Subscribe to Our Youtube Channel

Summary of Contents for Sno-Tek 920402

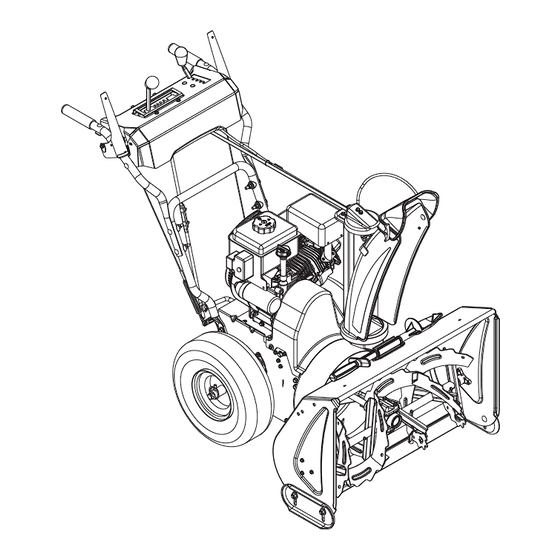

- Page 1 Operator’s Manual | Manuel de l'utilisateur Model 920402 – Sno-Tek 24E (SN 175000 +) ENGLISH • 04854200A 6/15 FRANÇAIS Printed in USA...

-

Page 2: Table Of Contents

TABLE OF CONTENTS WELCOME ..... . 1 ADJUSTMENTS ....14 Adjust Scraper Blade. -

Page 3: Welcome

WELCOME Congratulations on your purchase and welcome to the Ariens family! Every snow thrower in the Ariens lineup is designed for long-lasting and unsurpassed performance. We are confident your machine will be part of your family for many years to come. Have Questions or Need Assistance? ariens.custhelp.com •... -

Page 4: Safety

1. Danger SAFETY DANGER: Indicates an Read these safety rules and follow them IMMINENTLY HAZARDOUS closely. Failure to follow these rules could SITUATION! If not avoided, lead to loss of control of unit, severe personal WILL RESULT in death or injury or death to you or bystanders, or result serious injury. - Page 5 Safety Decal Locations Stop engine, remove key, and read manual before making any repairs or adjustments. Read operator’s manual. Wear appropriate hearing protection. 2. DANGER! Figure 2 Safety Decal Descriptions Danger! 1. CAUTION! Danger! ROTATING PARTS! Only use clean-out tool to clear blockages.

-

Page 6: Safety Rules

Complete a walk-around inspection of the 3. DANGER! unit to understand the unit, your work area and all safety decals. Understand how to operate all controls, the Danger! functions of all controls and how to STOP in an emergency. ROTATING PARTS! Keep Preparation clear of auger while engine is running. - Page 7 Never attempt to make any adjustments Do not run the engine indoors, except when while the engine is running (except when starting the engine and for transporting the specifically recommended by manufacturer). snow thrower in or out of the building. Open the outside doors;...

- Page 8 Avoid contact with sharp edges; sharp Always refer to operator's manual for edges can cut. important details if the snow thrower is to be stored for an extended period. Do not throw snow higher than necessary. Maintain or replace safety and instruction labels as necessary.

- Page 9 Fuel DO NOT run engine in an enclosed area. Always provide good ventilation. Fumes from engine exhaust can cause injury or death. Fuel is highly flammable and its vapors are explosive. Handle with care. Use only an approved gasoline container with an appropriately-sized dispensing spout.

-

Page 10: Controls & Features

CONTROLS & FEATURES Figure 3 1. Engine Key 14. Shear Bolt (2) 2. Engine Run / Stop Switch 15. Attachment Clutch Lever 3. Primer Bulb 16. Traction Drive Clutch Lever 4. Fuel Tank and Cap 17. Discharge Chute Rotation Lever 5. -

Page 11: Engine Key And Run / Stop Switch

CHOKE CONTROL KNOB WARNING: Read and See Figure 6. understand the Safety section Controls airflow to the engine. before proceeding. See Figure 3 for all controls and features locations. ENGINE KEY AND RUN / STOP SWITCH See Figure 4. Figure 6 The removable engine key and the run / stop switch are used together to start the engine. -

Page 12: Traction Drive Clutch Lever

TRACTION DRIVE CLUTCH LEVER (LEFT SIDE) See Figure 9. Allows unit to travel forward and in reverse. Figure 11 Figure 9 SCRAPER BLADE DUAL HANDLE INTERLOCK Contacts the surface being cleared and Allows auger / impeller to rotate without protects the housing from damage during holding attachment clutch lever continuously. -

Page 13: Start The Engine

2. Check fuel level and add fuel if needed. OPERATE UNIT IMPORTANT: Use fresh unleaded fuel with 1. Rotate discharge chute and move an octane rating of at least 87. DO NOT use deflector to desired positions. E85 blended fuels; the engine is not E20 / 2. -

Page 14: Maintenance

MAINTENANCE SCHEDULE MAINTENANCE WARNING: Read and understand the Safety section before proceeding. Service Performed Check Clutch Lever Operation • Your Ariens dealer can provide service and Check Dual Handle Interlock • adjustments to keep your unit operating at peak efficiency. Contact an authorized engine Check Fasteners •... -

Page 15: Check Fasteners

CHECK FASTENERS Check for loose hardware. CHECK CLUTCH CABLE ADJUSTMENTS Auger / impeller must stop within 5 seconds when attachment clutch lever is released. Wheels must stop quickly when traction drive clutch lever is released. If clutches do not engage or disengage correctly, see Adjust Attachment Clutch &... -

Page 16: Adjustments

Use the following key for all lubrication Auger Shaft procedures. See Figure 17. 1. Remove shear bolt nuts and bolts. 2. Apply grease at the grease zerks. Grease 3. Hand rotate auger on auger shaft. 4. Align shear bolt holes in auger with shear = Lubricate on Both Sides bolt holes in shaft. -

Page 17: Adjust Skid Shoes

3. Adjust skid shoes. See Adjust Skid Shoes on page 15. NOTICE: ALWAYS adjust skid shoes after adjusting blade to prevent premature wear of blade and auger housing damage. ADJUST SKID SHOES To adjust skid shoes: 1. Place unit on a hard, flat surface. 2. -

Page 18: Lever

ADJUST DISCHARGE CHUTE See Figure 20. If discharge chute does not stay in selected position, tighten nut on carriage bolt. 1. Shift Rod 2. Adjustment Pivot Pin 3. Speed Selector Arm 4. Hairpin Figure 21 Figure 20 ADJUST ATTACHMENT CLUTCH ADJUST SPEED SELECTOR &... - Page 19 6. Tighten jam nut on cable adjustment barrel. See Figure 22. 7. Reinstall belt cover and tighten hardware. 8. Reconnect spark plug wire. Check Attachment Idler Arm Roller Clearance 1. Place unit in service position and remove bottom cover. 2. Engage attachment clutch and check the clearance between the frame and plastic roller on the lower end of the attachment idler arm.

-

Page 20: Adjust Traction Drive Clutch

Check Belt Finger Clearance See Figure 27. With attachment clutch engaged, the belt finger located opposite the belt idler must be less than 3.2 mm (1/8") from belt, but must not touch the belt. To adjust belt finger: 1. Remove belt cover. 2. - Page 21 3. Loosen jam nut on traction cable adjustment barrel, and then turn adjustment barrel down to shorten cable and remove cable slack. 1. Swing Gate Tab 2. Stop Hole Figure 29 5. Reconnect spark plug wire. 1. Traction Drive Clutch Cable 2.

-

Page 22: Troubleshooting

TROUBLESHOOTING Problem Probable Cause Correction Engine switch is in off position. Push switch to on position. See Start The Engine on page 11. Engine key is not in unit. Insert key. See Start The Engine on page 11. Choke is off. Turn choke control knob to on position. - Page 23 TROUBLESHOOTING Problem Probable Cause Correction Friction disc is worn. Replace friction disc. Refer to the service guide for your unit. Traction drive cable is not Remove slack from cable. See Adjust Unit does not adjusted correctly. Traction Drive Clutch on page 18. drive forward or Traction belt is not functioning.

-

Page 24: Storage

5. Remove weight from wheels by putting STORAGE blocks under frame or axle. 6. Store unit in a cool, dry, protected area. Do not store unit outdoors. WARNING: AVOID INJURY. START-OF-SEASON FUEL Read and understand the Safety section before proceeding. PREPARATION Before opening the fuel valve for the first time SHORT TERM... -

Page 25: Specifications

SPECIFICATIONS Model Number 920402 Description Sno-Tek 24E Engine LCT Storm Force Gross Torque* – N•m (lbf-ft) 12.8 (9.5) 208 (12.7) Displacement – cm High Idle – RPM (min) 3600 ± 100 Electric Start 120V Fuel Tank Capacity – liter (qt) 2.7 (2.9) -

Page 26: Warranty

Sno-Thro ® , Sno-Tek ® and Chore Performing Equipment Limited Warranty Warranty Ariens Company (Ariens) warrants to the original purchaser that Ariens, Gravely, Parker, and Countax ® ® brand chore performing equipment (including Sno-Thro and Sno-Tek equipment) purchased on or after 1/1/2015 will be free from defects in material and workmanship for the time period noted in the chart below. - Page 27 Exceptions and Limitations The chart below details special exceptions to this warranty: Warranty Warranty Warranty Exception Detail Code Period Batteries 1 Year Prorated (Exc. SB) These components are not covered Belts, Muffler, Tires None Commercial when used commercially. Warranty is limited to 2 years for Cloth, Plastic, and consumer use.

- Page 28 Exclusions – Items Not Covered by This Warranty • Parts that are not genuine Ariens, Gravely, Parker or Countax service parts are not covered by this warranty and may void the warranty. • Damages resulting from the installation or use of any part, accessory, or attachment which is not approved by the Ariens Company for use with product(s) identified herein are not covered by this warranty.

- Page 30 655 West Ryan Street Brillion, WI 54110 ariensco.com ariens.com...

Need help?

Do you have a question about the 920402 and is the answer not in the manual?

Questions and answers