Table of Contents

Advertisement

Quick Links

~~ERATO~s

ttJ.

G

*o

i7

~

!

~

<.'

6

I.LJ

{1'\

-+t

*

-¥

¥-

*

SINCE 19'!11

*

..

OPERATORS MANUAL

FOR THE

44A FOUR • 35C THREE

448 FOUR • 350 THREE

44C FOUR • 35E THREE

MARINE Dl SEL ENGINES

...

PUBLICATION N0.044180

THIRD REVISION

MAY 2012

WESTERBEKE CORPORATION • 150 JOHN HANCOCK ROAD

MYLES STANDISH INDUSTRIAL PARK • TAUNTON MA 02780

WEBSITE: WWW. WESTERBEKE.COM

~A:f,A(j'

Member National Marine Manufacturers Association

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Westerbeke 44 A FOUR-35C THREE

- Page 1 448 FOUR • 350 THREE 44C FOUR • 35E THREE MARINE Dl SEL ENGINES PUBLICATION N0.044180 THIRD REVISION MAY 2012 WESTERBEKE CORPORATION • 150 JOHN HANCOCK ROAD MYLES STANDISH INDUSTRIAL PARK • TAUNTON MA 02780 WEBSITE: WWW. WESTERBEKE.COM ~A:f,A(j' Member National Marine Manufacturers Association...

- Page 2 CALIFORNIA PROPOSITION 65 WARNING Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm. wARNING Exhaust gasses contain Carbon Monoxide, an odorless and colorless gas. Carbon Monoxide is poisonous and can cause unconsciousness and death.

- Page 3 SAFETY INSTRUCTIONS INTRODUCTION PREVENT BURNS - FIRE Read this safety manual carefully. Most accidents are caused by failure to follow fundamental rules and precau- WARNING: Fire can cause injury or death! tions. Know when dangerous conditions exist and take the necessary precautions to protect yourself, your personne~ •...

- Page 4 SAFETY INSTRUCTIONS ACCIDENTAL STARTING TOXIC EXHAUST GASES WARNING: Accidental starting can cause injury WARNING: Carbon monoxide (CO) is a deadly gas! or death! • Ensure that the exhaust system is adequate to expel gases • Disconnect the battery cables before servicing the engine/ discharged from the engine.

- Page 5 SAFETY INSTRUCTIONS • Do not wear loose clothing or jewelry when servicing ABYC, NFPA AND USCG PUBLICATIONS FOR equipment; tie back long hair and avoid wearing loose INSTALLING DIESEL ENGINES jackets, shirts, sleeves, rings, necklaces or bracelets that Read the following ABYC, NFPA and USCG publications could be caught in moving parts.

- Page 6 A detailed 40 page Marine Installation Manual covering gasoline and diesel engines and generators is provided with each unit sold. Additional copies can be obtain off our website in pdf form. www. westerbeke.com & Engines Generators...

-

Page 7: Table Of Contents

TABLE OF CONTENTS Parts Identification ..........Water Heater ............. Introduction ............DC Electrical System ......... Warranty Procedures ........3 Alternator Troubleshooting ......25 Serial Number Location ........ .4 Battery ............26 Wiring Diagrams/Schematics ...... 27 Control Panels ....; ........Engine Troubleshooting ........ -

Page 8: Parts Identification

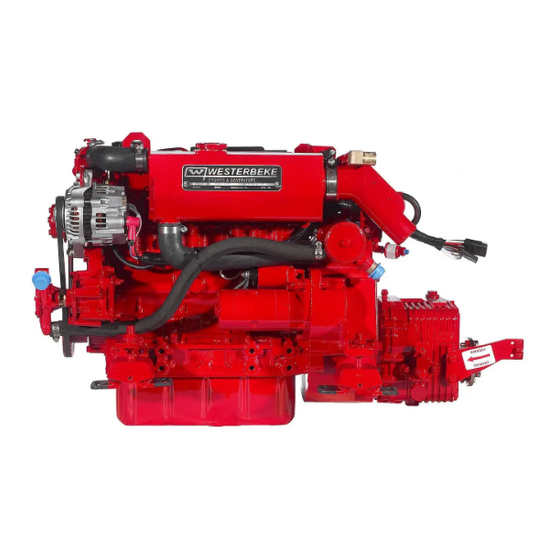

PARTS IDENTIFICATION COOLANT PRESSURE CAP WATER INJECTED EXHAUST ELBOW THERMOSTAT ASSEMBLY 2DACIRCUIT BREAKER WATER HEATER CONNECTION REAR FRONT BLOCK SIDE OIL FILL COOLANT DRAIN HOSE ZINC OIL DRAIN HOSE ANODE OIL COOLER RIGHT SIDE INTAKE/AIR FILTER FRONT LIFT PUMP DC ALTERNATOR RAW WATER PUMP REAR UNIT I.D. -

Page 9: Introduction

OF THE FURNISHING OR USE OF SUCH SOFTWARE. provided and a technical manual is available from your WESTERBEKE customers should keep in mind the time WESTERBEKE dealer. If you are planning to install this span between printings of WESTERBEKE product software equipment, contact your WESTERBEKE dealer for and the unavoidable existence of earlier WESTERBEKE WESTERBEKE'S installation manual. -

Page 10: Serial Number Location

(see the this information on the illustration of the name plate shown separately furnished Parts List). Insist upon WESTERBEKE below, as this will provide a quick reference when seeking packaged parts because will fit or generic parts are frequently technical information and/or ordering parts. -

Page 11: Control Panels

ADMIRAL CONTROL PANEL DESCRIPTION When the engine is shut down with the key switch turned off, the water temperature gauge will continue to register the last This manually-operated control panel is equipped with a temperature reading indicated by the gauge before electrical KEY switch and RPM gauge with an ELAPSED TIME power was turned off. -

Page 12: Captains Panel

CAPTAIN CONTROL PANEL DESCRIPTION The panel also includes an alann buzzer for low OIL PRESSURE or high COOLANT TEMPERATURE. The This manually-operated control panel is equipped with a RPM gauge is illuminated when the KEY switch is turned on KEY switch, an RPM gauge, PREHEAT and START but- and remains illuminated while the engine is in operation. -

Page 13: Diesel Fuel, Engine Oil And Engine Coolant

A coolant recovery tank kit is supplied with each ENGINE OIL WESTERBEKE diesel engine. The purpose of this recovery Use a heavy duty engine oil with an API classification of CF, tank is to allow for engine coolant expansion and contraction CG-4, CH-4 or CI-4. -

Page 14: Preparations For Initial Start-Up

PREPARATIONS FOR INITIAL START -UP PRESTART INSPECTION Before starting your engine for the first time or after a pro- longed layoff, check the following items: Check the engine oil level. Add oil to maintain the level PLASTIC RECOVERY TANK at the high mark on the dipstick. Turn on the fuel supply, then check the fuel supply and examine the fuel filter/water separator bowl for contami- nants. -

Page 15: Starting/Stopping Procedure

STARTING/STOPPING PROCEDURE THE STARTING SYSTEM 5. Should the engine not start when the START button is depressed for 10 to 20 seconds, release both buttons and The models in this manual have a 12V DC electric starter wait 30 seconds; repeat the procedure above and preheat assisted by a DC air intake heater for both normal and cold Never run the starter for more than 30 seconds. -

Page 16: Warning Lights, Alarms And Circuit Breaker

WARNING LIGHTS, ALARMS & CIRCUIT BREAKER ALTERNATOR WARNINGS LOW OIL PRESSURE ALARM SWITCH The Captain Control Panel indicates alternator low discharge A low oil pressure alarm switch is located off the engine's with a red warning light. oil gallery. This switch's sensor monitors the engine's oil pressure. -

Page 17: Engine Break-In Procedure

ENGINE BREAK-IN PROCEDURE DESCRIPTION 3. While using the vessel, run the engine at various engine speeds for the first hours. Avoid prolonged periods of Although your engine has experienced a minimum of one idling. hour of test operations at the factory to make sure accurate 4. -

Page 18: The Daily Operation

THE DAILY OPERATION CHECK LIST STARTING THE ENGINE Follow this check list each day before starting your engine. NOTE: See STARTING/STOPPING PROCEDURE in this Record the hourmeter reading in your log (engine hours manual for more detailed instructions. relate to the maintenance schedule.) 1. -

Page 19: Maintenance Schedule

MAINTENANCE SCHEDULE will In order to use this Maintenance Schedule, it be neces- WARNING: Never attempt to perform any service sary to log your engine hours. Use your engine hourmeter or record your engine hours by running time. while the engine is running. Wear the proper safety NOTE: equipment such as goggles and gloves, and use the Many of the following maintenance procedures are... - Page 20 300 hours or at winterizing. Remove raw water pump and inspect the pump's Raw Water Pump Drive shaft end and the slotted drive gear for wear. Replace components as needed. *WESTERBEKE recommends this service be performed by an authorized mechanic. Engines & Generators...

-

Page 21: Cooling System

When the engine is started cold, external coolant flow is pre- vented by the closed thermostat (although some coolant flow Westerbeke marine diesel engines are designed and equipped is bypassed around the thermostat to prevent the exhaust for fresh water cooling. Heat produced in the engine by com- manifold from overheating). -

Page 22: Thermostat

COOLING SYSTEM Refilling the Coolant Replacing the Thermostat After replacing the engine block drain plug, dose the heat Remove the cap screws and disassemble the thermostat hous- exchanger's coolant petcock. Then pour clean, premixed ing as shown. When installing the new thermostat and gas- coolant into the manifold and when the coolant is visable in ket, apply a thin coat of sealant on both sides of the gasket the manifold, start the engine and run it at slow idle. -

Page 23: Heat Exchanger

COOLING SYSTEM Changing the Raw Water Pump Impeller NOTE: Also follow the above procedure after having nm hard aground. Close the raw water intake valve. Remove the pump cover and, with the aid of two small screwdrivers, carefully pry the If the engine temperature gauge ever shows a higher than impeller out of the pump. -

Page 24: Air Intake/Silencer

COOLING SYSTEM Zinc Anode If the zinc anodes need replacement, hold the hex boss into which the zinc anode is threaded with a wrench while loos- A zinc anode, or pencil, is located in the raw water cooling ening the anode with another wrench. This prevents the hex circuit within the heat exchanger. -

Page 25: Fuel System

FUEL SYSTEM DIESEL FUEL FUEL FILTERS Use No. 2-D (SAE 1313) diesel fuel with a Cetane rating The fuel injection pump and the fuel injectors are precisely of #45 or higher. Grade of diesel fuel according to ASTM manufactured and they must receive clean diesel fuel, free D975. -

Page 26: Clow Plugs

GLOW PLUGS DESCRIPTION Re-install the plugs in the engine and test them again. plugs should get very (at the terminal end) within 7 to 15 glow plugs are wired through the preheat solenoid. seconds. If the plugs don't heat up quickly, check for a short When PREHEAT pressed... -

Page 27: Engine Lubricating Oil

ENGINE LUBRICATING OIL LUBRICATION DIAGRAM Replacing the Oil Filter. When removing the used oil fil- ter, you may find it helpful and cleaner to punch a hole in the upper and lower portion of the old filter to drain the OIL PRESSURE oil from it into a container before removing it. -

Page 28: Oil Pressure

An oil pressure relief valve is located on the engine block just below the injection pump. This valve opens at appoximately 50 psi [343 kpa] and maintains that pressure. OIL PRESSURE LOCATED JUST UNDER THE FUEL INJECTION PUMP ON THE ENGINE BLOCK. /"ttV'/WESTERBEKE Enaines & Generators... -

Page 29: Remote Oil Filter

Contact your WESTERBEKE dealer for more information. engine room bulkhead. NOTE: Westerbeke is not responsible for engine failure due to NOTE: Refer to ENGINE OIL CHANGE in this manual for incorrect installation of the Remote Oil Filter. -

Page 30: Water Heater

WATER HEATER WATER HEATER INSTALLATIONS The pressure cap on the engine's manifold should be aft~r installed the engine's cooling system is filled with This engine is equipped with connections for the plumbing of coolant. Finish filling the cooling system from the remote engine coolant to transfer heat to an on-board water heater. -

Page 31: Dc Electrical System

DC ELECTRICAL SYSTEM ALTERNATOR 1. Start the engine. 2. After the engine has run for a few minutes, measure the The charging system consists of a DC belt driven alternator starting battery voltage at the battery terminals using a with a voltage regulator, an engine DC wiring harness, a multimeter set on DC volts. -

Page 32: Battery

DC ELECTRICAL SYSTEM 7. Now check the voltage between the alternator output ter- Checking the Service Battery minal (B+) and ground. If the circuit is good, the voltage at Check the voltage of the service battery. This battery should the alternator will be the same as the battery, or if an isola- have a voltage between 13 and 14 volts when the engine is tor is in the circuit the alternator voltage will be zero. -

Page 33: Wiring Diagrams/Schematics

PROPULSION ENGINE WIRING SCHEMATIC #039144 PREHEAT n_flJUl _ _ _ _ I - - 1 SOL t--t---.,-<,1 : GLOWPI.UGS "l T[fi.NATO!l NO TIT: THIS PRODUCT IS PR0T[CT[O BY A MANUAL R[S[T CIRCUIT BR[AM[R LOCATED N£AR TN[ STARTER ElC[SSIV( CURRENT Will CAUSE HH BREAKER TO TRIP AND Hl£ ENGINE WILL l 1FT PUMP SHUT DOWN. - Page 34 PROPULSION ENGINE WIRING DIAGRAM #039144 l.l TERNATOR r.L~-rro-Aiil'i lloi PNK ~------ 1 5E£ NOTE I ...J 5C7S""~ +ili "" '""' li.AIIill' . . . ro~~c. o~ foEM~O ~O~~L~ lOPT CONF'IGUIU.TIDN SHOWN IS FOR i5A OLDER MODELS MAY HOT HAVE CONNECTOR FOR RUN SOL ENOl D AND BLACI( WIRE IS CONN[CT£0 PIL;"' TO TERM I HAL ON SOlENOID...

-

Page 35: Engine Troubleshooting

ENGINE TROUBLESHOOTING The following troubleshooting table describes certain problems NOTE: The engines electrical system is protected by a 20 relating engine service, the probable causes of these problems, ampere manual reset circuit breaker located on a bracket at and the recommendations to overcome these problems. the back of the engine. - Page 36 Remove the wire attached to the sender terminal at the terminals), the ground side will not necessarily be connected sender and connect it to ground. See if the gauge reads re~ding to the block. full scale, which is the normal for this situation. -.v- WESTERBEKE Engines & Generators...

-

Page 37: Tachometer

TACHOMETER TACHOMETER/HOUR METER NOTE: Current model tachometers use a coarse adjustment dial to set the tachometer to the crankshaft pulley rpms. The The tachometer/hour meter used in propulsion engine instru- calibrating screw is then used for fine tuning. ment panels contains two separate electrical circuits with a common ground. -

Page 38: Engine Adjustments

ENGINE ADJUSTMENTS DRIVE BELT ADJUSTMENT ADJUSTING THE IDLE SPEED Proper inspection, service and maintenance of the drive belts 1. Loosen the locknut on the idle adjustment bolt on the is important for the efficient operation of your engine (see fuel injection pump. Drive Belts under MAINTENANCE SCHEDULE). -

Page 39: Testing Engine Compression

ENGINE ADJUSTMENTS NOTE: WESTERBEKE recommends that the following engine adjust- ments be peiformed by a competent engine mechanic. The information below is provided to assist the mechanic. TESTING ENGINE COMPRESSION FUEL INJECTORS Make certain the oil level (dipstick) is at the correct level and In case of severe vibrations and detonation noise, have the the air intake filter is clean. -

Page 40: Valve Adjustments

ENGINE ADJUSTMENTS NOTE: WESTERBEKE recommends that the following engine adjust- ments be peiformed by a competent engine mechanic. The information below is provided to assist the mechanic. VALVE CLEARANCE ADJUSTMENT (b) With No.1 piston at top dead center on the compression stroke, the rocker arms will not be moved when the Make the following adjustments when the engine is cold. -

Page 41: And B.w. Transmission

J.S. AND B. W. TRANSMISSIONS DESCRIPTION If the throw distance (or travel) of the remote cable is too short, the gear box lever cannot fully engage the transmission The transmission's gear ratio is 2.47:1. The manual into FORWARD or REVERSE. In this situation, the trans- transmission turns a righthand propeller when engaged in mission's internal clutches will wear prematurely and the forward. - Page 42 If any seal on the transmission shows signs of leaking, have while sailing. Leaving the transmission in NEUTRAL while the transmission looked at by a qualified WESTERBEKE sailing alleviates unnecessary drag on the vessel because the dealer. This problem, especially concerning the rear seal, is propeller is able to freewheel (spin).

-

Page 43: Borg Warner Velvet Drive Transmission

This centers the actuating lever on the trans- mission. With the control in this position, hydraulic power is Before leaving the WESTERBEKE plant, each transmission Dextran III ATF completely interrupted and the output shaft of the transmis- undergoes a test run, with transmission fluid. - Page 44 BORG WARNER VELVET DRIVE TRANSMISSION Clean off the transmission and properly dispose of the used fluid. DEXTRON III ATF. Refill the transmission with quantity will vary depending on the transmission model and the installation angle. Fill through the dipstick hole. Check the dipstick for the proper fluid level.

- Page 45 The waters, maintenance, etc. it might only last half that time. transmission will eventually fail. WESTERBEKE recommends having a spare cooler aboard. Either case requires an immediate response: Install a new oil cooler.

- Page 46 CONNECTION OF GEAR BOX WITH PROPELLER threaded holes located above the shift cover on top of the gear housing. Refer to the WESTERBEKE parts list. HBW recommend a flexible connection between the transmission gearbox and the propeller shaft if the engine is CONTROL CABLES flexibly mounted, in order to compensate for·angular...

-

Page 47: Zf Transmissions

ZF MARINE TRANSMISSIONS INITIAL OPERATION OPERATING TEMPERATURE All HBW marine transmissions are test-run on a test stand The maximum permissible ATF temperature should not exceed with the engine at the factory prior to delivery. For safety 230° (110}. This temperature can only be reached for a short reasons the fluid is drained before shipment. - Page 48 WESTERBEKE reconunends having a spare cooler aboard. Inspect the gear shift cable, linkage, and attachments. Look for con-osion of the end fittings, cracks or cuts in the conduit, and bending of the actuator rods.

-

Page 49: Prm Newage Transmissions

PRM NEWAGE TRANSMISSIONS MODELS 80 AND 120 Push a suction pump hose down through the dipstick hole to the bottom of the housing and suck out the fluid. (If space allows, use the transmission drain). Remove the drain plug from the bottom of the transmission (1" with sealing washer) THE MODEL 720 HAS A BREATHER and allow the fluid to drain into a container, then reinstall the FITTING ON THE... - Page 50 TRANSMISSIONS LIMITED or a NEWAGE distributor to the correct specifications .. or your WESTERBEKE dealer. NEW AGE TRANSMISSIONS LTD. has distributors around Warranty the world. Listed here are those in the United States.

-

Page 51: Transmission Troubleshooting

WESTERBEKE dealer or an again. If it is still stiff, check the cable for kinks or authorized marine transmission facility. -

Page 52: Propeller Recommendation Chart

2. 72:1........200 x 11P........... 2 Blade 200 x 9P..........3 Blade 2.99:1 ........220 x 12P........... 2 Blade 220 x 10P..........3 Blade NOTE: For reductions not included, consult the WESTERBEKE factory for recommendations. -

Page 53: Lay-Up And Recommissioning

LAY-UP & RECOMMISSIONING GENERAL Fuel System [Gasoline] Many owners rely on their boatyards to prepare their craft, Top off your fuel tanks with unleaded gasoline of 89 octane including engines and generators, for Jay-up during the or higher. A fuel conditioner such as Sta-Bil gasoline off-season or for long periods of inactivity. - Page 54 Westerbeke engine to see if external items such as drive belts battery connections are shut off before attempting to remove or coolant hoses need replacement. Check your basic spares the starter.

- Page 55 44A, 448, 44C FOUR ENGINE SPECIFICATIONS SPECIFICATIONS FUEL SYSTEM Engine Type Diesel, four-cycle, tour-cylinder, fresh water- General Open flow, self priming. cooled, vertical in-line overhead valve Fuel No.2 diesel oil (cetane rating of 45 or higher). mechanism .. Fuel Injection Pump In-line plunger type (BOSCH).

-

Page 56: Three Engine Specifications

35C, 350, 35E THREE ENGINE SPECIFICATIONS SPECIFICATIONS FUEl SYSTEM Engine Type Diesel, four-cycle, three-cylinder, fresh water- General Open flow, self priming. cooled, vertical in-line overhead valve Fuel No. 2 diesel oil (cetane rating of 45 or higher). mechanism. Fuel Injection Pump In-line plunger type (BOSCH). -

Page 57: 44 Four And 35 Three Torque Specifications

44 FOUR AND 35 THREE TORQUE SPECIFICATIONS MAJOR BOLTS AND NUTS TORQUE Clamp Width Bolt or Nut Diameter Pitch across flats length kg -m ft- lb Alternator Bracket 3.8-5.3 27-38 36.6 Back Plate 3.3-4.8 24-35 32.5 Connecting Rod Cap 3.55±0.25 27±7 2 34.8±2.5 Coolant Pump... -

Page 58: Standard Hardware

STANDARD HARDWARE BOLT HEAD MARKINGS Metric bolt class numbers identify bolts by their strength with 10.9 the Bolt strength classes are em bossed on the head of each bolt. strongest. Customary (inch) bolts are identifed by markings two to grade eight (strongest). -

Page 59: Standard And Metric Conversion Data

STANDARD AND METRIC CONVERSION DATA LENGTH-DISTANCE Inches (in) x 25.4 = Millimeters (mm) x .0394 = Inches Feet (ft) x .305 = Meters (m) x 3.281 = Feet Miles x 1.609 = Kilometers (km) x .0621 = Miles VOLUME Cubic Inches (in x 16.387 = Cubic Centimeters x .061 =i n Imperial Pints (IMP pt) x .568 = Liters (L) x 1.76 = IMP pt Imperial Quarts (IMP qt) x 1.137 = Liters (L) x.88 = IMP qt... -

Page 60: Suggested Spare Parts

SUGGESTED SPARE PARTS WESTERBEKE MARINE DIESEL ENGINES CONTACT YOUR WESTERBEKE DEALER FOR SUGGESTIONS AND ADDITIONAL INFORMATION ---- HARDWARE KIT RAW WATER PUMP IMPELLER/GASKET AIR INTAKE FILTER WESTERBEKE RECOMMENDS CARR,YING ENOUGH SPARE ENGINE OIL (YOUR BRAND) FOR AN OIL CHANGE (5 OTS.) AND A GALLON OF PREMIXED COOLANT. - Page 61 Engines & Generators 1172-6-2012...

Need help?

Do you have a question about the 44 A FOUR-35C THREE and is the answer not in the manual?

Questions and answers