Summary of Contents for Century 400 Ninja 10070610

- Page 1 PORTABLE EXTRACTOR MODELS: 10070610 Operating Instructions Read these instructions before using the machine 86307580 - F 09/04/08...

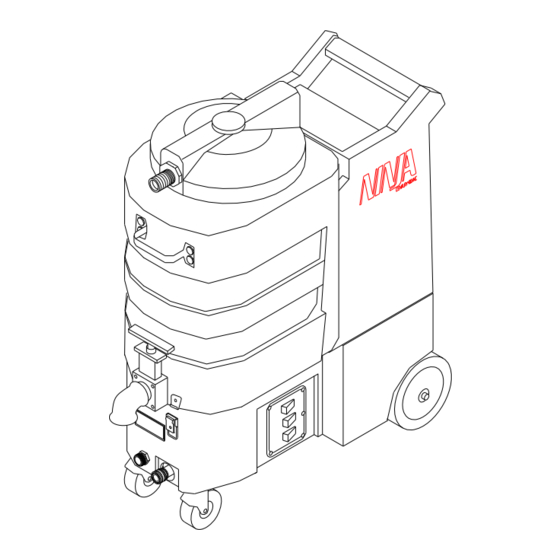

- Page 2 MACHINE DATA LOG/OVERVIEW Model: Date of Purchase: Serial Number: Sales Representative: Address: Phone Number: Copyright 2008 Windsor Industries, Printed in USA OVERVIEW The Ninja is an electric powered carpet extractor intended for commercial use. This appliance applies a cleaning solution to the carpet and then vacuums the soiled water back into the recovery tank.

-

Page 3: Table Of Contents

TABLE OF CONTENTS Machine Data Log/Overview........2 GROUP PARTS LIST Table of Contents..........3 Frame ..................5-1 HOW TO USE THIS MANUAL Controls..................5-3 Pump ..................5-5 How To Use This Manual........1-1 Pumpout.................5-7 Recovery and Solution Tank..........5-9 SAFETY Vacuum Motor ..............5-11 Wiring Group.................5-13 Important Safety Instructions .......2-1 Warranty.................5-15 Hazard Intensity Level..........2-2 Safety Label Location...........2-3... -

Page 4: How To Use This Manual

HOW TO USE THIS MANUAL The SAFETY section contains important information This manual contains the following sections: regarding hazard or unsafe practices of the machine. Levels of hazards are identified that could HOW TO USE THIS MANUAL result in product or personal injury, or severe injury SAFETY resulting in death. -

Page 5: Important Safety Instructions

SAFETY INSTRUCTIONS IMPORTANT SAFETY INSTRUCTIONS When using an electrical appliance, basic precaution must always be followed, including the following: READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE. This machine is for commercial use. WARNING: To reduce the risk of fire, electric shock, or injury: Connect to a properly grounded outlet. -

Page 6: Hazard Intensity Level

HAZARD INTENSITY LEVEL The following symbols are used throughout this guide as indicated in their descriptions: HAZARD INTENSITY LEVEL There are three levels of hazard intensity identified by signal words -WARNING and CAUTION and FOR SAFETY. The level of hazard intensity is determined by the following definitions: WARNING WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death . -

Page 7: Safety Label Location

SAFETY LABEL LOCATION NOTE: These drawings indicate the location of safety labels on the machine. If at any time the labels become illegible, promptly replace them. LABEL WARNING 86242230 PRV NO. 500009 LABEL CIRCUIT INTERRUPTER 86200570 PRV NO. 170-41 86307580 NINJA1200 01/31/08... -

Page 8: Grounding Instructions

GROUNDING INSTRUCTIONS THIS PRODUCT IS FOR COMMERCIAL USE ONLY. ELECTRICAL: In the USA this machine operates on a standard 15 amp 115V, 60 hz, A.C. power circuit. The amp, hertz, and voltage are listed on the data label found on each machine. Using voltages above or below those indicated on the data label will cause serious damage to the motors. -

Page 9: Technical Specifications

147 lbs (67 kg) Weight-Full Solution 222 lbs (101 kg) Height 36 inches (91.4 cm) Length 29 inches (73.6 cm) Width 19.5 inches (49.5 cm) Power cord (2) 22 feet (6.71 m) LENGTH WIDTH HEIGHT CENTURY 400 86307580 NINJA1200 01/31/08... -

Page 10: Controls

CONTROLS Pump Switch Vacuum Switch Sump Switch 86307580 NINJA1200 01/31/08... -

Page 11: Machine Operation

MACHINE OPERATION PRE-RUN INSPECTION AUTO FILL 1. Check all fittings and connectors for proper Connect standard garden hose from faucet to the assembly. rear of the solution tank. Turn on water and allow tank to fill check for leaks. 2. Check all hoses for leaks. Repair or replace any damaged hoses. - Page 12 MACHINE OPERATION EMPTYING AND CLEANING Always use defoamer if 3. When cleaning, keep the working opening (wand foaming occurs. Foam mouth) flat on the surface being cleaned. Keep will suspend large particles that may damage the wand moving when the valve is open. vacuum(s) as well as allow liquid into the vacuum motor(s) without activating the float shutoff.

- Page 13 NOTES 86307580 NINJA1200 01/31/08...

-

Page 14: Maintenance

MAINTENANCE DAILY MAINTENANCE PERIODIC MAINTENANCE Unplug power cords 1. Twice a month, flush a white vinegar solution before servicing or (One quart vinegar to two gallons of water) or making any repairs. anti-browning solution (mixed as directed) through the extractor, turning pump switch on/off 1. -

Page 15: Vacuum Motor Replacement

MAINTENANCE Only qualified 2. Replace carbon brush (A), by disconnecting at maintenance personnel the terminal connection (B). are to perform the following repairs. VACUUM MOTOR REPLACEMENT 1. Turn off all switches and unplug machine. 2. Remove recovery tank. 3. Locate the vacuum motor wires and disconnect at the connector. - Page 16 MAINTENANCE PUMP REPLACE KIT 1200 PSI CAM & BEARINGS P/N 86308380 VALVE & O-RING KIT (BOTH SIDES) 86308370 PLUNGER & SEAL KIT P/N 86308360 86307580 NINJA1200 01/31/08...

-

Page 17: Troubleshooting

TROUBLESHOOTING PROBLEM CAUSE SOLUTION Dead electrical circuit Check building circuit breaker or fuse box. Loss of Power Faulty power cord Replace Equipment not grounding Follow grounding instructions exactly Receptacle not grounded Contact an electrician to check building’s wiring Electrical shock Have a trained service technician check machine’s Internal wiring problem wiring... -

Page 18: Frame

FRAME 86307580 NINJA1200 01/31/08... - Page 19 FRAME SERIAL PART PRV NO DESCRIPTION NOTES: 86005680 57047 NUT,1/4-20 HEX NYLOCK 86010630 87013 WASHER, 1/4 ID X 5/8 OD SS CLAMP, 7/8 DIA “P” 86233390 80887 CUSHIONED 86005640 57030 NUT, 10-32 HEX NYLOCK 86279190 87095 WASHER, #10 FLAT PLTD 86274040 70076 SCR, 10-32 X 1 PFHMS...

-

Page 20: Controls

CONTROLS 86307580 NINJA1200 03/11/08... - Page 21 CONTROLS PART SERIAL PRV NO DESCRIPTION NOTES: 86270920 57049 NUT, 6-32 HEX NYLOCK SS 86298680 TRANSFORMER, 115/230V/24V 86006620 70127 SCR, 6-32 X 1/4 PPHMS SS PLATE, RELAY AND 86308160 TRANSFORMER 86298690 RELAY, 24VAC 86005720 57106 NUT, 8-32 W/STAR WASHER PLTD 86257400 14462 TERM BLOCK, 25A 250V 1-1/2...

-

Page 22: Pump

PUMP 86307580 NINJA1200 01/31/08... - Page 23 PUMP PART SERIAL NO. PRV NO. QTY DESCRIPTION NOTES: FROM 86308190 UNLOADER, 1200PSI, W/KNOB 86180040 790722 ELBOW, 1/4 MP X 1/2H 90DEG 86233150 20042 CLAMP, 3/8 HOSE (D-SLOT) HOSE, PULSE, 32 3/8MPT X 3/8 86308200 X MPTS 86197420 31026 ELBOW, 3/8NPT STREET 86197540 40013 HOSEBARB, 3/8MPT X 1/2 DL...

-

Page 24: Pumpout

PUMPOUT 86307580 NINJA1200 09/04/08... - Page 25 PUMPOUT PART SERIAL PRV NO QTY DESCRIPTION NOTES: 86197420 31026 ELBOW, 3/8 NPT STREET 86308150 SWITCH, TILT FLOAT 86308470 STRAINER, 30 MESH, 3/8 NPT 86075210 20062 CLAMP, 3/8 NYLON MCHD 86202210 030-76A WASHER, GARDEN HOSE 86273830 70020 SCR, 1/4-20 X 1/2 HHCS SS NP 86195060 15-808110 VALVE, FLOAT, TM...

-

Page 26: Recovery And Solution Tank

RECOVERY & SOLUTION TANK GROUP 86307580 NINJA1200 01/31/08... - Page 27 RECOVERY & SOLUTION TANK GROUP SERIAL NO. PART NO. PRV NO. DESCRIPTION NOTES: FROM 86033240 090-17 STAND PIPE ASSY 86199840 090-2A FLOAT SCREEN CAGE ASSY (SLIP) 86200290 260-33 HOSE BARB, 1.5 MPT X 1.5 86090320 87257 WASHER, HOSEBARB 86237770 35256 GASKET, DUMP VALVE 86033370 51355...

-

Page 28: Vacuum Motor

VACUUM MOTOR 5-11 86307580 NINJA1200 01/31/08... - Page 29 VACUUM MOTOR PART SERIAL NO. PRV NO. DESCRIPTION NOTES: FROM 86307630 SPACER, .25 X .50 X 1.31 86005810 57245 NUT, 1/4-20 HEX NYLOCK SS 86010630 87013 WASHER, 1/4 ID X 5/8 OD SS 86305930 PLATE, 7.0 VAC MOUNT 86276270 70619 SCR, 1/4-20 X 2.0 HHMS SS F/T 86199920 110-28A...

-

Page 30: Wiring Diagram

WIRING DIAGRAM PUMP POWER PANEL VACUUM POWER TRANSFORMER PUMP SWITCH BLU/BLK RELAY WHT/BRN VACUUM SWITCH FLOAT SUMP SWITCH TERMINAL BLOCK PUMP VACUUM SUMP GND WIRES FRAME BASE 86307580 NINJA1200 07/22/08 5-13... - Page 31 WIRING DIAGRAM PART SERIAL NO. PRV NO. DESCRIPTION NOTES: FROM 86268830 88636 WIRE, 8” BLK/14 76002 X 76029 86267810 880356 WIRE, 42” BLK/14 76029 X 76044 86308820 WIRE, 42” WHT/14 76044 X 76002 86267970 880419 WIRE, BLK/14 76044 X 76050 86267030 880180 WIRE, 6”...

-

Page 32: Warranty

The machine Registration Card must be completed and returned immediately at the time of purchase. If proof of purchase cannot be identified, the warranty start date is 90 days after the date of sale to an authorized Century 400 distributor. Parts replaced or repaired under warranty are guaranteed for the remainder of the original warranty period. - Page 33 If difficulty develops during the warranty period, contact the authorized CENTURY 400 agent from whom the product was purchased. CENTURY 400 may elect to require the return of components to validate a claim. Any defective part to be returned must be shipped freight prepaid to an authorized CENTURY 400 Distributor/Service Center or to the CENTURY 400 factory.

Need help?

Do you have a question about the Ninja 10070610 and is the answer not in the manual?

Questions and answers