Table of Contents

Advertisement

INSTALLATION MANUAL

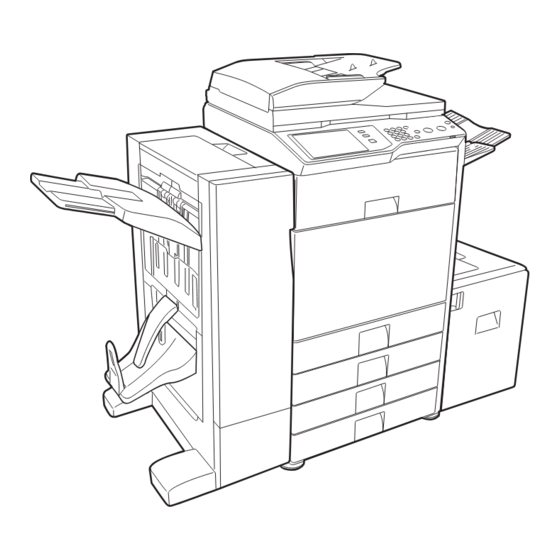

[1] MF 9626/9631/9841 (Main Unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SG-CPX4/CPX6 (Stand/2x500 sheet paper drawer) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] SG-ETX1/ETX2 (Exit tray unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[4] SG-GCX1 (Large capacity tray) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[5] SG-FNX3 (Inner Finisher) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] SG-PMX1 (Punch module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] SG-BPX2 (Paper pass unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] SG-FNX4 (Saddle stitch finisher) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[9] SG-PMX2 (Punch module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] SG-FEX2 (Facsimile expansion kit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

[11] SG-IFX1 (Internet fax expansion kit). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

[12] SG-KBX1 (Keyboard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

[13] SG-ECK1 (Enhanced compression kit). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

[14] SG-DSK2/DSK3 (Data security kit). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

[15] SG-PSX1 (PS3 expansion kit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

[16] SG-XEK1 (XPS expansion kit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-1

[17] SG-MEK1 (Expansion memory board) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-1

[18] SG-BF1 (Barcode font kit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-1

[19] SG-AMX2 (Application communication module). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-1

[20] SG-AMX3 (External account module). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-1

Parts marked with "

" are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used for after sales service only.

DIGITAL FULL COLOR

MULTIFUNCTIONAL SYSTEM

CONTENTS

The contents are subject to change without notice.

CODE: 00ZMF9841/I1E

MF 9626

MF 9631

MF 9841

MODEL

Advertisement

Table of Contents

Summary of Contents for SAGEMCOM MF 9626

-

Page 1: Table Of Contents

[1] MF 9626/9631/9841 (Main Unit) ........ -

Page 2: Configuration

EXIT TRAY UNIT DIGITAL FULL COLOR DIGITAL FULL COLOR PUNCH MODULE SG-ETX2 MULTIFUNCTIONAL SYSTEM MULTIFUNCTIONAL SYSTEM SG-PMX2 MF-9626/9631/9841 MF 9626/9631/9841 Paper feed system Printer expansion PS3 EXPANSION KIT BARCODE FONT KIT SG-BF1 SG-PSX1 LARGE CAPACITY TRAY SG-GCX1 XPS EXPANSION KIT... - Page 3 2. Combination of options Product Section Name Model name MF 9841 Remarks 9626/9631 key target ✕ Paper feed STAND/2 x 500 SHEET PAPER DRAWER SG-CPX4 system STAND/2 x 500 SHEET PAPER DRAWER SG-CPX6 ✕ LARGE CAPACITY TRAY SG-GCX1 ✕ Paper exit system EXIT TRAY UNIT SG-ETX1 ✕...

- Page 4 (3) Power frequency, waveform The frequency must be within the range of the specified frequency ±2%. If power waveform is deformed, a trouble may occur. MF 9841 MF 9626/9631/9841 1 – 1...

-

Page 5: Transit And Delivery

B. Removal of the fixing tape and protection material Transit and delivery Content Method Implements, facility, and Use a forklift. (If no forklift is manpower available, manpower of four persons is required.) Delivery Transit must be made in packed condition. MF 9841 MF 9626/9631/9841 1 – 2... - Page 6 (1) Tray rotation plate lock release Pull out the tray, and remove the rotation plate fixing material and the tray note label. Attach the removed fixing material to the position shown in the figure for storage. MF 9841 MF 9626/9631/9841 1 – 3...

- Page 7 Pinch the knob and remove the development unit. B. Developing (each color) installation Be careful not to attach fingerprints or oily dirt on the DV roller sur- face. Open the front cabinet. Remove the screws. MF 9841 MF 9626/9631/9841 1 – 4...

- Page 8 * When installing the developer unit, be sure to check that the Install the DV cover in the arrow direction A. DV lock lever is open. * When installing the DV cover, be sure to engage the pawl with the boss. MF 9841 MF 9626/9631/9841 1 – 5...

- Page 9 14) Install the waste toner box (package part No. 3). C. Set the control level for the reference toner density Insert the power plug into the power outlet. After entering the simulation, close the front cabinet. MF 9841 MF 9626/9631/9841 1 – 6...

- Page 10 * Dust from the transfer belt or shutter or some other adjacent part may fall onto the LSU during transport or installation. Be sure to clean the dust-proof glass before checking the image quality. Open the front cabinet. MF 9841 MF 9626/9631/9841 1 – 7...

- Page 11 Unit) is installed when installing the main unit, do not install the paper holding arm unit and the paper exit full detection actuator. Replace the LSU claning bar to the front cover and attach the waste toner box. MF 9841 MF 9626/9631/9841 1 – 8...

- Page 12 The guide plates A and B are slidable. Slide each guide plate while squeezing its lock lever. MF 9841 MF 9626/9631/9841 1 – 9...

- Page 13 (NOTE) In the case of Method 2, the right angle of paper to be used may not be exact. Be sure to check the right angle of paper to be used in advance. MF 9841 MF 9626/9631/9841 1 – 10...

- Page 14 All the highest density sections of all the print color patterns may not be aligned on a line. Compare only the same-color patterns.) If the above condition is not met, do the following: MF 9841 MF 9626/9631/9841 1 – 11...

- Page 15 ADJ17 and the ADJ18. Press [EXECUTE] key. The adjustment pattern is printed out. (Each paper is fed from selected paper feed tray, and the indi- vidual pattern according to each paper feed tray is printed out.) MF 9841 MF 9626/9631/9841 1 – 12...

- Page 16 Press [OK] key. The adjustment result becomes valid. Select [OC ADJ] with the key button. Select the paper feed tray with paper in it with the key button. (Any paper size will do.) MF 9841 MF 9626/9631/9841 1 – 13...

- Page 17 SPF adjustment front surface SIDE2 SPF adjustment back surface * By pressing the [REPRINT] button, you can return to the SPF adjustment front/back surface cassette selection screen and have the machine self-print RSPF adjustment patterns again. MF 9841 MF 9626/9631/9841 1 – 14...

- Page 18 Scanning of the DSPF adjustment pattern is started. 10) The adjustment result screen is displayed. 11) Press [OK] key. The adjustment value is saved in EEPROM and RAM and the display is shifted to the end screen. MF 9841 MF 9626/9631/9841 1 – 15...

- Page 19 Both are set to the standard color balance when shipping from the factory. For the service target, a customized color balance gamma can be registered with SIM63-7. MF 9841 MF 9626/9631/9841 1 – 16...

- Page 20 If there is any streak or unclear print on the printed check pat- tern, check the print engine for any problems. MF 9841 MF 9626/9631/9841 1 – 17...

- Page 21 S-D mode D-D mode Bookbinding operation When the finisher is installed Stapling operation When the finisher is installed Grouping operation When the finisher is installed Sorting operation When the finisher is installed MF 9841 MF 9626/9631/9841 1 – 18...

- Page 22 • Scanner (Optical section) • Paper cassette lift plate NOTE: Since the hard disk drive is built in the machine, use care not to exert vibrations or shocks to the machine when in transit. MF 9841 MF 9626/9631/9841 1 – 19...

-

Page 23: Sg-Cpx4/Cpx6 (Stand/2X500 Sheet Paper Drawer)

C. Check the packed items [2] SG-CPX4/CPX6 MF 9841 Service Manual Check that all the items are included in the package. Unpacking A. Removal of the desk unit Names of bundles Quantity Right adjuster Fixing screws (M4 x 8) Installation <Note before installation>... - Page 24 B. Installation of the adjuster Put the main unit on the desk unit. * Use man power of four persons or more to lift the main unit. Install the right adjuster (package part No. 1) to the desk unit. Turn each adjuster to fix the desk unit. * Place the main unit on the desk unit slowly by fitting the external lines.

- Page 25 Lift the connection plates on the right and left of the main unit Lift the connection plates, and fix them with the fixing screws. front side, and fix them with the fixing screws (package part No. 2). Replace the No. 3 and No. 2 trays to the original positions. Install the connection plate covers.

- Page 26 D. Release the lock E. Connector connection Pull out each tray. Remove the screw from the back of the main unit. Remove the connector cover. Turn and remove the fixing material, and remove the caution Connect the connector. sheet. Attach the removed fixing material to the position shown in the figure for storage.

- Page 27 F. Turn on the power of the main unit Select [ALL] with the key button. Insert the power plug of the main unit into the power outlet. Open the front cabinet. (Note) Turn ON the power switch in the front cabinet of the main unit. By pressing [LEAD] or [OFFSET] button, the following items can be executed individually.

- Page 28 [3] SG-ETX1/ETX2 MF 9841 Service Manual Open the front cabinet. Turn OFF the power switch in the front cabinet of the main unit. 1. Unpacking A. Removal of the exit tray unit Disconnect the power plug of the main unit from the power out- let.

- Page 29 Remove the paper exit cover. Install the connector cover, and fix it with the screw. [MF 9626/9631] Remove the screw, and remove the paper exit cover. Install the exit tray unit (A) and the full detection actuator (B) (package part No. 2).

-

Page 30: Sg-Gcx1 (Large Capacity Tray)

[4] SG-GCX1 MF 9841 Service Manual Remove the paper feed desk fixing screw. Unpacking A. Removal of the large capacity tray unit NOTE: Before turning on the power, check to insure that the fixing screw of the tray is removed. If the power is turned on without removing the fixing screw, a trouble may be resulted. - Page 31 Open the front cabinet. Disengage the pawl, and remove the right adjuster. Turn OFF the power switch in the front cabinet of the main unit. Remove the screw cap, and remove the screw. Disconnect the power plug of the main unit from the power out- let.

- Page 32 Insert the temporarily fixed screw B into the key hole in the Check to insure that the height adjustment check rib of the connection unit (package part No. 2), and temporarily fix the large capacity tray unit and the axis line of the mounting plate connection unit.

- Page 33 In the case of a shift to the right, press the front upper section Connect the connector, and tighten the screw. and fit the height adjustment check rib so that it is in the same line with the axis line of the mounting plate upper. Insert the large capacity tray unit into the main unit.

- Page 34 a. Side plate size switch Loosen the fixing screw (flat screw 1pc) of the auxiliary guide. Remove four fixing screws (blue screws) which are fixing the Set the mark position ( ) of the auxiliary guide and the cas- upper and the lower sections of the side plate F and the side sette R to the size from A4 to LT, and fix with the fixing screw plate R.

- Page 35 Slightly push the tray, restore the stopper to the original posi- Loosen the stopper fixing screw (1 pc) on the right lower side tion, and fix the fixing screw. of the tray so that the stopper does not function. Pull out the tray again until it stops. At that time, check to insure that the stopper pawl is engaged with the stopper reception of the large capacity tray unit.

- Page 36 Slightly push the tray, restore the stopper to the original posi- F side R side tion, and fix the fixing screw. b. Auxiliary guide size switch * Since the auxiliary guide setting is not required, fix the auxiliary At that time, check to insure that the stopper pawl is engaged guide to either of A4 or LT.

- Page 37 Open the front cabinet. Select a paper feed tray to be adjusted. Turn ON the power switch in the front cabinet of the main unit. Press [EXECUTE] key. The adjustment pattern is printed out. Turn ON the power switch on the operation panel. Set the adjustment pattern on the document table.

- Page 38 Loosen the stopper fixing screw (1 pc) on the right lower side b. When the shift is in the rear side of the tray so that the stopper does not function. To adjust the print line in the direction B from the paper center as shown in the figure: Loosen two fixing screws (red screws) of the front/rear size guide adjustment plate, and move the size guide adjustment...

- Page 39 B. Removal of the fixing tape and protection [5] SG-FNX3 MF 9841 Service Manual material Remove the fixing tape and protection material. Unpacking A. Removal of the inner finisher C. Check the packed items Check that all the items are included in the package. * When removing the inner finisher, lift it as shown in the table below.

- Page 40 Installation B. Removal of the paper holding arm unit Push up the section A to disengage the pawl, and remove the <Note before installation> paper holding arm and the paper holding arm holder together * Before starting installation, check to insure that the data lamp on as a unit.

- Page 41 Disengage two pawls, and remove the paper exit tray cover. Engage the projection on the main unit frame with the hole in the finisher fixing plate (package part No. 1). Fix the right cover plate with the fixing screw (package part No. Remove four screws, and remove the paper exit tray.

- Page 42 10) Check to insure that the slide roller is in the rail groove, and 14) Fix the punch cover (package part No. 5) together with the insert the inner finisher. band (metal fixture) with the fixing screw (package part No. 8). 11) Fix the rear slide rail with the fixing screw (package part No.

- Page 43 F. Turn on the power of the main unit Connect the finisher connector with the main unit connector, and tighten with a screw. Insert the power plug of the main unit into the power outlet. Open the front cabinet. Turn ON the power switch in the front cabinet of the main unit. E.

-

Page 44: Sg-Pmx1 (Punch Module)

[6] SG-PMX1 MF 9841 C. Check the packed items Service Manual Check that all the items are included in the package. Unpacking A. Removal of the punch unit Packed part names Quantity Punch position label (For scanner) Punch position label (For RSPF/DSPF) Installation * When the punch unit is installed together with installation of the SG-FNX3 (inner finisher), first install the inner finisher,... - Page 45 Open the front cabinet. Remove the coin screw, and remove the finisher slide stopper. Turn OFF the power switch in the front cabinet of the main unit. Slide the inner finisher further more. Disconnect the power plug of the main unit from the power out- let.

- Page 46 Remove the screw, and remove the dummy punch unit. 11) Remove the dust box. 12) Fix the punch cover and the band together with one screw. Fix the punch unit with a screw. * When installing the punch unit, be careful not to bump it against the drawer connector.

- Page 47 D. Turn on the power of the main unit 16) Slide the inner finisher to the original position, and close the front cover. Insert the power plug of the main unit into the power outlet. Open the front cabinet. Turn ON the power switch in the front cabinet of the main unit. C.

- Page 48 [7] SG-BPX2 MF 9841 C. Check the packed items Service Manual Check that all the items are included in the package. Unpacking the SG-BPX2 A. Removal of the interface pass unit Packed part names Quantity Right cover plate Interface left cabinet Reverse tray Fixing screw A Resin clip...

- Page 49 Disconnect the power plug of the main unit from the power out- Disengage the pawls, and remove the paper exit tray cover. let. Remove the screws, and remove the paper exit tray. B. Removal of the paper holding arm unit Push up the section A to disengage the pawl, and remove the paper holding arm and the paper holding arm holder together as a unit.

- Page 50 Engage the projection of the main unit frame with the hole in Insert the reverse tray (package part No. 3) along the groove in the right cover plate (package part No. 1), and install the right the interface left cabinet and the top surface of the right cover cover plate and fix it with the fixing screw A (package part No.

- Page 51 11) Insert the interface pass unit along the guide rail. 12) Fix the interface pass disconnection preventing lever with the fixing screw A (package part No. 4). 13) Go to the saddle finisher installing procedure. MF 9841 SG-BPX2 7 – 4...

-

Page 52: Sg-Fnx4 (Saddle Stitch Finisher)

[8] SG-FNX4 MF 9841 Service Manual Remove the skid and packing cushions. Unpacking the SG-FNX4 A. Removal of the saddle finisher * For removal of the saddle stitch finisher, manpower of two per- sons or more is required. Remove the fixing material, and remove the top case. Remove the packing cushion and bundled items. - Page 53 Installing the SG-FNX4 B. Removal of the fixing tape and protection material <Note before installation> Remove the fixing tape and protection material. * Make sure that none of the data lamps on the operation panels are lit or flashing before starting the installation work. * Installing the SG-FNX4 requires that the option desk (SG-CPX4/ CPX6) and junction unit (SG-BPX2) be installed in advance.

- Page 54 D. Height adjustment of the finisher Fix the paper holding A with fixing screws A (package part No. Put the finisher closer to the main unit, and check to insure that the guide pin is smoothly inserted into the connection hole. Connection hole Guide pin Installation of tee saddle tray and paper holding B.

- Page 55 Loosen the fixing screw of the adjustment section on the front Loosen four fixing screws of the adjustment section, and turn side. If the guide pin is inserted smoothly, tighten the fixing the height adjustment screws on the front/rear sides to adjust screws of the adjustment section on the front/rear sides.

- Page 56 G. Staple position label attachment Install the rail bracket to the frame with fixing screws C (pack- age part No. 8). Attach the label to the position indicated in the figure. [For scanner] (package part No. 10) Corner R end fitting Label attachment Corner R end fitting reference...

- Page 57 Open the front cabinet. Turn ON the power switch in the front cabinet of the main unit. Turn ON the power switch on the operation panel. <State of switch> MF 9841 SG-FNX4 8 – 6...

- Page 58 [9] SG-PMX2 MF 9841 Service Manual Open the front cabinet. Turn OFF the power switch in the front cabinet of the main unit. 1. Unpacking A. Removal of the punch unit Disconnect the power plug of the main unit from the power out- let.

- Page 59 B. Installation of the punch unit Open the front cover. Remove the screw, and remove the front inner cover. Release the lock and separate the saddle finisher from the main unit. Remove the screw, and remove the rear cover. Remove the screw, and remove the dummy punch guide. Remove the screw, and remove the front lower cover.

- Page 60 Connect the harness on the punch unit side with the PWB on 10) Fix the rear cover with a screw. the finisher side. 11) Install the saddle finisher to the main unit. Fix the front inner cover with screws, and close the front cover.

- Page 61 D. Punch position label attachment E. Turn on the power of the main unit Attach the label to the position indicated in the figure. Connect the connector. [For scanner] Lose the clearance. Second label First label Corner R end fitting Label attachment Corner R end fitting reference...

-

Page 62: Sg-Fex2 (Facsimile Expansion Kit)

[10] SG-FEX2 MF 9841 Service Manual Remove the power plug of the main unit from the outlet. Unpacking A. Parts included Installation M3 Screw: directions: Line cable: B. Attach the fax box unit to the rear part of the main unit. Remove the two screws from the rear cabinet of the main unit. - Page 63 E. Attach the interface cable. Remove the screw from the right rear cabinet and remove the right rear cabinet. Connect the interface cable to the control PWB unit. [Note] Check that the connector is not obliquely inserted. Push the interface cable into the recessed portion of the sheet metal on the control PWB unit.

- Page 64 H. Set the destination and the logo type. Fit the interface cable into the opening that has been cut. Attach the right rear cabinet cover to the main unit. Switch the operation panel to the copy mode and use the key At this time, check that the four hooks are properly fitted to the operation [P], [∗], [C], and [∗] to enter the simulation mode.

- Page 65 K. Connect the line cable to the fax box unit. • Country code list screen * Press the [DEST CODE] button on the initial screen to move to Connect the line cable of the line side to the modular jack indi- the country code list screen.

- Page 66 [11] SG-IFX1 MF 9841 Service Manual 1. Unpacking A. Parts included Packed part names Quantity CD-ROM Product key sheet 2. Installation <Note before installation> • In order to enable the Internet Fax send function, the product key must be acquired. •...

- Page 67 Installation [12] SG-KBX1 MF 9841 Service Manual <Note before installation> Unpacking * Before starting installation, check to insure that the data lamp on the operation panel does not light up or blink. A. Turn off the power of the main unit Turn OFF the power switch on the operation panel.

- Page 68 B. Install the USB hub PWB. Connect the connector of the scan mother harness, and con- nect the mother PWB connection harness (part No.4 in the Remove the screw, and remove the rear cabinet. package). Disconnect the connector of the scan mother harness, and remove the screws.

- Page 69 Open the front cabinet, and remove the screw, and remove the Remove the screw, and remove the panel angle. front cabinet upper. Install the keyboard unit (part No.1 in the package), and fix it with the fixing screw A (part No.5 in the package) and the fix- ing screw B (part No.6 in the package).

- Page 70 Connect the connector. Attach the front cabinet upper, and fix it with the screws. Install the operation panel to the main unit, and fix it with the screw. E. Adjust the position of the key top unit When the cabinet position of the key top unit is shifted, loosen the screws which are fixing the key top unit and adjust the position up and down.

- Page 71 Turn ON the power switch on the operation panel. Touch [Default Settings]. S S y y s s t t e e m m S S e e t t t t i i n n g g Admin Password Exit List Print Total Count...

-

Page 72: Sg-Eck1 (Enhanced Compression Kit)

[13] SG-ECK1 MF 9841 B. Pull out the control PWB Service Manual • If cables are connected to the control PWB unit, remove all cables. Unpacking Push the location indicated in the illustration to unlock, and A. Parts included remove the ozone filter cover from the right rear cabinet. Remove the screw from the right rear cabinet. - Page 73 C. Installation of the scanner function expansion D. Reattach the control PWB and the right rear cabinet Remove four screws for fixing the scanner function expansion • If the fax box unit is installed, carry out steps 1), 2), and 3) PWB from the control PWB.

- Page 74 E. Turn ON the power of the main unit Insert the power plug of the main unit into the power outlet. Open the front cabinet. Turn ON the power switch in the front cabinet of the main unit. Turn ON the power switch on the operation panel. <State of switch>...

-

Page 75: Sg-Dsk2/Dsk3 (Data Security Kit)

[14] SG-DSK2/DSK3 MF 9841 Service Manual Remove the power plug of the main unit from the outlet. Unpacking A. Check the packed items Check that all the items are included in the package. Packed part names Quantity MFP_PRG1 ROM MFP_PRG2 ROM Operation manual B. - Page 76 C. Mount the data security kit ROMs to the • If the fax box unit is installed, carry out step 6) addition- ally. control PWB unit. Fit the interface cable into the right rear cabinet cover. Remove the ROMs (PROG1 and PROG2) from the control PWB Attach the right rear cabinet cover to the main unit.

-

Page 77: Reading Data

F. Installation of the DSK firmware (3) DSK Firmware installing procedures in the boot mode (1) MFP booting operations after replacement Boot the machine in the boot mode. With "Version Check" dis- Turn ON the power, and the main program error is displayed. played, press [MENU] key, and the machine enters the firm- ware update mode. - Page 78 Check the result of installation (update) of the firmware. By using [UP] key and [DOWN] key, the results of installation (update) of all the firmware files. Firm Update IcuM Result : OK Firm Update IcuM Result : Not Update Firm Update IcuM Result : NG •...

- Page 79 [15] SG-PSX1 MF 9841 Service Manual 1. Unpacking A. Parts included Packed part names Quantity CD-ROM (For Screen Font) Product key sheet NOTE: To set up the PS driver, do not use the CD-ROM which is included in the SG-PSX1 but use the PCL CD-ROM which is included in the main unit.

- Page 80 [16] SG-XEK1 MF 9841 Service Manual 1. Unpacking A. Parts included Packed part names Quantity CD-ROM Operation manual Product key sheet 2. Installation A. Preparation for enabling XPS 1GB Expansion memory is required. To enable XPS, enter the product key by the key operation of the copier machine.

-

Page 81: Sg-Mek1 (Expansion Memory Board)

[17] SG-MEK1 MF 9841 B. Pull out the control PWB. Service Manual • If cables are connected to the control PWB unit, remove all cables. Unpacking Push the location indicated in the illustration to unlock, and A. Parts included remove the ozone filter cover from the right rear cabinet. 1GB expansion memory Installation Remove the screw from the right rear cabinet. - Page 82 Push the sections indicated with → at the same time with D. Reattach the control PWB and the right rear both hands. cabinet. * When handling the expansion memory, be careful not to • If the fax box unit is installed, carry out steps 1), 2), and 3) touch the pin section.

- Page 83 E. Turn on the main power switch of the main unit. Insert the power plug of the main unit to the outlet. Turn on the main power switch. Turn on the power switch located on the operation panel. <State of switch> MF 9841 SG-MEK1 17 –...

- Page 84 [18] SG-BF1 MF 9841 Service Manual Remove the power plug of the main unit from the outlet. 1. Unpacking A. Parts included SG-BF1 barcode font ROM PWB B. Pull out the control PWB. • If cables are connected to the control PWB unit, remove all cables.

- Page 85 C. Installation of the barcode font ROM PWB Fit the interface cable into the right rear cabinet cover. Attach the right rear cabinet cover to the main unit. Install the barcode font ROM PWB to the barcode connector. At this time, check that the four hooks are properly fitted to the * Check to confirm that the silver push lever extends out when the main unit.

- Page 86 Turn on the power switch located on the operation panel. <State of switch> F. PCL expansion font list check PCL expansion font list check Select the PCL expansion font list by the procedures described in the printer test page in the system setup guide. Check to confirm that the barcode font list is printed.

-

Page 87: Sg-Amx2 (Application Communication Module)

[19] SG-AMX2 MF 9841 Service Manual When the [Default Display Setting] key is touched, the screen for setting the default display that appears when the [DOCU- MENT FILING] key is pressed will appear. 1. Unpacking • To set the base screen of document filing as the default dis- play, touch the [Document Filing] key. -

Page 88: Sg-Amx3 (External Account Module)

[20] SG-AMX3 MF 9841 Service Manual When [External Account Setting] key is touched, the screen for setting the calculation by the external applica- tion and for enabling user authentication is displayed. 1. Unpacking (The two settings are linked together.) • When the check box of [External Account Management A. - Page 90 COPYRIGHT 2009 BY SHARP CORPORATION All rights reserved. Reproduction, adaptation or translation of the contents of the manual without prior written permission is prohibited, except as allowed under copyright laws. Trademark acknowledgements ® ® Microsoft Windows operating system is a trademark or copyright of Microsoft Corporation in the U.

Need help?

Do you have a question about the MF 9626 and is the answer not in the manual?

Questions and answers