O.S. engine MAX-21XM Owner's Instruction Manual

Engine o.s. max-21xm

Hide thumbs

Also See for MAX-21XM:

- Owner's instruction manual (15 pages) ,

- Owner's instruction manual (15 pages)

Table of Contents

Advertisement

Quick Links

It is of vital importance, before attempting to

operate your engine,

'SAFETY INSTRUCTIONS AND WARNINGS'

section on pages 2-3 of this booklet and to

strictly adhere to the advice contained

therein.

•

Also, please study the entire contents of

this instruction manual, so as to familiarize

yourself with the controls and other

features of the engine.

•

Keep these instructions in a safe place so

that you may readily refer to them whenever

necessary.

•

It is suggested that any instructions

supplied with the model radio control

equipment, etc., are accessible for checking

at the same time.

to read the general

Advertisement

Table of Contents

Summary of Contents for O.S. engine MAX-21XM

- Page 1 It is of vital importance, before attempting to operate your engine, to read the general 'SAFETY INSTRUCTIONS AND WARNINGS' section on pages 2-3 of this booklet and to strictly adhere to the advice contained therein. • Also, please study the entire contents of this instruction manual, so as to familiarize yourself with the controls and other features of the engine.

-

Page 2: Table Of Contents

CONTENTS SAFETY INSTRUCTIONS AND WARNINGS ABOUT YOUR O.S. ENGINE FITTING THE GLOWPLUG, INSTALLATION OF THE CARBURETTOR BASIC ENGINE PARTS PIPING, INSTALLATION, LINKAGES FUEL AND GLOWPLUG FLEXIBLE DRIVE SHAFT, PROPELLER, BEFORE STARTING THE ENGINE ADJUSTING THE CARBURETTOR, REALIGNMENT OF MIXTURE CONTROL VALVE STARTING RUNNING-IN (''Breaking-in'') ADJUSTMENT,CARBURETTOR CLEANLINESS... -

Page 3: Safety Instructions And Warnings About Your O.s. Engine 2

SAFETY INSTRUCTIONS AND WARNINGS ABOUT YOUR WARNINGS O.S. ENGINE • Never touch, or allow any object to come Remember that your engine is not a " toy ", but a highly into contact with, the rotating propeller. efficient internal-combustion machine whose power is capable of harming you, or others, if it is misused. - Page 4 NOTES This engine was designed for model boats. When starting your engine, use an electric Do not attempt to use it for any other purpose. starter.The wearing of safety glasses is also strongly recommended. Mount the engine in your model securely, following manufacturers' recommendations, using When handling the boat immediately...

-

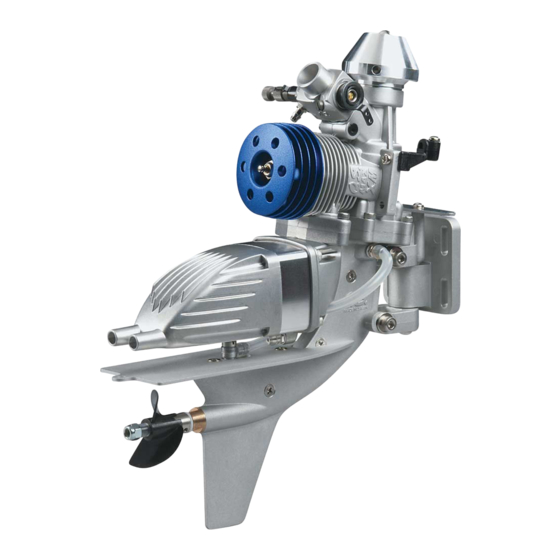

Page 5: Fitting The Glowplug, Installation Of The Carburettor

The O.S. MAX-21XM is a high-performance FITTING THE GLOWPLUG water-cooled outboard marine engine for small Fit washer to glowplug and insert and medium-size radio-controlled outboard carefully into cylinder-head, making boats. It is of sturdy construction and designed sure that it is not cross-threaded before for easy maintenance. -

Page 6: Basic Engine Parts

BASIC ENGINE PARTS Flywheel(OS No.2J) Carburettor(OS TYPE 20J) Needle-Valve Mixture Control Screw Crankcase Throttle Lever Water-Cooled Cylinder Head Throttle Linkage Bracket Steering Arm E-2050 Silencer Transom Mounting Plate Water Inlet Tube Oil Transfer Tube Exhaust Outlets Cavitation Plate Cooling Water Pickup Outboard Unit Lower Housing Carbon-Reinforced Propeller Skeg... -

Page 7: Piping, Installation, Linkages

PIPING LINKAGES Steering Linkage Connect the water inlet tube (L=170mm) and oil transfer pipe Use a high-torque servo, preferably with dual pushrods as (L=65mm) securely as shown on page 5. In the event of either shown below.(A single pushrod will bend easily which results tube becoming damaged, it should be replaced with best in poor steering accuracy.) quality 5.5mm OD 2.5mm ID silicone tubing. -

Page 8: Fuel And Glowplug

The O.S. No.8 glowplug is recommended and one is supplied For consistent performance and long engine life, it is essential with this engine. The MAX-21XM may not always run so well to use fuel containing AT LEAST 18%(volumetric ratio)best- with other types of plug. -

Page 9: Flexible Drive Shaft, Propeller, Before Starting The Engine

PROPELLER corroded. Engine tends to cut when idling. The MAX-21XM's special carbon-fibre propeller has a Starting qualities deteriorate. diameter of 42mm and a P/D ratio of 1.2. If any other propeller is substituted, make sure that it is properly balanced. -

Page 10: Adjusting The Carburettor, Realignment Of Mixture Control Valve

Before starting the engine for the first run of the day, ADJUSTING THE CARBURETTOR remove the glowplug and check the engine by rotating the Two adjustable controls are provided on this carburettor. flywheel by hand. It should rotate smoothly. Now turn the engine with an electric starter until fuel is drawn into the The Needle-Valve: carburettor. -

Page 11: Starting

Heat the glowplug by connecting the battery leads. Mixture Control Valve Nozzle (Mixture Control Screw) Make sure that the direction of rotation of the electric starter is Clockwise- correct, namely, clockwise. rotation If necessary, reverse leads on battery to provide clockwise rotation. Bring the starter into contact with the flywheel and depress the starter Throttle Rotor Hole... -

Page 12: Running-In (''Breaking-In'')

It is necessary to warm up the engine by running it at RUNNING-IN (''Breaking-in'') around the idling setting for a while after starting, as with For long life and high-performance, every engine needs to be the engine of a full size boat. High r.p.m. operation without warming up will shorten engine life or damage it. -

Page 13: Adjustment,Carburettor Cleanliness 12

Aim to have the model achieving its highest performance ADJUSTMENT after the engine has consumed about one litre of fuel. WARNING : Having found the optimum needle-valve setting, make a Running the engine with the boat out of the water, with- note of the number of turns necessary to re-establish this from the closed position. -

Page 14: Carburettor Cleanliness

With the optimum mixture control valve position, light CARBURETTOR CLEANLINESS smoke is visible during high-speed running and engine Proper functioning of the carburettor depends on its small fuel revolutions increase smoothly during acceleration. orifices remaining clear. Remember that, if the engine is operated with the fuel/air The minute particles of foreign matter that are present in any mixture slightly too lean, it will overheat and run unevenly fuel, can partially obstruct these orifices and upset mixture... -

Page 15: Care And Maintenance

To reduce such risks, it is helpful to inject some corrosion CARE AND MAINTENANCE inhibiting oil into the engine's air intake. Rotate the engine many times to distribute the oil to all the To ensure that you obtain long life and peak performance working parts. -

Page 16: Trouble Shooting When The Engine Fails To Start

TROUBLE SHOOTING WHEN THE ENGINE FAILS TO START Four key points For quick, reliable starting, the following four conditions are required. 1 Good compression. 2 Adequate "glow" at glowplug. 3 Correct mixture. 4 Sufficient electric starter rotating speed. If the engine fails to start, or does not keep running after being started, check symptoms against the following chart and take necessary corrective action. -

Page 17: Exploded View

EXPLODED VIEW N.+M3X10 23-F N.+M4X8 C.M3X12 23-G 13-3 N.M3X10 C.M4X12 C.M2.6X18 23-C1 23-C 23-J 23-C2 11-1 23-H N.M3X12 23-I C.M2.6X18 C.M4X12 23-L F.M3X8 13-1 23-K 13-2 F.M3X10 23-B 23-D C.M2.6X10 C.M3X10 23-A 23-E 23-M C.M2.6X8 Type of screw C Cap Screw M Oval Fillister-head Screw F Flat Head Screw N Round Head Screw S Set Screw... -

Page 18: Parts List

PARTS LIST Description Description Code No. Code No. Flywheel Assembly (No.2J) Outboard Unit Fixing Screw (4pcs.) 7 1802 100 2 3871 130 Flywheel Nut Crankcase Rear Housing 2 7721 700 2 3861 000 Crankshaft Ball Bearing ( Outer ) PTO Shaft Ball-Bearing ( Outer ) 4 1614 000 2 2631 019 Crankcase... -

Page 19: Carburettor Exploded View & Parts List

CARBURETTOR EXPLODED VIEW & PARTS LIST S.3X3 S.3X3 Code No. Description Code No. Description 2 4981 405 Throttle Lever Assembly 2 2681 953 Fuel Inlet 2 6381 501 2 7881 900 Set-screw Needle Valve Assembly 2 5381 203 Carburettor Rotor 2 4981 959 Needle 2 6781 309... -

Page 20: Three View Drawing And Specification

THREE VIEW DRAWING SPECIFICATION Displacement 3.46 c.c. ( 0.211 cu.in.) Bore 16.6 mm ( 0.654 in.) Stroke 16.0 mm ( 0.630 in.) Practical R.P.M. 3,000~25,000 r.p.m. Power output 1.3 bhp / 25,000r.p.m. Weight 670g ( 23.6 oz.) 37.5 48.5 149.5... - Page 21 MEMO...

- Page 22 6-15 3-Chome Imagawa Higashisumiyoshi-ku Osaka 546-0003, Japan TEL. (06) 6702-0225 FAX. (06) 6704-2722 URL : http://www.os-engines.co.jp Copyright 2000 by O.S.Engines Mfg. Co., Ltd. All rights reserved. Printed in Japan. 100101...

Need help?

Do you have a question about the MAX-21XM and is the answer not in the manual?

Questions and answers