Advertisement

Quick Links

2000225024C.07.02

Installation & Servicing Instructions

T o b e l e f t w i t h t h e u s e r

BBU 54/4

G.C. No. 44 - 047 - 05

For Use Only With Specially Designed Firefronts

This is a Cat I

Appliance

2H

Hepworth Heating Ltd.,

Customer Services:

Nottingham Road, Belper, Derbyshire. DE56 1JT

Tel: (01773) 828100

General/Sales enquiries:

One Contact Local Service

Tel: (01773) 824141 Fax: (01773) 820569

Fax: (01773) 828070

Advertisement

Summary of Contents for Glow-worm BBU 54/4 Miami 4

- Page 1 2000225024C.07.02 Installation & Servicing Instructions T o b e l e f t w i t h t h e u s e r BBU 54/4 G.C. No. 44 - 047 - 05 For Use Only With Specially Designed Firefronts This is a Cat I Appliance Hepworth Heating Ltd.,...

-

Page 2: Important Information

Important Information TESTING AND CERTIFICATION It is important that no alteration is made to the boiler without permission, in writing, from Hepworth Heating Ltd. Any alteration that is not approved by Hepworth Heating Ltd., could invalidate the B.S.I. Certification, the boiler warranty and could also infringe the current issue of the Statutory Requirements, see Section 1.1. - Page 3 1.2 Data The boiler is for use only with a specially designed Glow-worm Gas firefront, see table 1. See diagram 1.1, Range Rating table for friefronts and Table 1. This boiler is NOT suitable for fitting to precast flues.

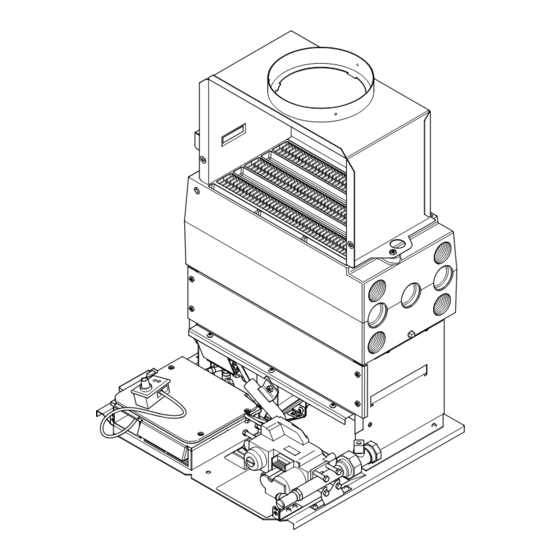

- Page 4 1 General BOILER DRAIN POINT SIDE ELEVATION FRONT ELEVATION WATER GAS CONNECTION CONNECTIONS RC ( in BSPT) DIMENSION BBU 54/4 Diagram 1.1 OVERALL DIMENSIONS Maximum Minimum Medium Maximum Minimum Medium Miami 4 Miami 4 Miami 4 Heartbeat 4 Heartbeat 4 Heartbeat 4 Dovedale 4 Dovedale 4...

- Page 5 1 General 1.5 Site Requirements 1.6 Water System - Open Vented Refer to diagram 1.1 for dimensions appropriate to the back This boiler can be used on an unrestricted open vented system boiler. with the water supply taken from a feed and expansion cistern, having a head between 1m (3ft 3in) minimum and 27m (90ft) For all types of installation a standard builder’s front opening is maximum.

- Page 6 1 General 1.7 Hot Water Cylinder 22mm VENT The back boiler is suitable for open vented systems using an indirect cylinder. The cylinder must be fitted to the manufacturer’s 15mm COLD FEED recommendations and the system must conform to the requirements of the current issue of BS5449.

-

Page 7: Types Of Installation

2 Types of Installation 2.1 With Non-combustible Hearth For minimum dimensions of a hearth, see diagram 2.1. The back boiler must be installed level with the hearth or above PREPARED it, see diagram 2.1. BOILER Carpet or similar floor covering must not be placed on the BASE hearth. - Page 8 3 Flue and Ventilation 3.1 General RIGID The general recommendations of the current issue of BS5440 FLUE Part 1 should be followed. LINER In all cases the flue should be lined, preferably with a flexible liner. It is essential that the flue has an equivalent height of at least 2.5m (8.2ft) measured from the flue connection on the appliance.

- Page 9 3 Flue and Ventilation 3.3 New Chimney VENT SIZES TABLE A newly built chimney can be lined with a moisture resistant lining, such as salt glazed pipe, of an appropriate diameter as 54/4 specified in the Building Regulations In the case of a salt glazed lined flue, it is recommended that a short vertical length of flue pipe, preferably flexible metallic be Dovedale 4 77cm...

- Page 10 4 Installation 4.1 Preparation HEAT Remove draught diverter body, draught diverter, flueway baffles EXCHANGER and fittings pack from carton. Check contents of fittings pack against packed list. Remove back boiler body from carton. Remove the combustion chamber extension by loosening the two securing screws and lift off, see diagram 4.1.

- Page 11 4 Installation 4.6 Chatsworth 4, Dovedale 4 Only IMPORTANT: With the control/burner assembly removed, fit the blanking plate, supplied with the fire front, to the rear of the combustion chamber and secure with a number 6 screw provided, see diagram 4.11. Please note that the hole for the securing screw in the blanking plate is offset to avoid incorrect fitting.

- Page 12 4 Installation Chatsworth 4 and Dovedale 4 only and tighten, making sure the sensing tube is correctly positioned, see diagram 4.7. The back boiler must be positioned so that a line across the opening of the wall face coincides with the fire fixing wall face Where a flexible flue liner is being used, fully fit the No.8x positioning line, see diagram 4.3.

- Page 13 4 Installation GAS SERVICE COCK (OFF) SENSING TUBE TUBING NUT SECURING SCREW Diagram 4.8 COMBUSTION CHAMBER SCREW (4) SENSING TUBE SECURING MANIFOLD BRACKET SCREW FLUE SENSING BLOCKAGE TUBE SAFETY SILICONE LOCATING DEVICE TUBE Diagram 4.9 Diagram 4.6 REAR COMBUSTION Fully fit No. 8 3 / 8 in. No.

-

Page 14: Electrical Wiring

5 Electrical Wiring 5.1 General WARNING. This boiler must be earthed. Froststat Pipestat ISOLATE THE ELECTRICAL SUPPLY BEFORE DOING ANY Double WIRING Pole Programmer Roomstat Switchspur All of the electrical installation must be correctly earthed and be in accordance with the current issue of BS7671 and be carried out by a competent person. - Page 15 5 Electrical Wiring Plug the short connecting lead (supplied in the fire front fittings MAINS pack) into the boiler user control SUPPLY Slide the boiler user control into position on the control box front, PLUG making sure that it fits into the groove in the control box, and connect the lead plug on to P.C.B., see diagrams 5.8 and10.4.

- Page 16 5 Electrical Wiring FLUE BLOCKAGE SAFETY DEVICE AND PILOT GAS VALVE THERMISTOR EARTH POST r b wh bk y g OVERHEAT CUT-OFF MAINS IN SAFETY DEVICE (SEALED SYSTEM ONLY) BOILER Black USER Blue CONTROL Brown Green Yellow Green/Yellow g/y White Orange Diagram 5.8 2000225024C...

- Page 17 6 Commissioning 6.1 Commissioning the Back Boiler continued - Before commissioning the back boiler, the whole of the system Make sure the thermistor phial is fitted correctly, see diagram should be thoroughly flushed out with cold water with the 5.4. circulation pump removed.

- Page 18 6 Commissioning Technical Sequence of Operation Relight the back boiler by turning control thermostat knob "A" clockwise to maximum. When an external control calls for heat there is approximately a 5 second delay. The control board (PCB) energises the 1st Use the self-adhesive arrow from the fittings pack and stick it gas valve solenoid, the valve will open and the spark unit will against the relevant heat input figure on the Data Label.

- Page 19 6 Commissioning 6.2 Testing the Back Boiler Controls Make sure the back boiler control thermostat knob "A" is turned clockwise to maximum, which is about 82 C (180 C), against To test the flame failure, turn the boiler on. After about 3 the setting point, allow the water to reach maximum working minutes, turn the gas service cock off, the lockout device should temperature.

- Page 20 7 Fire Installation Fire Front Installation and Servicing Instructions are packed with the fire. 7.1 Completion - After Installation of the Fire Front Instruct and demonstrate to the user, the efficient and safe operation of the boiler, heating and hot water system and fire front.

- Page 21 8 Servicing REMEMBER, When replacing a part on this appliance, use only spare parts that you can be assured conform to the safety and performance specification that we require. Do not use DRAUGHT reconditioned or copy parts that have not been clearly authorised DIVERTER by Hepworth Heating Ltd.

- Page 22 8 Servicing 8.4 Controls Assembly and Burner. Disconnect the union at the gas service cock, see diagram 8.2. Disconnect the mains electrical plug from the control box, see diagram 8.2. Remove the thermistor phial from the phial pocket taking care not to damage the cable, see diagram 5.4.

- Page 23 8 Servicing 8.7 Main Burner - Injector Inspect the main burner injector for damage or blockage, clean or replace as necessary, see diagram 8.5. Do not use a wire or sharp instrument to clean the injector hole. PILOT TUBE MANIFOLD SECURING CONTROL SCREWS...

- Page 24 8 Servicing 8.8 Flue Blockage Safety Device Assembly Firelite 4, Contour 4, Miami 4, Heartbeat 4 and Black Beauty 4 only Gain access as relevant part of Section 8.4. Remove any dust and lint, inspect the pilot for damage. Remove the sensing tube BAFFLES adapter, to clean, blow through, do not use a wire or sharp BACK...

-

Page 25: Fault Finding

9 Fault Finding 9.1 Electrical NOTE. If the electrical supply is switched rapidly off and on Carry out the preliminary electrical system checks as without gas present the control will purge for 100 sec. Neither contained in a multimeter instruction book. of the indicators will be lit. - Page 26 9 Fault Finding Refer to electrical fault finding chart, diagram 9.1 and functional 9.2 Electrical Fault Finding Back Boiler flow wiring diagram 9.2. Refer to diagram 9.1. On completion of the fault finding task which has required the breaking and remaking of electrical connections, the checks for 9.3 Flue Blockage Safety Device and Ignition earth continuity, short circuit, polarity and resistance to earth Fault Finding...

-

Page 27: Replacement Of Parts

10 Replacement of Parts IMPORTANT. When replacing the heat exchanger please 10.3 Electrode remember that it exceeds the recommended weight for a one Proceed as in Section 10.2. man lift, refer the Manual Handling Operations, 1992 Regulations for further information. 10.4 Ignition Lead and Sensing Lead Notes. - Page 28 10 Replacement of Parts 10.6 Gas Valve CONTROL Refer to the relevant parts of Section 8.4 to remove the controls VALVE BOARD assembly. ELECTRICAL PLUG (PCB) Refer to diagram 10.2. SENSING PLUG Remove securing screw and disconnect electrical plug, see IGNITION LEAD diagram 10.2.

- Page 29 10 Replacement of Parts 10.10 Overheat Cut-off Safety Device (Sealed systems only) Unclip the overheat cut-off safety device from the flow pipe, it is located near where the flow pipe exits from the heat exchanger. Withdraw the retaining clip with the overheat cut-off safety device from the lead plug.

- Page 30 11 Spare Parts When spare parts are required apply to your local supplier. Please quote the name of the appliance, also the serial number of the boiler, to be found on the data label on the appliance. If ordering from the local gas undertaking the appropriate appliance GC number should also be quoted together with the GC number of the part.

- Page 31 2000225024C...

- Page 32 Because of our constant endeavour for improvement, details may vary slightly from those shown in these instructions. 2000225024C...

Need help?

Do you have a question about the BBU 54/4 Miami 4 and is the answer not in the manual?

Questions and answers