Summary of Contents for MasterForce 15A Jobsite Table Saw

- Page 1 15A Jobsite Table Saw 240-0035 OPERATOR’S MANUAL CAUTION: To Reduce The Risk Of Injury, User Must Read And Understand Operator’s Manual. Save These Instructions For Future Reference. Page 1...

-

Page 2: Table Of Contents

TAbLE OF CONTENTS Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2 Safety Instructions . -

Page 3: Safety Symbols

SAFETy SyMbOLS Some of these following symbols may be used on this tool . Please study them and learn their meaning . Proper interpretation of these symbols will allow you to operate the tool better and safer . Symbol Designation / Explanation Name Volts Voltage... -

Page 4: Safety Instructions

SAFETy INSTRUCTIONS The purpose of safety symbols is to attract your attention to possible dangers . The safety symbols and the explanations with them deserve your careful attention and understanding . The symbol warnings do not, by themselves, eliminate any danger . The instructions and warnings they give are no substitutes for proper accident prevention measures . - Page 5 SAFETy INSTRUCTIONS RULES FOR SAFE OPERATION 9) Use the proper extension cord. Make sure that your extension cord is in good KNOW THE TOOL condition . When using an extension cord, To reduce the risk of injury, user must read be sure to use one that is heavy enough instruction manual .

-

Page 6: Specific Safety Rules

SAFETy INSTRUCTIONS 19) Check damaged parts. Before further 6) Always use a push stick for ripping narrow stock. A push stick is a device that use of the tool, any guard or other part that is damaged should be carefully checked to is used to push a workpiece through the determine whether it will operate properly blade instead of using your hands . - Page 7 SAFETy INSTRUCTIONS D) Not releasing the work before it is 28) Use a push-stick when required. 29) Disconnect the tool and be sure the pushed all the way past the saw blade blade has come to a complete stop before using a push stick .

- Page 8 SAFETy INSTRUCTIONS ELECTRICAL SAFETy (FIG.1) Repair or replace a damaged or worn cord immediately. Permanently connected tools: This tool FIG. 1 should be connected to a grounded metal permanent wiring system or to a system that has an equipment-grounding conductor . GUIDELINES FOR EXTENSION CORDS Use a proper extension cord .

-

Page 9: Glossary Of Terms

SAFETy INSTRUCTIONS Recommended size of extension cords Table 1 Total length of the Amperage rating extension cord of tool (120 V circuit only) 25’ 50’ 100’ 150’ More than Not more than Minimum Gauge for the extension cord (AWG) Not recommended GLOSSARy OF TERMS 9 . - Page 10 SAFETy INSTRUCTIONS 17 . bevel scale: The easy-to-read scale on 28 . Sliding table extension: Located on the the front of the table saw cabinet shows the right side of the saw table, this extension exact blade angle . table gives the operator additional support 18 .

-

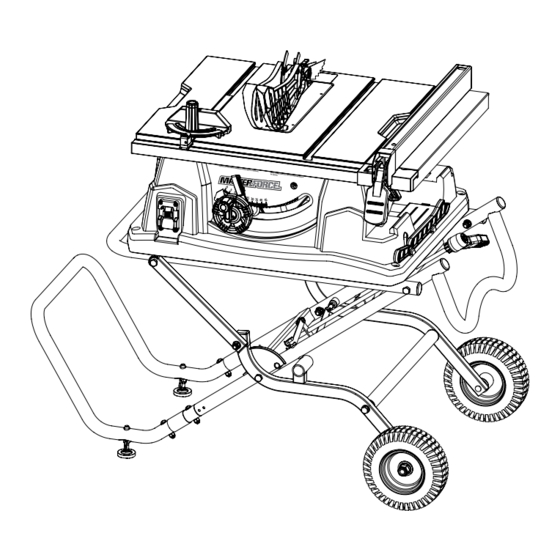

Page 11: Overview / Specifications

OVERVIEW FIG. 2 Anti-kickback pawls Blade guard Rip fence Fence-locking lever Miter gauge Locking knob Mounting hole Handle Handle Stand Bevel-locking lever Bevel-adjusting ON/OFF switch hand wheel assembly Height-adjusting handle SPECIFICATIONS Motor 120 V, 60 Hz, 15 A Rated speed 4000 RPM Wheel Diameter 10”... -

Page 12: Assembly

ASSEMbLy CONTENTS WARNING: Do not attempt to modify this tool or create accessories not Blade guard . . . . . . . . . . . . . . . . . . . . 1 pc recommended for use with this tool. - Page 13 ASSEMbLy OPEN THE STAND (FIG. 3, 4, 5) FIG. 5 Keep body clear of hinge points when opening or closing the stand . 1 . Place the stand upright on floor in front of you . FIG. 3 CLOSE THE STAND (FIG. 6-7) 1 .

- Page 14 ASSEMbLy STORAGE OF ACCESSORIES FIG. 7 The table saw has two convenient storage areas specifically designed for accessories: the miter gauge, wrench, and anti-kickback pawls . Store the accessories securely when they are not in use . REMOVING/REPLACING THE THROAT PLATE (FIG. 9) FIG.

- Page 15 ASSEMbLy SPREADER/RIVING KNIFE 3 . Raise the saw blade as high as it will go by turning the height-adjusting handle POSITIONS (FIG. 10-11) clockwise blade perpendicular to the table . 4 . Unlock the release lever by pivoting Release lever FIG.

- Page 16 ASSEMbLy 6 . Push the riving knife down until the To loosen the blade: internal slots engage and the spreader is 1 . Unplug the saw . below the saw blade . 2 . Locate and remove the blade wrench 7 .

-

Page 17: Blade Guard Assembly

ASSEMbLy INSTALLING THE 2 . Locate the anti-kickback pawls in the storage compartment on the right side of ANTI-KICKbACK PAWLS AND the table saw housing (Fig . 14) . bLADE GUARD ASSEMbLy 3 . Holding the anti-kickback pawls lever (FIG. 14-17) with both hands, pivot the left lever forward to unlock the pawls . - Page 18 ASSEMbLy 3 . Press and hold the yellow button on the NOTICE: Place the framing square between right side of the blade guard . the carbide teeth, and measure from the 4 . Lower the back of the guard into the blade .

-

Page 19: Changing The Blade

ASSEMbLy CHANGING THE bLADE 1 . Unplug the saw . 2 . Loosen the bevel control by pulling DEPTH (FIG. 20) the bevel-locking lever out . 3 . To adjust the bevel angle, turn the hand FIG. 20 wheel counter-clockwise to increase the angle of the blade (bringing it closer to 45º);... -

Page 20: Adjusting The Bevel

ASSEMbLy ADJUSTING THE bEVEL 4 . Place the framing square beside the blade, and move the rip fence up to the INDICATOR (FIG. 23) square . Note the measurement on the rip scale . 5 . Move the fence back, and rotate the FIG. - Page 21 ASSEMbLy USING THE RIP FENCE (FIG. 26) The miter gauge provides greater accuracy in angled cuts . For very close tolerances, test cuts are recommended . There are two FIG. 26 miter gauge channels, one on either side of the blade . When making a 90° crosscut, use either miter gauge channel .

- Page 22 ASSEMbLy Increase the length of the saw table by using WARNING: The blade must be the extension table . square so that the wood does not bind, 1 . Set the rip fence to 13-3/4” (35 cm) . resulting in kickback. Failure to do so 2 .

-

Page 23: Operation

OPERATION bASIC OPERATION OF THE WARNING: Do not allow familiarity TAbLE SAW with a tool to make you careless. Remember that a fraction of a second of carelessness is sufficient to cause serious The 3-pronged plug must be plugged into injury. -

Page 24: Avoiding Kickback

OPERATION AVOIDING KICKbACK Push sticks are devices used for safely pushing a workpiece through the blade instead of using your hands . They can be 1 . Always use the correct blade depth made from scrap wood in various sizes setting . - Page 25 OPERATION FEATHERbOARD 4 . Mark the board from the point at 6” (15 cm), 8” (20 cm), 10” (25 cm), and 12” (30 cm) . Drill a 3/8” (9 .5 mm) hole at the A featherboard is a device used to help 8”...

- Page 26 OPERATION SWITCH ASSEMbLy (FIG. 36) 5 . Attach a C-clamp (available separately) to secure the featherboard to the edge of the saw table . FIG. 36 SWITCH KEY WARNING: Do not locate the featherboard to the rear of the workpiece. If positioned improperly, kickback can result from the featherboard pinching the workpiece and binding the blade in the...

-

Page 27: Overload Protection

OPERATION 4 . Never store blades stacked on top of WARNING: ALWAyS make sure one another . Place material such as that your workpiece is not in contact with cardboard between them to keep the the blade before operating the switch to blades from coming into contact with start the tool. - Page 28 OPERATION 4 . Hold the workpiece flat on the table and WARNING: Never touch the “free against the fence . Keep the workpiece end” of the workpiece or a “free piece” approximately 1” (25 mm) away from the that is cut off while the power is ON and/ blade .

- Page 29 OPERATION bEVEL RIPPING (FIG. 38) FIG. 39 FIG. 38 When the width of rip is narrower than 2” (5 cm), the push stick cannot be used because the guard will interfere . USE the WARNING: This operation is the auxiliary fence and push block . Attach an same as ripping, except that the bevel auxiliary fence (2) to the rip fence with two angle is set to an angle other than 0°.

- Page 30 OPERATION CROSSCUTTING (FIG. 43) Feed the workpiece by hand until the end is approximately 1” (25 mm) from the front edge of the table . Continue to feed using the push block on top of auxiliary fence FIG. 43 until the cut is complete (Fig . 41) . FIG.

- Page 31 OPERATION bEVEL CROSSCUTTING (FIG. 44) WARNING: Use caution when starting the cut to prevent binding of the guard against the workpiece, resulting in FIG. 44 damage to saw and possible injury. WARNING: When using a block as a cut-off gauge, the block must be at least 3/4”...

-

Page 32: Compound Mitering

OPERATION MITERING (FIG. 45) COMPOUND MITERING This is a combination of bevel crosscutting FIG. 45 and mitering . Follow the instructions for both bevel crosscutting and mitering . MAKING A NON-THROUGH CUT (FIG. 46) FIG. 46 CAUTION: Miter angles greater than 45°... - Page 33 OPERATION 7 . Allow the blade to reach full speed 1 . Unplug the saw . before moving the workpiece into the 2 . Remove the blade guard, anti-kickback blade . pawls, and throat plate . 8 . After the cut is made, turn the saw off . 3 .

-

Page 34: Dust Collection

OPERATION DUST COLLECTION STORING THE TAbLE SAW ON THE FOLDED STAND (FIG. 49) Your table saw is equipped with a dust extraction port . For best results, connect a vacuum to the port at the rear of the saw . FIG. -

Page 35: Maintenance

MAINTENANCE GENERAL MAINTENANCE LUbRICATION Avoid using solvents when cleaning plastic 1 . This saw’s motor bearings have been parts . Most plastics are susceptible to packed at the factory with proper damage from various types of commercial lubrication . solvents . Use clean cloths to remove dirt, 2 . -

Page 36: Troubleshooting

TROUbLESHOOTING PRObLEM CAUSE SOLUTION 1 . Excess vibration . 1 . Blade is out of balance . 1 . Replace blade . 2 . Blade is damaged . 2 . Replace blade . 3 . Saw is not mounted securely . 3 . - Page 37 TROUbLESHOOTING PRObLEM CAUSE SOLUTION 8 . Saw does not start . 1 . Power cord is not plugged in . 1 . Plug in Power cord . 2 . In-house circuit fuse is blown . 2 . Replace the fuse . 3 .

- Page 38 NOTES Page 37...

-

Page 39: Day Money Back Guarantee

Limited Warranty to the original purchaser . If, during normal use, this MASTERFORCE® power tool breaks or fails due to a defect in material or workmanship within three (3) years from the date of original purchase, simply bring this tool with the original sales receipt back to your nearest MENARDS® retail store . - Page 40 © 2011 Menard, Inc ., Eau Claire, WI 54703 10/2011 Page 40...

Need help?

Do you have a question about the 15A Jobsite Table Saw and is the answer not in the manual?

Questions and answers

Model 2400035. Our rip fence clamp broke. Where to find replacement ?