Advertisement

Table of Contents

- 1 Electrical Requirements

- 2 Plumbing Requirements

- 3 Table of Contents

- 4 Control Thermostat

- 5 Limit Thermostat

- 6 ON/OFF Switch

- 7 Solenoid

- 8 Start Switch (Brew)

- 9 Tank Heater

- 10 Brew Timer (Early Models)

- 11 Digital Timer (Late Models)

- 12 Liquid Level Board

- 13 Relay

- 14 Warmer Element

- 15 Thermal Cut-Off

- 16 Wiring Diagrams

- Download this manual

Advertisement

Table of Contents

Summary of Contents for Bunn S

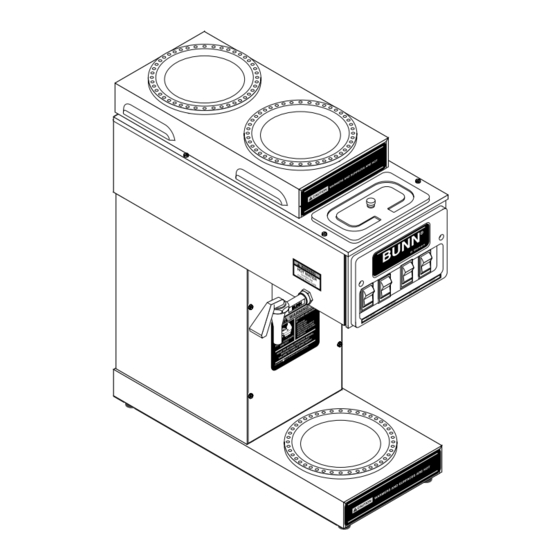

- Page 1 S,SA BUNN ® ST,STA STF,STFA OPERATING & SERVICE MANUAL BUNN-O-MATIC CORPORATION POST OFFICE BOX 3227 SPRINGFIELD, ILLINOIS 62708-3227 PHONE: (217) 529-6601 FAX: (217) 529-6644 www.bunnomatic.com 29251.0000G 04/01 ©1998 Bunn-O-Matic Corporation...

- Page 2 SPECIFIED HEREIN, TO REPAIR OR, AT BUNN’S SOLE OPTION, REPLACEMENT OR REFUND. In no event shall Bunn be liable for any other damage or loss, including, but not limited to, lost profits, lost sales, loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute equipment, facilities or services, or any other special, incidental or consequential damages.

- Page 3 USER NOTICES (Continued) #00882.0000 #00656.0000 #02763.0000 #02765.0000 #02769.0000 29251 101598 Page 3...

-

Page 4: Electrical Requirements

" water supply line. A tight coil of copper tubing in the water line will facilitate moving the brewer to clean the countertop. Bunn-O-Matic does not recommend the use of a saddle valve to install the brewer. The size and shape of the hole made in the supply line by this type of device may restrict water flow. - Page 5 Fill the tank with water as directed: 4A. Models S & SA: Pour three pitchers of tap water into the screened area on top of the brewer. Allow approximately two minutes between pitchers for water to flow into the tank. While the third pitcher of water is entering the tank, the tank will fill to capacity and the excess will flow from the sprayhead, out of the funnel, and into the dispenser.

- Page 6 Slide the funnel into the funnel rails. Place an empty dispenser beneath the funnel. Operate the brewer as directed: 5A. Models S & SA: Pour one pitcher of tap water into the screened area on top of the brewer. 5B. Models ST, STF, STA & STFA: Place the "ON/OFF"...

- Page 7 TROUBLESHOOTING A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic Technical Service Department. • Inspection, testing, and repair of electrical equipment should be performed only by qualified service personnel.

- Page 8 TROUBLESHOOTING (cont.) PROBLEM PROBABLE CAUSE REMEDY Refer to Service - ON/OFF Switch Brew cycle will not start (cont.) 3. ON/OFF switch (ST, STF, STA & STFA) for testing. See page 17 4. Start switch Refer to Service - Start Switch for testing procedures.

- Page 9 TROUBLESHOOTING (cont.) PROBLEM PROBABLE CAUSE REMEDY Inconsistent beverage level in dis- 3. Syphon system The brewer must be level or slightly penser (cont.) lower in front to syphon properly. 4. Lime build-up Inspect the tank assembly for ex- CAUTION - Tank and tank compo- cessive lime deposits.

- Page 10 TROUBLESHOOTING (cont.) PROBLEM PROBABLE CAUSE REMEDY Dripping from sprayhead 1. Syphon system The brewer must be level or slightly lower in front to syphon properly. 2. Lime build-up Inspect the tank assembly for ex- CAUTION - Tank and tank compo- cessive lime deposits.

- Page 11 Rebuild or replace the valve if necessary. See page 18 1. Filter type Weak beverage The BUNN® paper filter must be used for proper extraction. 2. Coffee grind A fine or drip grind must be used for proper extraction.

- Page 12 TROUBLESHOOTING (cont.) PROBLEM PROBABLE CAUSE REMEDY Brewer is making unusal noises 3. Water supply (A) The brewer must be connected (ST, STF, STA & STFA)(cont.) to a cold water line. (B) Water pressure to the brewer must not exceed 90 psi (620 kPa). Install a regulator if necessary to lower the working pressure to ap- proximately 50 psi (345 kPa).

-

Page 13: Table Of Contents

SERVICE This section provides procedures for testing and replacing various major components used in this brewer should service become necessary. Refer to Troubleshooting for assistance in determining the cause of any problem. WARNING - Inspection, testing, and repair of electrical equipment should be performed only by qualified service personnel. -

Page 14: Control Thermostat

FIG. 2 CONTROL THERMOSTAT control thermostat is operating properly. Location: If voltage is not present as described, replace the Models S & SA: The control thermostat is mounted thermostat. on a bracket inside the rear inspection cover on the left side. - Page 15 CONTROL THERMOSTAT (cont.) cal termination and not kinked. Removal and Replacement: Models S & SA: Using two #8-32 screws secure Remove wires from control thermostat leads. the control thermostat inside the rear inspection Remove the thermostat capillary bulb by firmly panel.

-

Page 16: Limit Thermostat

SERVICE (cont.) LIMIT THERMOSTAT Removal and Replacement: Remove all wires from limit thermostat termi- nals. Carefully slide the limit thermostat out from under the retaining clip and remove limit thermo- stat. Carefully slide the new limit thermostat into the retaining clip. Refer to FIG. -

Page 17: On/Off Switch

SERVICE (cont.) With the black wire removed, remove from the lower terminal the white/red wire for the lower ON/OFF SWITCH (Models ST, STA, STF & STFA) warmer switch, the brown/black wire for the top front warmer switch or the blue/black wire for the top rear switch. -

Page 18: Solenoid

SERVICE (cont.) Check the solenoid valve for coil action. Connect SOLENOID VALVE (Models ST, STA, STF & STFA) the brewer to the power source. With "ON/OFF" switch in the "ON" upper position press start switch and listen carefully in the vicinity of the solenoid valve for a"... -

Page 19: Start Switch (Brew)

SERVICE (cont.) START SWITCH (Models ST, STA, STF & STFA) Removal and Replacement: Remove the WHI/YEL and WHI/ORA wires from the start switch. Compress the clips inside the hood and gently push the switch through the opening. Push new switch into the opening and spread the clips to hold the start switch in the hood. -

Page 20: Tank Heater

SERVICE (cont.) TANK HEATER c) 200 to 240 volts ac for two wire 200 or 240 volt models. d) 100 volts ac for two wire 100 volt models. Disconnect the brewer from the power source. If voltage is present as described, proceed to #4 If voltage is not present as described, refer to the Wiring Diagrams and check wiring harness. - Page 21 SERVICE (cont.) TANK HEATER (Cont.) Disconnect the black wire and the white or red 21. Reconnect the wires to the limit thermostat and wire from the tank heater terminals. control thermostat. See limit thermostat and Remove the three #8-32 nuts and holddown control thermostat sections in this manual when brackets securing the tank lid to the tank.

-

Page 22: Brew Timer (Early Models)

SERVICE (cont.) BREW TIMER (Early Models ST, STA, STF & STFA) If voltage is present as described, proceed to #5. If voltage is not present as described, refer to the Wiring Diagrams and check the brewer wiring har- ness. 5. Disconnect the white/orange wire from terminal TL3 and the white/yellow wire from terminal TL5. - Page 23 SERVICE (cont.) BREW TIMER (Early Models)(cont.) Removal and Replacement: Remove all wires from the timer. Remove the circuit board and dial plate from the WHI/RED TL1 to ON/OFF Switch brackets. WHI TL2 to Terminal Block and Warmer Install new timer circuit board as described in Element (120V Two Pole, 120/208V or Late Model Timer section on the following pages.

-

Page 24: Digital Timer (Late Models)

SERVICE (cont.) DIGITAL BREW TIMER (Late Models) 4. With a voltmeter, check the voltage across termi- nals TL1 and TL4 when the "ON/OFF" switch is in the "ON" position. Connect the brewer to the power source. The indication must be zero volts. If voltage is as described, proceed to #5. - Page 25 SERVICE (cont.) NOTE: Several ounces of water will continue to syphon DIGITAL BREW TIMER (Late Models)(cont.) from the tank after turning the switch "OFF". The Timer Setting: brewer remembers this volume and will continue to NOTE: Check that the brewer is connected to water brew batches of this size until the volume setting supply, the tank is properly filled, and a funnel and procedure is repeated.

-

Page 26: Liquid Level Board

SERVICE (cont.) LIQUID LEVEL CONTROL BOARD (Models STF & Disconnect the brewer from the power source. STFA) If voltage is present as described, proceed to #5. If voltage is not present as described, refer to the wiring diagrams and check the brewer wiring harness. Reconnect the blue wire to terminal 1. - Page 27 200 to 240 volts ac for two wire 200 or 240 volt models after a delay of approximately 5 seconds. 15. Move the probe's flat end to the brewer housing. The indication must be 0. 16. Move the probe's flat end away from the brewer housing.

-

Page 28: Relay

SERVICE (cont.) If continuity is present as described, reconnect the TIMER RELAY (Models STF & STFA) WHI/RED and WHI/BLU wires to the relay, relay is operating properly. Location: If continuity is not present as described, replace the The relay is located inside the front inspection relay. -

Page 29: Warmer Element

SERVICE (cont.) Check voltage across the WHI wire from the terminal block and the wire from the "ON/OFF" WARMER ELEMENTS switch to the warmer element with a voltmeter Location: with the "ON/OFF" switch in the "ON" position. The warmer elements are located under the The indication must be: warmer plates. -

Page 30: Thermal Cut-Off

SERVICE (cont.) THERMAL CUT-OFF (Models SA, STA & STFA) Location: The thermal cutoffs are located on both tank heater terminals. Test Procedures: Disconnect the brewer from the power source. Disconnect the thermal cutoff from the tank heater terminal and the limit thermostat or wir- ing harness. - Page 31 29251 052500 Page 31...

- Page 32 29251 052500 Page 32...

- Page 33 29251 052500 Page 33...

- Page 34 29251 052500 Page 34...

- Page 35 29251 052500 Page 35...

- Page 36 29251 052500 Page 36...

- Page 37 29251 052500 Page 37...

- Page 38 29251 052500 Page 38...

- Page 39 29251 052500 Page 39...

- Page 40 29251 052500 Page 40...

- Page 41 29251 052500 Page 41...

- Page 42 29251 080400 Page 42...

-

Page 43: Wiring Diagrams

29251 052500 Page 43...

Need help?

Do you have a question about the S and is the answer not in the manual?

Questions and answers