT

WITHOUT

READING

THIS

MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED

THROUGHOUT. And, most

importantly, think before you act

and be careful.

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

RETURN TO MAIN MENU

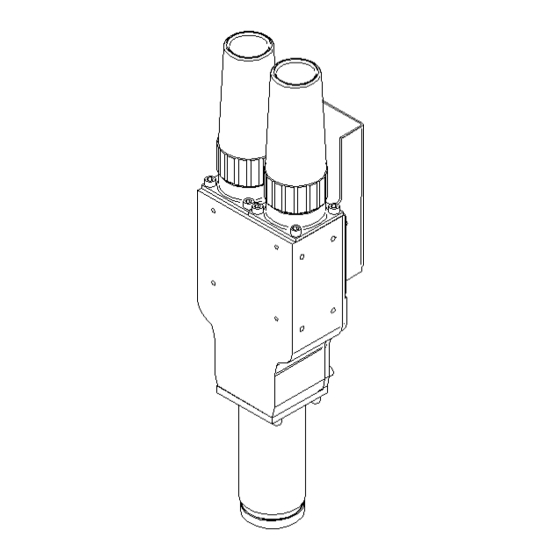

Tandem MIG Torch

G3494-2, 3, 4, 5, 6

G3494-2A, 3A, 4A, 5A, 6A

OPERATOR'S MANUAL

• World's Leader in Welding and Cutting Products •

Copyright © 2005 Lincoln Global Inc.

IM666-A

February, 2005

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Lincoln Electric TANDEM IM666-A

- Page 1 Tandem MIG Torch Safety Depends on You Lincoln arc welding and cutting equipment is designed and built with safety in mind. However, your overall safety can be increased by proper installation ... and thought- ful operation on your part. DO NOT INSTALL, OPERATE OR REPAIR THIS EQUIPMENT WITHOUT...

-

Page 2: California Proposition 65 Warnings

351040, Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS. -

Page 3: Electric Shock Can Kill

ELECTRIC SHOCK can kill. 3.a. The electrode and work (or ground) circuits are electrically “hot” when the welder is on. Do not touch these “hot” parts with your bare skin or wet clothing. Wear dry, hole-free gloves to insulate hands. - Page 4 WELDING SPARKS can cause fire or explosion. 6.a. Remove fire hazards from the welding area. If this is not possible, cover them to prevent the welding sparks from starting a fire. Remember that welding sparks and hot materials from welding can easily go through small cracks and openings to adjacent areas.

- Page 5 PRÉCAUTIONS DE SÛRETÉ Pour votre propre protection lire et observer toutes les instructions et les précautions de sûreté specifiques qui parraissent dans ce manuel aussi bien que les précautions de sûreté générales suiv- antes: Sûreté Pour Soudage A L’Arc 1. Protegez-vous contre la secousse électrique: a.

- Page 6 The code number is especially important when identifying the correct replacement parts. - Register your machine with Lincoln Electric either via fax or over the Internet. • For faxing: Complete the form on the back of the warranty statement included in the literature packet accompanying this machine and fax the form per the instructions printed on it.

-

Page 7: Table Of Contents

Installation...Section A Technical Specifications ...A-1 General Description...A-2 Design Summary ...A-2 Case Assembly ...A-3 Consumables ...A-3 Mounting Brackets...A-3 Liner Installation and Trimming Instructions ...A-4 Contact Tip and Gas Nozzle Installation ...A-4 Connecting the Torch to the Welding Equipment ...A-4 Water Cooling Equipment ...A-5 Mounting the Torch ...A-6 Work Leads ...A-7 Seam Tracking ...A-7... -

Page 8: Installation

TECHNICAL SPECIFICATIONS - Tandem MIG Torch Tandem MIG Torch Cable Length Availability Product Number Water Cooling Flow Rate for each Power Cable Water cooling flow rate for nozzle/gas cable 100% at 450 amps per side / 900 amps Total Maximum current draw per electrode 650 amp / 60% duty cycle HEIGHT WIDTH 17.54 in. -

Page 9: General Description

GENERAL DESCRIPTION The Tandem MIG torch delivers two wire electrodes to the weld pool. The wires are insulated from each other for the purpose of independent arc regulation. When welding, the wires or arcs are oriented one behind the other. The torch provides a small but rugged housing for delivering the two wires and it provides secure delivery of the shielding gas. -

Page 10: Cable Assembly

CABLE ASSEMBLY Three cable assemblies deliver the necessary power and cooling fluids to the torch. a) G3494-X Series: Two of the cable assemblies supply power, wire and water cooling to each side of the torch. The third bundle is made up of the nozzle water cooling hoses, the air blast line and the shielding gas line. -

Page 11: Liner Installation And Trimming Instructions

CONNECTION DIAGRAM For G3494-2 thru -6 and G3494-2A thru -6A LINER INSTALLATION AND TRIMMING INSTRUCTIONS a) Lay the torch and cable on a flat surface and straighten the cables. b) With a 12 mm open-end wrench, unscrew the nut on the cable connector that restrains the liner. Remove the nozzle, and then remove both dif- fusers. -

Page 12: Water Cooling Equipment

b) Push the end connector from torch into K489-7 Fast-Mate adapter on the wire feeder, and then tighten the locking nut. Do this for both of the torch power cables. c) Attach the water lines from the torch power cables to a supply of cooling water. -

Page 13: Mounting The Torch

MOUNTING THE TORCH Always insulate the torch from any equipment or fixturing. Use M19190 Bracket Arm to Torch Body Insulator if necessary. (See Figure 4, Torch mounting dimensions) Check to make sure the cables are free to flex and do not get tangled or caught on other equipment. -

Page 14: Work Leads

WORK LEAD Minimize the length of the electrode and work lead cables. Do not exceed 50 ft (15m) of combined elec- trode and work lead length. To make the work lead connection, run a properly sized lead from the work connection on the power source directly to the fixture. -

Page 15: Operation

Do not allow dolly wheels or trucks to run over cables. OPERATION e) Use only clean, rust-free electrodes. Electrodes manufactured by Lincoln Electric have proper surface lubrication. f) Replace the contact tips when the arcs start to become unstable or the contact tip ends are fused or deformed. -

Page 16: Accessories

GENERAL OPTIONS / ACCESSORIES The following options/accessories are available for your Tandem MIG Torch from your local Lincoln Distributor. K489-7 Connector Kit - Magnum Fast-Mate Adapter Liners Steel, Stainless and Metal Cored Electrodes S24198-10 .035-.045" / 0.9-1.2mm, 9 ft.(2.7m) S24198-12 .035-.045"... -

Page 17: Maintenance

SAFETY PRECAUTIONS WARNING Have qualified personnel do the maintenance work. If a problem cannot be corrected by following the instructions, take the equipment to the nearest Lincoln Field Service Shop for repair. ----------------------------------------------------------------------- ELECTRIC SHOCK can kill. • Do not touch electrically live parts or electrode with skin or wet clothing. -

Page 18: Contact Tip Replacement

MAINTENANCE CONTACT TIP REPLACEMENT Each application will dictate the frequency of contact tip replacement. Higher amperage higher duty cycle operations will require more frequent contact tip replacement. The condition of the contact tip greatly effects the welding performance. A routine tip replace- ment schedule should be established and adhered to. -

Page 19: Troubleshooting

HOW TO USE TROUBLESHOOTING GUIDE Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. - Page 20 Observe all Safety Guidelines detailed throughout this manual PROBLEMS (SYMPTOMS) The drive rolls turn, but wire will not feed or wire feeding is rough. The arc starts, but during the weld the arc goes out and wire keeps feeding. Water leaks from the torch. Porosity in the weld.

- Page 21 Observe all Safety Guidelines detailed throughout this manual PROBLEMS (SYMPTOMS) Porosity in the weld. (Continued) The arc length is inconsistent. There is arcing to the nozzle. There is arcing between the contact tips or arc flaring. If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

- Page 22 NOTES TANDEM MIG TORCH...

- Page 23 ● WARNING ● Spanish ● AVISO DE PRECAUCION ● French ● ATTENTION ● ● German WARNUNG ● Portuguese ● ATENÇÃO ● Japanese Chinese Korean Arabic ● ● ● ● ● ● ● ● ● ●...

- Page 24 ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● Spanish ● PRECAUCION French ● ATTENTION ● German WARNUNG Portuguese ● ● Japanese Chinese Korean Arabic WARNING AVISO DE ATENÇÃO...

- Page 25 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...

Need help?

Do you have a question about the TANDEM IM666-A and is the answer not in the manual?

Questions and answers