Table of Contents

Advertisement

Owner/Operator Manual

Manuel Du Propriétaire/Utilisateur

Gasoline containing up to 10% ethanol (E10) or up to 10% MTBE (methyl tertiary butyl ether) is

acceptable for use in this machine.

The use of any gasoline exceeding 10% ethanol (E10) or 10% MTBE will void the product

warranty.

Il est possible d'utiliser de l'essence contenant jusqu'à 10% d'éthanol (E10) ou 10% de MTBE

(éther méthyl-tertiobutylique) sur cette machine.

L'utilisation d'une essence contenant plus de 10% d'éthanol (E10) ou de 10% de MTBE annulent

la garantie.

ENGLISH

FRANÇAIS

Models

920402 – Sno-Tek 24E

(Serial No. 35000 and up)

920403 – Sno-Tek 28E

(Serial No. 35000 and up)

920404 – Sno-Tek 24E

(Serial No. 000101 and up)

04335200A 5/11

Printed in USA

Advertisement

Table of Contents

Summary of Contents for Sno-Tek 920402-Sno-Tek 24E

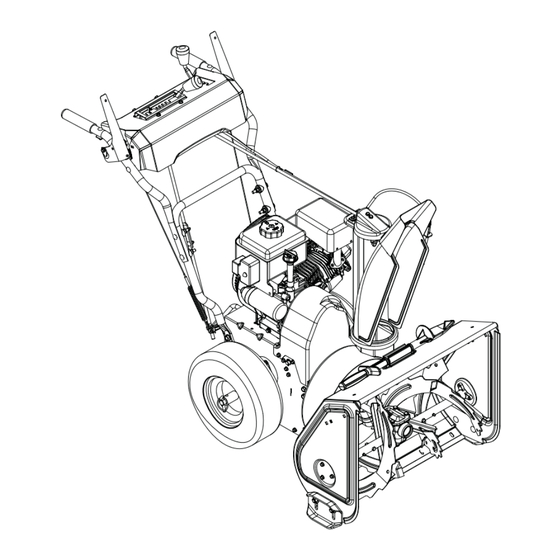

- Page 1 Owner/Operator Manual Manuel Du Propriétaire/Utilisateur Models 920402 – Sno-Tek 24E (Serial No. 35000 and up) 920403 – Sno-Tek 28E (Serial No. 35000 and up) 920404 – Sno-Tek 24E (Serial No. 000101 and up) Gasoline containing up to 10% ethanol (E10) or up to 10% MTBE (methyl tertiary butyl ether) is acceptable for use in this machine.

-

Page 2: Table Of Contents

TABLE OF CONTENTS SAFETY......4 STORAGE ..... . . 28 ASSEMBLY . -

Page 3: Unauthorized Replacement Parts

DISCLAIMER Serial Number Label Ariens reserves the right to discontinue, make changes to, and add improvements upon its products at any time without public notice or obligation. The descriptions and specifications contained in this manual were in effect at printing. Equipment described within this manual may be optional. -

Page 4: Safety

SAFETY PRACTICES AND LAWS WARNING: To avoid injury to hands Practice usual and customary safe working and feet, always disengage clutches, precautions, for the benefit of yourself and shut off engine, and wait for all others. Understand and follow all safety movement to stop before unclogging messages. -

Page 5: Emission Control System

1. WARNING! 3. DANGER! Read Owner/Operator Manual. ROTATING PARTS. Keep clear of auger while engine is running. • Read Operator’s Manual. • Allow operation only by OL1801 OS2080 properly trained adult, Keep people away from unit while never children. operating. Keep children out of •... - Page 6 Keep children and people away. Keep Never direct discharge towards persons or children out of work area and under watchful property that may be injured or damaged by care of a responsible adult. thrown objects. Use extreme caution on gravel surfaces. Stay alert for hidden hazards NEVER allow children to operate or play on or traffic.

- Page 7 Before cleaning, removing clogs or making NEVER fill fuel tank when engine is running any inspections, repairs, etc.: disengage or hot from operation. clutch(es), stop unit and engine, remove key, NEVER fill or drain fuel tank indoors. allow moving parts to stop. Allow hot parts to Replace fuel cap securely and clean up cool.

-

Page 8: Assembly

6. Check tension on auger and traction clutch cables. IMPORTANT: Cables should not be slack nor under tension. Adjust as necessary. 1. Sno-Tek™ Unit 3. Chute Crank 2. Discharge 4. Literature Pack Chute Figure 3 1. - Page 9 Install Discharge Chute Install Discharge Chute Crank (Figure 5) (Figure 6) 1. Remove mounting hardware from the 1. Slide chute crank through the support bottom of the chute pedestal. bracket. 2. Install discharge chute over opening in NOTE: Be careful not to damage nylon the auger housing and secure pedestal bushing when attaching crank to the dash.

- Page 10 Install Remote Deflector Cable 6. Position rubber seal cap over the top of snap fitting. (920402, 403) 7. Move deflector control lever to rear most (Figure 7 and 8) position. 1. Slide cable through clip on top of 8. Attach cable eye to pin on bottom of discharge chute pedestal (Figure 7).

- Page 11 Check Function of Dual Handle Check Auger Gearcase Oil Interlock Check oil level in auger gearcase (see Check Auger Gearcase on page 19). Without the engine running, press down (engage) both clutch levers. Release Check Engine Crankcase Oil attachment clutch lever. Attachment clutch IMPORTANT: The engine is shipped with should remain engaged until traction clutch 5W-30 oil in crankcase.

-

Page 12: Controls And Features

CONTROLS AND FEATURES Figure 9 1. Attachment Clutch Lever 13. Oil Fill and Dipstick 2. Speed Selector 14. Gas Tank and Cap 3. Traction Drive Clutch Lever 15. Recoil Starter Handle 4. Chute Crank 16. Primer Bulb 5. Muffler Guard 17. -

Page 13: Operation

OPERATION Attachment Clutch – WARNING: AVOID INJURY. Read Right Hand Lever and understand the entire Safety section before proceeding. Squeeze attachment clutch lever against handlebar (1) to WARNING: To avoid injury to hands engage attachment. and feet, always disengage clutches, Release both clutch shut off engine, and wait for all levers (2) to disengage... - Page 14 Speed Selector Snow Clean-Out Tool Position the speed selector in the appropriate (Figure 10) speed notch to control forward and reverse travel. WARNING: Hand contact with the rotating impeller is the most common cause of injury associated with snow throwers. Never use your hand to clean out the discharge chute.

-

Page 15: Filling Fuel Tank

Remote Discharge Chute Deflector Scraper Blade Control (920402, 403) The scraper blade allows better contact with the surface being cleared. It also prevents Place deflector into position before operation. damage to the housing from wear. DO NOT throw snow any higher than necessary. - Page 16 Add Fuel to Fuel Tank If clutches do not engage or disengage properly, adjust or repair before operation 1. ALWAYS place unit in open or well- (see Attachment Clutch/Brake Adjustment on ventilated area. page 23). 2. Stop engine and allow to cool. 3.

-

Page 17: Snow Removal

NOTE: When temperature is below -15° F Shut Off (-26° C) additional priming may be needed. 1. Release traction drive clutch lever and 4. If engine is cold, apply choke. See allow unit to come to a complete stop. engine manual for detailed instructions. 2. -

Page 18: Maintenance

MAINTENANCE MAINTENANCE SCHEDULE Ariens dealers will provide any service or adjustments which may be required to keep The chart below shows the recommended your unit operating at peak efficiency. Should maintenance schedule that should be engine service be required, contact an Ariens performed on a regular basis. -

Page 19: Check Tire Pressure

CHECK CLUTCH OPERATION CHECK AUGER GEARCASE Auger / impeller must stop within 5 seconds (Figure 13) when attachment clutch/impeller brake lever IMPORTANT: Proper oil level must be is released. maintained. Wheels must stop quickly when traction drive Gear cases are filled to the correct level at clutch lever is released. -

Page 20: Service And Adjustments

GENERAL LUBRICATION The unit should be lubricated (Figure 14) at beginning of season or every 25 operating (Figure 14) hours. IMPORTANT: Wipe each fitting clean before Auger Shaft and after lubrication. NOTE: To grease auger shaft, remove shear IMPORTANT: DO NOT allow grease or oil to bolt nuts, and shear bolts. -

Page 21: Skid Shoes

SKID SHOES (Figure 15) Skid Shoes should be adjusted as conditions require. 1. Position unit on a hard, flat, smooth level surface. 2. Adjust skid shoes by inserting a spacer of desired thickness under center of scraper blade, loosen skid shoe hardware, slide skid shoes to flat surface. -

Page 22: Speed Selector Adjustment

REMOTE DISCHARGE DEFLECTOR CONTROL ADJUSTMENT (920402, 403) (Figure 18) Deflector must stay in selected position while throwing snow. If deflector does not stay in set position: 1. Tighten nut beneath control panel to increase pressure on deflector control (Figure 18). If deflector does not follow full range of travel: 1. - Page 23 Remove Attachment Cable Slack (Figure 21 and 22) 1. Shut off engine, remove key, disconnect spark plug wire and allow unit to cool completely. 2. Loosen hardware securing belt cover to unit. NOTE: DO NOT completely remove hardware from unit. 3.

- Page 24 Roller should be 1/2 – 7/8 in. (12.7 – With the attachment clutch disengaged, 22.2 mm) from the frame when the check the attachment idler arm position attachment clutch is engaged. here. The attachment idler arm should lightly touch the frame. ROLLER FRAME Figure 23...

-

Page 25: Attachment Drive Belt Replacement

Check Belt Finger Clearance 6. Remove attachment drive belt from engine sheave (it may be necessary to (Figure 25) turn engine sheave using recoil starter 1. With clutch lever engaged, the belt handle). finger located opposite the belt idler must be less than 1/8 in. (3.2 mm) from CAUTION: Always support the unit belt, but not touching the belt. -

Page 26: Traction Drive Belt Replacement

1/8 in. (3.2 mm) WARNING: AVOID INJURY. Auger (Maximum) must stop within 5 seconds when attachment lever is released or serious injury or unit damage may result. 6. Replace chute crank and secure with spring pin. IMPORTANT: Reconnect chute lock cable and deflector cable, if equipped (920402, 403). - Page 27 FRICTION DISC REPLACEMENT Remove Friction Disc (Figure 31 and 32): 1. Shut off engine, remove key, disconnect spark plug wire and allow unit to cool completely. CAUTION: Before tipping unit, remove enough fuel so that no spills occur. 2. Place the unit into the service position on a level surface.

-

Page 28: Storage

13. Insert new friction disc assembly into frame. Install washers onto carrier bearing and slide into speed selector arm. 14. Slide hex shaft through new friction disc assembly. Install pinion gear and washer onto hex shaft and slide shaft into right bearing. -

Page 29: Service Parts

6. Slow the engine to an idle speed. 7. Repeat step 1 above. ACCESSORIES See your authorized Ariens dealer to add the additional accessories available to your Sno-Tek model. Part No. Description 72000200 Slicer Bar 72406500 Front Weight Kit 72600300 Composite Skid Shoe Kit... - Page 30 TROUBLESHOOTING PROBLEM PROBABLE CAUSE CORRECTION Engine stops. 1. Out of fuel. 1. Fill fuel tank. DO NOT OVERFILL! (see Filling Fuel Tank on page 15). 2. Open fuel shut-off valve. 2. Fuel shut-off valve closed. 3. Turn off engine, remove key, 3.

-

Page 31: Specifications

SPECIFICATIONS Model Number 920402 920403 920404 Description Sno-Tek 24 Sno-Tek 28 Sno-Tek 24 Engine LCT Storm Force LCT Storm Force LCT Storm Force Gross Torque* - ft-lbs (N-m) 9.5 (12.9) 9.5 (12.9) 7.1 (9.6) *Engine output stated in gross torque per SAE J1940 as rated by engine manufacturer. -

Page 32: Warranty

® ® Sno-Thro , Sno-Tek Chore Performing Equipment Limited Warranty Ariens Company (Ariens) warrants to the original purchaser that Ariens, Gravely, Parker, and Countax ® ® brand chore performing equipment (including Sno-Thro and Sno-Tek equipment) purchased on or after 1/1/2011 will be free from defects in material and workmanship for the time period noted in the chart below. - Page 33 Exceptions and Limitations The chart below details special exceptions to this warranty: Warranty Warranty Warranty Exception Detail Code Period Batteries 1 Year Prorated These components are not covered Belts, Muffler, Tires None Commercial when used commercially. Warranty is limited to 2 years for Cloth, Plastic, and consumer use.

-

Page 34: Manuals

Exclusions - Items Not Covered by This Warranty • Parts that are not genuine Ariens, Gravely, Parker or Countax service parts are not covered by this warranty and may void the warranty. • Damages resulting from the installation or use of any part, accessory, or attachment which is not approved by the Ariens Company for use with product(s) identified herein are not covered by this warranty. - Page 35 CALIFORNIA AND EPA (UNITED STATES ENVIRONMENTAL PROTECTION AGENCY) EVAPORATIVE EMISSION CONTROL WARRANTY STATEMENT YOUR WARRANTY RIGHTS AND OBLIGATIONS The CARB (California Air Resources Board), the EPA, and Ariens Company are pleased to explain the evaporative emission control system's warranty on your 2011 model year small off-road equipment. In California, new equipment that uses small off-road engines must be designed, built, and equipped to meet the State's stringent anti-smog standards.

- Page 36 (4.) Repair or replacement of any warranted part under the warranty provisions of this article must be performed at no charge to the owner at an authorized Ariens, Gravely, or Parker service representative. (5.) Notwithstanding the provisions of subsection (4) above, warranty services or repairs must be provided at authorized Ariens, Gravely, or Parker service representatives that are franchised to service the subject small off-road equipment.

- Page 38 Brillion, WI 54110 Sno-Tek Cover Waterproof, washable and tear-resistant, this cover protects your Sno-Tek when it is not in use. Non-Abrasive Skid Shoes Protect the decorative surfaces around your home. Sno-Tek LCT® Engine Maintenance Kit Includes Ariens 32oz. 5W30 engine oil, Spark Plug, Fuel stabilizer and a spare ignition key.

Need help?

Do you have a question about the 920402-Sno-Tek 24E and is the answer not in the manual?

Questions and answers