Table of Contents

Advertisement

Breakfa st

Linch on

One Dish

Bar

the Run

Popcorn

Baked

Dinners

Sensor

Custom

Potatoe s

Reheat

More from your Microwav

Help

e

Sensor Cooking

1

2

Super

3

Compu

Beverag e

Defrost

Defrost

Vegetab les

center

Main

Frozen

Kitchen

Entrees

Foods

Timer/C lock

6

7

8

BEFORE SERVICING ......................................................................................................INSIDE FRONT COVER

WARNING TO SERVICE PERSONNEL ................................................................................................................ 1

MICROWAVE MEASUREMENT PROCEDURE ................................................................................................... 2

FOREWORD AND WARNING ............................................................................................................................... 3

PRODUCT SPECIFICATIONS .............................................................................................................................. 4

GENERAL INFORMATION ................................................................................................................................... 4

OPERATION .......................................................................................................................................................... 6

TROUBLESHOOTING GUIDE ............................................................................................................................ 10

TEST PROCEDURE ............................................................................................................................................ 12

TOUCH CONTROL PANEL ................................................................................................................................. 20

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE ................................................................ 25

PICTORIAL DIAGRAM ........................................................................................................................................ 32

POWER UNIT CIRCUIT ...................................................................................................................................... 33

CPU UNIT CIRCUIT ............................................................................................................................................ 34

PRINTED WIRING BOARD ................................................................................................................................. 36

PARTS LIST ........................................................................................................................................................ 37

PACKING AND ACCESSORIES ......................................................................................................................... 39

SHARP CORPORATION

SERVICE MANUAL

MODELS

4

5

Power

Minute

Level

PLus

9

0

STOP

START

Clear

Touch on

In the interest of user-safety the oven should be restored to its original

condition and only parts identical to those specified should be used.

WARNING TO SERVICE PERSONNEL: Microwave ovens con-

tain circuitry capable of producing very high voltage and

current, contact with following parts may result in a severe,

possibly fatal, electrical shock. (High Voltage Capacitor, High

Voltage Power Transformer, Magnetron, High Voltage Recti-

fier Assembly, High Voltage Harness etc..)

TABLE OF CONTENTS

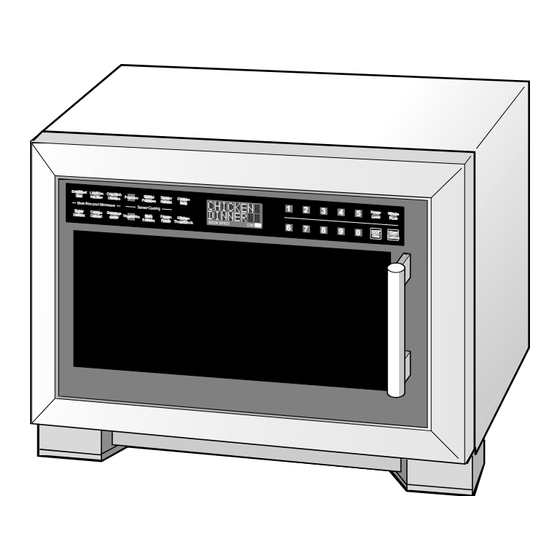

MICROWAVE OVEN

R-630DK

R-630DW

R-630DS

This document has been published to be used for after

sales service only.

The contents are subject to change without notice.

R - 630DK

R -630 DW

R - 630 DS

S7017R630DPW/

Page

Advertisement

Table of Contents

Summary of Contents for Sharp R-630DK

-

Page 1: Table Of Contents

R - 630DK R -630 DW R - 630 DS SERVICE MANUAL S7017R630DPW/ MICROWAVE OVEN R-630DK MODELS R-630DW Breakfa st Linch on One Dish the Run Popcorn Baked Dinners Sensor Custom Potatoe s Reheat More from your Microwav Help Sensor Cooking... -

Page 2: Precautions To Be Observed Before And During Servicing To Avoid Possible Exposure To Excessive Microwave Energy

Before servicing an operative unit, perform a microwave emission check as per the Microwave Measurement Procedure outlined in this service manual. If microwave emissions level is in excess of the specified limit, contact SHARP ELECTRONICS CORPORATION immediately @1-800-237-4277. If the unit operates with the door open, service person should 1) tell the user not to operate the oven and 2) contact SHARP ELECTRONICS CORPORATION and Food and Drug Administration's Center for Devices and Radiological Health immediately. -

Page 3: Warning To Service Personnel

R -630DK R-630DW R -630DS WARNING TO SERVICE PERSONNEL Microwave ovens contain circuitry capable of pro- ducing very high voltage and current, contact with following parts may result in a severe, possibly fatal, electrical shock. (Example) High Voltage Capacitor, High Voltage Power Trans- former, Magnetron, High Voltage Rectifier Assem- bly, High Voltage Harness etc.. -

Page 4: Microwave Measurement Procedure

R- 630DK R-630DW R -630 DS MICROWAVE MEASUREMENT PROCEDURE A. Requirements: 1) Microwave leakage limit (Power density limit): The power density of microwave radiation emitted by a microwave oven should not exceed 1mW/cm at any point 5cm or more from the external surface of the oven, measured prior to acquisition by a purchaser, and thereafter (through the useful life of the oven), 5 mW/cm at any point 5cm or more from the external surface of the oven. - Page 5 MICROWAVE OVEN R-630DK/ R-630DW/ R-630DS GENERAL INFORMATION FOREWORD This Manual has been prepared to provide Sharp Electronics Corp. Service Personnel with Operation and Service Information for the SHARP MICROWAVE OVEN, R-630DK, R-630DW, R-630DS. OPERATION It is recommended that service personnel carefully study the entire text of this manual so that they will be qualified to render satisfactory customer service.

-

Page 6: General Information

R- 630DK R-630DW R -630 DS SPECIFICATION ITEM DESCRIPTION Power Requirements 120 Volts / 14 Amperes 60 Hertz Single phase, 3 wire grounded Power Output 1100 watts (IEC TEST PROCEDURE) Operating frequency of 2450MHz Case Dimensions Width 19-1/2" Height 14" Depth 20-5/8"... -

Page 7: Oven Diagram

R -630DK R-630DW R -630DS Where a two-pronged wall-receptacle is encountered, it is the personal Grounded 3-Pronged Plug responsibility and obligation of the customer to contact a qualified Receptacle Box electrician and have it replaced with a properly grounded three-pronged wall receptacle or have a grounding adapter properly grounded and polarized. -

Page 8: Operation

(Figure O-1). If the secondary interlock switch and primary interlock relay 1. The display will show "SHARP SIMPLY THE BEST (RY2) fail with the contacts closed when the door is opened, PRESS CLEAR AND PRESS CLOCK".To set any... - Page 9 R -630DK R-630DW R -630DS An example of how sensor works: (POTATOES) 1. Potates at room temperature. Vapor is emitted very slowly. 2. Heat Potates. Moisture and humidity is emitted rapidly. You can smell the aroma as it cooks. AH SENSOR 3.

- Page 10 R- 630DK R-630DW R -630 DS SCHEMATIC NOTE: CONDITION OF OVEN 1. DOOR CLOSED 2. CLOCK APPEARS ON DISPLAY THERMAL MONITOR THERMAL CUT-OUT (OVEN) FUSE 20A CUT-OUT (MG.) N.O. POWER N.O. TRANSFORMER (RY-1) (RY-2) PRIMARY INTERLOCK RELAY CONTROL UNIT COM. COM.

- Page 11 R -630DK R-630DW R -630DS DESCRIPTION AND FUNCTION OF COMPONENTS DOOR OPEN MECHANISM CAUTION: BEFORE REPLACING A BLOWN MONITOR FUSE TEST THE DOOR SENSING SWITCH, The door is opened by pulling the door. Refer to the Figure PRIMARY INTERLOCK RELAY (RY2), RELAY D-1.

-

Page 12: Troubleshooting Guide

R- 630DK R-630DW R -630 DS TROUBLESHOOTING GUIDE Never touch any part in the circuit with your hand or an uninsulated tool while the power supply is connected. When troubleshooting the microwave oven, it is helpful to follow the Sequence of Operation in performing the checks. Many of the possible causes of trouble will require that a specific test be performed. -

Page 13: Test Procedure

R -630DK R-630DW R -630DS CK = Check / RE = Replace RE RE A B C D E F F G H RE RE CK I CK CK CK J K L M N TEST PROCEDURE PROBLEM CONDITION Home fuse or circuit breaker blows when power cord is plugged into wall receptacle Monitor fuse blows when power cord... - Page 14 R- 630DK R-630DW R -630 DS TEST PROCEDURES PROCEDURE COMPONENT TEST LETTER MAGNETRON ASSEMBLY TEST 1. Disconnect the power supply cord, and then remove outer case. 2. Open the door and block it open. 3. Discharge the high voltage capacitor. 4.

- Page 15 R -630DK R-630DW R -630DS TEST PROCEDURES PROCEDURE COMPONENT TEST LETTER (HIGH VOLTAGES ARE PRESENT AT THE HIGH VOLTAGE TERMINAL, SO DO NOT ATTEMPT TO MEASURE THE FILAMENT AND HIGH VOLTAGE.) HIGH VOLTAGE RECTIFIER TEST 1. Disconnect the power supply cord, and then remove outer case. 2.

- Page 16 R- 630DK R-630DW R -630 DS TEST PROCEDURES PROCEDURE COMPONENT TEST LETTER 5. Reconnect all leads removed from components during testing. 6. Reinstall the outer case (cabinet). 7. Reconnect the power supply cord after the outer case is installed. 8. Run the oven and check all functions. CAUTION: IF THE THERMAL CUT-OUT INDICATES AN OPEN CIRCUIT AT ROOM TEMPERATURE, REPLACE THERMAL CUT-OUT.

- Page 17 R -630DK R-630DW R -630DS TEST PROCEDURES PROCEDURE COMPONENT TEST LETTER actuator is pushed by a screw driver through the lower latch hole on the front plate of the oven cavity with the door opened (in this condition the plunger of the monitor switch is pushed in), the meter should indicate an open circuit.

- Page 18 R- 630DK R-630DW R -630 DS TEST PROCEDURES PROCEDURE COMPONENT TEST LETTER 2-1 In connection with pads. a) When touching the pads, a certain group of pads do not produce a signal. b) When touching the pads, no pads produce a signal. 2-2 In connection with indicators a) At a certain digit, all or some segments do not light up.

- Page 19 R -630DK R-630DW R -630DS TEST PROCEDURES PROCEDURE COMPONENT TEST LETTER 6. After that procedure, re-connect the power supply cord. 7. Remove the outer case and check voltage between Pin No. 1 of the 2 pin connector (A) and the normal open terminal of the relay RY1 on the control unit with an A.C.

- Page 20 R- 630DK R-630DW R -630 DS TEST PROCEDURES PROCEDURE COMPONENT TEST LETTER 6) Reconnect all leads removed from components during testing. 7) Re-install the outer case (cabinet). 8) Reconnect the power supply cord after the outer case is installed. 9) Run the oven and check all functions. 2.

- Page 21 R -630DK R-630DW R -630DS TEST PROCEDURES PROCEDURE COMPONENT TEST LETTER WARNING : The oven should be fully assembled before following procedure. Make sure the oven has been plugged in at least two minutes before checking sensor cook operation. The cabinet should be installed and screws tightened. (1) Fill approximately 200 milliliters (7.2 oz) of tap water in a 1000 milliliter measuring cup.

-

Page 22: Touch Control Panel

R- 630DK R-630DW R -630 DS TEST PROCEDURES PROCEDURE COMPONENT TEST LETTER (11) Open the door and block it open. (12) Discharge high voltage capacitor. (13) Disconnect the dummy resistor circuit from the sensor connector of control panel. (14) Carry out necessary repair. (15) Reconnect all leads removed from components during testing and repairing. - Page 23 R -630DK R-630DW R -630DS LSI(IXA054DR) The I/O signal of the LSI(IXA054DR) is detailed in the following table. Pin No. Signal Description AN10 Signal coming from touch key. When either G10 line on key matrix is touched, a corresponding signal out of P10 - P17 will be input into ANI0.

- Page 24 R- 630DK R-630DW R -630 DS Pin No. Signal Description Oven lamp, fan motor and turntable motor driving signal To turn on and off shut off relay (RY1). The 16.7 msec. square waveform voltage is delivered to the H : GND RY1 driving circuit and RY2 control circuit.

- Page 25 R -630DK R-630DW R -630DS Pin No. Signal Description 95-98 AN4-AN7 Terminal to change cooking input according to the Model. By using the A/D converter contained in the LSI, DC voltage in accordance with the Model in operation is applied to set up its cooking constant. Signal similar to ANI7.

- Page 26 R- 630DK R-630DW R -630 DS TOUCH CONTROL PANEL SERVICING 1. Precautions for Handling Electronic Components 4) Re-install the outer case (cabinet). 5) Re-connect the power supply cord after the outer This unit uses CMOS LSI in the integral part of the case is installed.

-

Page 27: Component Replacement And Adjustment Procedure

WARNING FOR WIRING To prevent an electric shock, take the following pre- and Oven cavity. cautions. 3) Sharp edge: 1. Before wiring, Base plate, Oven cavity, Waveguide flange, Angles, 1) Disconnect the power supply cord. Guides and other metallic plates. -

Page 28: Pictorial Diagram

R- 630DK R-630DW R -630 DS 7. Lift entire outer case from the unit. COMPONENTS OR WIRING. CAUTION: 1. DISCONNECT OVEN FROM POWER SUP NOTE: When replacing the outer case, the 2 special PLY BEFORE REMOVING OUTER CASE. Torx screws must be reinstalled in the same 2. - Page 29 R -630DK R-630DW R -630DS 3. Discharge the high voltage capacitor. 9. Disconnect rectifier terminal from the capacitor. 4. Disconnect the high voltage wire B from the power High voltage rectifier assembly is now free. transformer. 10.Disconnect the high voltage wire B from the high voltage 5.

- Page 30 5. Disconnect wire leads from turntable motor. CAUTION: NO SHARP EDGES MUST BE EVIDENT AF- (See "Positive lock connector removal") TER REMOVAL OF THE TURNTABLE MO- 6. Remove two (2) screws holding turntable motor to oven TOR COVER.

- Page 31 R -630DK R-630DW R -630DS DOOR SENSING SWITCH/SECONDARY INTERLOCK SWITCH AND MONITOR SWITCH ADJUSTMENT 1. Disconnect the power supply cord, and then remove the latched position. First check upper position of latch hook, pushing and pulling upper portion of door toward outer case.

-

Page 32: Power Unit Circuit

R- 630DK R-630DW R -630 DS Note: The door on a microwave oven is designed to act as Wire harness an electronic seal preventing the leakage of microwave energy from oven cavity during cook cycle. This function does not require that door be air-tight, Power unit Door Wire harness... - Page 33 R -630DK R-630DW R -630DS PWB Cover Tabs Tabs Door screen wire harness Tabs Tabs Tabs Figure C-10. Routing of wire harness NOTE: For key sheet 1. Before attaching a new key sheet, wipe off remaining adhesive on the door screen surfaces completely with a soft cloth soaked in alcohol.

- Page 34 R- 630DK R-630DW R -630 DS...

- Page 35 R -630DK R-630DW R -630DS CN-A CN-C S1NB10 GND1 GND2 – – 2SB1238 R2 680 1/2w BA4558 BUZZER OVEN LAMP TURNTABLE MOTOR FAN MOTOR 1.8kF 360kF MICRO OVEN LAMP TURNTABLE MOTOR FAN MOTOR MICRO DOOR N.C. SENSING SWITCH DOOR SENSING CN-B SWITCH CN-F...

- Page 36 R- 630DK R-630DW R -630 DS SEG6 SEG7 SEG8 SEG9 SEG10 SEG11 SEG12 SEG13 SEG14 SEG15 SEG16 SEG17 SEG18 SEG19 TEST SEG20 OSC1 OSC2 AVSS AN11 AN10 SEG35 /50v 0.01 /25v 0.01 330pF/50v 330pF/50v 330pF/50v 330pF/50v (J16) 4.7k (J17) (J14) 4.7k (J15) 270k...

- Page 37 R120 4.7k R121 4.7k R122 4.7k R123 4.7k R124 4.7k R125 4.7k R126 4.7k R127 4.7k R128 4.7k R134 15k R129 4.7k R130 4.7k C124 0.1 /50v R131 4.7k C125 0.1 /50v R132 33k R133 510k C128 C127 0.1 /50v 0.1 /50v OSC4 OSC3...

-

Page 38: Printed Wiring Board

R- 630DK R-630DW R -630 DS CN - H (D7) Figure S-5. Printed Wiring Board of Power Unit... -

Page 39: Parts List

CABINET PARTS 2- 1 FDAI-A215WRYZ Base plate 2- 2 GLEGPA074WRE0 Foot 2- 3 GLEGPA081WRFZ 2- 4 GCABUA773WRPZ Outer case cabinet [R-630DK] 2- 4 GCABUA775WRPZ Outer case cabinet [R-630DW] 2- 4 GCABUA777WRPZ Outer case cabinet [R-630DS] 2- 5 GLEGPA080WRFZ Front leg [R-630DK]... - Page 40 Cushion DOOR PARTS 5- 1 FDORFA343WRTZ Door panel 5- 2 PSHEPA735WREZ Sealer film 5- 3 FPNL-A042WRKZ Door screen assembly [R-630DK] 5- 3 FPNL-A043WRKZ Door screen assembly [R-630DW] 5- 3 FPNL-A042WRKZ Door screen assembly [R-630DS] 5-3-1 PSHEPA741WREZ Key sheet [R-630DK] 5-3-1...

-

Page 41: Packing And Accessories

1. MODEL NUMBER 2. REF. NO. 3. PART NO. 4. DESCRIPTION Order Parts from the authorized SHARP parts Distributor for your area. Defective parts requiring return should be returned as indicated in the Service Policy. PACKING AND ACCESSORIES TOP PAD ASSEMBLY... - Page 42 R -630DK R-630DW R -63 0 DS 7-13 OVEN AND CABINET PARTS 7-18 4-23 1-15 7-14 4-26 4-17 1-13 7-12 4-12 4-24 7-14 4-28 4-18 4-27 4-30 7-11 4-11 4-19 4-14 7-11 7-11 4-15 1-10 7-10 7-11 4-16 1-11 4-10 7-17 4-20 1-12...

- Page 43 R - 630DK R -630 DW R - 630 DS 5-13 5-13 DOOR PARTS 5-20 5-10 5-11 5-12 5-14 5-17 4-13 5-13 5-11 5-12 5-12 5-21 5-12 5-19 5-21 5-18 5-15 5-16 5-3-1 MISCELLANEOUS Actual wire harness may be different from illustration. (CAPACITOR) 6-11 6-12...

- Page 44 No part of this publication may be repro- duced, stored in retrieval systems, or trans- mitted in any form or by any means, elec- tronic, mechanical, photocopying, record- ing, or otherwise, without prior written per- mission of the publisher. 2000 SHARP CORP. (7S2.530E) Printed in U.S.A...

Need help?

Do you have a question about the R-630DK and is the answer not in the manual?

Questions and answers