Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Service Manual

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Westerbeke W-70GA

- Page 1 ." ",' OPERATORS MANUAL W-70GA MARINE GASOLINE FIRST EDITION MARCH 2004 rWESTERBEKE WESTERBEKE CORPORATION • 150 JOHN HANCOCK ROAD • MYLES STANDISH INDUSTRIAL PARK· TAUNTON MA 02780 WEB SITE: WWW.WESTERBEKE.COM - ..A'A'A'A' NMMA Member National Marine Manufacturers Association...

- Page 2 Shut down the unit and do not restart until it has been inspected and repaired. A WARNING DECAL is provided by to a WESTERBEKE and should be fixed bulkhead near your engine generator. WESTERBEKE also recommends installing CARBON MONOXIDE DETECTORS in the living/sleeping quarters of your vessel.

- Page 3 SAFETY INSTRUCTIONS INTRODUCTION PREVENT BURNS - FIRE Read this safety manual carefully. Most accidents are caused by failure to follow fundamental rules WARNING: Fire.can cause injury Dr death! precautions. Know when dangerous conditions exist and the necessary precautions to protect yourself, your toke •...

- Page 4 SAFETY INSTRUCTIONS ACCIDENTAL STARTING TOXIC EXHAUST GASES WARNING: Accidental starting can cause injury WARNING: Carbon monoxide (CO) is deadly gas! or death! • Ensure that the exhaust system is adequate to expel gases • Disconnect the battery cables before servicing the engine/ discharged from the engine.

- Page 5 SAFETY INSTRUCTIONS • Do not wear loose clothing or jewelry when servicing ABYC, NFPA AND USCG PUBLICATIONS FOR equipment; tie back long hair and avoid wearing loose INSTALLING DIESEL ENGINES jackets, shirts, sleeves, rings, necklaces or bracelets that Read the following ABYC, NFPA and USCG publications could caught in moving parts.

- Page 6 INSTALLATION When installing WESTERBEKE engines and generators it is important that strict attention paid to the following information: CODES AND REGULATIONS Strict federal regulations, ABYC guidelines, and safety codes must be complied with when installing engines and generators in a marine environment.

-

Page 7: Table Of Contents

TABLE OF CONTENTS Parts Identification ..........2 Engine Adjustments ........... Spark Plugs ............. 29 Introduction ............3 Drive Belt Adjustment........29 Fuel, Engine Oil, and Engine Coolant...~ ..... 5 Electric Choke ..........30 Instrument Panel ..........6 I .. gnltIon Imlng .......... -

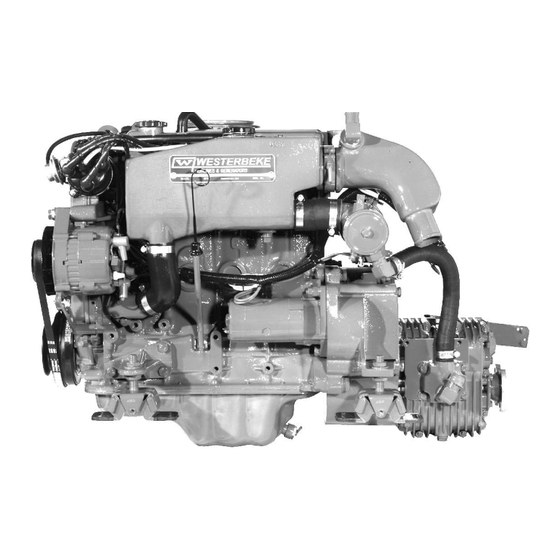

Page 8: Parts Identification

70GA PARTS IDENTIFICATION COOLANT FILLER PRESSURE CAP FUEL FILTER EXHAUST ELBOW FLAME ARRESTER/AIR FILTER WATER INJECTED OIL FILL REAR RAW WATER PUMP VACUUM ADVANCE UNIT FRONT STARTER MOTOR DC ALTERNATOR OIL SUMP-------4-... "ii; LEFT SIDE DISTRIBUTER FILL COOLANT PRESSURE CAP PCV VALVE FUEL FILTER... -

Page 9: Introduction

This manual is designed to help you do this. Please read this manual carefully and observe all the safety precautions WESTERBEKE customers should also keep in mind the time throughout. Should your engine require servicing, contact span between printings of WESTERBEKE product software your nearest WESTERBEKE dealer for assistance. - Page 10 NOTE: A carbon monoxide warning decal has been provided camshaft which is chain-driven. The engine utilizes a solid- by WESTERBEKE. Affix this decal in a visable location in state distributor which is horizontally mounted and camshaft- the engine room. driven. The engine incorporates a pressure type lubrication...

-

Page 11: Fuel, Engine Oil And Engine Coolant

FUEL, ENGINE OIL AND ENGINE COOLANT ENGINE COOLANT GASOLINE WESTERBEKE recommends a mixture of 50% antifreeze and 50% distilled water. Distilled water is free from the chemicals CAUTION: Only use unleaded fuel with an octane that can corrode internal engine surfaces. -

Page 12: Instrument Panel

GASOLINE ENGINE INSTRUMENT PANEL NOTE: Be certain to install the instrument panel in a location The following a description of the panel components. that is accessible and where the gauges can be continually Tachometer - Registers revolutions per minute of the engine monitored by the helmsman. -

Page 13: Preparations For Initial Start-Up

PREPARATIONS FOR INITIAL START-UP PREST ART INSPECTION Visually examine the engine. Look for loose or missing parts, disconnected wires, and unattached hoses. Check Before starting your engine for the first time or after a pro- the threaded connections and engine attachments. longed layoff, check the following items: Examine the air inlet and outlet for air flow obstructions. -

Page 14: Starting/Stopping Procedure

STARTING • STOPPING PROCEDURE STARTING PROCEDURE STOPPING PROCEDURE Place the transmission in neutral and advance the throttle To stop the engine, bring the throttle to an idle position and control to slightly open. place the transmission in neutral. Allow the engine to idle for a few moments to stabilize temperatures, then shut the 2. -

Page 15: Engine Break-In Procedure

ENGINE BREAK-IN PROCEDURE DESCRIPTION 3. While using the vessel, run the engine at various engine speeds for the fIrst 25 hours. Avoid prolonged periods of Although your engine has experienced a minimum of one idling. hour of test operations at the factory to make sure accurate 4. -

Page 16: The Daily Operation

THE DAILY OPERATION CHECK LIST 2. Tum the KEY SWITCH to the ON position (2 o'clock). [The panel is energized, gauges are lit}. Follow this check list each day before starting your engine. 3. Depress the PREST ART BUTTON, hold for 5 seconds. Visually inspect the engine for fuel, oil, or water leaks.

Need help?

Do you have a question about the W-70GA and is the answer not in the manual?

Questions and answers