Glow-worm Hideaway 80B Instructions For Use Manual

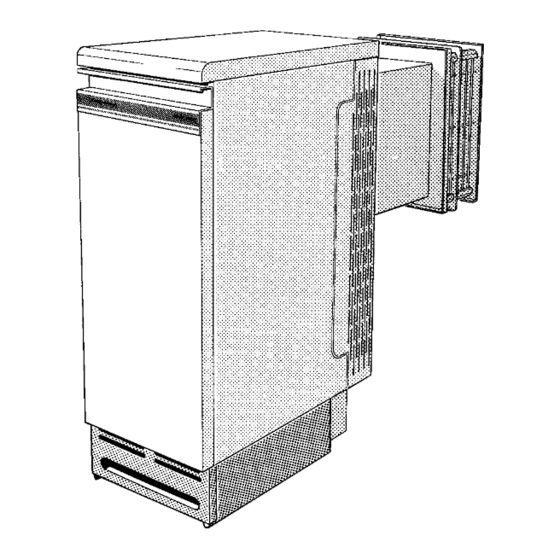

Balanced flue boiler

Hide thumbs

Also See for Hideaway 80B:

- Instructions for use installation and servicing (32 pages) ,

- Instructions for use manual (28 pages)

Table of Contents

Advertisement

Installation and Servicing

Hideaway

80B

G.C. No. 41 313 24

Balanced Flue Boiler

This is a Cat I

Reference in these instructions to British Standards and Statutory

Regulations/Requirements apply only to the United Kingdom.

For Ireland the rules in force must be used.

The instructions consist of three parts, User, Installation and Servicing Instructions, which includes the Guarantee Registration

Card. The instructions are an integral part of the appliance and must, to comply with the current issue of the Gas Safety

(Installation and Use) Regulations, be handed to the user on completion of the installation.

Thank you for installing a new Glow-worm appliance in your home.

Glow-worm appliances' are manufactured to the very highest standard so we are pleased

In the centre pages are to be found your Guarantee Registration Card, which we recommend you complete and

If this card is missing you can obtain a copy or record your registration by telephoning the Heatcall Customer

Our Guarantee gives you peace of mind plus valuable protection against breakdown by covering the cost of:

All replacement parts

All labour charges

All call-out charges

One Contact Local Service

Instructions for Use

T o b e l e f t w i t h t h e u s e r

BS 6332

BS 5258

Appliance

2H

Guarantee Registration

to offer our customers' a Comprehensive First Year Guarantee.

return as soon as possible.

Service number 01773 828100.

REGISTER YOUR GLOW-WORM APPLIANCE

FOR 1ST YEAR GUARANTEE PROTECTION

CALL 0208 247 9857

Customer Services:

Tel: (01773) 828100

Fax: (01773) 828070

Hepworth Heating Ltd.,

Nottingham Road, Belper, Derbyshire. DE56 1JT

General/Sales enquiries:

Tel: (01773) 824141 Fax: (01773) 820569

221763A.10.00

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Glow-worm Hideaway 80B

-

Page 1: Instructions For Use

Guarantee Registration Thank you for installing a new Glow-worm appliance in your home. Glow-worm appliances' are manufactured to the very highest standard so we are pleased to offer our customers' a Comprehensive First Year Guarantee. In the centre pages are to be found your Guarantee Registration Card, which we recommend you complete and return as soon as possible. -

Page 2: Table Of Contents

Important Information Testing and Certification This boiler is tested and certificated for safety and performance. It is therefore important that no alteration is made to the boiler, without permission, in writing, from Hepworth Heating Ltd. Any alteration not approved by Hepworth Heating Ltd., could invalidate the certification, boiler warranty and may also infringe the current issue of the Statutory Requirements, see Section 1.4. - Page 3 The Brown cable must be connected to the terminal marked “L” or “Red”. Glow-worm Hideaways are central heating boilers, to provide heating and if required, an indirect domestic hot water supply. The Green and yellow cable must be connected to the terminal marked “E”...

- Page 4 Instructions for Use Air may be present in the supply pipe so the lighting of the pilot Replacement Parts/Boiler Identification may need to be repeated until all the air has been expelled. If replacement parts are required apply to your local supplier. When the pilot is alight, view through window “E”, keep gas Please quote the name of the boiler and its serial number which control knob “A”...

-

Page 5: General Data

General Data Refer to BOILER CASING GAS CONNECTION WATER CONNECTIONS Rc1 reduced in. B.S.P.T.) HEIGHT diagram with DISTRIBUTOR TUBE to in. B.S.P.T.) (pumped return) A SPECIAL TOP CASING WATER CONNECTIONS TO SUIT 600mm (23 in.) Rc1 (1in. B.S.P.T.) WORKTOPS IS AVAILABLE F(MIN.) G(MIN.) G(MIN.) - Page 6 General Data 1.5 B.S.I. Certification This boiler is certificated by B.S.I. for safety and performance. BOILER BOILER It is, therefore, important that no alteration is made to the boiler, WITHOUT WITH TOP without permission, in writing, from Hepworth Heating Ltd. floor TOP CASING CASING...

-

Page 7: Water Systems

1 General Data To facilitate minimum clearances it may be necessary to modify 1.8 Heating System Controls the kitchen units or fixtures, depending upon which type of The heating system should have installed: a programmer and connections are used. room thermostat controlling the boiler. A front access clearance should be provided as shown in Thermostatic radiator valves may be installed in addition to the diagram 1.5. -

Page 8: Flue And Ventilation

2 Water Systems 2.6 Cylinder 2.8 Drainage For all systems supplying domestic hot water the cylinder must A drain tap must be provided at the lowest points of the system be indirect and to the appropriate British Standard. which will allow the entire system, including the boiler and domestic hot water cylinder to be drained. -

Page 9: Installation

3 Flue and Ventilation 3.6 Room Ventilation The boiler is room sealed and does not require the room or space containing it to have permanent air vents. 3.7 Cupboard/Compartment Ventilation Where the boiler is fitted in a cupboard or compartment, the high and low level permanent air vents must have effective areas in accordance with the Compartment Air Vent Table. - Page 10 4 Installation Domestic gravity return, any one of the three remaining lower UPPER CASING connections may be used for the gravity domestic hot water BRACKET return. Fit plugs into all unused connections. NOTE, if only limited clearance is available it is recommended that the front tappings are used.

- Page 11 4 Installation Cement around the wall plate to make good and provide a If suitable clearances are not available it will be necessary to weatherproof seal. pre-plumb the gas and water connections prior to positioning the boiler. Refit the inner baffle/flue duct assembly over the boiler flue duct and slide in until the baffle contacts the wire guards.

-

Page 12: Casing Location / Fitting

4 Installation VIEW ON VIEW ON ARROW 'A' ARROW 'B' 57 MAX. BOILER in.) BOILER 57 MAX. in.) 57 MAX. in.) 57 MAX. MINIMUM in.) CLEARANCE REAR CONNECTION PIPEWORK CASING PIPEWORK (28mm) Diagram 4.7 Diagram 4.8 CLEARANCES BOILER WALL AIR DUCT PLATE INNER BAFFLE/ FLUE DUCT... - Page 13 5 Casing Location / Fitting 5.3 Top Casing The top casing can be fitted in four alternative positions, that is, PLASTIC PEG (4) TOP CASING with either a rolled or square front edge, flush with the door or overhanging it. Select either a rolled or square front edge and for a flush fitting top casing, fit four plastic pegs into holes “A”...

-

Page 14: Electrical Wiring

6 Electrical Wiring 6.1 Control Box Cable Connection. Remove the screw and cover from the mains inlet connector, COVER supplied loose, see diagram 6.1. Using heat resistant flexible cable of a suitable length and rating as stated in Section 1.7 “Electrical” connect the three wires to the appropriate terminals in the connector. -

Page 15: Commissioning

If any doubt exists, the gas rate should be checked at the gas meter, this should be in the range: Set thermostat control knob “B” to “O”. Hideaway 80B - 2.5 to 2.8m /h 87 to 99ft Remove the burner pressure test point screw “G” and connect a suitable pressure gauge. - Page 16 7 Commissioning 7.3 Operational Checks 13 ( in.) SPARK GAP APPROX. FLAME Check operation of the flame failure device as follows, with the DIMENSION DIMENSION main burner alight, turn the gas valve control knob “A” fully clockwise to its stop , this will extinguish the main and pilot burners.

-

Page 17: Servicing

8 Servicing Servicing must be carried out by a competent person. Before commencing any servicing, turn off the gas supply at the SERVICE gas service cock, see diagram 8.1 and isolate the electrical COCK (turn off) supply to the boiler. (shown Always test for gas soundness after completing any servicing or closed) -

Page 18: Replacement Of Parts

8 Servicing 8.4 Service Checks Inspect the thermocouple and pilot burner, clean or renew as BURNER BURNER necessary. END CAP Check the condition of the insulation panels in the combustion chamber, renew if necessary. Check the condition of the seals on the cleaning door and the combustion chamber cover, renewing if necessary. - Page 19 9 Replacement of Parts Disconnect the pilot tube nut, ease out the tube and injector PILOT TUBE which is hooked on to the pilot tube. Remove the nut retaining the spark electrode and remove. Remove the two screws and nuts securing the pilot burner and VALVE shield to the combustion chamber cover.

- Page 20 9 Replacement of Parts ELECTRICAL CONTROL BOX COVER HOOK THERMOSTAT CUT-OUT FOR AND CAPILLARY CAPILLARY COVER SECURING SCREW (4) IGNITION LEAD (BLACK END) THERMOSTAT SECURING SCREW (2) PIEZO ELECTRICAL UNIT CONTROL BOX THERMOSTAT ELECTRICAL CONTROL KNOB CONNECTORS SECURING SCREW Diagram 9.4 CONTROL BOX Disconnect the lead at the spark electrode, see diagram 9.2.

-

Page 21: Fault Finding

10 Fault Finding - Electrical 10.1 Electrical GAS VALVE IMPORTANT, the preliminary electrical system checks as CONTROL SOLENOID contained in the British Gas Multimeter Instruction book or similar publication, are the first checks to be carried out during THERMOSTAT a fault finding procedure. On completion of the service fault finding task which has required the breaking and remaking of electrical connections then checks, earth continuity, polarity and resistance to earth must be repeated. - Page 22 10 Fault Finding - Thermocouple Disconnect appliance thermocouple from the multifunctional control. Check that all connections are clean and in good condition. Fit test meter interrupter into the magnet unit. Fit appliance thermocouple into the test meter interrupter. Hold down control tap in ignition position. Ignite burner, allowing thermocouple to attain operating temperature.

- Page 23 10 Fault Finding - Pilot PILOT WILL NOT LIGHT START HERE Does pilot stay alight when Check gas line-open all cocks, gas valve knob is released? rectify any blockages, purge out any air. Does pilot light? Apply match to pilot burner instead of pressing piezo unit button.

-

Page 24: Spare Parts

11 Spare Parts When ordering spare parts please quote the part number and description, stating the model and serial number, from the data label “L”, see diagram 7.1. If ordering from British Gas also quote the GC number of the part and appliance.

Need help?

Do you have a question about the Hideaway 80B and is the answer not in the manual?

Questions and answers