Summary of Contents for Factory Cat 29

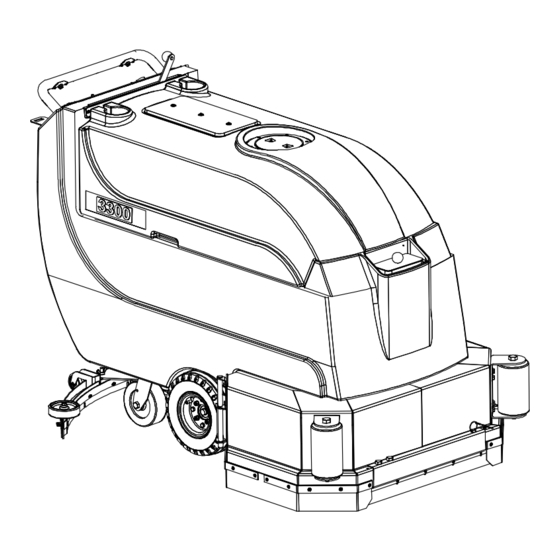

- Page 1 ACTORY Operator and Parts Manual 29,33 Walk-Behind Scrubber 28,32 Cylindrical R.P.S. Corporation Phone: 1-800-634-4060 P.O. Box 368 Fax: 1-866-901-3335 Racine, Wisconsin 53401 www.factorycat.com...

- Page 2 CYLINDRICAL CONFIGURATIONS. OUR MACHINES ARE DESIGNED TO WITHSTAND THE DAILY USE OF CONTRACT CLEANERS. THE TWO "DISK" MACHINES WITH 29" AND 33" SCRUB PATHS OFFER NEARLY 50% MORE CLEANING POWER THAN OTHER MACHINES. THE DISK DECK IS PROTECTED BY HEAVY STEEL GUARDS OR LOW MOUNTED SHROUDS AT NO EXTRA COST.

-

Page 3: Table Of Contents

PAGE 25-26 SAFETY MESSAGES PAGE 5 CHASSI PAGE 27-28 !!SAFETY PRECAUTIONS!! PAGE 6 DISK BRUSH HEAD WITH JAWS PAGE 29-30 MACHINE FEATURES AND CONTROLS PAGE 7-8 DISK BRUSH HEAD WITH SHROUDS PAGE 31-32 MACHINE SETUP PAGE 9-10 SQUEEGEE SUSPENSION PAGE 33-34... -

Page 4: Warranty Registration Form

DEALER:________________________________________________________ SERIAL NUMBER:_________________ LOCATION (CITY, STATE):_________________________________________ INSTALL DATE:____________________ CUSTOMER:_____________________________________________________ HOUR METER:____________________ CONTACT:______________________________________________________ INSTALLED BY:___________________ ADDRESS:_______________________________________________________ CITY:_______________________STATE_______ZIP______________________ PHONE:_______________________ FAX:__________________________ FACTORY CAT MODEL NUMBER:_______________________________________ OPTIONS: 1.______________________________________ 4.______________________________________ 2.______________________________________ 5.______________________________________ 3.______________________________________ 6.______________________________________ PADS:_____________________________________________ BRUSHES:__________________________________________ SQUEEGEE SIZE:____________________________________ BUYER'S REPRESENTAVE HAS: RECEIVED INSTRUCTION IN PROPER OPERATION OF THIS MACHINE. - Page 5 TRANSAXLE DESCRIPTION: .75 HP, SEALED .75 HP, SEALED 0-5 MPH SPEED CONTROL: 0-5 MPH PRODUCTIVITY SCRUBBING WIDTH: DISK 29 INCHES DISK 33 INCHES CYLINDRICAL 32 INCHES CYLINDRICAL 28 INCHES SCRUBBING RATE/HOUR (NORMAL): DISK 33,000 FT/HR DISK 29,000 FT/HR CYLINDRICAL 32,000 FT/HR...

-

Page 6: Common Wear Parts

COMMON WEAR PARTS MODEL MODEL MODEL MODEL ITEM 3000-D 3000-C 3400-D 3400-C BRUSH TYPE DISK CYLINDRICAL DISK CYLINDRICAL BRUSHES SUPER-GRIT 15-421SS 17-421SS TOUGH-GRIT 15-421S 28-521S 17-421S 32-521S MIDI-GRIT 15-421C 28-521C 17-421C 32-521C LIGHT-GRIT 15-421PS 28-521PS 17-421PS 32-521PS POLY (.028) 15-421P 28-521P 17-421P 32-521P... -

Page 7: Safety Messages

SAFETY MESSAGES YOUR SAFETY, AND THE SAFETY OF OTHERS, IS VERY IMPORTANT, AND OPERATING THIS UNIT SAFELY IS AN IMPORTANT RESPONSIBILITY. TO HELP YOU MAKE INFORMED DECISIONS ABOUT SAFETY, WE HAVE PROVIDED OPERATING PROCEDURES AND OTHER SAFETY INFORMATION IN THE MANUAL. THIS INFORMATION INFORMS YOU OF POTENTIAL HAZARDS THAT COULD HURT YOU OR OTHERS. -

Page 8: Safety Precautions

!! SAFETY PRECAUTIONS!! : ALWAYS USE THE CHARGER PROVIDED WARNING WARNING: HAZARDOUS VOLTAGE. SHOCK, BURNS BY THE MAUFACURER TO CHARGE THE MACHINE. OR ELECTROCUTION CAN RESULT. ALWAYS DISCON- IT IS AN AUTOMATIC CHARGER, SPECIFICALLY NECT THE BATTERIES BEFORE SERVICING MACHINE. DESIGNED TO CHARGE AT THE APPROPRIATE RATE. -

Page 9: Machine Controls And Features

MACHINE CONTROLS AND FEATURES FIGURE 1. FIGURE 1. FIGURE 1. 20 21 22 23 FIGURE 1. FIGURE 1. PAGE 7... - Page 10 THE MACHINE IS EQUIPED WITH TWO CUP HOLDERS. 26. CUP HOLDER: PROTECT THE SCRUB DECK FROM BEING DAMAGED AND CONTROL SPLASHING. OPEN TO CHANGE BRUSHES. 27. JAWS: PROVIDE PROPULTION FOR MACHINE. 28. DRIVE WHEELS: 29. REAR CASTERS: TWIN CASTERS FOR STABILITY. PAGE 8...

-

Page 11: Machine Setup

MACHINE SETUP UNCRATING MACHINE ATTACHING SQUEEGEE LOWER THE SQUEEGEE MOUNTING PLATE BY SLIDING THE LEVER ALL THE WAY TO THE RIGHT. CAREFULLY CHECK THE CRATE FOR ANY SIGNS OF DAMAGE. BATTERIES ARE IN THE UNIT. (SEE FIGURE 7.) TO UNCRATE THE MACHINE, REMOVE BANDING FROM AROUND THE CRATE. -

Page 12: Cylindrical Brushes

ATTACHING ATTACHING DISK BRUSHES CYLINDRICAL BRUSHES TURN ON MACHINE POWER TURN ON MACHINE POWER RAISE THE SCRUB DECK BY DEPRESSING THE RAISE THE SCRUB DECK BY DEPRESSING THE BRUSH SWITCH TO THE UP AND OFF POSITION BRUSH SWITCH TO THE UP AND OFF POSITION AND TURN MACHINE POWER BACK OFF. -

Page 13: Operation

OPERATION ONE PASS SCRUBBING PRE-CLEANING CHECK LIST STEPS: (SEE FIGURE 16.) READ AND UNDERSTAND THE SAFETY SECTION ON TURN MACHINE ON, MAKE SURE THE SPEED PAGE 5 AND 6 BEFORE OPERATING MACHINE. KNOB IS AT THE LOWEST SETTING. LOWER SQUEEGEE BY MOVING THE LIFT LEVER 1. -

Page 14: Draining Solution Tank

OPERATING HINTS DRAINING RECOVERY TANK 1. OBSERVE THE AMOUNT OF SOLUTION THE MACHINE IS ALWAYS EMPTY RECOVERY TANK WHEN REFILLING THE DISPENSING ON THE FLOOR AND ADJUST TO THE DESIRED SOLUTION TANK. TO DRAIN THE RECOVERY TANK, PERFORM THE FLOW. TO INCREASE THE SOLUTION FLOW RATE, MOVE FOLLWING STEPS. - Page 15 BATTERY CHARGING CAUTION: THE FOLLOWING INSTRUCTIONS ARE 4. CHECK THE WATER LEVEL IN EACH BATTERY. INTENDED FOR THE 24V CHARGER SUPPLIED WITH DO NOT CHARGE THE MACHINE UNLESS THE THE MACHINE. DO NOT USE ANY OTHER WATER IS SLIGHTLY HIGHER THAN THE PLATES. IF CHARGER WITH THIS MACHINE.

-

Page 16: Maintenance

MAINTENANCE MONTHLY DAILY MAINTENANCE MAINTENANCE REMOVE AND CLEAN PADS OR BRUSHES. NEVER CHECK SCRUB HEAD AND SQUEEGEE LIFTING CABLES FOR USE SOILED PADS WHEN CLEANING. REPLACE WEAR AND SPRING TENSION. PADS WHEN THEY BECOME PACKED WITH RESIDUE. CHECK MACHINE FOR WATER LEAKS AND LOOSE NUTS AND REMOVE AND CLEAN DEBRIS FROM THE FLOAT BOLTS. -

Page 17: Preventative Maintenance Records

PREVENTATIVE MAINTENANCE RECORDS USE THIS FORM TO MAKE COPIES FOR YOUR INTERNAL RECORDS PREVENTATIVE MAINTENANCE CHECKED NOTE ROTATE BRUSHES _____________ ____________________________________ ROTATE SIDE BROOMS _____________ ____________________________________ DRAIN SOLUTION TANK _____________ ____________________________________ FLUSH SOLUTION SYSTEM _____________ ____________________________________ CLEAN SOLUTION SCREEN _____________ ____________________________________ DRAIN RECOVERY TANK _____________... - Page 18 PREVENTATIVE MAINTENANCE RECORDS USE THIS FORM TO MAKE COPIES FOR YOUR INTERNAL RECORDS PREVENTATIVE MAINTENANCE CHECKED NOTE ROTATE BRUSHES _____________ ____________________________________ ROTATE SIDE BROOMS _____________ ____________________________________ DRAIN SOLUTION TANK _____________ ____________________________________ FLUSH SOLUTION SYSTEM _____________ ____________________________________ CLEAN SOLUTION SCREEN _____________ ____________________________________ DRAIN RECOVERY TANK _____________...

- Page 19 LCD SCREEN MENU DISPLAYS LCD SCREEN MENU DISPLAYS SCREEN # 1 SCREEN # 2 (FIGURE 23.) (FIGURE 22.) SCREEN #3 SCREEN #1 W/ERROR CODE (FIGURE 24.) (FIGURE 25.) *** USE GREEN MENU SELECTION BUTTON ON CONTROL PANEL TO CHANGE SCREENS*** FIGURES 22-25.

-

Page 20: Troubleshooting Central Command

EITHER THE BATTERIES ARE MIS-WIRED, OR THE CHARGER IS STILL PLUGGED INTO THE MACHINE. (FIGURE 28.) THE VACUUM 4. 7700, 7701, 7702, AND 7703 ERROR. MOTOR HAS EXCEEDED THEIR AUTHORIZED POWER LIMITS. TURN OFF KEY AND TURN ON AGAIN TO CLEEAR. (FIGURE 29.) PAGE 18... - Page 21 TROUBLESHOOTING CENTRAL COMMAND 5. 7900 AND 7901 ERROR. THE EMERGENCY STOP BUTTON IS OUT (FIGURE 30.) 6. 2FO1 ERROR. YOU PRESSED THE FOOT PEDAL BEFOR TURNING ON THE KEY. TURN OFF THE KEY AND TRY AGAIN, LEAVING FOOT OFF OF THE PEDAL. (FIGURE 32.) 7.

-

Page 22: Troubleshooting

TROUBLE SHOOTING PROBLEM CAUSE SOLUTION NO POWER, NOTHING OPERATES FAULTY KEY SWITCH CONTACT LOCAL SERVICING DEALER BATTERIES NEED CHARGING SEE CHARGING BATTERIES FAULTY BATTERY REPLACE BATTERY LOOSE BATTERY CABLE TIGHTEN LOOSE CABLE MAIN CIRCUIT BREAKER TRIPPED WAIT 5 MINUTES FOR AUTO RESET DETERMINE CAUSE AND CORRECT BRUSH MOTOR(S) DO NOT OPERATE BRUSH DECK IS NOT DOWN... - Page 23 TROUBLE SHOOTING PROBLEM CAUSE SOLUTION NO SOLUTION FLOW NO SOLUTION IN TANK FILL SOLUTION TANK SOLUTION VALVE OFF ROTATE LEVER TO ON SOLUTION SWITCH OFF TURN SOLUTION SWITCH ON SOLUTION SCREEN CLOGGED REMOVE AND CLEAN SCREEN FAULTY SOLUTION SOLENOID CONTACT LOCAL SERVICING DEALER FAULTY SOLUTION SWITCH CONTACT LOCAL SERVICING DEALER POOR WATER RECOVERY...

-

Page 24: Machine Parts

MODEL 3000/3400 MACHINE PARTS SECTION TANKS ARE MADE IN RED AND YELLOW. IF YOU NEED YELLOW USE THE ALTERNATE PART NUMBER. IF YOU NEED RED PARTS, USE THE NORMAL PART. IF THERE IS ONLY ONE PART NUMBER, THAT IS THE ONLY COLOR THAT PART COMES IN. - Page 25 BLANK...

-

Page 26: Solution Tank Lower Body

SOLUTION TANK LOWER BODY PAGE 23... - Page 27 Item Part No. Alt. Part No. Description Comments 32-4141 32-4140 SOLUTION TANK 32-4150 1/4 ID X 18" TUBE 32-7190 TANK CABLE 32-1087 BATTERY WALL 32-1090 ACTUATOR MOUNT PANEL 32-1480 BATTERY TRAY LINER 32-4010 FILL DOOR 32-4020 FILL DOOR GASKET 32-4025 FILL DOOR SCREEN 32-4026 3/4 ID X 42"...

-

Page 28: Recovery Tank Upper Body

Recovery Tank Upper Body PAGE 25... - Page 29 Item Part No. Alt. Part No. Description 32-7010 32-7011 RECOVERY TANK 7-712 OVERFILL SHUTOFF BALL 32-4091 VACUUM COVER, LOWER 32-4090 VACCUUM LID GASKET 32-4080 VACUUM BALL PLATE 32-4050 VACUUM COVER, UPPER 290-7210 DRAIN HOSE 21-4095 VAC MOTOR SCREEN 21-4074 VAC HOSE, 31" 21-4060 6"...

-

Page 30: Chassi

Chassis FOR MACHINES WITH SERIAL # 4000 AND HIGHER USE PART NUMBER 21-4500 PAGE 27... - Page 31 Item Part No. Description Comments 32-1000 MAINFRAME 32-1010 FRAME BRACE 32-1030 BRUSHHEAD PIVOT PLATE 32-1051 SPLASH BRACKET 32-1052 SPLASH BAND 32-1055 REAR SPLASH CURTAIN 32-3000 EUCLID TRANSAXLE MODEL 278 32-3040 TIRE, GRAY, PNEUMATIC, 4.10/3.50-5 32-3045 TIRE, BLACK, PNEUMATIC, 4.10/3.50-5 32-3050 TIRE, GRAY, FOAM, 4.10/3.50-5 TIRE, 32-3055...

- Page 32 Disk Brush Heads PAGE 29...

- Page 33 Item Part No. Description Item Part No. Description 7-402 SCRUB HEAD PLATFORM 7-126 HD ROLLER BRACKET 7-165 SWITCH BRACKET 7-125A ROLLER 32-1350 MODEL 3000 LEFT JAW H-11380 HB 5/8"- 11 X 11" 7-134L LH JAW HINGE H-37038 JNYL 5/8"- 11 32-1310 33"...

- Page 34 Dual Disk Shroud System TO 32-4140 OR 32-4141 PAGE 31...

- Page 35 Item Part No. Description Comments 32-1101 LEFT SHROUD (17") 32-1111 RIGHT SHROUD (17") 32-1142 BANDEAU COVER 32-1165 SHROUD SPLASH CURTAIN (17") 32-1120 END SHROUD SUPPORT 32-1124 RIGHT SHROUD BAND (17") 32-1126 ROLLER BRACKET 32-1136 LEFT SHROUD BAND (17") 32-1138 CENTER SHROUD SUPPORT 21-1127 ROLLER 21-1115...

-

Page 36: Squeegee Suspension

Squeegee Suspension SHOWN FOR REFERENCE ONLY 30 34 SIZE STAMP ORIENTED AS SHOWN PAGE 33... - Page 37 Item # Part # Description Comments 22-7181 30" SQUEEGEE WELDMENT 25-7181 35" SQUEEGEE WELDMENT 28-7181 38" SQUEEGEE WELDMENT 290-7181 45" SQUEEGEE WELDMENT 22-755G 30" SQUEEGEE BLADE, FRONT 25-755G 35" SQUEEGEE BLADE, FRONT 28-755G 38" SQUEEGEE BLADE, FRONT 290-756G 45" SQUEEGEE BLADE, FRONT 22-7170 30"...

-

Page 38: Cylindrical Mechanical

Cylindrical Mechanical PAGE 35... - Page 39 Item Part # Description Comments 1-305 BEARING HOUSING 22-7970 MOVABLE IDLER ARM 22-8300 DRIVE CHAIN 22-9021 CHAIN GUARD 290-8260 10 TOOTH SPROCKET 4-317 IDLER PULLEY 4-319 TENSION SPRING 5-793 IDLER SPACER 5-796 GREASE (USE ONLY OEM GREASE - NOT SHOWN) 5-798 SPRING PIVOT 5-822...

- Page 40 Cylindrical Mechanical 59 56 PAGE 37...

- Page 41 Item Part No. Description 1-421 IDLER BEARING 21-1127 ROLLER 22-2110 2 HP MOTOR 22-8430 ADJ. LATERAL ARM 22-9021 CHAIN GUARD 25-8320 HOPPER RAIL, 25" 28-8320 HOPPER RAIL, 28" 5-832 HOPPER RAIL, 32" 25-9050 25" HOPPER 28-9050 28" HOPPER 7-811 32" HOPPER 28-1126 RH ROLLER BRACKET 28-1127...

- Page 42 CENTRAL COMMAND II PAGE 39...

- Page 43 Item Part No Part Description 290-2020 BRACKET 7-283 SWITCH, TOGGLE, MOM/OFF/MOM (DPDT) 7-292 5K POTENTIOMETER H-01196 PROTECTIVE BOOT, TOGGLE SWITCH, (RED) 21-4520 SPEED CONTROL KNOB, RED 290-2891 LCD SCREEN 5-293 15 AMP RELAY 7-229 PUSH BUTTON SWITCH H-01200 PROTECTIVE BOOT, TOGGLE SWITCH, (BLACK) 8-231 SWITCH, ON-OFF ROCKER SPST 7-285A...

Need help?

Do you have a question about the 29 and is the answer not in the manual?

Questions and answers