Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Miller Two Fifty Twin

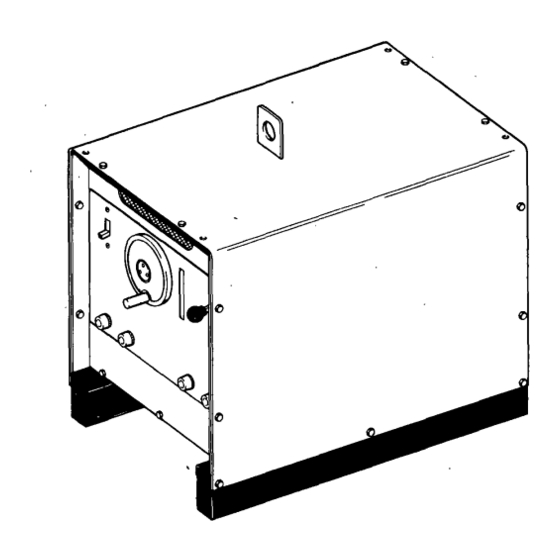

- Page 1 No. 72-61 2483 STOCK NO. MODEL Twin 901 973 Fifty Twin-P 901 976 Fifty MODEL/STOCK NO. SERIAL/STYLE NO. DATE PURCHASED OWNERS MANUAL MILLER ELECTRIC MFG. CO. APPLETON, WISCONSIN, USA 54911 ADDITIONAL COPY NWSA CODE NO. 4579 PRICE 60 CENTS...

-

Page 3: Table Of Contents

TABLE OF CONTENTS Page Paragraph SECTION 1 SAFETY RULES FOR OPERATION OF ARC WELDING MACHINE 1-1. General Welding Cables Electrode Holder Code Conformance 1 -5. Parallel Connections Power Disconnect Switch 1-7. Polarity Switch Range Switch Exhaust Gases 1-10. Power Circuit Ground 1-11. -

Page 5: Safety Rules For Operation Of Arc Welding Machine

SECTION SAFETY RULES OPERATION OF ARC WELDING MACHINE 1. GENERAL These rules apply and dc welding generators. trans former and ac/dc welding machines, and dc transformer recti fier welding machines. arc-welding operations, where electrically energized parts exposed, observe the following safety rules insure imum... -

Page 6: Power Circuit Ground

When you know the container held liquid which will readily dissolve in water: Clean thouroughly with cleansing steam agent and purge all air inert with such carbon dioxide nitrogen before repairing. Carbon dioxide is heavier than air and tend remain in the container if the will opening the top. -

Page 7: Solvents

1-15. SOLVENTS with grounded electrode the table top contact 1-7) metallic surface. (Figure weld where chlorinated hydrocarbon vapors from de cleaning, reach spraying be drawn into air electrode holder greasing, When place never use, surrounding welding operation. The heat of the other metallic surface in with the tabletop... -

Page 8: Clothing

Keep clean in front of the filter glass for the cover plate Whenever it is necessary grind chip metal, protec. wear protection thereof. Frequent renewal of these glasses goggles specifically designed for this purpose. Serious eye cover tive since they become covered with spatter, necessary, reducing... -

Page 9: Receiving-Handling

SECTION 2-INTRODUCTION Input Ruled Welding Mao. Rated Amperes 60Hz. Ooerull Weight Current Open Wsldieg Output Ciruuit Current Oimensions Ranges 208)260 Vults Volts Volts Inches) Ship Model Vollugo Amperes Amperes 250W 20.7 11.8 Without Volts, Power Outy Cycle Poctor 25-125 Correction Volts, 16.1 26-1/4... -

Page 10: 3. Primary Connections

PRIMARY CABLE PRIMARY VOLTAGE INPUT HOLE JUMPER LINKS ~ldi should be loca ted that ng p the front and panels with the air rear clear vents obstruction. Cooling air is drawn through front upper air vent expelled of the panel rear vent. -

Page 11: Section 4 Operation

Use Table 3-2 guide selecting welding Twist wire until the entire tie wire Correct cable (or the size anticipated maximum weld that will around the insulation of the weld current twisted and is tight be used. Table 3-2 takes into for the the total cable account... -

Page 12: On-Off Power Switch

of desired within VOLT-AMPERE CURVE exact amount welding current 4-5. range chosen be selected by rotating the Fine Current Control the front of the welding The Cur voltage available power source. volt-ampere shows the output curve Indicator the front panel will show the selec rent... -

Page 13: Transformer

6-2. TRANSFORMER FAN MOTOR 6-3. Occasional blowing of the dust and firt from around the models equipped with exhaust rely transformer is recommended. This should be done periodi forced draft for adequate cooling high duty cycles cally depending location unit overloads. - Page 15 1973 August FORM: OM-313 MODEL STOCK NO. Twin Fifty Fifty Twin-P 901 976 MODELJSTOCK NO. SERIAL/STYLE NO. DATE PURCHASED PARTS LIST msuuer MILLER ELECTRIC MFG. CO. USA 54911 APPLETON, WISCONSIN, NWSA CODE NO. 4579...

- Page 16 Quantity Models Item Dia. Without With Factory Part No. Mkgs. Description Figure Main Assembly 014 632 WRAPPER Figure PANEL ASSEMBLY, (See Page 2) rear TERMINAL BOARD 038934 ASSEMBLY, primary (See Fig. Page 027283 REACTOR & SHUNT (See Fig. Page 4) 010 615 SPRING, indicator...

- Page 17 Item Dia. Factory Mkgs. Part No. Description Quantity (See Figure Panel Assembly, Rear Fig. Page 1 Item 032603 MOTOR, (consisting *024 601 BEARING 019073 WINDTUNNEL rectifier 010489 SPACER, mtg 032 612 BLADE, 014 623 PANEL, rear 038 315 diode BOARD, junction leads 027 198 RECTIFIER,...

- Page 18 Item Factory Part No. Quantity Description Figure 038 934 Terminal Board Assy, Primary (See Fig. Page 1 Item WJS 662 BOAI-LL), components 038 618 LINK, jumper- brass 038 887 STUD, hex collar brass 10-32 1-3/8 010 910 flat brass 3/16 WASHER, 601 835 NUT,...

- Page 19 Item Dia. Factory Mkgs. Part No. Description Quantity Figure 027 283 Reactor & Shunt (See 1 Item Fig. Page **027 282 REACTOR (consisting **027 191 COIL, (top) **027 192 COIL, (bottom) *027 230 REACTOR SUBASSEMBLY (consisting 020 284 WEDGE, coil front 020 301 GUIDE, wedge...

- Page 20 Item Factory Fart No. Description Quantity 027 215 Figure Shunt (See Fig. Page 4 Item 027 673 SCREW, lead 024 785 COLLAR 027 672 BLOCK, travel shunt 601 860 NUT,hex8-32 028 108 BLOCK, shunt 027 674 PLATE, lock SCREW, fiat hd 10-32 1-1/2 605 609 machine...

- Page 21 Item Dia. Factory Mkgs. Part No. Description Quantity Front (See Figure Panel Assembly, Fig. Page 1 Item NAMEPLATE (order by stock, model & serial number) 027 710 BEARING, nylon 027 227 PANEL, front *025 865 SWITCH, 2PST 60 ampere 027925 SWITCH, current selector (See...

- Page 22 Item Factory Part No. Description Quantity Figure 027 925 Switch, Current Selector (See 125) Fig. Page 6 Item 019 603 KNOB 604 318 NUT, self locking 1/4-20 010 805 HANDLE 011 950 CONTACT, bottom front copper rear or 011 951 CONTACT, front bottom...

Need help?

Do you have a question about the Two Fifty Twin and is the answer not in the manual?

Questions and answers