Table of Contents

Advertisement

Quick Links

Installation and Instruction Manual

GAS-FIRED DIRECT VENT BOILER

Potential dangers from accidents during installation and use are divided into the following three

categories. Closely observe these warnings, they are critical to your safety.

DANGER

WARNING

CAUTION

WARNING:

If the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

Prohibited

Requests to Installers

• In order to use the boiler safely, read this installation and instruction manual carefully, and follow

the installation instructions.

• Failures and damage caused by erroneous work or work not as instructed in this manual are not

covered by the warranty.

• Check that the installation was done properly in accordance with this installation and instruction

manual upon completion.

• After completing installation, please either place this installation and instruction manual in a

plastic pouch and attach it to the side of the boiler or hand it to the customer. Also, be sure to fill in

all of the required items on the warranty and to hand the warranty to the customer along with the

User's information manual.

CERTIFIED

R

Low NOx

Approved by

SCAQMD

SAR8582-2

Rev. 09/07

NH-2001-DV

NH-1501-DV

DANGER indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

Disconnect

Power

CAUTION

Installation must conform with local codes, or in the absence of local codes, the

National Fuel Gas Code, ANSI Z223.1/NFPA 54- latest edition and/or CSA

B149.1, Natural Gas and Propane Installation Code (NSCNGPIC).

Where required by the authority having jurisdiction, the installation must con-

form to the Standard for Controls and Safety Devices for Automatically Fired

Boilers, ANSI/ASME CSD-1.

Noritz America reserves the right to discontinue, or change at any time, the

designs and/or specifications of its products without notice.

Noritz America Corporation

11160 Grace Avenue,

Fountain Valley, CA 92708

www.noritz.com

(Indoor Installation)

(Indoor Installation)

Ground

NORITZ AMERICA

CORPORATION

Be sure to do

*SAR8582 C*

Advertisement

Table of Contents

Summary of Contents for Noritz NH-2001-DV

- Page 1 Low NOx Approved by Noritz America reserves the right to discontinue, or change at any time, the SCAQMD designs and/or specifications of its products without notice. Noritz America Corporation 11160 Grace Avenue, SAR8582-2 Fountain Valley, CA 92708 Rev. 09/07 www.noritz.com...

-

Page 2: Included Accessories

The following accessories are included with the Included Accessories boiler in the inside of package.Check for any miss- ing items before starting installation. Part Shape Part Shape Q’ty Q’ty User's Information Manual, Tapping Screw Warranty, Installation and each Instruction Manual (this document) Safety Relief Valve Safety Relief Valve Fitting and Gasket... -

Page 3: Before Installation

Do Not Use Equipment for Purposes Other Than Those Specified • The NH-2001-DV/ NH-1501-DV is a boiler to be used for space heating or indirect water heating only. Do not use the hot water supplied by the boiler for drinking purposes. -

Page 4: Choosing Installation Site

Choosing Installation Site * Locate the appliance in an area where leakage from the boiler or connections will not result in dam- age to the area adjacent to the appliance or to the lower floors of the structure. When such locations cannot be avoided, it is recommended that a suitable drain pan, adequately drained, be installed under the appliance. - Page 5 CAUTION • Avoid installation above gas ranges or stoves. • Avoid installation between the kitchen fan and stove. If oily fumes or a large amount of steam are present in the installa- Prohibited tion location, take measures to prevent the fumes and steam from entering in the equipment.

-

Page 6: Installation Clearances

Installation Clearances WARNING Before installing, check for the following: Install in accordance with relevant building and mechanical codes, as well as any local, state or national regulations, or in the absence of local and state codes, to the National Fuel Gas Code ANSI Z223.1/NFPA 54 –... - Page 7 Clearance Requirements from Vent Terminations to Building Openings * All clearance requirements are in accordance with ANSI Z21.13 and the National Fuel Gas Code, ANSI Z223.1 and in Canada, in accordance with NSCNGPIC. Vent Terminal Area Where Terminal is Not Permitted Air Supply Inlet Clearance Above grade, veranda, porch, deck,...

-

Page 8: Installation

Installation Securing to the wall • The weight of the device will be applied to the wall. If the strength of the wall is not suffi- cient, reinforcement must be done to prevent the transfer of vibration. • Do not drop or apply unnecessary force to the device when installing. Internal parts may be damaged and may become highly dangerous. -

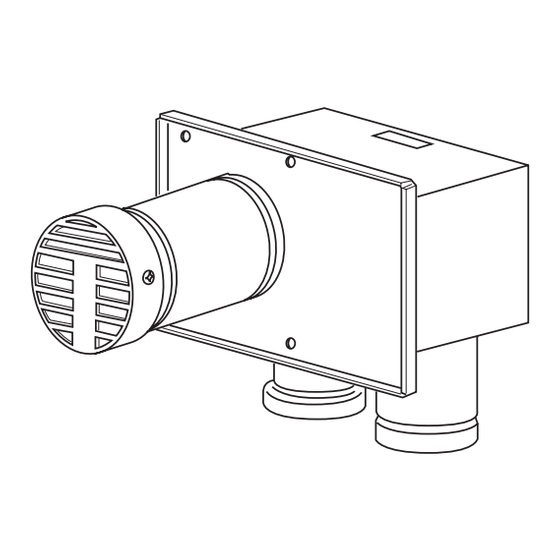

Page 9: Vent Pipe Installation

Vent Pipe Installation Vent Terminal Installation • Follow the installation instructions included with the vent terminal. It is suggested that the appliance be vented horizontally through a sidewall. If a vertical vent termination is required, it must follow the requirements of this section (p.9-12). Vent Terminal Installation Precautions Note the following vent terminal installation requirements •... - Page 10 WARNING CARBON MONOXIDE POISONING Follow all vent system requirements in accordance with relevant local or state regulation, or, in the absence of local or state code, in the U.S. to the National Fuel Gas Code ANSI Be sure to do Z233.1/NFPA 54 –...

- Page 11 DANGER The boiler is not intended to be common vented with any other existing appliance! Boiler removal from a common vent system At the time of removal of an existing heater, the following steps shall be followed with each appliance remaining connected to the common venting system placed in operation, while the other appliances remaining connected to common venting system are not operating.

- Page 12 Vertical Vent Termination • Terminate at least 6' from the combustion air Exhaust intake of any appliance, and 3' from any 1-2' RainCap other building opening, gas utility meter, Intake Air service regulator etc. Min. Storm • Enclose exterior vent systems below the roof Collar Roof line to limit condensation and protect against...

-

Page 13: Gas Piping

(25,000 Btuh) (65,000 Btuh) Outlet D: 25' (Use 30'), 25,000 Btuh requires 1/2" Section 3: 45' (Use 50'), 175,000 Btuh requires 1" Outlet E: 25' (Use 30'), NH-2001-DV (199,900 Btuh) requires 3/4", Natural Gas Meter NH-1501-DV (150,000 Btuh) requires 3/4", **See next page for the pipe capacity charts. - Page 14 Gas Line Sizing Charts Adapted from UPC 1997 Maximum Natur Natural Gas Delivery Capacity in Cubic Feet per Hour (0.60 Specific Gravity, 0.5" WC Pressure Drop) Length in Feet Pipe Size 100' 125' 1/2" 3/4" 1" 1 1/4" 1404 1 1/2" 2103 1445 1161...

-

Page 15: Water Piping

This pressure relief valve must have the hourly rated temperature discharge capacity (199,900 Btuh for the NH-2001-DV, 150,000 Btuh for the NH-1501-DV). The relief capacity must not exceed 30 psi. No valve shall be placed between the relief valve and the boiler. The relief valve must be installed such that the discharge will be conducted to a suitable place for disposal when relief occurs. - Page 16 Relief Valve Mounting Before installing the relief valve, test the piping at 45 psi with the cap on. 6. Insert the relief valve assembly into the housing being 1. Remove the front cover of the unit. careful not to damage the o-ring. Insert and tighten 2.

-

Page 17: Plumbing Applications

Plumbing Applications The boiler piping system of a hot water boiler connected to heating coils located in air handling units where they may be exposed to refrigerated air circulation must be equipped with flow control valves or other automatic means to prevent gravity circulation of the boiler water during the cooling cycle. - Page 18 HYDRONIC HEATING WITH INDIRECT DOMESTIC HOT WATER (SINGLE PUMP PER SYSTEM)

- Page 19 HYDRONIC HEATING WITH INDIRECT DOMESTIC HOT WATER (ADDITIONAL PUMP REQUIRED ON HEATING LOOP)

- Page 20 HYDRONIC HEATING WITH ZONE CONTROLLER AND INDIRECT DOMESTIC HOT WATER...

- Page 21 Flow rate (L/min) 3.8 7.6 11.4 15.2 19.0 22.8 26.6 30.4 34.2 38.0 41.8 45.6 49.4 53.2 57.0 60.8 64.6 • The NH-2001-DV / NH-1501-DV is a boiler to be used for space heating or indirect water heating only. Do not use the hot water supplied by the boiler for drinking purposes.

-

Page 22: Electrical Wiring

Consult a qualified electrician Electrical Wiring for the electrical work. Do not connect electrical power to the unit until all electrical wiring has been completed. Disconnect Power This appliance must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National Electrical Code, ANSI/NFPA 70. - Page 23 Aquastat Room thermostat Signal line from PRIORITY1 Signal line from PRIORITY2 Ground Power supply Power to the PRIORITY 1 pump. Power to the PRIORITY 2 pump. *Max 2.2 Amp. or less. *Max 2.2 Amp. or less. Input up to Input up to 120VAC 1Amp.

- Page 24 Power connection to the boiler. Neutral Power Input AC120Volts Connection to the terminal. 120VAC Ground Input Circulation terminal Priority 1 (Indirect Tank) Priority 2 (Heating) Hot Neutral Hot Neutral Hot Neutral Hot Neutral Burner Power Burner Power Priority 1 Priority 2 Priority 1 Priority 2 (Indirect Tank)

-

Page 25: Maintenance

Relay connection with larger pumps (>2.2 Amp.) 1. Instead of wiring the pump directly to the Priority 1 or Priority 2 terminals, wire a relay to the terminal as shown below. 2. Choose a suitable location for the relay where it will be protected from moisture. 3. -

Page 26: Trial Operation

The installer should test operate the unit, explain to Trial Operation the customer how to use the unit, and give the owner this manual before leaving the installation. • Preparation ... (1) Open the gas supply valve. (2) Turn on the power supply. Priority1 (Indirect tank) operation Priority2 (Heating) operation Operation stops ( *2) -

Page 27: Lighting Instructions

CAUTION Handling after trial operation <When Using Anti-Freeze> • When not planning to use the boiler immediately, close the gas and water shutoff valves to prevent gas leakage from the boiler. • Drain a little boiler water from the drainage shutoff valve, check the pressure, then attach the "CONTAINS ANTI-FREEZE"... - Page 28 Dimensions HEIGHT OF EACH FITTING FROM BOTTOM OF CASE (VIEW FROM TOP) WATER SUPPLY 2.6'' 14.2" WATER RETURN 3.4'' 10.6" WIRING THROUGHWAYS GAS INLET 2.2'' 8.9" 2.4" 17.7" WATER SUPPLY (1") WATER RETURN (1") 3.2" GAS INLET (3/4") 5" 6.7" 0.4"...

-

Page 29: Other Settings

Other Settings Manual Pump Operation Procedure Use this procedure when bleeding air out of the system or when confirming proper operation of the pump(s). 1. Set the Power on/off button to the off position. 2. To circulate Priority 1, press and hold in the PRIORITY 1 switch for at least 5 seconds. To circulate Priority 2, press and hold in the PRIORITY 2 switch for at least 5 seconds. -

Page 30: Error Codes

Error descriptions and possible cause / check points Error Code Possible Cause Check Point (Location of Failure) Ignition failure Is the gas valve closed? Does the igniter spark? Are all wiring connections to the gas valves secure? Is the lead from the flame rod securely connected? Flame rod is triggered Is the gas valve closed? Are all wiring connections to the gas valves secure?

Need help?

Do you have a question about the NH-2001-DV and is the answer not in the manual?

Questions and answers