U-Line Echelon 2075DWRR Service And Parts Manual Supplement

Hide thumbs

Also See for Echelon 2075DWRR:

- Specifications (2 pages) ,

- Installation manual (15 pages) ,

- User manual (48 pages)

Table of Contents

Advertisement

Service and Parts Manual

Supplement

For Models

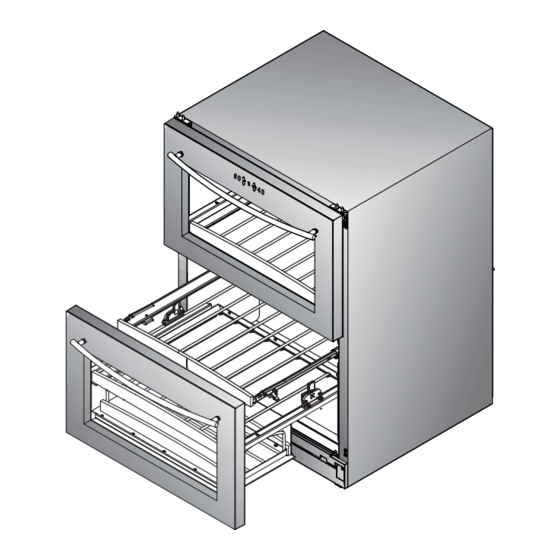

• 2075DWRR • CO2075DWR • 2075DWRWC

U-Line Corporation

U-Line Corporation

8900 North 55th Street

PO Box 245040

Milwaukee, WI 53223

Milwaukee, WI 53224-9540

www.U-LineService.com

Phone (414) 354-0300 • FAX (414) 354-7905

Service & Parts Tech Lines Phone (800) 779-2547 • FAX (414) 354-5696

Advertisement

Table of Contents

Summary of Contents for U-Line Echelon 2075DWRR

- Page 1 Service and Parts Manual Supplement For Models • 2075DWRR • CO2075DWR • 2075DWRWC U-Line Corporation U-Line Corporation 8900 North 55th Street PO Box 245040 Milwaukee, WI 53223 Milwaukee, WI 53224-9540 www.U-LineService.com Phone (414) 354-0300 • FAX (414) 354-7905 Service & Parts Tech Lines Phone (800) 779-2547 • FAX (414) 354-5696...

- Page 3 INTRODUCTION Design Features Performance General Information 2075DWRR 2075DWRWC CO2075DWR...

- Page 4 Design Features Performance NOTES...

- Page 5 Design Features Performance INTRODUCTION Three generations of pride and quality manufacturing and design improvements are built into all U-Line products. The result: U-Line leads the market with innovative technology and superior craftsmanship. This manual contains specific instructions for servicing the U-Line Échelon 2075DWRR, CO2075DWR and 2075DWRWC.

-

Page 6: Serial Number Format

The next four digits, 1234, represent the shop order number. Every model is assigned a new shop order number at the beginning of a production run. The second two digit segment, 01, represents the month the unit was made. The last four digits, 5678, are an internal control number used at U-Line Corporation. 031234-01-5678 Month... -

Page 7: General Information

General Information... - Page 8 GENERAL INFORMATION Design Features Performance...

-

Page 9: Limited Warranty

U-Line product to be free from defects in materials and workmanship for a period of five years from the date of purchase. During the initial one-year warranty period for all U-Line products U-Line shall: (1) at U-Line’s option, repair any product or replace any part of a product that breaches this warranty;... -

Page 10: Warranty Claims Procedure

Please be sure the claim is legible. If the claim form cannot be read, it will be returned, unpaid. U-Line will not cover part or labor claims for the replacement of a complete ice maker assembly. All ice maker parts are available as replacement parts and are stocked in our inventory. Remember: we do not pay customer education calls. -

Page 11: Parts Listing

It will be noted on your packing list if we require you to return a part or if you may field scrap it. If U-Line requires a defective part to be returned, a prepaid shipping label will be included with your new replacement part. -

Page 12: Safety Precautions

GENERAL INFORMATION Design Features Performance SAFETY PRECAUTIONS Do not attempt to service or repair the unit until you have read the entire procedure. Safety items through- out this manual are labeled with Warning or Caution. WARNING Warning means that failure to follow this safety statement may result in extensive product damage, serious personal injury, or death. - Page 13 2075DWRR...

- Page 14 2075DWRR Design Features Performance...

-

Page 15: Compressor/Electrical Specifications

2075DWRR Design Features Performance COMPRESSOR/ELECTRICAL SPECIFICATIONS 2075DWRR EMU30HSC OVERLOAD PROTECTOR RELAY COVER STARTING RELAY UL183-3C COMPRESSOR PINS To measure start winding resistance, measure across the C-S pins. To measure run winding resistance, measure across the C-R pins. These pins should never measure any resistance to ground. -

Page 16: Refrigeration Systems

2075DWRR Design Features Performance REFRIGERATION SYSTEMS Normal Vapor/Compression Cycle Refrigeration • Refrigerant is pumped from the compressor to the condenser as a high pressure, high temperature vapor. • As the refrigerant cools in the high pressure condenser, the vapor condenses to liquid. During this phase change, a great amount of heat is rejected with the help of the condenser fan. - Page 17 SERVICE NOTES 2075DWRR The 2075DWRR has the same basic refrigeration system as the 2075R with a few exceptions. • The compressor is a high efficiency Embraco EMU30HSC. • The electro-mechanical gas bulb is replaced with an electronic controller. The controller features a digital temperature display and control with two LED indicators and three touch pad buttons.

- Page 18 • Under most conditions, the refrigerator will remain frost-free by clearing itself between refrigeration cycles. Because there is no thermostat bulb on the evaporator, like other U-Line refrigerators, the con- troller runs a 45 minute off-cycle for every 12 hours of clock time. The refrigerator will not cool during this off-cycle even if the refrigerator thermistor is calling for cooling.

- Page 19 2075DWRR Design Features Performance 2075DWRR WARMER WARMER COOLER COOLER TEMP TEMP CLRCO011B The temperature controller is located in the top drawer. The LED display shows the temperature set point and is calibrated in degrees Fahrenheit. The controller is factory programmed for a set point of 38°F which will show when the unit is first powered-up.

-

Page 20: Refrigeration System Diagnosis Guide

REFRIGERATION SYSTEM DIAGNOSIS GUIDE SystemSuction Suction Compressor Condenser Capillary Evaporator Wattage Condition Pressure Line Discharge Tube Normal Normal Slightly below Very hot Very hot Warm Cold Normal room temperature Overcharge Higher than Very cold Slightly warm Hot to warm Cool Cold Higher than normal... - Page 21 2075DWRR Design Features Performance 2075DWRR WIRING DIAGRAM 42184-F...

-

Page 22: Troubleshooting

Remedy a. Blocked drain a. Remove blockage Excessive frost build-up Cause Remedy a. Gasket not sealing a. Repair or replace gasket b. Product too tall for drawer or product not b. Instruct customer allowing top bin to move forward (2075DWRR) - Page 23 2075DWRR Design Features Performance Noisy Cause Remedy a. Copper refrigeration tube touching cabinet a. Carefully adjust tubing b. Fan blade touching shroud b. Adjust fan mounting or shroud c. Fan blade obstruction (wiring, foam insulation, c. Remove obstruction packaging material)

- Page 24 2075DWRR Design Features Performance 2075DWRR (1 OF 2) 10 11 DWR023...

- Page 25 2075DWRR Design Features Performance 2075DWRR (1 OF 2) Item Description Black Stainless Steel Control Housing 26006 26006 Control Assembly 68005 68005 Organizer Assembly 80-48001-00 80-48001-00 Top Bin 26000 26000 Switch Box 26010 26010 Light Switch 42179 42179 Drawer Slides 80-47001-00...

- Page 26 2075DWRR Design Features Performance 2075DWRR (2 OF 2) DWR024...

- Page 27 2075DWRR Design Features Performance 2075DWRR (2 OF 2) Item Description Black Stainless Steel Rocker Switch 2053 2053 Transformer 68014 68014 Thermo Cutoff Switch 66001 66001 Condenser 2303-S 2303-S Fan Blade 5188 5188 Fan Motor 5263 5263 Drain Pan 31550-1-F 31550-1-F...

- Page 28 Design Features Performance NOTES...

- Page 29 2075DWRWC...

- Page 30 2075DWRWC Design Features Performance...

-

Page 31: Compressor Pins

2075DWRWC Design Features Performance COMPRESSOR/ELECTRICAL SPECIFICATIONS 2075DWRWC EMU30HSC OVERLOAD PROTECTOR RELAY COVER STARTING RELAY UL183-3C COMPRESSOR PINS To measure start winding resistance, measure across the C-S pins. To measure run winding resistance, measure across the C-R pins. These pins should never measure any resistance to ground. - Page 32 2075DWRWC Design Features Performance REFRIGERATION SYSTEMS Normal Vapor/Compression Cycle Refrigeration • Refrigerant is pumped from the compressor to the condenser as a high pressure, high temperature vapor. • As the refrigerant cools in the high pressure condenser, the vapor condenses to liquid. During this phase change, a great amount of heat is rejected with the help of the condenser fan.

- Page 33 2075DWRWC Design Features Performance • From the dryer, the refrigerant flows through the capillary tube which meters the liquid refrigerant to the evaporator. The pressure of the refrigerant is reduced to the evaporating or low side pressure. • The reduction of pressure on the liquid refrigerant causes it to boil or vaporize until it reaches satura- tion temperature.

- Page 34 2075DWRWC Design Features Performance The top and bottom valve can never be open at the same time. After initial startup whichever compartment calls for cooling first, will have priority. Once the setpoint is achieved the other compartment will be cooled if necessary. When both compartments have reached setpoint and the compressor shuts off, the last bypass valve that was open will remain open for four minutes.

- Page 35 2075DWRWC Design Features Performance THE ELECTRONIC TEMPERATURE CONTROLLERS 2075DWRWC DWR034 The temperature controls are integrated in the top, front drawer panel. They consist of an LED display and touch sensors for each drawer and a touch sensor to control the lighting (“ ”, “...

-

Page 36: Interior Lighting

2075DWRWC Design Features Performance INTERIOR LIGHTING (2075DWRWC) The interior lighting can be controlled by the controller. Each time the light “ ” symbol is touched, the lighting is scrolled through the following options: Touch once – Both compartment lights on. Touch twice –... -

Page 37: Refrigeration System Diagnosis Guide

REFRIGERATION SYSTEM DIAGNOSIS GUIDE System Suction Suction Compressor Condenser Capillary Evaporator Wattage Condition Pressure Line Discharge Tube Normal Normal Slightly below Very hot Very hot Warm Cold Normal room temperature Overcharge Higher than Very cold Slightly warm Hot to warm Cool Cold Higher than... - Page 38 POWER CORD ASSEMBLY BLACK-HOT (SMOOTH) BLACK GREEN GROUND BLACK-NEUTRAL (RIBBED) WHITE WHITE WHITE CONTROL BOARD VALVE VALVE (WHITE) 9 BLACK (BLACK) 8 (BLACK W/YELLOW) 6 BLACK (RED) 5 COND WITH (YELLOW) 4 YELLOW YELLOW (PURPLE) 3 PURPLE BLACK (BROWN) 2 (BLUE) 1 BROWN BOTTOM...

- Page 39 2075DWRWC Design Features Performance WARNING TROUBLESHOOTING DO NOT service the unit until the main electrical power has been disconnected. 2075DWRWC Before servicing this unit, take readings from the electronic control (refer to The Electronic Temperature Control for checking actual temperatures, if needed). These actual readings are important to take before having the drawers open for more than 30 seconds to obtain accurate readings.

-

Page 40: Not Cooling

2075DWRWC Design Features Performance 3 Drawers will not close properly • The drawer slides contain a self-closing feature which engages when the drawer is about 1 inch from being closed. At the point the closers engage, there may be some resistance. If this resistance is hard to overcome, try closing the drawers with more force a couple times and then try slowly again. - Page 41 2075DWRWC Design Features Performance CASCADING PARTS NOT OPERATING PROPERLY A - Cascade mechanism in the correct opening position. DWR065 B - Cascade mechanism in the correct closing position.

- Page 42 2075DWRWC Design Features Performance 2075DWRWC (1 OF 2) 9,10 DWR067...

- Page 43 2075DWRWC Design Features Performance 2075DWRWC (1 OF 2) Item Description Black Stainless Steel Drawer & Rack Assembly Bottom 80-17030-01 80-17030-03 Drawer & Rack Assembly Top 80-17028-01 80-17028-03 Cascade Assembly Left Side 26028-02-S 26028-02-S Top Rack Assembly 80-33005-S 80-33005-S Drawer Slide Assembly 80-47001-00 80-47001-00 Evaporator Assembly...

- Page 44 2075DWRWC Design Features Performance 2075DWRWC (2 OF 2) DWR068...

- Page 45 2075DWRWC Design Features Performance 2075DWRWC (2 OF 2) Item Description Black Stainless Steel Board 68019-S 68019-S Condenser Assembly 2303-S 2303-S Fan Blade 5188 5188 Fan Motor 5263 5263 Power Cord 2916 2916 Valve Coil 73002 73002 Valve Assembly 73002-S 73002-S Drier 2694 2694...

- Page 46 2075DWRWC Design Features Performance NOTES...

- Page 47 CO2075DWR...

- Page 48 CO2075DWR Design Features Performance...

- Page 49 CO2075DWR Design Features Performance EMI70HER OVERLOAD PROTECTOR STARTING RELAY RELAY COVER UL183-3D COMPRESSOR PINS To measure start winding resistance, measure across the C-S pins. To measure run winding resistance, measure across the C-R pins. These pins should never measure any resistance to ground.

-

Page 50: U-Line Frost Free Refrigeration System

CO2075DWR Design Features Performance U-LINE FROST FREE REFRIGERATION SYSTEM Cooling Mode: • Bypass solenoid valve closed • Evaporator fan operating • Refrigerant flows through capillary tube • Normal vapor/compression cycle refrigeration Defrost Mode: • Bypass solenoid valve open • Refrigerant flows through bypass system •... -

Page 51: General Operation Notes

CO2075DWR Design Features Performance SERVICE NOTES CO2075DWR The CO2075DWR has the same basic refrigeration system as the CO2075F with a few exceptions. • The compressor is an Embraco EMI70HER. • The electro-mechanical gas bulb is replaced with an electronic controller which features a digital temperature display. - Page 52 CO2075DWR Design Features Performance When checking the thermistors to see if they are reading accurately, it is common to place them in an icebath to see if they read 32°F. Do not place them directly in the water. Use a plastic bag to protect them from moisture.

- Page 53 CO2075DWR Design Features Performance THE ELECTRONIC TEMPERATURE CONTROLLER WARMER WARMER COOLER COOLER TEMP TEMP CLRCO011 The temperature controller is located in the top drawer. It consists of an LED display, two LED status indi- cator lights and three touch pad buttons. The LED display shows the compartment temperature set point and is calibrated in degrees Fahrenheit.

- Page 54 REFRIGERATION SYSTEM DIAGNOSIS GUIDE System Suction Suction Compressor Condenser Capillary Evaporator Wattage Condition Pressure Line Discharge Tube Normal Normal Slightly below Very hot Very hot Warm Cold Normal room temperature Overcharge Higher than Very cold Slightly warm Hot to warm Cool Cold Higher than...

- Page 55 CO2075DWR Design Features Performance CO2075DWR WIRING DIAGRAM...

- Page 56 CO2075DWR Design Features Performance DANGER TROUBLESHOOTING DO NOT service the unit until the main electrical power has been disconnected. Before servicing this unit, take readings from the electronic control (refer to The Electronic Temperature Control for checking actual temperatures if needed). These actual readings are important to take before having the drawers open for more than 30 seconds to obtain accurate readings.

- Page 57 CO2075DWR Design Features Performance 2. Some cooling • Clean condenser. • Check condenser fan. • Possible system leak. 3. No cooling • Check compressor/fan operation • Check refrigeration system pressure • Check wiring and power at circuit board 4. Noise •...

-

Page 58: Ice Maker Operation

CO2075DWR Design Features Performance Ice maker Operation DWR057 1. Freeze cycle • Ice maker relay is not energized. • Unit is cooling ice maker down to the 15°F setpoint. • The unit may cycle on and off as it is pulling ice maker to setpoint in order to maintain ideal refrigerator and freezer temperatures. -

Page 59: Harvest Cycle

CO2075DWR Design Features Performance 2. Harvest cycle 1 DWR058 • Ice maker relay on circuit board energizes for 30 seconds. This allows power to the ice maker to allow the blades rotate. • Refrigeration system is independent of the ice maker. •... - Page 60 CO2075DWR Design Features Performance 3. Harvest cycle 2 DWR055 • The drawer switch must remain depressed for this cycle to continue. • The ice maker relay is now de-energized • This cycle initiates when the blades move to approximately the 2 o’clock position. •...

-

Page 61: Water Fill Cycle

CO2075DWR Design Features Performance 4. Water fill cycle DWR056 • This cycle initiates when the blades move to approximately the 10 o’clock position. • At this point the ice has moved out of the mold and is dropping into the bucket. •... -

Page 62: Disassembly Procedures

CO2075DWR Design Features Performance DWR041 DISASSEMBLY PROCEDURES Note: Échelon models do not require removal of the ice maker or freezer housing to access the fan motor, drain or evaporator. To replace evaporator fan motor: 1. Disconnect unit from power source. 2. - Page 63 CO2075DWR Design Features Performance REPLACING ICE MAKER ASSEMBLY DWR064 1. Remove unit from installation. 2. Disconnect water and unplug unit. 3. Disconnect ice maker wire harness at plug in back of unit (1). 4. Remove thermistor from the sensing tube on ice maker assembly (2). 5.

- Page 64 CO2075DWR Design Features Performance NOTES...

- Page 65 CO2075DWR Design Features Performance REPLACING MOLD AND HEATER DWR061 1. Remove ice maker assembly. Refer to REPLACING ICE MAKER ASSEMBLY. 2. Remove one stripper screw (1) and stripper (2). 3. Remove three face plate screws (3) and face plate. 4. Remove one screw (4) and detach limit switch from mold. 5.

- Page 66 CO2075DWR Design Features Performance CO2075DWR (1 OF 3) 11, 12 28 29 DWR025...

- Page 67 CO2075DWR Design Features Performance CO2075DWR (1 OF 3) Item Description Black Stainless Steel Control Housing 26006 26006 Display Board Assembly 68024 68024 Control Harness 68025 68025 Organizer Assembly 80-48001-00 80-48001-00 Top Bin 26000 26000 Drawer Slides 80-47002-00 80-47002-00 Light Switch Top Drawer 42179 42179 Chimney...

- Page 68 CO2075DWR Design Features Performance CO2075DWR (2 OF 3) DWR063...

- Page 69 CO2075DWR Design Features Performance CO2075DWR (2 OF 3) Item Description Black Stainless Steel Water Line Assembly 404-CO2075DWR 404-CO2075DWR Water Valve 2552A 2552A Plastic Nut & Sleeve 41254 41254 Brass Fitting 41826 41826 Drier 72018 72018 Compressor Assembly 70079-FFS 70079-FFS Overload 71025 71025 Relay...

- Page 70 CO2075DWR Design Features Performance CO2075DWR (3 OF 3) DWR060...

- Page 71 * Parts included in the 150-DWRCO Faceplate assembly U-Line will not pay warranty claims for the replacement of a complete ice maker assembly. Complete ice maker assembly replacement is not necessary because all ice maker parts are available as replacement...

- Page 72 Design Features Performance NOTES...

- Page 73 INTRODUCTION Design Features Performance NOTES...

- Page 74 INTRODUCTION Design Features Performance NOTES...

- Page 75 FAX PARTS ORDER FORM FAX # 414-354-7905 Account# ____________________________________ Ship to:______________________________________ Bill to: ______________________________________ ____________________________________________ ____________________________________________ ____________________________________________ ____________________________________________ Attention: Date:________________________________________ P.O. ________________________________________ Phone#______________________________________ Fax# ________________________________________ PART# COLOR DESCRIPTION MODEL SERIAL UNIT IN NUMBER WARRANTY? SPECIAL INSTRUCTIONS: All part shipments will be sent ground delivery. We have air shipment available at an additional cost to you.

- Page 76 P.O. Box 245040 Milwaukee, WI 53224-9540 Phone 414.354.0300 FAX 414.354.7905 Printed in U.S.A. – February 2005 P/N 30017...