Table of Contents

Advertisement

Quick Links

Installation and Servicing

Hideaway

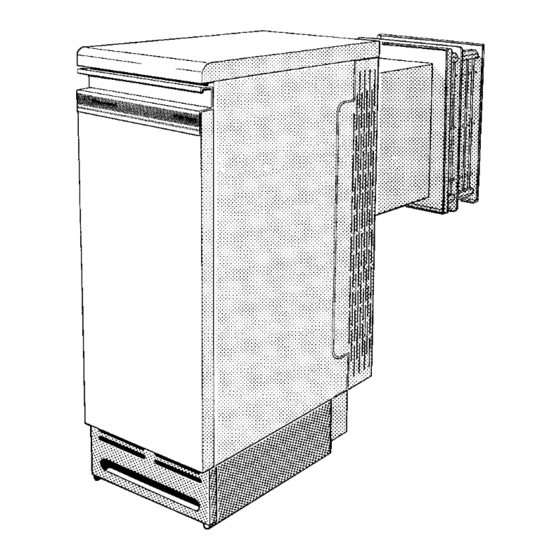

40B

G.C. No. 41 313 16

Balanced Flue Boiler

This is a Cat I

Reference in these instructions to British Standards and Statutory

Regulations/Requirements apply only to the United Kingdom.

For Ireland the rules in force must be used.

The instructions consist of three parts, User, Installation and Servicing Instructions, which includes the Guarantee Registration

Card. The instructions are an integral part of the appliance and must, to comply with the current issue of the Gas Safety

(Installation and Use) Regulations, be handed to the user on completion of the installation.

Thank you for installing a new Glow-worm appliance in your home.

Glow-worm appliances' are manufactured to the very highest standard so we are pleased

In the centre pages are to be found your Guarantee Registration Card, which we recommend you complete and

If this card is missing you can obtain a copy or record your registration by telephoning the Heatcall Customer

Our Guarantee gives you peace of mind plus valuable protection against breakdown by covering the cost of:

All replacement parts

All labour charges

All call-out charges

One Contact Local Service

Instructions for Use

T o b e l e f t w i t h t h e u s e r

BS 6332

BS 5258

Appliance

2H

Guarantee Registration

to offer our customers' a Comprehensive First Year Guarantee.

return as soon as possible.

Service number 01773 828100.

REGISTER YOUR GLOW-WORM APPLIANCE

FOR 1ST YEAR GUARANTEE PROTECTION

CALL 0208 247 9857

Customer Services:

Tel: (01773) 828100

Fax: (01773) 828070

Hepworth Heating Ltd.,

Nottingham Road, Belper, Derbyshire. DE56 1JT

General/Sales enquiries:

Tel: (01773) 824141 Fax: (01773) 820569

221691B.12.00

Advertisement

Table of Contents

Summary of Contents for Glow-worm Hideaway 40B

-

Page 1: Instructions For Use

Guarantee Registration Thank you for installing a new Glow-worm appliance in your home. Glow-worm appliances' are manufactured to the very highest standard so we are pleased to offer our customers' a Comprehensive First Year Guarantee. In the centre pages are to be found your Guarantee Registration Card, which we recommend you complete and return as soon as possible. -

Page 2: Table Of Contents

Important Information Testing and Certification This boiler is tested and certificated for safety and performance. It is therefore important that no alteration is made to the boiler, without permission, in writing, from Hepworth Heating Ltd. Any alteration not approved by Hepworth Heating Ltd., could invalidate the certification, boiler warranty and may also infringe the current issue of the Statutory Requirements, see Section 1.3. - Page 3 The boiler is automatic in operation, once the pilot has been lit and the controls set. Glow-worm Hideaways are central heating boilers, to provide heating and if required, an indirect domestic hot water supply. Gas Safety (Installation and Use) Regulations...

- Page 4 Instructions for Use To Connect an Electrical Plug To Turn the Boiler Off The standard colours of three core flexible cable are, For short periods, turn the boiler thermostat control knob “B” anticlockwise to “O”. The pilot will stay alight. To relight the Brown - live, Blue - neutral, Green and Yellow - earth.

-

Page 5: General Data

General Data Refer to BOILER CASING GAS CONNECTION WATER CONNECTIONS Rc1 reduced in. B.S.P.T.) HEIGHT diagram with DISTRIBUTOR TUBE to in. B.S.P.T.) (pumped return) A SPECIAL TOP CASING WATER CONNECTIONS TO SUIT 600mm (23 in.) Rc1 (1in. B.S.P.T.) WORKTOPS IS AVAILABLE F(MIN.) G(MIN.) Diagram 1.1... - Page 6 General Data 1.3 Statutory Requirements The installation of this must be carried out by a competent BOILER BOILER person and must be in accordance with the relevant requirements WITHOUT WITH TOP floor of the current issue of: TOP CASING CASING level Manufacturer’s instructions supplied.

-

Page 7: Water Systems

1 General Data The base temperature is within the requirements of the current 1.8 Heating System Controls issue of BS5258. The boiler may stand on a wooden floor but The heating system should have installed: a programmer and a metal base plate is required to protect plastic tiles and similar room thermostat controlling the boiler. -

Page 8: Flue And Ventilation

2 Water Systems 2.3 Gravity Domestic and Pumped Heating 22mm VENT It is recommended that a cylinder thermostat is used to prevent the stored water temperature becoming unnecessarily high 15mm when the central heating pump is off. COLD FEED The domestic primary flow and return must be 28mm o.d. The installation must comply with the current issue of BS5546 and 1 metre TO INDIRECT... - Page 9 3 Flue and Ventilation 3.4 Terminal Guard A terminal guard is required if persons could come into contact with the terminal or the terminal could be subject to damage. If a terminal guard is required, it must be positioned to provide a minimum of 50mm clearance from any part of the terminal and be central over the terminal.

-

Page 10: Installation

4 Installation Before fixing the boiler make sure that the location selected is UPPER CASING in accordance with the requirements of Section 1.7. BRACKET 4.1 Unpacking The boiler casing panels are packed separately within the main carton and are designed to enable gas and water connections to be made before fitting the casing panels. - Page 11 4 Installation 4.6 Pipework ALTERNATIVE FLOW When the front tappings are used, it is essential that any POSITIONS pipework of fittings do not project more than shown in diagram 4.5. When using a rear tapping with Rc (1in BSP) fitting for 28mm od pipework, it is recommended that a short nipple and an R thread (BSP) to copper elbow is used.

-

Page 12: Casing Location / Fitting

4 Installation 4.8 Boiler Connection in.) Connect the boiler to the system pipework. Make the gas connection to the service cock, at the lower right hand side of the boiler. BALANCED FLUE DUCT in.) FROM BOILER PREPARED HOLE IN in.) THE WALL (19 in.) MIN. - Page 13 5 Casing Location / Fitting 5.3 Top Casing Fit four plastic pegs into the appropriate holes in the top casing, PLASTIC PEG (4) TOP CASING if being fitted, see diagram 5.3. The plastic pegs are a tight fit and are best pushed home with a flat faced tool. The top casing can be arranged to fit flush with or overhang the door.

-

Page 14: Electrical Wiring

6 Electrical Wiring 6.1 Control Box Cable Connection Warning. This boiler must be earthed. COVER Remove the screw and cover from the mains inlet connector, supplied loose, see diagram 6.1. Using heat resistant flexible cable of suitable length and rating as in Section 1.6, connect the three cables to the required terminals in the connector. -

Page 15: Commissioning

See that the mains electrical supply is switched off. This should be in the range of: Set thermostat control knob “B” to “O”. Hideaway 40B : 1.1 to 1.4m /h 38 to 50ft Remove gas pressure test nipple screw “G” and fit a suitable pressure gauge. - Page 16 7 Commissioning Check the operation of the flame failure device as follows: with 13 ( in.) SPARK GAP the main burner alight, turn gas control knob “A” fully anti- APPROX. FLAME DIMENSION clockwise to its stop , the main and pilot burners will go out. DIMENSION Relighting the boiler will not now be possible as a safety device has been activated.

-

Page 17: Servicing

8 Servicing Servicing must be carried out by a competent person. Before starting a service, turn off the gas supply at the service THERMOSTAT cock, see diagram 8.1 and isolate the boiler from the electrical CAPILLARY supply. LOCATION Always test for gas soundness after completing a service or WASHER replacement of parts. - Page 18 8 Servicing 8.2 Burner and Injector Follow instructions to remove the cover, burner and controls assembly as in Section 8.1. Remove the two screws and nuts securing the burner support bracket to the combustion chamber cover, see diagram 8.7. Remove the graphite coated nuts on the supply feed pipe at the FLUEWAY rear of the burner to release the burner, take care not to damage BAFFLE...

-

Page 19: Replacement Of Parts

9 Replacement of Parts 9.3 Thermocouple Before removing or replacing any parts, turn off the gas supply at the gas service cock, see diagram 8.1 and isolate the Remove the door and plinth as in Section 8.1 electrical supply to the appliance. Disconnect thermocouple by unscrewing nuts at gas valve and Always test for gas soundness after replacing any gas carrying pilot burner, see diagrams 9.1 and 9.3. - Page 20 9 Replacement of Parts 240V~ 50Hz MAINS SUPPLY FUSED AT 3A THERMOSTAT C N/C VALVE ORANGE GRN/YEL BLUE CHASSIS EARTH Diagram 9.2 CONTROL BOX WIRING 9.6 Piezo Unit and Ignition Lead SECURING SCREW (2) Follow the relevant instructions in Section 8.1. AND NUT (2) Pull off ignition lead at piezo unit, see diagram 9.1.

-

Page 21: Fault Finding

10 Fault Finding - Electrical 10.1 Electrical Refer to electrical fault finding chart, diagram 10.1, functional GAS VALVE THERMOSTAT flow diagram 10.2 and wiring diagram 9.2. CONTROL SOLENOID IMPORTANT: The preliminary electrical system checks as contained in the British Gas Multimeter Instruction Book, or similar publication, are the first checks to be carried out during a fault finding procedure. - Page 22 10 Fault Finding - Thermocouple Disconnect appliance thermocouple from the multi-functional control. Check that all connections are clean and in good condition. Fit test meter interrupter into the magnet unit. Fit appliance thermocouple into the test meter interrupter. Hold down control tap in ignition position. Ignite burner, allowing thermocouple to attain operating temperature.

- Page 23 10 Fault Finding - Pilot PILOT WILL NOT LIGHT START HERE Does pilot stay alight when Check gas line-open all cocks, gas valve knob is released? rectify any blockages, purge out any air. Does pilot light? Apply match to pilot burner instead of pressing piezo unit button.

-

Page 24: Spare Parts

11 Spare Parts The key number in the first column of the list will help identify If ordering from British Gas you will also require the GC each part in diagram 11.1. appliance number off the data label and the required spare part GC number.

Need help?

Do you have a question about the Hideaway 40B and is the answer not in the manual?

Questions and answers