Subscribe to Our Youtube Channel

Summary of Contents for Factory Cat 48 Series

- Page 1 ACTORY Operator and Parts Manual 48 Rider Sweeper R.P.S. Corporation Phone: 1-800-634-4060 P.O. Box 368 Fax: 1-866-901-3335 Racine, Wisconsin 53401 www.factorycat.com...

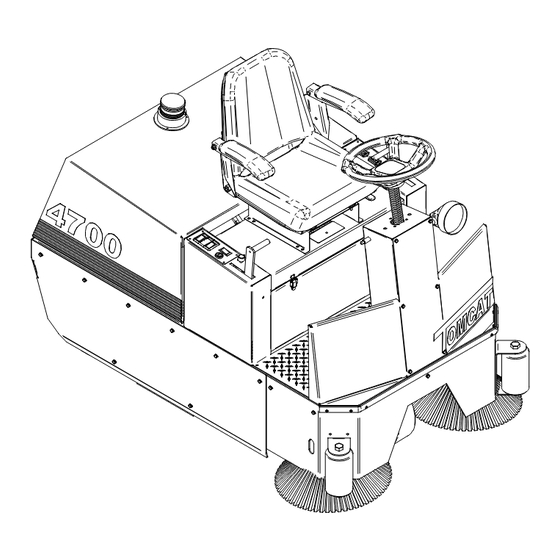

- Page 2 Operator and Parts Manual 4700 Rider Sweeper Mid-Central Corporation Phone: 1-800-450-9824 P.O. Box 241 Fax: 1-866-632-6961 Racine, Wisconsin 53401 www.tomcatequip.com...

- Page 3 COURTS IS EASILY CONTAINED IN THE LONG LIFE FILTER. THE FILTER IS CLEANED AT THE TOUCH OF A BUTTON. THE FACTORY CAT 48 HAS A POWERFUL 2.0 HP SEALED DRIVE MOTOR FOR CLIMBING STEEP RAMPS, AND THE NON-MARKING TIRES PROTECT EXPENSIVE FLOORS. THE OPERATOR'S HIGH BACK SEAT INCLUDES ARMREST, IS ADJUSTABLE, AND THE PARKING BRAKE SETS AUTOMATICALLY.

-

Page 4: Table Of Contents

THIS OPERATORS AND PARTS MANUAL SHOULD BE CONSIDERED A PERMANENT PART OF THE UNIT AND SHOULD REMAIN WITH THE UNIT AT ALL TIMES. THIS OPERATORS AND PARTS MANUAL COVERS ALL THE DFACTORY CAT 48 SERIES RIDER SWEEPERS. YOU MAY FIND DESCRIPTIONS AND FEATURES THAT ARE NOT ON YOUR PARTICULAR MODEL. THE INFORMATION AND SPECIFICATION INCLUDED IN THIS PUBLICATION WERE IN EFFECT AT THE TIME OF PRINTING. -

Page 5: Machine Delivery Form

R.P.S. CORPORATION P.O. BOX 368 RACINE, WI 53401 PHONE: 800-450-9824 FAX 866-632-6961 WWW.FACTORYCAT.COM MACHINE DELVERY FORM DEALER:________________________________________________________ SERIAL NUMBER:_________________ LOCATION (CITY, STATE):_________________________________________ INSTALL DATE:____________________ CUSTOMER:_____________________________________________________ HOUR METER:____________________ CONTACT:______________________________________________________ INSTALLED BY:___________________ ADDRESS:_______________________________________________________ CITY:_______________________STATE_______ZIP______________________ PHONE:_______________________ FAX:__________________________ TOMCAT MODEL NUMBER:_______________________________________ OPTIONS: 1.______________________________________ 4.______________________________________ 2.______________________________________ 5.______________________________________ 3.______________________________________... -

Page 6: Machine Specifications

40 AMP, 110 VOLT DRIVE SYSTEM 2.0 HP, SEALED TRANSAXLE DESCRIPTION: VARIABLE 0-320 FT. SPEED CONTROL: 70 dBA NOISE LEVEL: PRODUCTIVITY 48 INCHES CLEANING WIDTH: 60,000 SQ. FT/HR CLEANING RATE/HOUR (MAX): 55,000 SQ. FT/HR CLEANING RATE/HOUR (NORMAL): WARRANTY 3 YEARS PARTS:... -

Page 7: Common Wear Parts

COMMON WEAR PARTS ITEM MODEL 48 WE RECOMMEND YOU USE OUR BROOMS. THEY ARE MADE FOR YOUR MACHINE. OUR BRAND OF BROOMS HAS A PRECISION PLASTIC CORE THAT IS CAREFULLY BALANCED AND HAS MACHINED INSERT MAIN BROOM POINTS SO THE BROOM FITS TIGHTLY ON THE MACHINE'S HUBS. -

Page 8: Safey Messages

SAFETY MESSAGES YOUR SAFETY, AND THE SAFETY OF OTHERS, IS VERY IMPORTANT, AND OPERATING THIS UNIT SAFELY IS AN IMPORTANT RESPONSIBILITY. TO HELP YOU MAKE INFORMED DECISIONS ABOUT SAFETY, WE HAVE PROVIDED OPERATING PROCEDURES AND OTHER SAFETY INFORMATION IN THE MANUAL. THIS INFORMATION INFORMS YOU OF POTENTIAL HAZARDS THAT COULD HURT YOU OR OTHERS. -

Page 9: Safety Precautions

!! SAFETY PRECAUTIONS!! : ALWAYS USE THE CHARGER PROVIDED WARNING WARNING: HAZARDOUS VOLTAGE. SHOCK, BURNS BY THE MAUFACTURER TO CHARGE THE MACHINE. OR ELECTROCUTION CAN RESULT. ALWAYS DISCON- IT IS AN AUTOMATIC CHARGER, SPECIFICALLY NECT THE BATTERIES BEFORE SERVICING MACHINE. DESIGNED TO CHARGE AT THE APPROPRIATE RATE. -

Page 10: Machine Controls And Features

MACHINE CONTROLS AND FEATURES (FIGURE 1.) (FIGURE 2.) (FIGURE 4.) (FIGURE 3.) (FIGURE 7.) (FIGURE 6.) (FIGURE 5.) PAGE 7... - Page 11 CONTROLS AND FUNCTIONS SEE FIG. (1-7) ON PAGE 7 FIURE 1. KEEPS HOPPER IN PLACE. 1. HOPPER LATCH: 2. ACCESS PANEL LATCH: GIVES YOU QUICK ACCESS TO MAIN BROOM. STEERS MACHINE. 3. FRONT WHEEL: 4. HEADLIGHT: HELPS YOU SEE IN LOW LIGHT AREAS AND TO WORN ONCOMING TRAFFIC.. 5.

-

Page 12: Machine Preparation

MACHINE PREP ATTACHING SIDE BROOMS UNCREATING MACHINE CAREFULLY CHECK THE CRATE FOR ANY SIGNS OF LOWER THE SIDE BROOM LINKAGE BY PULLING DAMAGE. BATTERIES ARE IN THE UNIT. BACK ON THE LEVER AND THEN SLIDING THE LEVER ALL THE WAY TO THE REAR. (SEE FIGURE 9.) TO UNCREATE THE MACHINE, REMOVE BANDING FROM AROUND THE CRATE. -

Page 13: Machine Setup

MACHINE SETUP REPLACING MAIN BROOM 3. SLIDE THE NEW BROOM IN. WHEN YOU GET THE 1. TURN THE MACHINE OFF. USE A 9/16 INCH BRUSH ON THE DRIVER SPIN IT WITH YOUR HAND WRENCH TO REMOVE THE 3/8-16 HCS SCREW UNTIL YOU FEEL IT CATCH ON THE DRIVER AND THEN AND REMOVE THE IDLER ARM. -

Page 14: Pre-Sweeping Check List

PRE- SWEEPING CHECK LIST READ AND UNDERSTAND SAFETY INSTURCTIONS ON PAGE 5 AND 6 BEFOR OPERATING THIS MACHINE CHECK BATTERY CONDITION ON BATTERY CLEAN THE FILTER BY PRESSING THE CONDITION METER. MAKE SURE BATTERIES ARE SHAKER SWITCH FOR ABOUT 10 SECONDS. FULLY CHARGED BEFORE USING. -

Page 15: Operation

OPERATION ONE PASS SWEEPING OPERATING HINTS TURN MACHINE ON WITH THE KEYSWITCH. TURN ON THE FILTER BEATER FOR ABOUT 1. OBSERVE THE SPEED OF THE MACHINE AND SECONDS TO CLEAR THE FILTER. ADJUST TO THE DESIRED RATE. TO INCREASE THE SPEED, DEPRESS THE FOOTPEDAL MORE. -

Page 16: Charging Batteries

BATTERY CHARGING THE FOLLOWING INSTRUCTIONS ARE CAUTION: INTENDED FOR THE 24V CHARGER SUPPLIED WITH THE MACHINE. DO NOT USE ANY OTHER CHARGER WITH THIS MACHINE. 4. CHECK THE WATER LEVEL IN EACH BATTERY. CHARGER DO NOT CHARGE THE MACHINE UNLESS THE WATER IS SLIGHTLY HIGHER THAN THE PLATES. -

Page 17: Maintenance

MAINTENANCE MONTHLY DAILY MAINTENANCE MAINTENANCE CLEAN THE FILTER WITH THE SHAKER SWITCH FOR LUBRICATE FRONT CASTERS WITH A WATERPROOF 20 SECONDS. GREASE. REMOVE AND CLEAN DEBRIS FROM THE HOPPER CHECK MACHINE FOR VACUUM LEAKS AND AND RINCE OUT IF NECESSARY. LOOSE NUTS AND BOLTS CHARGE THE MACHINE WITH THE HOOD OPEN TO ALLOW THE BATTERIES TO VENTILATE PROPERLY. -

Page 18: Preventative Maintenance Records

PREVENTATIVE MAINTENANCE RECORDS USE THIS FORM TO MAKE COPIES FOR YOUR INTERNAL RECORDS PREVENTATIVE MAINTENANCE CHECKED NOTE CHECK BROOM FOR DEBRIS _____________ ___________________________________ SHAKE FILTER WITH SWITCH _____________ ___________________________________ EMPTY HOPPER _____________ ___________________________________ CHECK BROOM FIBER LENGTH _____________ ___________________________________ CHECK SIDE BROOM ADJUSTMENT _____________ ___________________________________ CHECK FLOOR SEALS... - Page 19 PREVENTATIVE MAINTENANCE RECORDS USE THIS FORM TO MAKE COPIES FOR YOUR INTERNAL RECORDS PREVENTATIVE MAINTENANCE CHECKED NOTE CHECK BROOM FOR DEBRIS _____________ ___________________________________ SHAKE FILTER WITH SWITCH _____________ ___________________________________ EMPTY HOPPER _____________ ___________________________________ CHECK BROOM FIBER LENGTH _____________ ___________________________________ CHECK SIDE BROOM ADJUSTMENT _____________ ___________________________________ CHECK FLOOR SEALS...

- Page 20 PREVENTATIVE MAINTENANCE RECORDS USE THIS FORM TO MAKE COPIES FOR YOUR INTERNAL RECORDS PREVENTATIVE MAINTENANCE CHECKED NOTE CHECK BROOM FOR DEBRIS _____________ ___________________________________ SHAKE FILTER WITH SWITCH _____________ ___________________________________ EMPTY HOPPER _____________ ___________________________________ CHECK BROOM FIBER LENGTH _____________ ___________________________________ CHECK SIDE BROOM ADJUSTMENT _____________ ___________________________________ CHECK FLOOR SEALS...

-

Page 21: Touble Shooting

TROUBLE SHOOTING SOLUTION CAUSE PROBLEM CONTACT LOCAL SERVICING DEALER FAULTY KEY SWITCH NO POWER, NOTHING OPERATES SEE CHARGING BATTERIES BATTERIES NEED CHARGING REPLACE BATTERY FAULTY BATTERY TIGHTEN LOOSE CABLE LOOSE BATTERY CABLE WAIT 5 MINUTES FOR AUTO RESET MAIN CIRCUIT BREAKER TRIPPED DETERMINE CAUSE AND CORRECT PUT BRUSH DECK DOWN MAIN BROOM IS NOT DOWN... - Page 22 TROUBLE SHOOTING CAUSE SOLUTION PROBLEM POOR DUST CONTROL FILTER CLOGGED TURN ON FILTER BEATER HOPPER NOT CLOSED TIGHTLY ADJUST SCREW ON HOPPER CLAMP TO TIGHTEN SEAL HOPPER GASKET FAULTY CONTACT LOCAL SERVICING DEALER HOPPER FULL REMOVE DEBRIS FAULTY VACCUM FAN CONTACT LOCAL SERVICING DEALER BATTERY CHARGE IS LOW CHARGE BATTERIES OVER NIGHT...

-

Page 23: Parts Breakdown

MODEL 48 PARTS BREAKDOWN PAGE 20... -

Page 24: Frame Top

FRAME TOP 5 28 PAGE 21... - Page 25 Item 48 Part No. Part Description Qty. 8-110 MAIN FRAME H-19901 FB CASHD 1/4"-20 X 1/2" H-250HCN HCN 1/4"-20 SEE PG. 29 AND 30 MAIN BROOM LIFT ASM. H-70003 HCS 1/4"- 20 X 3/4" SS SEE PG. 33 AND 34...

-

Page 26: Frame Bottom

FRAME BOTTOM PAGE 23... - Page 27 Item Part No. Part Description Qty. 8-110 MAIN FRAME 8-125 BROOM COMPT. REAR PANEL H-19901 FB CASHD 1/4"-20 X 1/2" H-250HCN HCN 1/4"-20 8-119H REAR SKIRT H-71063 LW 1/4" SS H-70003 HCS 1/4"- 20 X 3/4" SS 8-120H RIGHT HAND SKIRT 8-182H LEFT REAR SKIRT 8-181...

-

Page 28: Central Command

CENTRAL COMMAND PAGE 25... - Page 29 CENTRAL COMMAND Item Part No. Part Description. Qty. 8-288 CENTRAL COMAND BOX COVER 8-283 RELAY, 80 AMP 8-285 CIR. BREAKER - 120A 8-285A CIR. BREAKER - 40A 8-285A CIR BREAKER 24V 40A 8-289 COMPUTER CONTROL H-29049 PPH #10-32 X 1/2" H-37408 KN #10-32 8-287-00...

-

Page 30: Drive System

STEERING AND DRIVE SYSTEM PAGE 27... - Page 31 Item Part No. Part Description Qty. 8-110 MAIN FRAME 8-720A DROP PLATE 8-723 BEARING BLOCK 8-711-00 U-JOINT, STEERING 8-710 STEERING SHAFT, UPPER 8-701 STEERING WHEEL 8-701A STEERING COVER 8-712 LOWER STEERING SHAFT 8-722 9 TOOTH SPROCKET 8-723B BEARING 8-730 STEERING YOKE & SPROCKET 8-731 FRONT WHEEL 8-731...

-

Page 32: Main Broom And Linkage

MAIN BROOM AND LINKAGE 44 45 66 65 DETAIL A PAGE 29... - Page 33 Item Part No. Part Description Item Part No. Part Description 1 SEE PG. 35 HOPPER H-K1432 3/16" X 1/2" KEY AND 36 36 H-25283 SSS CP #10-32 X 1" 8-454 MAIN BROOM LINKAGE CHASSIS 1 37 H-25435 SSS CP 5/16" X 1/4" 8-451 MAIN BROOM LIFT LEVER 38 H-33622...

-

Page 34: Side Broom And Linkage

SIDE BROOMS AND LINKAGE 15 24 25 PAGE 31... - Page 35 Item Part No. Part Description 8-553B REMV. BALL JOINT END FITTING 1/4"-28 1 8-461 LEVER, SIDE BROOM 8-462 SIDE BROOM SUSPENSION AXLE H-33012 FW 1/2" SS 8-467 LIFT LEVER ANGLE 8-452 LIFT HANDLE H 00702 FLANGE BUSHING H-71016 FW 5/16" X 7/8" USS H-77862 NYLOK 3/8"- 16 SS H-70105...

-

Page 36: Vacuum And Filter System

FILTERING SYSTEM AND SEAT PAGE 33... - Page 37 Item No. Part Number Part Description 8-140 FILTER CHAMBER 8-222 MOTOR GASKET 8-223 GASKET BACKING PLATE 8-221 FILTER CLEANER/SIDE BROOM MOTOR 8-561 FILTER CLEANER MOTOR COUPLER 8-506 FILTER BEATER BAR PLATE 8-138A LATCH W/SPRING H-37015 NYLOK #10-32 H-29073 PPH #10-32 X 1" H-38558 HCS M6-1.0 X 14 H-33618...

-

Page 38: Hopper

HOPPER PAGE 35... - Page 39 Item Document Title Quantity Number Number 8-123 HOPPER BODY 8-163 HDPE SLIDE RAIL 4-127 HANDLE 5-130 SIDE DOOR LATCH 8-124A HOPPER WHEEL 8-128 HOPPER HANDLE 8-573 REAR FLOOR SEAL 8-575 HOPPER FLOOR SEAL CLAMP H-37408 KN #10-32 H-37015 NYLOK #10-32 H-ZCP44 1/4"...

Need help?

Do you have a question about the 48 Series and is the answer not in the manual?

Questions and answers