Lochinvar 502 Service Manual

Copper-fin ii/iie pool heater

Hide thumbs

Also See for 502:

- Installation & operation manual (80 pages) ,

- Service manual (44 pages) ,

- User's information manual (12 pages)

Table of Contents

Advertisement

CPX-SER Rev A

Copper-fin II/IIE

Pool Heater

Service Manual

Models: 502 - 2072

This manual must only be used

WARNING

by a qualified heating installer

/ service technician. Read all

instructions,

including

this

manual and the Installation

and Operation Manual, before

installing. Perform steps in the

order given. Failure to comply

could result in severe personal

injury, death, or substantial

property damage.

Save this manual for future reference.

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Lochinvar 502

- Page 1 CPX-SER Rev A Copper-fin II/IIE Pool Heater Service Manual Models: 502 - 2072 This manual must only be used WARNING by a qualified heating installer / service technician. Read all instructions, including this manual and the Installation and Operation Manual, before installing.

-

Page 2: Table Of Contents

Contents 2. MAINTENANCE CONTENTS ................ 2 Maintenance and Annual Startup ........ 17-24 Hazard Definitions .............. 2 3. TROUBLESHOOTING PLEASE READ BEFORE PROCEEDING ......3 Before Troubleshooting ............ 25 Handling Ceramic Fiber Materials ........3 Check Control Module Fuses .......... 25 When servicing appliance .......... -

Page 3: Please Read Before Proceeding

Copper-fin II/IIE Pool Heater Service Manual Please read before proceeding Installer – Read all instructions, including When servicing appliance – WARNING this manual and the Installation and • To avoid electric shock, disconnect electrical supply Operation Manual, before installing. before performing maintenance. Perform steps in the order given. -

Page 4: What Is In This Manual

Copper-fin II/IIE Pool Heater Service Manual What is in this manual? Maintenance Service The Copper-fin display • Service and maintenance schedules • Address reported problems • Display panel readout, buttons and their functions • Inspect appliance area and appliance interior Control module inputs •... -

Page 5: Service

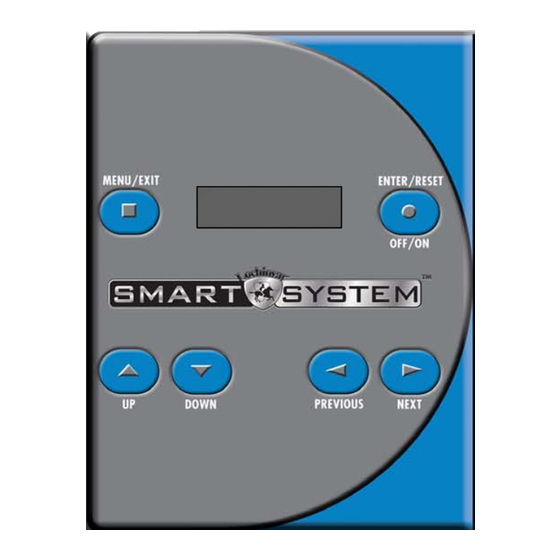

Copper-fin II/IIE Pool Heater Service Manual Service The Copper-fin display • Hold 5 seconds to enter code Input Mode (Menu Mode) • Press to turn heater off or back on • 2-Line / 16 character LCD display • Press to move up one level •... -

Page 6: Control Inputs

Copper-fin II/IIE Pool Heater Service Manual Service Control inputs POOL SUPPLY SENSOR SENSOR CONNECTION BOARD POOL SENSOR VOLTAGE CONNECTION BOARD CASCADE ENABLE LOUVER PROVING SWITCH SMART (FIELD PROVIDED) SYSTEM CONTROL BOARD MODBUS BOARD MODBUS (OPTIONAL) INLET TEMPERATURE SENSOR OUTLET TEMPERATURE/ LIMIT SENSOR LOW WATER CUTOFF (OPTIONAL) -

Page 7: Control Outputs

Copper-fin II/IIE Pool Heater Service Manual Service (continued) Control outputs MODBUS VOLTAGE MODBUS CONNECTION BOARD 0-10V BOARD (OPTIONAL) FIRING RATE CASCADE THREE WAY VALVE LOUVER RELAY BUILDING MANAGEMENT SYSTEM RUN TIME CONTACTS ALARM CONTACTS SMART SYSTEM ALARM CONTROL (OPTIONAL) BOARD HEATER PUMP HOT SURFACE IGNITER... -

Page 8: General Operation

Copper-fin II/IIE Pool Heater Service Manual Service General Operation How the appliance operates Access modes The Copper-fin uses a finned copper tube heat exchanger to User transfer heat from the flue products to the water. An electronic The user can adjust pool set point by entering the USER code control module monitors various inputs to initiate a call for (0704). -

Page 9: Sequence Of Operation

5. Once the HSI is hot, the trial for ignition begins with the opening of the gas valve. OUT: 123.9F(129) HTR: POSTPURGE, PREPURGE 6. If the SMART SYSTEM control does not sense flame, then OUT: 123.9F(129) it will lock out. 7. If... -

Page 10: Display Panel Menu Access

Copper-fin II/IIE Pool Heater Service Manual Service Display panel menu access Table 1B_Use this procedure to access menus from the display panel... -

Page 11: Display Panel Parameter Access

Copper-fin II/IIE Pool Heater Service Manual Service (continued) Display panel parameter access Table 1C_This is a typical example of accessing a parameter, shown for parameter H1, PH pump delay Cascade... -

Page 12: Parameter Table

Copper-fin II/IIE Pool Heater Service Manual Service Parameter table Table 1D_This table lists SMART SYSTEM control module parameters and where to access them User Access Installer Access Menu Description Item Page Display Modify Display Modify User Code Date and Time... -

Page 13: Viewable And Changeable Control Parameters

B7: PH supply high limit the unit. When a new software version becomes available, the The SMART SYSTEM control also includes an integrated auto existing control can be replaced with a new control to update reset high limit (ARHL) feature, based on the pool supply the software. - Page 14 In order to prevent the water in the heater from freezing, the The burner cycles parameter shows the total number of times SMART SYSTEM control turns on the unit pump whenever the unit has attempted to fire. This parameter can be viewed by the inlet temperature goes below the minimum temperature.

- Page 15 Copper-fin II/IIE Pool Heater Service Manual Service (continued) E: Anti-cycling F3: ModBus timeout When the heater is being controlled or is receiving temperature E1: Anti-cycle time readings through ModBus, the information sent to the heater Once a PH demand has been satisfied, a set amount of time must be refreshed periodically.

- Page 16 H3: PH pump purge Once the time period defined by parameter H2 has elapsed, the SMART SYSTEM control will turn the unit pump on at the start of the next call for heat, then wait a period of time before firing the heater.

-

Page 17: Maintenance

Copper-fin II/IIE Pool Heater Service Manual Maintenance Maintenance and annual startup Table 2A_Service and Maintenance Schedules Service technician Owner maintenance (see the following pages for instructions) (see the User’s Information Manual for instructions) • Check appliance area General: • Address reported problems •... - Page 18 Copper-fin II/IIE Pool Heater Service Manual Maintenance Follow the service and maintenance procedures given throughout this manual and in component literature WARNING shipped with the appliance. Failure to perform the service and maintenance could result in damage to the appliance or system. Failure to follow the directions in this manual and component literature could result in severe personal injury, death, or substantial property damage.

- Page 19 Copper-fin II/IIE Pool Heater Service Manual Maintenance (continued) Check relief valve Inspect/replace hot surface igniter This unit uses a proven hot surface ignition module and a 1. Inspect the relief valve and lift the lever to verify flow. hot surface igniter. The hot surface ignition module is not Before operating any relief valve, ensure that it is piped with repairable.

- Page 20 The following cleaning procedure must only 1. Set the SMART SYSTEM control module display to be performed by a qualified serviceman or installer. Proper Parameter Mode and check all settings. See Section 1 of this service is required to maintain safe operation.

- Page 21 Copper-fin II/IIE Pool Heater Service Manual Maintenance (continued) Checking combustion air pressure Access to the burner will require the following steps: Turn off main electrical power to the appliance. The combustion air fans are factory pre-set and should not require adjustment in most cases. Follow the steps in the Turn off main manual gas shutoff to the appliance.

- Page 22 Copper-fin II/IIE Pool Heater Service Manual Maintenance Adjusting combustion air pressure Checking manifold gas pressure The following is a recommended method for setting the Turn the appliance power switch to the “OFF” position. combustion air pressure. The following pressure settings are Remove the upper outer access panels.

- Page 23 (UNDER CAP PRESSURE SCREW) INLET OUTLET TO BARBED MANOMETER VALVE FITTING CONTROL KNOB TABLE 2B Net Manifold Pressure Regulator Pressure Less Front Chamber Pressure MODEL Nat. Gas 502 - 752 1.8'' w.c. 4.6’’ w.c. 992 - 2072 1.2'' w.c. 4.6’’ w.c.

- Page 24 Copper-fin II/IIE Pool Heater Service Manual Maintenance Inspect and clean the heat exchanger Turn off the main electrical power to the appliance. Turn off the main manual gas shutoff to the appliance. Remove the lower outer fron access door. Disconnect the manifold(s) from the gas train using the union(s) just below each gas valve.

-

Page 25: Troubleshooting

Copper-fin II/IIE Pool Heater Service Manual Troubleshooting Check control module fuses Label all wires prior to disconnection when WARNING servicing controls. Wiring errors can cause ALWAYS check control module fuses before improper and dangerous operation. Always NOTICE replacing control module or any major disconnect power to the appliance before components (blower, etc.). -

Page 26: Table 3A - Troubleshooting Chart - No Display

Copper-fin II/IIE Pool Heater Service Manual Troubleshooting Table 3A Troubleshooting Chart - No Display FAULT CAUSE CORRECTIVE ACTION • Check external line switch, fuse, or breaker. • Check position of ON/OFF switch. Turn switch to the - No 120 VAC supplied to unit. ON position. -

Page 27: Checking Temperature Sensors

Copper-fin II/IIE Pool Heater Service Manual Troubleshooting (continued) Checking temperature sensors The appliance temperature sensors (inlet water, outlet water, system water, tank water, flue, and outdoor air) are all resistance type devices. The following tables show the correct values for the sensors at various temperatures. Use an ohmmeter to read the resistance of the sensor at a known temperature. -

Page 28: Table 3C - Troubleshooting Chart - Noisy System

Copper-fin II/IIE Pool Heater Service Manual Troubleshooting Table 3C Troubleshooting Chart - Noisy System FAULT CAUSE CORRECTIVE ACTION - Gas supply problem. • Refer to the Gas Connections Section of the Installation Operation Manual detailed information concerning the gas supply. - Gas/air mixture problem. -

Page 29: Table 3D - Troubleshooting Chart - Fault Messages

Press the RESET button on the SMART SYSTEM display to reset.) The flame detector circuit is seeing a flame • Check supply voltage for proper polarity. Flame Sequence signal while the gas valve is de-energized. - Page 30 Press • If more than 2.6 amps replace the control module. the RESET button on the SMART SYSTEM display to reset.) The main control board has detected an • Replace the main control board.

- Page 31 Press damaged. the RESET button on the SMART SYSTEM display • Verify that the vent/air intake pipes are installed to reset.) correctly and there are no obstructions. • Refer to the Checking Manifold Gas Pressure and Combustion Analysis Procedure on pages 21 and 22 of this manual for the proper settings.

- Page 32 Replace the main control board if been corrected. Press necessary. the RESET button on the SMART SYSTEM • If 120 VAC is present on a call for heat and the pump is not operating, replace the pump. display to reset.) •...

- Page 33 • Check for jumper on air pressure switch. automatically after 5 minutes or may be The SMART SYSTEM control sensed that reset immediately once • Check for an unusually high negative draft in the vent the air pressure switch was closed before the stack.

- Page 34 Press the RESET button on the • Verify that the appliance is piped properly into the SMART SYSTEM display filter system. Refer to the Water Connections Section of to reset.) the Installation and Operation Manual for the proper piping methods.

- Page 35 Copper-fin II/IIE Pool Heater Service Manual Troubleshooting (continued) Table 3D (continued from previous page) Troubleshooting Chart - Fault Messages Displayed on Operator Interface FAULT DESCRIPTION CORRECTIVE ACTION • Establish a heating load to remove heat from the system. • Verify that the system is full of water and that all air has been properly purged from the system.

-

Page 36: Revision Notes

Revision Notes: Revision A (ECO #C11226) initial release. CPX-SER Rev A 9/12...

Need help?

Do you have a question about the 502 and is the answer not in the manual?

Questions and answers