Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Grizzly G9749

-

Page 1: Variable Speed

VARIABLE SPEED DRILL PRESS OWNER'S MANUAL COPYRIGHT © SEPTEMBER, 2006 BY GRIZZLY INDUSTRIAL, INC. WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC. #TS8502 PRINTED IN TAIWAN... - Page 2 ���� ������ �������� �������� ������ ������������ �� ��� ������ ������ ���������� ����������� ��� ������� �� ���� ������������������ ������� �� ����� ���������� ��� ������ ��� ������������ ����� �� ���� ������ ��� ������ �� ������� �������� ������� ��������� ����������� ������������� �� ������ ���...

-

Page 3: Table Of Contents

Machine Data Sheet ... 3 Identification ... 5 SECTION 1: SAFETY... 6 Safety Instructions for Machinery ... 7 Additional Safety for Drill Presses ... 8 SECTION 2: CIRCUIT REQUIREMENTS ... 9 110/220V Operation ... 9 Grounding ... 10 Extension Cords ... 10 SECTION 3: SETUP ... -

Page 4: Introduction

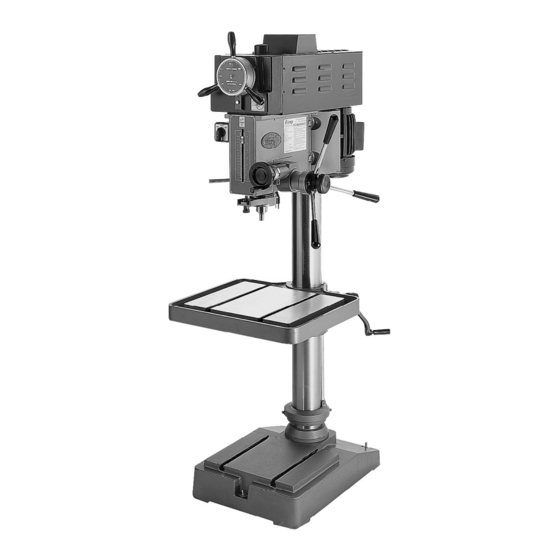

INTRODUCTION Foreword We are proud to offer the Model G9749 Variable Speed Drill Press. This machine is part of a grow- ing Grizzly family of fine metalworking machinery. When used according to the guidelines set forth in this manual, you can expect years of trouble-free, enjoyable operation and proof of Grizzly’s com-... -

Page 5: Machine Data Sheet

Customer Service #: (570) 546-9663 · To Order Call: (800) 523-4777 · Fax #: (800) 438-5901 MODEL G9749 VS DRILL PRESS Product Dimensions: Weight... 615 lbs. Length/Width/Height... 33-1/8 x 22 x 75 in. Foot Print (Length/Width)... 26 x 19 in. - Page 6 The information contained herein is deemed accurate as of 3/18/2007 and represents our most recent product specifications. Model G9749 Due to our ongoing improvement efforts, this information may not accurately describe items previously purchased. PAGE 2 OF 2 G9749 Variable Speed Drill Press...

-

Page 7: Identification

D. Depth Stop: Stops the quill travel at a pre-set drilling depth. E. Fine Downfeed Indicator: Indicates fine downfeed adjustments in 0.001" increments. G9749 Variable Speed Drill Press Identification Figure 2. Left side controls. Clutch Knob: Switches between rapid and fine downfeed control. -

Page 8: Section 1: Safety

����� ����������� ����� ��������� ��� �������� ������������������������������������� �� ����� ������� ��������� ���� ����� �� ����� ��� ��������� �� ��������� ����� �� �������� ������������������ ������������������������������������ ��������� ����������� G9749 Variable Speed Drill Press � � ��� ��� ������ �� ��� � ������ ������� �... -

Page 9: Safety Instructions For Machinery

��� �������� ��������� ���� ������ ����������������������������������������� �������������������������������������������� ������������������������������������� ��� ���� ���� ������ ��� �� ����� ��� ���� ��������� ������ ����� ���������� G9749 Variable Speed Drill Press ��� ������ ��������������������������������������� ����� ���� ���������� ��������� ������� ����� ����������������� ��� ����� ������ ����� ���������������������... -

Page 10: Additional Safety For Drill Presses

Use this and other machinery with caution and respect. Failure to do so could result in serious per- sonal injury, damage to equipment, or poor work results. G9749 Variable Speed Drill Press... -

Page 11: Section 2: Circuit Requirements

G9749 Variable Speed Drill Press Figure 3. L5-30 plug and receptacle. NOTICE The Model G9749 is prewired for 220V oper- ation. If you plan to rewire your machine for 110V, you must change the motor wir- ing, plug, and power receptacle. Consult... -

Page 12: Grounding

Use at least a 12 gauge cord no longer than 50 feet! • The extension cord must also contain a ground wire and plug pin. • A qualified electrician MUST size cords over 50 feet long to prevent motor damage. G9749 Variable Speed Drill Press... -

Page 13: Section 3: Setup

Shop Rags (for clean-up) ... As needed • Open end wrench ⁄ " ... 1 G9749 Variable Speed Drill Press Site Considerations Floor Load Refer to the Machine Data Sheet on Page 3 for the weight and footprint specifications of your machine. -

Page 14: Unpacking And Lifting

The Model G9749 weighs 615 lbs. You will need power lifting equipment and assistance to remove this machine from the pallet and position it. Inspect all lifting equipment and make sure that all is in perfect working order and is rated for the load before attempting to lift and move this drill press. -

Page 15: Mounting To Shop Floor

Mounting to Shop Floor The Model G9749 should be mounted to the floor. Because floor materials may vary, floor mounting hardware is not included. It is also necessary to level your machine with a precision level. Bolting to Concrete Floors... -

Page 16: Inventory

Remove this protective coating with a solvent cleaner or citrus-based degreaser such as Grizzly’s G7895 Degreaser. Some parts may need to be removed for thorough cleaning. For optimum performance from your machine, make sure you clean all moving parts or slid- ing contact surfaces that are coated. -

Page 17: Assembly

Use a ⁄ " wrench to tighten the shaft to the control base. G9749 Variable Speed Drill Press To install the table crank handle: Screw the table crank handle into the thread- ed hole on the table crank (see Figure 11). -

Page 18: Test Run And Spindle Break-In

Use the speed control to reduce the speed starting to 300 RPM and let the drill press run for a minimum of 10 minutes. Listen and watch for abnormal noises or vibrations. The machine should run smooth- — Unusual noises or vibrations should be... -

Page 19: Section 4: Operations

OMMEND that you read books, trade maga- zines, or get formal training before begin- ning any projects. Regardless of the con- tent in this section, Grizzly Industrial will not be held liable for accidents caused by lack of training. Wear safety glasses when operating this machine. -

Page 20: Installing/Removing Drill Bits

OFF could damage the variable speed mechanism. The Model G9749 drill press is capable of variable speeds from 300-2000 RPM. Refer to Choosing Speeds on Page 19 for the correct speed for the cutting tool and material being used. -

Page 21: Choosing Speeds

One-Piece Type T e n o n / P l u g C u t t e r s 3/8" – 1/2" 5/8" – 1" G9749 Variable Speed Drill Press Lubrication Suggestions Wood & Cast Iron ...None Plastics ... Soapy Water Brass ... -

Page 22: Drilling

Clamp the workpiece to the table before drilling. Quill Travel The Model G9749 has both a rapid and a fine downfeed control for quill travel. Quill travel can be set to a specific distance using the depth gauge and depth stop. - Page 23 (see Figure 16). Use the fine downfeed control to hold the quill in place while you unlock the quill (see Figure 17). G9749 Variable Speed Drill Press Control Indicator Figure 17. Fine downfeed control and indicator. Use the fine downfeed control and the attached indicator to move the quill to the desired position.

-

Page 24: Table Adjustments

(see Figure 20). Lock Lever Lock Levers Figure 20. Headstock lock levers. Rotate the headstock to the desired position and use the lock levers to secure the head- stock in place. G9749 Variable Speed Drill Press... -

Page 25: Removing/Installing Arbor And Chuck

Removing/Installing Arbor and Chuck Use the drawbar included with the Model G9749 to connect the included drill chuck arbor. To remove the arbor and chuck from the spindle: UNPLUG THE DRILL PRESS! Use a 3mm hex wrench to remove the belt housing cover (see Figure 21). - Page 26 Finish tightening by making a 17mm wrench. Replace and secure the belt housing cover. NOTICE overtighten Overtightening the drawbar may cause dam- age to the mating surfaces of the spindle and arbor. G9749 Variable Speed Drill Press ⁄ turn with a drawbar.

-

Page 27: Section 5: Accessories

" - ⁄ "; G8866: ⁄ "- ⁄ ". Figure 25. Model G8865 13-PC Alloy Drill Bits. G9749 Variable Speed Drill Press H5685—4" Rotary Table ⁄ " x ⁄ ", ⁄ " The perfect rotary table for all you model makers ⁄... -

Page 28: Section 6: Maintenance

Keep tables rust-free with regular applications of products like G96 Gun Treatment or Boeshield ® T-9. See below for Grizzly model numbers: G2871—Boeshield T-9 12 oz Spray ® G2870—Boeshield T-9 4 oz Spray ®... -

Page 29: Section 7: Service

SECTION 7: SERVICE This section is provided for your convenience—it is not a substitute for the Grizzly Service Department. If you need help troubleshooting, need replacement parts, or are unsure how to perform the procedures in this section, then feel free to call our Technical Support at (570) 546-9663. - Page 30 Replace. Clean shaft and lubricate with a light coat of oil. Fully release the quill lock. Replace the feed shaft return spring. Replace the bearings. Replace the quill shaft. Remove drill bit and reinstall. G9749 Variable Speed Drill Press...

-

Page 31: Electrical Components

Electrical Components Figure 30. G9749 switch wiring. Figure 32. G9749 motor capacitors. Figure 31. G9749 motor wiring (220V). -29- G9749 Variable Speed Drill Press... -

Page 32: Wiring Diagram

��� ���� ���� ��� ������������ �� �� �� �� �� ������ �� �� �� �� �� �� � � � � � � �� �������� ��������� ������ ������ ��������� �� ����� ������ �� G9749 Variable Speed Drill Press �� ��... -

Page 33: Headstock Parts Breakdown

��� ��� ��� ��� �� �� �� ��� �� ��� ��� ��� ��� Page 32 ��� ��� ��� G9749 Variable Speed Drill Press �� �� �� �� �� �� �� ��� ��� �� �� �� ��� �� �� �� ��... -

Page 34: Headstock Components Parts Breakdown

Page 31 ��� ���� ���� ���� ���� �� � Page 31 ����� ����� ��� � Page 31 Headstock Component Parts �� � ���� Page 33 ��� ��� ��� ��� ��� ��� ��� ��� ����� ����� ����� G9749 Variable Speed Drill Press... -

Page 35: Variable Speed Parts Breakdown

Variable Speed Parts Breakdown ��� �� � Page 32 �� �� �� �� ��� �� �� ��� ��� �� �� �� ��� �� ��� �� ��� ��� ��� � �� �� Page 32 �� �� -33- G9749 Variable Speed Drill Press... -

Page 36: Base Parts Breakdown

��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� ��� -34- G9749 Variable Speed Drill Press... -

Page 37: Parts List

HEX NUT 5/8-18 P9749052 PIVOT SHAFT PN08 HEX NUT 3/8-16 PW02 FLAT WASHER 3/8 P9749055 1-1/2HP 110V/220V 1PH MOTOR 55-1 P9749055-1 CAPACITOR 50MFD 250VAC G9749 Variable Speed Drill Press Parts List PART # 55-2 P9749055-2 55-3 P9749055-3 55-4 P9749055-4 55-5 P9749055-5 55-6... - Page 38 P9749512 PS18 P9749514 P9749515 P9749516 P9749517 PW03M PSB68M P9749520 P9749521 G9749 Variable Speed Drill Press DESCRIPTION SET SCREW 5/16-18 X 5/16 HANDLE FEED ASSEMBLY FEED HOUSING WORM SHAFT BALL BEARING 6202ZZ EXT RETAINING RING 15MM BEARING SPACER CAP SCREW 5/16-18 X 3/4...

-

Page 39: Label Placement

MUST maintain the original location and readability of the labels on the machine. If any label is removed or becomes unreadable, REPLACE that label before using the machine again. Contact Grizzly at (800) 523-4777 or www.grizzly.com to order new labels. G9749 Variable Speed Drill Press... -

Page 40: Warranty And Returns

WARRANTY AND RETURNS Grizzly Industrial, Inc. warrants every product it sells for a period of 1 year to the original purchaser from the date of purchase. This warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence, accidents, repairs or alterations or lack of maintenance. - Page 41 ���������������������������������������������������������������������������������� � ������������������������������������������������������������������������������������ ����� ����������������������� ������ � ������������������������ ���� ��������������������� ���������������������������� ������ ������������������������ ���������� � ���������������� ���������������������������� ������������������������������� ��������������������������� ��� ��������� ����������� �� ����� �� � ��������� ������ �� ���� �� ���� ��� ��������� �������� �� ���� �� ������� ������ �������� ��� ��������� �� ������� ��� ����������� �� �������� ������������� ���...

- Page 42 ���������������������� ���������������������� ����������������������������������� ������� ����������� ���� ���� ��� ���� ����������� �� ���������� ����������������������������������� ������������������������������������� �������������������������������������� �������������������������������������� ����� ����� ����...

- Page 44 ��� ������ ��� ���� ���� ������� ����� ��� ������� ����� ��� �������� ��� ������� � � � ���� ����� ��� � � �������� ������ ��� � ����� ������ � �� ��� �������� ������� � ������ �������� ������ ������� ������ �� ����� ������...

Need help?

Do you have a question about the G9749 and is the answer not in the manual?

Questions and answers